Blog by Paresh Deshpande

There a quite a few WDCs that I have inherited from my old man and the one on my table now is a “Demuth, Gold Dot”. I love the classic Bulldog and Rhodesian shape in pipes and am naturally attracted to pipes with this shape. Thus, no surprise here that I chose to work on this WDC Demuth Gold Dot in a classic Bulldog shape!!

This is the first WDC from my grandfather’s collection, a smooth Gold Dot in an impressive Bulldog shape. The beautiful straight grain follow a circular pattern on the right and front of the bowl while linear pattern adorns the left side of the bowl and along the diamond shank, neatly divided by the spine on either side. The shank is stamped on the left with the trademark inverted equilateral triangle with letters “WDC” enclosed in it. This is followed by “Demuth” over “GOLD DOT” in block capital letters. On the right, the shank is stamped “IMPORTED” over “BRIAR ROOT” followed by the shape number “77” towards the bowl and shank joint. A half inch thick gold band adorns the shank end and is stamped on the left with the trademark WDC triangle over “14 K”, indicating the purity of the gold band. The ¾ bent saddle stem has two gold filled dots in the center of the saddle portion of the stem on the left side.

I searched pipedia.com for more information on this pipe and attempt at estimating the vintage of this pipe. Here is what I have found on pipedia:-

I searched pipedia.com for more information on this pipe and attempt at estimating the vintage of this pipe. Here is what I have found on pipedia:-

William Demuth. (Wilhelm C. Demuth, 1835-1911), a native of Germany, entered the United States at the age of 16 as a penniless immigrant. After a series of odd jobs he found work as a clerk in the import business of a tobacco tradesman in New York City. In 1862 William established his own company. The William Demuth Company specialized in pipes, smoker’s requisites, cigar-store figures, canes and other carved objects.

The Demuth Company is probably well known for the famous trademark, WDC in an inverted equilateral triangle. William commissioned the figurative meerschaum Presidential series, 29 precision-carved likenesses of John Adams, the second president of the United States (1797-1801) to Herbert Hoover, the 30th president (1929-1933), and “Columbus Landing in America,” a 32-inch-long centennial meerschaum masterpiece that took two years to complete and was exhibited at the World’s Columbian Exposition in Chicago in 1893.

The Presidential series was the result of Demuth’s friendship with President James A. Garfield, a connoisseur of meerschaum pipes. Demuth presented two pipes to Garfield at his inauguration in 1881, one in his likeness, the other in the likeness of the President’s wife. Later, Demuth arranged for another figurative matching the others to be added to the collection as each new president acceded to the White House, terminating with President Hoover.

In early 1937, the City of New York notified S.M. Frank & Co. of their intent to take by eminent domain, part of the land on which the companies pipe factory was located. This was being done to widen two of the adjacent streets. As a result of this, Frank entered into negotiations to purchase the Wm. Demuth Co.’s pipe factory in the Richmond Hill section of Queens. It was agreed upon that Demuth would become a subsidiary of S.M. Frank and all pipe production of the two companies would be moved to DeMuth factory. New Corporate offices were located at 133 Fifth Avenue, NYC.

Demuth pipes continued to be made at the Richmond Hill plant till December 31. 1972. Then the Wm. Demuth Company met its official end as a subsidiary company by liquidation.

