By Al Jones

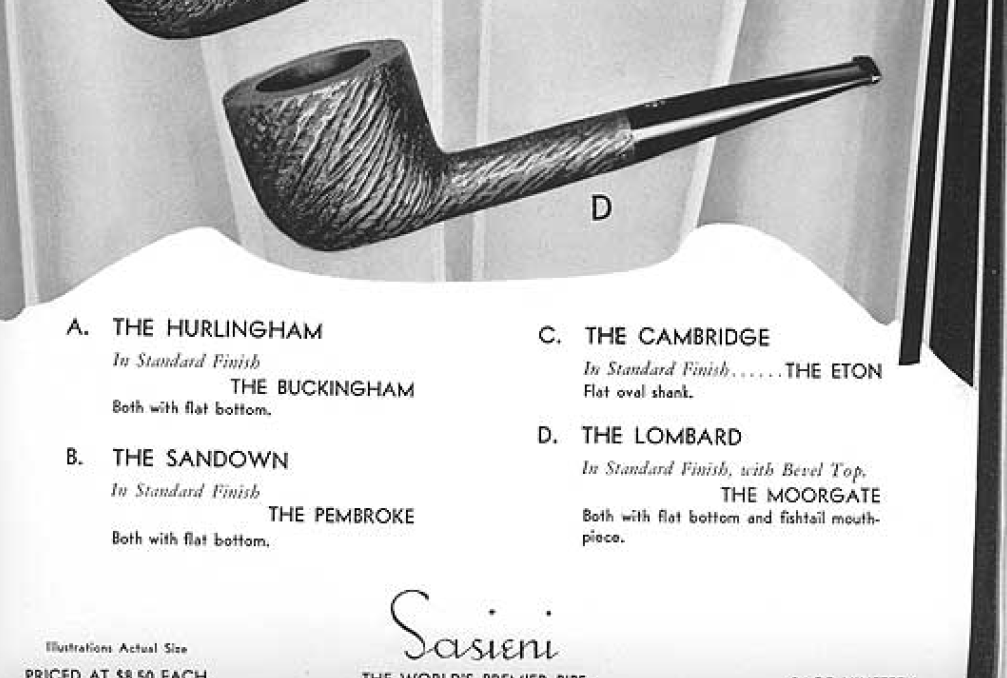

The Comoy’s “Author” shape 256 is one of my favorite shapes, similar to the Sasieni Ashford. This one is a Comoy’s seconds line, “Lions Head” version. I’ve had numerous Comoy’s seconds line pipes over the years, including multiple versions of the shape 256. However this is the first Lions Head to land on my workbench.

I don’t find anything in Comoy’s literature for the shape 256. If anyone has a catalog depicting this shape, please send me a copy. This pipe caught my attention because of the “Made In England” round country of manufacture stamp. This stamp dates to the 1930’s and was used until the start of World War II. We read this about the stamp from Pipedia:

Made in England

This is stamped in a circle with “MADE” at the top, “IN” in the middle, and “ENGLAND” forming the bottom of the circle. This can be seen on a Cecil as early as 1910 and on an Old Bruyere of 1921 and more frequent from the 1930s. It can also appear as “MADE” arched, “IN” below, and “ENGLAND” arched the other way. These stamps are in an oval rugby-ball shape rather than a circle round shape.

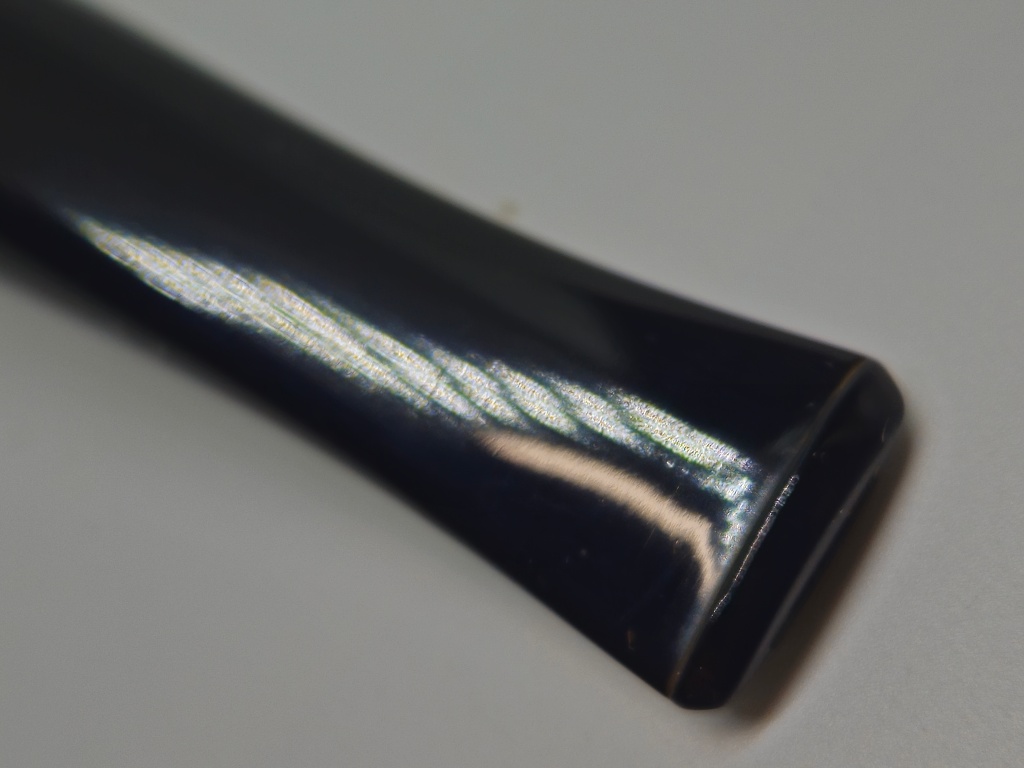

The pipe as delivered was in very restorable condition. The finish was faded from the sun, the stem heavily oxidized and some black build-up on the bowl top. The stem fitment was very good and the button was also not damaged. The stamped L stem logo was still visible. I wasn’t sure that could be salvaged. Below is the pipe as it was received:

I used a piece of worn scotch brite to remove the build-up on the bowl top. I revived the finish with a heavily diluted Feiblings Medium Brown stain (diluted with 91% isopropyl alcohol). The bowl was then lightly buffed with White Diamond rouge and several coats of carnuba wax, taking care around the stamping. The bowl was then soaked with alcohol and sea salt. Following the soak, I scrubbed the shank with a bristle brush dipped in alcohol, until it came out clean.

The stem was mounted, and oxidation removed with 600, 800, 1,500 and 2,000 grade wet paper. The stem was then buffed with White Diamond and Meguiars plastic polish. Surprisingly, the stamped L logo is still visible.

Below is the finished pipe: