Blog by Aaron Henson – 11/29/15

I think the thrill of the hunt is part of what makes this hobby so enjoyable. Going into a new store or happening upon a pipe in an unlikely place, never knowing just exactly what you are going to find and always keeping a lookout for that forgotten gem.

This past summer I was on vacation with my family in Seaside, Oregon. Between Seaside and Astoria I visited 14 different antique stores and only two had any pipes at all. And of those, they were all on the pricy side; too rich for me.

Partly on a whim and partly out of desperation, I went into a second-hand store that I had passed by several times. It was more “junk” than “antique” and of course that is where I made my score although I didn’t think so at first. Three pipes: the first was a non-briar volcano with “Italy” stamped on the bottom, the second was a Medico that was in such bad shape it could only be used for parts but the third was intriguing with a silver band. I could not read the markings for all the filth on the pipe. I negotiated with guy behind the counter and walked out will all three for $15. It was clear that this had been a very nice pipe in its day. The wood grain that could be seen through the grime was beautiful and the Army Style push stem I thought gave the pipe a classy feel. When I got it back to the house and looked it over in better light, I noticed that the band had been rotated on the shank so the writing was upside down and in the dim light of the store I could not read it. Now I could see that it clearly said “Peterson” and “Dublin” stamped in the silver band.

It was clear that this had been a very nice pipe in its day. The wood grain that could be seen through the grime was beautiful and the Army Style push stem I thought gave the pipe a classy feel. When I got it back to the house and looked it over in better light, I noticed that the band had been rotated on the shank so the writing was upside down and in the dim light of the store I could not read it. Now I could see that it clearly said “Peterson” and “Dublin” stamped in the silver band.

A Peterson, my heart skipped a beat. I was well aware of Peterson’s long history of making quality pipes and now I had picked up an early model for 5-bucks!

The bowl had a good build up of cake and a fair amount of unburned tobacco in the bottom. Some build up of tars on the rim but otherwise seemed to be in good condition. The shank had clearly been broken, however and the glue used for the repair was spread all over one side of the bowl. The stamping on the band, as stated before, were worn and not very readable. The stem was oxidized and had a hole in the top near the button. This must have been a favorite pipe of the previous owner.

The bowl had a good build up of cake and a fair amount of unburned tobacco in the bottom. Some build up of tars on the rim but otherwise seemed to be in good condition. The shank had clearly been broken, however and the glue used for the repair was spread all over one side of the bowl. The stamping on the band, as stated before, were worn and not very readable. The stem was oxidized and had a hole in the top near the button. This must have been a favorite pipe of the previous owner.

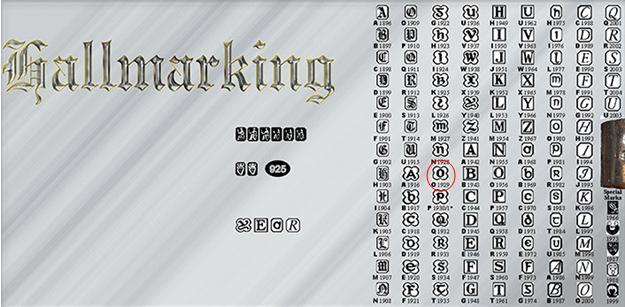

When I got home from vacation, I tried to understand the symbolic hallmarks on the band. Not being familiar with Peterson marking I sent a picture to Steve Laug to ask his opinion. Steve very graciously referred me to his Peterson expert, Mark Irwin. With Mark’s help I was able to understand Peterson’s hallmarking and dated the pipe as 1929 – placing it in the Irish Free State era: 1922 – 1937. At least, that was my interpretation of the third hallmark, an “O”.

I began by reaming out the cake with a Castleford reamer and took the interior back to bare wood. There were some burn marks under the tar on the rim so I elected to top the bowl with some 220 grit paper laid on the flat work bench.

I began by reaming out the cake with a Castleford reamer and took the interior back to bare wood. There were some burn marks under the tar on the rim so I elected to top the bowl with some 220 grit paper laid on the flat work bench. Next I heated the band with a flame and then using leather jawed pliers and carefully rotated the band back into correct alignment.

Next I heated the band with a flame and then using leather jawed pliers and carefully rotated the band back into correct alignment. The outside of the bowl I wiped down with a cotton pad soaked in acetone. This removed the grime and the glue. I had been worried that the glue was covering a crack in the bowl but it turned out that the person doing the shank repair had just been sloppy. The glue came away and revealed pristine briar underneath. In just the right light, I also could see a very faint IRISH FREE STATE stamped into the bottom side of the shank – Confirmation!

The outside of the bowl I wiped down with a cotton pad soaked in acetone. This removed the grime and the glue. I had been worried that the glue was covering a crack in the bowl but it turned out that the person doing the shank repair had just been sloppy. The glue came away and revealed pristine briar underneath. In just the right light, I also could see a very faint IRISH FREE STATE stamped into the bottom side of the shank – Confirmation! The break between the bowl and the shank had been complete. I could see the seam all the way around the shank but it had been a clean break. There were no gaps, rounded edges nor missing pieces; so far, so good.

The break between the bowl and the shank had been complete. I could see the seam all the way around the shank but it had been a clean break. There were no gaps, rounded edges nor missing pieces; so far, so good.