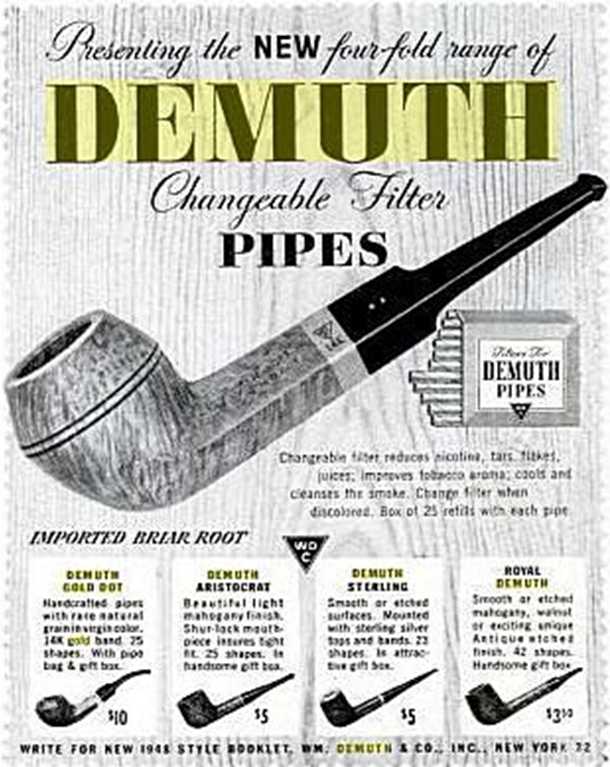

I came across an interesting advertisement on the same page on pipedia.com which shows the exact same pipe that I am now working on. It is the same pipe as the first pipe on the left. A close scrutiny of the picture confirms the following:

(a) The Gold Dot line of WDC pipes was offered sometime before 1941 as inferred from the bottom line of this flyer which encourages readers to “WRITE FOR NEW 1941 STYLE BOOKLET”, implying that this flyer was published prior to 1941!!!!!

(b) The Gold Dot line of WDC pipes was at the time their top of the line product as it is the most expensive of all the pipes advertised in the flyer, retailing at $10!!! Pipephil.eu too has the same pipe shown with shape # 77. Here is the link; http://www.pipephil.eu/logos/en/logo-w1.html

Pipephil.eu too has the same pipe shown with shape # 77. Here is the link; http://www.pipephil.eu/logos/en/logo-w1.html

From the above gleaned information, it is safe to conclude that the pipe now on my worktable is of 1940s vintage and at that point in time was WDC’s top-of-the-line offering!!!!

INITIAL VISUAL INSPECTION

Age definitely shows on the stummel surface!!! The briar is dull and lifeless and has taken on a layer of aged patina, through which one can make out the beautiful straight grain patterns all around. There is a heavy overflow of lava all over the entire stummel surface. The bowl cap, bowl, shank and even the stem is covered in oils, tars and grime accumulated over the years of storage and is sticky to the touch. To be honest, the stummel is filthy to say the least. A thorough cleaning of the stummel followed by polish should accentuate the beautiful straight grain pattern seen on the stummel through all the dirt. The double ring that separates the cap from the rest of the bowl is even and undamaged; however, it is filled with dust, dirt and grime. The chamber exudes a strong, but not definitely unpleasant, smell. I hope that this will be addressed once the chamber has been reamed and internals of the shank and mortise is cleaned with isopropyl alcohol.

There is heavy buildup of cake with a thick layer in the chamber. The buildup is such that I am barely able to squeeze my little finger in to the bowl. The condition of the inner walls of the chamber can be ascertained only after the cake has been removed completely and taken down to bare briar. The bowl however, feels robust and solid to the touch from the outside. The rim top has a thick layer of overflowing lava. The condition of the beveled inner and outer edge and rim top can be commented upon once the overflow of lava is removed and the chamber is reamed. The shank end of the pipe is clean. However, the mortise does show signs of accumulated dried oils, tars and remnants of ash, greatly restricting the air flow, or dare I say, completely restricting air flow. These issues should be a breeze to address, unless some hidden gremlins present themselves!!

There is heavy buildup of cake with a thick layer in the chamber. The buildup is such that I am barely able to squeeze my little finger in to the bowl. The condition of the inner walls of the chamber can be ascertained only after the cake has been removed completely and taken down to bare briar. The bowl however, feels robust and solid to the touch from the outside. The rim top has a thick layer of overflowing lava. The condition of the beveled inner and outer edge and rim top can be commented upon once the overflow of lava is removed and the chamber is reamed. The shank end of the pipe is clean. However, the mortise does show signs of accumulated dried oils, tars and remnants of ash, greatly restricting the air flow, or dare I say, completely restricting air flow. These issues should be a breeze to address, unless some hidden gremlins present themselves!!

The vulcanite stem has deep tooth indentations and minor tooth chatter on the upper and lower surface. It is heavily oxidized and has traces of overflowing lava, dust, oils and tars on the saddle portion of the stem. The opening of the tenon is filled with dried oils and tars. The air flow through the stem is greatly restricted to say the least. The fit of the stem in to the mortise is very tight, which will loosen further after the mortise and tenon have been cleaned. The metal tenon has a slot like groove extending more than half way towards the stem end on either side; probably to securely seat the “changeable filter” as advertised in the flyer above (actually I was wondering the purpose of the metal tenon, which as it is, was new to me, with slots on either side. This doubt was cleared by the flyer!!).

The vulcanite stem has deep tooth indentations and minor tooth chatter on the upper and lower surface. It is heavily oxidized and has traces of overflowing lava, dust, oils and tars on the saddle portion of the stem. The opening of the tenon is filled with dried oils and tars. The air flow through the stem is greatly restricted to say the least. The fit of the stem in to the mortise is very tight, which will loosen further after the mortise and tenon have been cleaned. The metal tenon has a slot like groove extending more than half way towards the stem end on either side; probably to securely seat the “changeable filter” as advertised in the flyer above (actually I was wondering the purpose of the metal tenon, which as it is, was new to me, with slots on either side. This doubt was cleared by the flyer!!).

The overall condition of the pipe, with the thick build-up of cake in the chamber, clogged mortises and stem airway, overflowing of lava covering the entire stummel, makes me believe that this would have been one of my grandfather’s favorite pipes.

The overall condition of the pipe, with the thick build-up of cake in the chamber, clogged mortises and stem airway, overflowing of lava covering the entire stummel, makes me believe that this would have been one of my grandfather’s favorite pipes.

THE PROCESS

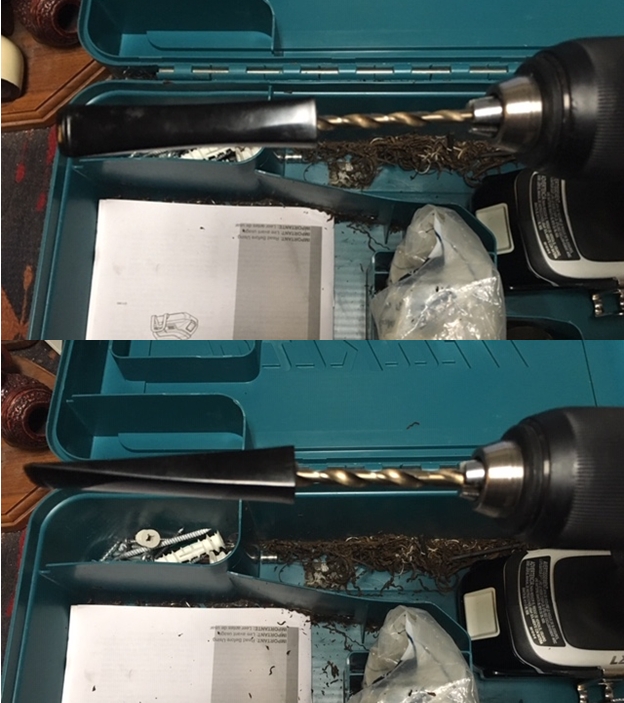

I started this project by reaming the chamber with size 2 and followed it up with size 3 head of PipNet reamer. I used a 220 grit sand paper, pinched between my thumb and forefinger, to sand the inner walls of the chamber of the pipe. Once I had reached the bare briar, I wiped the chamber with a cotton pad dipped in isopropyl alcohol. This removed all the residual carbon dust from the chamber. The walls of the chamber are nice and solid with no signs of heat fissures or cracks. I scrapped out the overflowing lava from the rim top with my fabricated knife. The inner and outer rim edges are pristine and that was a big relief. This was followed by cleaning the mortise and air way of the pipe using hard bristled and regular pipe cleaners, q-tips dipped in alcohol. The mortise and the draught hole were given a final clean with shank brushes dipped in alcohol. I dried the mortise with a rolled paper napkin. The shank internals and the draught hole are now nice and clean with an open and full draw. The gunk in the mortise had hardened to such an extent that I had to resort to using all the tools of the trade to get rid of the accumulated gunk, not to mention the time spent on cleaning it. The crud that was extracted from the mortise can be seen in the picture below.

