Blog by Steve Laug

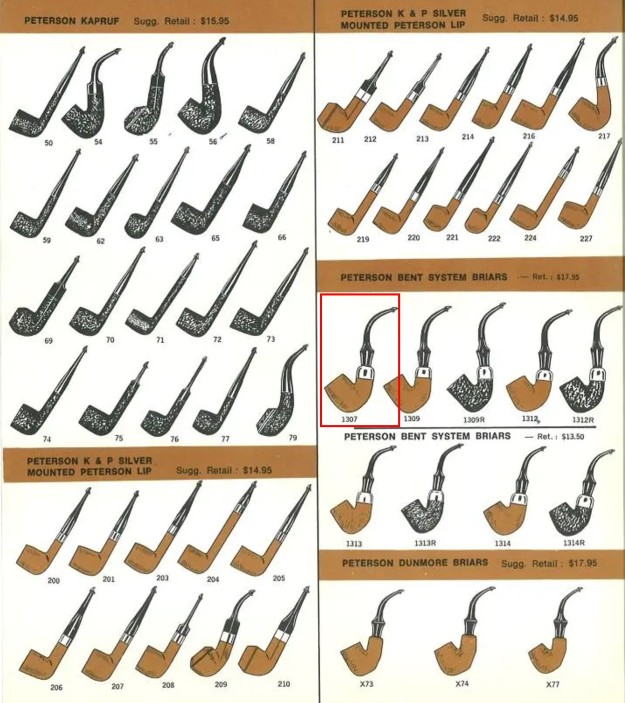

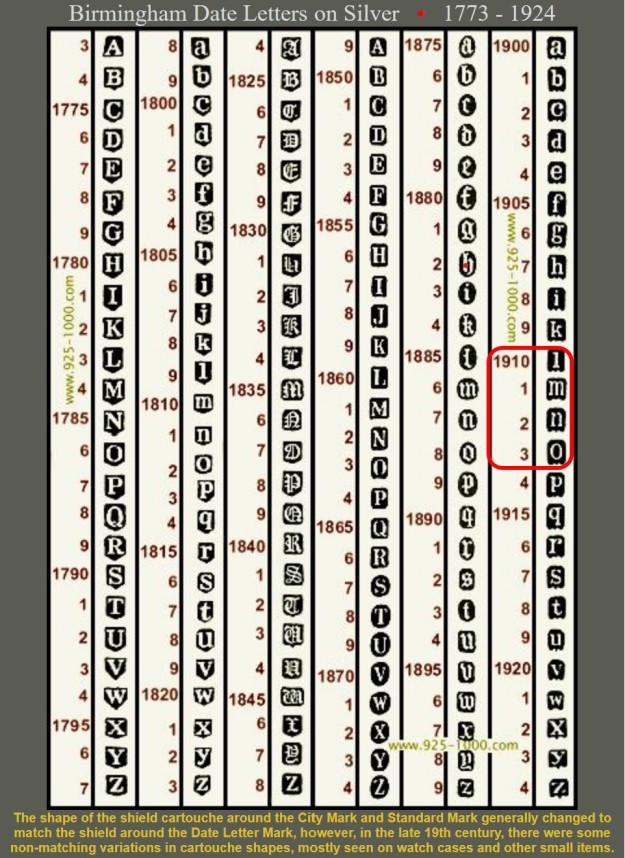

The next pipe I have chosen is another smooth finished Peterson’s System – this time a System Standard shape 302. It came to us from our source in Copenhagen, Denmark on 01/29/24. It had fishtail stem rather than a P-lip stem. The finish was smooth with some nice grain around the sides and shank. It was stamped on the left side of the shank and read Peterson’s [arched over] System [over] Standard. On the right side of the shank it was stamped Made in the Republic of Ireland (three lines) over the shape number 302. It was dirty with grime ground into the finish around the bowl and shank. There was a moderate cake in the bowl and some light lava spots on the rim top. The nickel ferrule was in good shape but had some scratches that would need to be polished. It is stamped as well and reads K & P [over] Peterson on the left. The vulcanite fishtail stem was unstamped and there was some oxidation, calcification and light chatter near the button that would polish out. Jeff took photos of the pipe before he started my work.