At this point I turned my attention to the stem. I put the stem to soak in a mild chlorine bath to raise the oxidation. A light sanding with some worn 400 grit paper removed the oxidation completely. I picked the loose material out of the hole, made backing plug out of toothpicks and slipped it into the airway. This would hold my patching material in place. Next I mixed up some StewMac black super glue with some activated charcoal powder and worked it into the hole with another tooth pick. I set the stem aside to cure over night.

When I came back to the stem I sanded down the fill with 220 grit paper. The plug blended nicely and I proceeded to polish the stem with 1500 – 12000 micromesh pads. Cleaning the inside of the stem was quite simple, four of alcohol soaked pipe cleaners (2 bristled and 2 soft) took care of the insides and the stem was done.

When I came back to the stem I sanded down the fill with 220 grit paper. The plug blended nicely and I proceeded to polish the stem with 1500 – 12000 micromesh pads. Cleaning the inside of the stem was quite simple, four of alcohol soaked pipe cleaners (2 bristled and 2 soft) took care of the insides and the stem was done. Returning to the stummel, I began to work the bowl-shank joint back and forth with ever increasing force. I caught myself holding my breath, afraid of breaking the pipe beyond repair but dismissed that thought as fear of the unknown and pushed on. Eventually the crack began to open up and the shank and bowl were separated. I was surprised to see that the original repair had included two small brads – or pins – set on either side of the air hole to strengthen the break. Since the brads were already in proper alignment I decided to reuse them in my repair.

Returning to the stummel, I began to work the bowl-shank joint back and forth with ever increasing force. I caught myself holding my breath, afraid of breaking the pipe beyond repair but dismissed that thought as fear of the unknown and pushed on. Eventually the crack began to open up and the shank and bowl were separated. I was surprised to see that the original repair had included two small brads – or pins – set on either side of the air hole to strengthen the break. Since the brads were already in proper alignment I decided to reuse them in my repair. After some research, I settled on the J-B Kwik Weld as my epoxy of choice. Its resistant temperature is less than that of original J-B Weld (300 vs 550 degrees); however, I do not think the shank should reach 300 degrees during a smoke. But the real advantage in my minds was that the set time is only 6 minutes compared to 4-6 hours. I didn’t want to have to come up with a way to hold the two parts together for several hours and risk the parts slipping.

After some research, I settled on the J-B Kwik Weld as my epoxy of choice. Its resistant temperature is less than that of original J-B Weld (300 vs 550 degrees); however, I do not think the shank should reach 300 degrees during a smoke. But the real advantage in my minds was that the set time is only 6 minutes compared to 4-6 hours. I didn’t want to have to come up with a way to hold the two parts together for several hours and risk the parts slipping.

In order to keep the airway clear during the repair, I pushed a pipe cleaner through the airway before smearing the epoxy on the both surfaces with a tooth pick. With the clock running on the set time, I pushed to the two parts together using the old brads as alignment pins. Looking back I think it would have been better if I had only used one of the pins. The fit was tight and I was fighting against the pins to get the two parts tight together when the time ran out on the epoxy. I was left with a larger gap between the pieces than I thought was right; I had been hoping for a flush fit. Before setting the pipe aside to cure I wiped off the excess epoxy and removed the pipe cleaner. I let the pipe sit overnight and the next day I used a dental pick to remove some of the epoxy from the gap between the stummel and bowl. The gap was very small, less than a 1/32 of an inch on top and near flush on the bottom. When the crack was as clean as I could get it, I filled it with briar dust and placed drops of clear super glue on top to hold the dust in place. When the super glue dried I smoothed out the repair with 220 grit sand paper.

I let the pipe sit overnight and the next day I used a dental pick to remove some of the epoxy from the gap between the stummel and bowl. The gap was very small, less than a 1/32 of an inch on top and near flush on the bottom. When the crack was as clean as I could get it, I filled it with briar dust and placed drops of clear super glue on top to hold the dust in place. When the super glue dried I smoothed out the repair with 220 grit sand paper. There were some minor dents in the bowl and I decided to steam them out by wrapping the bowl with a damp terry cloth rag and going over the rag with a clothes iron set on high. If you used this method I would advise keeping your figures well clear of the iron. Speaking from personal experience, you don’t have to be very close to the iron get burned by the steam. Fortunately, I did not drop bowl!

There were some minor dents in the bowl and I decided to steam them out by wrapping the bowl with a damp terry cloth rag and going over the rag with a clothes iron set on high. If you used this method I would advise keeping your figures well clear of the iron. Speaking from personal experience, you don’t have to be very close to the iron get burned by the steam. Fortunately, I did not drop bowl!

I sanded the entire bowl with 400 – 2000 grit paper to remove all the dents and scratches but being sure to stay clear of the marking on the shank. The markings were faint but I wanted to preserve as much of them as I could.

The bowl had beautiful grain and I wanted to use a light brown stain to highlight it. I used one part Fiebing’s light brown mixed with 2 parts isopropyl alcohol applied with a cotton swab in layers until the color looked just right. I flaming each layer and wiped off the excess with a cotton pad moistened with alcohol.

The next to last step was to polish the sterling silver band. For this I tried a new technique that I had recently learned on this blog using a small amount of cigar ash and saliva. I was careful not to polish too much – or at all – around the hallmarks. The final step was a trip to the buffer for three coats of carnauba wax on the briar and stem. I hand applied a light coat of Walker Briar Works carnauba wax sealer on the silver band and I buffed the pipe with a micro fiber cloth to bring up the shine.