This was followed by cleaning the mortise and air way of the pipe using hard bristled and regular pipe cleaners, q-tips dipped in alcohol. The mortise and the draught hole were given a final clean with shank brushes dipped in alcohol. I dried the mortise with a rolled paper napkin. The shank internals and the draught hole are now nice and clean with an open and full draw. The gunk in the mortise had hardened to such an extent that I had to resort to using all the tools of the trade to get rid of the accumulated gunk, not to mention the time spent on cleaning it. The crud that was extracted from the mortise can be seen in the picture below.  I had expected that the ghosting would be history by this stage. However, that was not to be the case. I had to resort to alcohol treatment to get rid of all the ghosting. I packed a few cotton balls in to the chamber. Drawing out a wick from one cotton ball, I inserted it in to the mortise of the pipe. Using a syringe, I topped the chamber with isopropyl alcohol and set it aside. Half hour later, I topped the chamber again with isopropyl alcohol as the level of alcohol had gone down from spreading inside the stummel. This process is usually done using Kosher salt as it leaves no aftertaste or smells. But here, in my part of the world, Kosher salts costs a huge bomb and from my personal experience, I have realized that cotton works equally well in drawing out all the oils and tars from the internals of the stummel exactly as Kosher salt does, but at a very economical cost. I set the stummel aside overnight to allow the alcohol to do its intended task. Next morning, I discard the wick and cotton balls from the stummel and wipe the bowl clean. Though the cotton balls and the cotton wick did not turn a dirty color as usual, the old smells were completely eliminated.

I had expected that the ghosting would be history by this stage. However, that was not to be the case. I had to resort to alcohol treatment to get rid of all the ghosting. I packed a few cotton balls in to the chamber. Drawing out a wick from one cotton ball, I inserted it in to the mortise of the pipe. Using a syringe, I topped the chamber with isopropyl alcohol and set it aside. Half hour later, I topped the chamber again with isopropyl alcohol as the level of alcohol had gone down from spreading inside the stummel. This process is usually done using Kosher salt as it leaves no aftertaste or smells. But here, in my part of the world, Kosher salts costs a huge bomb and from my personal experience, I have realized that cotton works equally well in drawing out all the oils and tars from the internals of the stummel exactly as Kosher salt does, but at a very economical cost. I set the stummel aside overnight to allow the alcohol to do its intended task. Next morning, I discard the wick and cotton balls from the stummel and wipe the bowl clean. Though the cotton balls and the cotton wick did not turn a dirty color as usual, the old smells were completely eliminated.  While the stummel was soaking in the alcohol bath, I cleaned out the internals of the stem using hard bristled and regular pipe cleaners dipped in alcohol. Well, that sounds easier than actually done. From the amount of overflowing lava deposits on the stem, I had anticipated a difficult time in cleaning the stem internals. But what really confronted me was a nightmare of a time cleaning it. For starters, the pipe cleaners would not move an inch in to the airway from either ends!!! I soak the internals of the stem, after packing the slot with a pipe cleaner, by filling it with isopropyl alcohol using a syringe. This helped in loosening the hardened oils and tars in the air way. Thereafter began the tedious process of cleaning the stem internals with a straightened paper clip and scrubbing the aluminum tenon with the fabricated dental spatula. The blobs of accumulated gunk removed from the air way could not be photographed as my table and tray was cleaned out by my helper before I could take a few pictures!!!! After a great deal of struggle, time and lots of pipe cleaners, the air way is finally clean with an open draw.

While the stummel was soaking in the alcohol bath, I cleaned out the internals of the stem using hard bristled and regular pipe cleaners dipped in alcohol. Well, that sounds easier than actually done. From the amount of overflowing lava deposits on the stem, I had anticipated a difficult time in cleaning the stem internals. But what really confronted me was a nightmare of a time cleaning it. For starters, the pipe cleaners would not move an inch in to the airway from either ends!!! I soak the internals of the stem, after packing the slot with a pipe cleaner, by filling it with isopropyl alcohol using a syringe. This helped in loosening the hardened oils and tars in the air way. Thereafter began the tedious process of cleaning the stem internals with a straightened paper clip and scrubbing the aluminum tenon with the fabricated dental spatula. The blobs of accumulated gunk removed from the air way could not be photographed as my table and tray was cleaned out by my helper before I could take a few pictures!!!! After a great deal of struggle, time and lots of pipe cleaners, the air way is finally clean with an open draw. The deep bite marks on the stem were flamed using a Bic lighter. However, this did not work. From my experience, I have learnt that getting rid of the oxidation from and around the surface to be filled helps in subsequent better blending of the fill with the stem surface. With a folded piece of used 220 grit sand paper, I sand the area that is required to be filled. I cleaned the sanded portion of the stem with cotton pad dipped in alcohol and spot filled the damaged area with a mixture of activated charcoal and clear superglue. I set the stem aside for the fill to cure.

The deep bite marks on the stem were flamed using a Bic lighter. However, this did not work. From my experience, I have learnt that getting rid of the oxidation from and around the surface to be filled helps in subsequent better blending of the fill with the stem surface. With a folded piece of used 220 grit sand paper, I sand the area that is required to be filled. I cleaned the sanded portion of the stem with cotton pad dipped in alcohol and spot filled the damaged area with a mixture of activated charcoal and clear superglue. I set the stem aside for the fill to cure.

Now, it was the turn of the stummel to get cleaned up. Using a hard bristled tooth brush dipped in undiluted Murphy’s oil soap, I very deliberately scrubbed the stummel, cleaning the surface thoroughly. I was very deliberate on the surface areas which were covered in overflowed lava over which dirt and grime had accumulated over the years. I rinsed the stummel under tap water, taking care that water does not enter the mortise or the chamber. I dried the stummel using cotton cloth and paper napkins. On close inspection, I observed a couple of dents and ding on the front portion of the crown. These would need to be addressed. Other than this, the stummel is now clean and devoid of any grime and dirt. It is really surprising that the rim top, inner bevel and edges and the stummel is in such pristine condition after so many years of storage and without a single fill. Speaks volumes about the quality of this line of pipes from WDC!!

Now, it was the turn of the stummel to get cleaned up. Using a hard bristled tooth brush dipped in undiluted Murphy’s oil soap, I very deliberately scrubbed the stummel, cleaning the surface thoroughly. I was very deliberate on the surface areas which were covered in overflowed lava over which dirt and grime had accumulated over the years. I rinsed the stummel under tap water, taking care that water does not enter the mortise or the chamber. I dried the stummel using cotton cloth and paper napkins. On close inspection, I observed a couple of dents and ding on the front portion of the crown. These would need to be addressed. Other than this, the stummel is now clean and devoid of any grime and dirt. It is really surprising that the rim top, inner bevel and edges and the stummel is in such pristine condition after so many years of storage and without a single fill. Speaks volumes about the quality of this line of pipes from WDC!!

I addressed the dents and dings to the front portion of the crown by the steaming process. I heated my fabricated knife over a candle. I placed a soaked Turkish hand towel over the dents and placed the hot knife over the wet towel. The steam that was generated pulled the dents to the surface. The stummel is now without any blemishes.

I addressed the dents and dings to the front portion of the crown by the steaming process. I heated my fabricated knife over a candle. I placed a soaked Turkish hand towel over the dents and placed the hot knife over the wet towel. The steam that was generated pulled the dents to the surface. The stummel is now without any blemishes. To further clean and highlight the grains, I sand the stummel with micromesh pads, wet sanding with 1500 to 2400 grit pads and dry sanding with 3200 to 12000 grit pads. I wiped the stummel after each wet pad with a moist cloth to remove the resulting dust. I rub a small quantity of “Before and After Restoration Balm” in to briar and let it rest for a few minutes. The balm almost immediately works its magic and the briar now has a nice vibrant appearance. I further buff it with a horse hair shoe brush. The pipe now looks lovely with beautiful grains showing off their beauty in all glory!!

To further clean and highlight the grains, I sand the stummel with micromesh pads, wet sanding with 1500 to 2400 grit pads and dry sanding with 3200 to 12000 grit pads. I wiped the stummel after each wet pad with a moist cloth to remove the resulting dust. I rub a small quantity of “Before and After Restoration Balm” in to briar and let it rest for a few minutes. The balm almost immediately works its magic and the briar now has a nice vibrant appearance. I further buff it with a horse hair shoe brush. The pipe now looks lovely with beautiful grains showing off their beauty in all glory!!

With the stummel nice and clean and attractive, I worked the stem of the “GOLD DOT” by sanding the fills with a flat heat needle to achieve a rough match with the surrounding stem surface. I sharpened the lip edges using a needle file and sand the entire stem with 220 followed by 400, 800 and 1000 grit sand paper to perfectly blend the filled surface with the rest of the stem surface. This helps to reduce the sanding marks left behind by the more abrasive 220 grit paper. By mere sanding itself, the minor tooth marks seen on stem surfaces were completely addressed. This process also eliminated the deep oxidation seen on the vulcanite stem. To bring a deep shine to the vulcanite stem, I went through the complete set of micromesh pads, wet sanding with 1500 to 2400 grit pads and dry sanding with 3200 to 12000 grit pads. I rubbed the stem down with Extra Virgin Olive oil after every three pads.

With the stummel nice and clean and attractive, I worked the stem of the “GOLD DOT” by sanding the fills with a flat heat needle to achieve a rough match with the surrounding stem surface. I sharpened the lip edges using a needle file and sand the entire stem with 220 followed by 400, 800 and 1000 grit sand paper to perfectly blend the filled surface with the rest of the stem surface. This helps to reduce the sanding marks left behind by the more abrasive 220 grit paper. By mere sanding itself, the minor tooth marks seen on stem surfaces were completely addressed. This process also eliminated the deep oxidation seen on the vulcanite stem. To bring a deep shine to the vulcanite stem, I went through the complete set of micromesh pads, wet sanding with 1500 to 2400 grit pads and dry sanding with 3200 to 12000 grit pads. I rubbed the stem down with Extra Virgin Olive oil after every three pads.

I completed the restoration of the stummel by cleaning the grooves between the twin rings separating the crown from the rest of the stummel, of all the dust, grime and polishing compounds accumulated during the restoration process. Lucky me, there is no damage to the rings, which would have been a challenge to restore.

I completed the restoration of the stummel by cleaning the grooves between the twin rings separating the crown from the rest of the stummel, of all the dust, grime and polishing compounds accumulated during the restoration process. Lucky me, there is no damage to the rings, which would have been a challenge to restore. To finish, I re-attach the stem with the stummel. I mount a cotton cloth buffing wheel on to my local machine which is similar to a Dremel. I set the speed at about half of the full power and polished the entire pipe with White Diamond compound. I wiped/ buffed the pipe with a soft cotton cloth to clear it of any leftover compound dust. I then mounted another cotton cloth wheel on to the polishing machine and applied several coats of carnauba wax over the stummel and the stem. I finished the restoration by giving the pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The completed pipe, with the dark brown hues of the grains on the stummel contrasting with the shiny black stem, looks lovely, fresh and vibrant; the photographs speak for themselves. If only the pipe could tell some of my grand Old man’s stories and recount incidents witnessed while being smoked.…Cheers!!