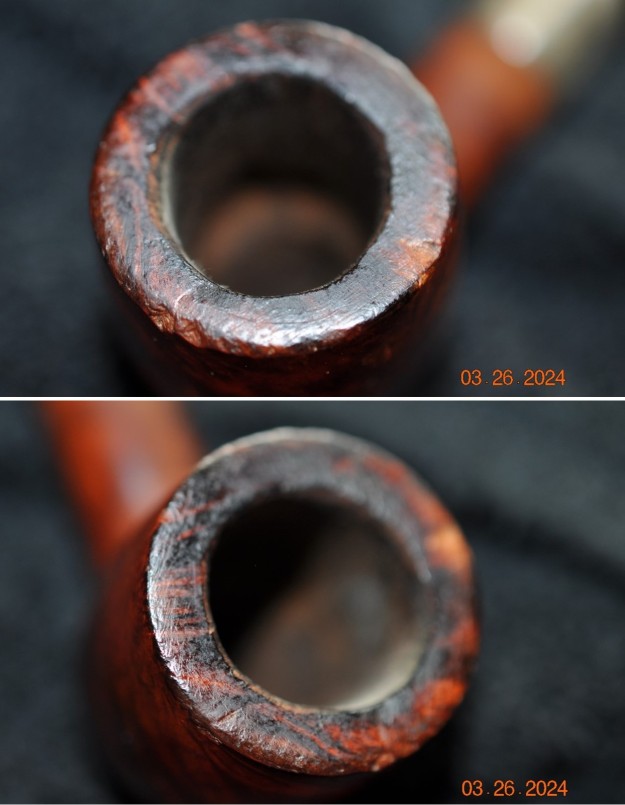

He took photos of the rim top and stem to show the general condition of the pipe. The bowl is moderately caked and the rim top and edges have a spotty lava overflow. The stem looks good but it has light tooth marks on the top and underside near the button.

He took photos of the rim top and stem to show the general condition of the pipe. The bowl is moderately caked and the rim top and edges have a spotty lava overflow. The stem looks good but it has light tooth marks on the top and underside near the button.

He took photos of the sides and heel of the bowl to show the grain that was very visible around the bowl and shank.

He took photos of the sides and heel of the bowl to show the grain that was very visible around the bowl and shank.

He took photos of the stamping on the shank sides and the ferrule. It read as noted above and was clear and readable.

He took photos of the stamping on the shank sides and the ferrule. It read as noted above and was clear and readable.

I am including the information from Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson). I have included a bit of the pertinent history here.

I am including the information from Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson). I have included a bit of the pertinent history here.

1950 – 1989 The Republic Era – From 1950 to the present time, the stamp for this era is “Made in the Republic of Ireland” in a block format generally in three lines but two lines have been used with or without Republic being abbreviated.

During the 1950’s and 60’s the Kapp & Peterson company was still in the ownership of the Kapp family. However 1964 saw the retiral of the company Managing Director Frederick Henry(Harry) Kapp.

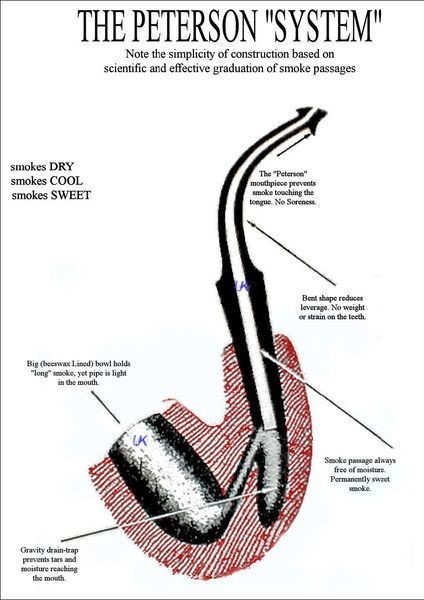

Pipedia also included a section of information on the System pipes including a diagram of the sytems look (https://pipedia.org/wiki/Peterson#Republic_Era_Pipes). I quote a section of the article in part and include a link to another article on Pipedia on the System pipe.

The Peterson System pipes are the standard bearers of the Peterson pipe family, famous for the excellent smoking pleasure they provide. Often imitated but never equalled, the Peterson System smokes dry, cool and sweet, thanks to the scientific effectiveness of the original design. The heart of the System is the unique graduated bore in the mouthpiece. This makes the suction applied by the smoker 15 times weaker by the time it reaches the tobacco chamber. The result is that all the moisture flows into the reservoir and, thus cannot reach the smoker’s mouth. The Peterson Lip further enhances the effectiveness of the graduated bore by directing the flow of smoke upwards and away from the tongue. This achieves a uniquely even distribution of smoke and virtually eliminates any chance of tonguebite or bitterness. Furthermore, the shape is contoured so that the tongue rests comfortably in the depression under the opening. Each “PLip” mouthpiece is made from Vulcanite. For the Peterson System pipes to work properly, the stem/tenon has to have an extension, the tip of which will pass by the draft hole from the bowl and into the sump. Upon the smoker drawing in smoke, this extension then directs the smoke down and around the sump to dispense a lot of the moisture before the smoke enters the extension and stem. On the System Standards and other less expensive systems, this extension with be made of Vulcanite turned integrally with the stem. On the more expensive System pipes this extension will be made of metal which screws into the Vulcanite stem. This extension on the earlier pipes will be of brass and the newer pipes will be of aluminium. Most smokers not knowing this function of the metal extension, assumes that it is a condenser/stinger and will remove it as they do with the metal condensers of Kaywoodie, etc. Should you have a System pipe with this metal extension, do not remove it for it will make the System function properly and give you a dryer smoke (https://pipedia.org/wiki/A_closer_look_at_the_famous_Peterson_Standard_System_Pipe).

The Peterson System pipes are the standard bearers of the Peterson pipe family, famous for the excellent smoking pleasure they provide. Often imitated but never equalled, the Peterson System smokes dry, cool and sweet, thanks to the scientific effectiveness of the original design. The heart of the System is the unique graduated bore in the mouthpiece. This makes the suction applied by the smoker 15 times weaker by the time it reaches the tobacco chamber. The result is that all the moisture flows into the reservoir and, thus cannot reach the smoker’s mouth. The Peterson Lip further enhances the effectiveness of the graduated bore by directing the flow of smoke upwards and away from the tongue. This achieves a uniquely even distribution of smoke and virtually eliminates any chance of tonguebite or bitterness. Furthermore, the shape is contoured so that the tongue rests comfortably in the depression under the opening. Each “PLip” mouthpiece is made from Vulcanite. For the Peterson System pipes to work properly, the stem/tenon has to have an extension, the tip of which will pass by the draft hole from the bowl and into the sump. Upon the smoker drawing in smoke, this extension then directs the smoke down and around the sump to dispense a lot of the moisture before the smoke enters the extension and stem. On the System Standards and other less expensive systems, this extension with be made of Vulcanite turned integrally with the stem. On the more expensive System pipes this extension will be made of metal which screws into the Vulcanite stem. This extension on the earlier pipes will be of brass and the newer pipes will be of aluminium. Most smokers not knowing this function of the metal extension, assumes that it is a condenser/stinger and will remove it as they do with the metal condensers of Kaywoodie, etc. Should you have a System pipe with this metal extension, do not remove it for it will make the System function properly and give you a dryer smoke (https://pipedia.org/wiki/A_closer_look_at_the_famous_Peterson_Standard_System_Pipe).

With that information in hand I knew what I was dealing with in terms of the stamping and the age of this pipe. I knew from the information that the pipe was made during the Late Republic Era between 1950 and the present day. Personally I think this is probably a 60s-70s pipe. Now it was time to work on the pipe.

Jeff had cleaned up the pipe with his usual thoroughness. He reamed the pipe with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He soaked the stem in Before & After Deoxidizer and rinsed it off with warm water. Somewhere along the way as it sat here it picked up some stickiness on the top of the stem that looks a lot like what is left behind by a gummed label. I took photos of the pipe 3 years later when I finally got around to working on it. As you can see it is another beautiful looking pipe.

I took photos of the rim top and bowl as well as the stem to give a sense of the condition of both. The rim top and the inner edge had some darkening and burn damage on the inner edge on the back of the bowl. The stem was clean but had light tooth marks and chatter on the top and underside ahead of the button.

I took photos of the rim top and bowl as well as the stem to give a sense of the condition of both. The rim top and the inner edge had some darkening and burn damage on the inner edge on the back of the bowl. The stem was clean but had light tooth marks and chatter on the top and underside ahead of the button. I took photos of the stamping on the sides of the shank. They are clear and readable as noted above. I took the stem out of the shank and took a photo of the overall look of the pipe. It is another beauty. There are a few small dings from the journey of the pipe that will remain as a part of its story.

I took photos of the stamping on the sides of the shank. They are clear and readable as noted above. I took the stem out of the shank and took a photo of the overall look of the pipe. It is another beauty. There are a few small dings from the journey of the pipe that will remain as a part of its story.

I started my work on the pipe by working on the damage to the top and inner edge of the rim with a folded piece of 220 grit sandpaper. I was able to remove the darkening on the top completely but I also took care of the burn damage on the inner edge to give it a slight bevel. It looks much better. I worked the top and edge over with a 320 grit sanding sponge and wiped it down with a damp cloth. It looked much better.

I started my work on the pipe by working on the damage to the top and inner edge of the rim with a folded piece of 220 grit sandpaper. I was able to remove the darkening on the top completely but I also took care of the burn damage on the inner edge to give it a slight bevel. It looks much better. I worked the top and edge over with a 320 grit sanding sponge and wiped it down with a damp cloth. It looked much better.

I polished the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth.

I polished the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. The product works to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. The product works to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I polished the nickel ferrule with a jeweller’s cloth to protect and polish the metal. It really adds a sparkle to the metal ferrule.

I polished the nickel ferrule with a jeweller’s cloth to protect and polish the metal. It really adds a sparkle to the metal ferrule.

I set the bowl aside and turned to work on the stem. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I gave it a final coat of Obsidian Oil and set it aside to dry.

I set the bowl aside and turned to work on the stem. I polished the stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem. I gave it a final coat of Obsidian Oil and set it aside to dry.

This Republic Era Peterson’s System Standard 302 Bent Apple with a vulcanite, fish tail, saddle stem is a great looking pipe now that it has been restored. The beautiful grain that shines through the polished finish is stunning. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peterson’s System Standard 302 fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 69 grams/2.43 ounces. This pipe has been spoken for so it will soon be heading out with a couple of others that have been set aside for their new trustee. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This Republic Era Peterson’s System Standard 302 Bent Apple with a vulcanite, fish tail, saddle stem is a great looking pipe now that it has been restored. The beautiful grain that shines through the polished finish is stunning. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Peterson’s System Standard 302 fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 69 grams/2.43 ounces. This pipe has been spoken for so it will soon be heading out with a couple of others that have been set aside for their new trustee. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!