To finish, I re-attach the stem with the stummel. I mount a cotton cloth buffing wheel on to my local machine which is similar to a Dremel. I set the speed at about half of the full power and polished the entire pipe with White Diamond compound. I wiped/ buffed the pipe with a soft cotton cloth to clear it of any leftover compound dust. I then mounted another cotton cloth wheel on to the polishing machine and applied several coats of carnauba wax over the stummel and the stem. I finished the restoration by giving the pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The completed pipe, with the dark brown hues of the grains on the stummel contrasting with the shiny black stem, looks lovely, fresh and vibrant; the photographs speak for themselves. If only the pipe could tell some of my grand Old man’s stories and recount incidents witnessed while being smoked.…Cheers!!

I am grateful to all the readers for their valuable time spent in reading this write up and joining me on this part of the journey in to the world of pipe restoration while I attempt to preserve a heritage and past memories of a part of me.

I am grateful to all the readers for their valuable time spent in reading this write up and joining me on this part of the journey in to the world of pipe restoration while I attempt to preserve a heritage and past memories of a part of me.

About the same time I picked up the Calich, I received an email from the collector in Idaho asking for help. This is what he wrote to me:

About the same time I picked up the Calich, I received an email from the collector in Idaho asking for help. This is what he wrote to me: I took an end view photo to show the snapped off tenon in the shank of the pipe. You can see in that photo that it is also a clean break.

I took an end view photo to show the snapped off tenon in the shank of the pipe. You can see in that photo that it is also a clean break. This morning I was “chatting” with Charles Lemon on the Tobacco Pipe Restorers Group on Facebook about Jobey Links and how easy they were to work with when replacing a tenon. I went through my container of tenons and I did not have one that would work in this shank without a lot of work. I took out my box of Jobey Link replacement tenons and one of them was absolutely the perfect size for this shank. I would need to use it backwards and do some modifications but it was exactly what I wanted for this repair. I used a topping board to flatten out the remnants of the broken tenon on the stem. I used a knife to bevel the airway to make drilling it easier. I took the following photo to show the parts of the repair.

This morning I was “chatting” with Charles Lemon on the Tobacco Pipe Restorers Group on Facebook about Jobey Links and how easy they were to work with when replacing a tenon. I went through my container of tenons and I did not have one that would work in this shank without a lot of work. I took out my box of Jobey Link replacement tenons and one of them was absolutely the perfect size for this shank. I would need to use it backwards and do some modifications but it was exactly what I wanted for this repair. I used a topping board to flatten out the remnants of the broken tenon on the stem. I used a knife to bevel the airway to make drilling it easier. I took the following photo to show the parts of the repair. I tried my usual method for removing a broken tenon from the shank – a drywall screw turned into the airway in the shank until it was tight and then wiggling the broken tenon out of the shank. It failed to produce any results. It was almost like the tenon was glued/bonded to the walls of the shank. I used a cotton swab to dribble alcohol down the shank around the broken tenon. I left the shank and tenon sitting while I went to work for the day. When I came home I tried the screw again and still absolutely no movement on the tenon… it was stuck.

I tried my usual method for removing a broken tenon from the shank – a drywall screw turned into the airway in the shank until it was tight and then wiggling the broken tenon out of the shank. It failed to produce any results. It was almost like the tenon was glued/bonded to the walls of the shank. I used a cotton swab to dribble alcohol down the shank around the broken tenon. I left the shank and tenon sitting while I went to work for the day. When I came home I tried the screw again and still absolutely no movement on the tenon… it was stuck.

Now with that half of the job done I set the bowl aside and picked up the stem. I used a drill bit slightly smaller than the threaded portion of the Jobey Link. I drilled out the airway in the stem with increasingly larger drill bit until it was the perfect size for the Link. I still needed to tap the newly drilled airway so that I could turn the tenon into the stem.

Now with that half of the job done I set the bowl aside and picked up the stem. I used a drill bit slightly smaller than the threaded portion of the Jobey Link. I drilled out the airway in the stem with increasingly larger drill bit until it was the perfect size for the Link. I still needed to tap the newly drilled airway so that I could turn the tenon into the stem.

I used a tap set that I have and tapped threads into the newly drilled airway in the stem. It did not take long to tap thread into the vulcanite. I tapped the airway until it was deep enough for to take the threaded tenon.

I used a tap set that I have and tapped threads into the newly drilled airway in the stem. It did not take long to tap thread into the vulcanite. I tapped the airway until it was deep enough for to take the threaded tenon.  I shortened the threaded end of the tenon to deal with the taper of the stem. I used a Dremel and sanding drum and then smoothed it out on the 220 grit sandpaper topping board. I used the Dremel and sanding drum to remove the hip on the Jobey Link. I flattened it out to match the smooth part of the tenon that would go into the shank. The added length of the tenon fit perfect in the depth of the mortise on the pipe. I turned the tenon into the airway with a pair of pliers.

I shortened the threaded end of the tenon to deal with the taper of the stem. I used a Dremel and sanding drum and then smoothed it out on the 220 grit sandpaper topping board. I used the Dremel and sanding drum to remove the hip on the Jobey Link. I flattened it out to match the smooth part of the tenon that would go into the shank. The added length of the tenon fit perfect in the depth of the mortise on the pipe. I turned the tenon into the airway with a pair of pliers. I sanded out the scratch marks from the Dremel removal of the hip on the tenon with 220 grit sandpaper and polished it with 1500-2400 grit micromesh and took a photo of the stem with the new tenon and the tools I used to work on it.

I sanded out the scratch marks from the Dremel removal of the hip on the tenon with 220 grit sandpaper and polished it with 1500-2400 grit micromesh and took a photo of the stem with the new tenon and the tools I used to work on it. When I looked over the stem I could see a few tooth marks on the surface on both the top and underside near the button. I figured that since I was working on it anyway I would remove those areas. I sanded the stem with 220 grit sandpaper to remove the damage and polished the sanding marks with 400 grit wet dry sandpaper.

When I looked over the stem I could see a few tooth marks on the surface on both the top and underside near the button. I figured that since I was working on it anyway I would remove those areas. I sanded the stem with 220 grit sandpaper to remove the damage and polished the sanding marks with 400 grit wet dry sandpaper.

I polished the vulcanite stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the stem down after each pad with Obsidian Oil. When I finished the last pad I gave it a final coat of Obsidian Oil and set it aside to dry.

I polished the vulcanite stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I wiped the stem down after each pad with Obsidian Oil. When I finished the last pad I gave it a final coat of Obsidian Oil and set it aside to dry.

I set the stem aside and turned my attention to the bowl. I examined it and found that there were a few small nicks and chips around the rim top and outer edge of the bowl. I touched these up with a walnut stain pen to blend them into the rest of the finish on the bowl. I rubbed the bowl down with Before & After Restoration Balm to enliven the wood and protect the newly finished portions of the briar. I took these photos after to show the bowl and the repairs are unnoticeable.

I set the stem aside and turned my attention to the bowl. I examined it and found that there were a few small nicks and chips around the rim top and outer edge of the bowl. I touched these up with a walnut stain pen to blend them into the rest of the finish on the bowl. I rubbed the bowl down with Before & After Restoration Balm to enliven the wood and protect the newly finished portions of the briar. I took these photos after to show the bowl and the repairs are unnoticeable.

I put the stem back on the shank and buffed the pipe with a clean buffing pad to bring a shine back to the bowl and stem. I gave it several coats of Conservator’s Wax and continue the buff. I hand buffed it with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. Tomorrow I will box it up and send it back to Idaho. Can’t wait to see what he thinks when he has it in his hands. Thanks for reading this. Cheers.

I put the stem back on the shank and buffed the pipe with a clean buffing pad to bring a shine back to the bowl and stem. I gave it several coats of Conservator’s Wax and continue the buff. I hand buffed it with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. Tomorrow I will box it up and send it back to Idaho. Can’t wait to see what he thinks when he has it in his hands. Thanks for reading this. Cheers.