Blog by Steve Laug

I received this pair of pipes from Charles Lemon of Dad’s Pipes Blog. He picked them up as part of an estate from London, Ontario, Canada. They are both stamped on the bottom of the shank on a smooth surface with the words Beaver Cut in script over a block script Genuine Briar. He did some hunting on the web and could find nothing that gave any sense of history of the brand. When I got them I did the same and found absolutely nothing. The Genuine Briar stamping tells me it is post WW2 and is made in the USA. I found another Beaver Cut for sale on Worthpoint but it also did not have any information. From what I can find that is the extent of the information available.

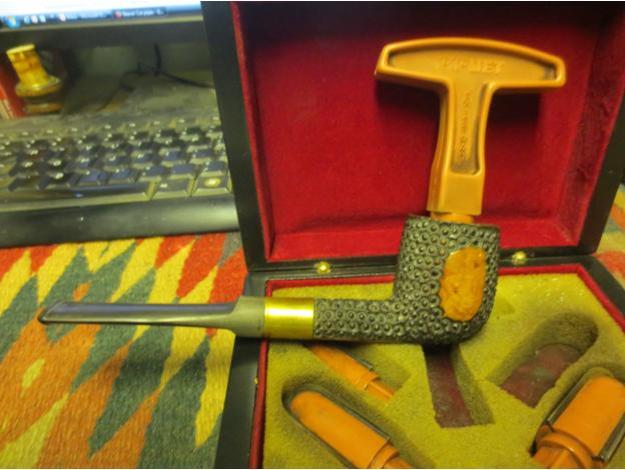

The top pipe in the photo is Prince. The rustication was dirty and a lot of dirt and debris had collected in the grooves. It had a rustication pattern that I had not seen before. It is like rows and rows of birdseye cuts in the surface of the briar. There is a smooth patch on both sides and on the bottom of the shank. The bowl had a thick cake and the shank had a lot of debris and oils in it. The rim had an overflow of lava and oils on the top of the bevel. The inner and outer edge of the rim was in great shape and the bowl was still in round. The brass band on the shank appeared to be factory as it was on both pipes and was identical. It was scarred and had tarnished. When it was installed the installer had made a mess of the shank. He had cut the shank back farther than the length of the band so that when it was installed it left a groove between the edge of the band and the rustication on the shank. It looked almost as if the band was an afterthought. I am pretty certain that it was sent out from the factory with that look. The stamping had been cut in two by the chopping of the briar to fit the band. The stem did not fit the shank due to the buildup internally. The stem was also missing a large chunk on the right side near the button and someone had cut a groove in the top of the stem to begin cutting a new button but had not finished the work.

The lower pipe is a Billiard with the exact same grain pattern. It was in a bit better shape than the Prince. The grooves in the unique rustication were actually clean. There was a varnish coat on the smooth parts of the bowl even though there were several sandpits in each smooth spot. The bowl had a thick cake and the rim had an overflow of tars and lava which obscured the bevel. The fit of the band to the shank on this one was better though looking at it from the end of the mortise it was clear that the shank was out of round. The brass was also scratched and marred on this pipe. The stamping on this one was clean and deep. The stem diameter extended further on the right side than on the left though the stem was of equal diameter all the way around. There were some light tooth marks on the top and the bottom of the stem near the button and there was tooth chatter. The stem was oxidized but was faintly stamped with a B in a circle.

I took a close up photo of the rim on each of the pipes. The first photo below shows the rim on the Prince and the second shows the rim on the Billiard. The buildup and the uneven cake are visible in both pipes. It is hard to see the bevel on the rim in the Prince but it matches the one on the rim of the Billiard.

I took a close up photo of the rim on each of the pipes. The first photo below shows the rim on the Prince and the second shows the rim on the Billiard. The buildup and the uneven cake are visible in both pipes. It is hard to see the bevel on the rim in the Prince but it matches the one on the rim of the Billiard.

I also took some close up photos of the stems on both pipes to show the state of the stem. The first two photos show the stem on the Prince. You can see the damage of the broken area on the side of the button and the cut off button. You can also see the groove or divot that had been cut in the stem to make the pipe useable. The third and fourth photos show the stem on the Billiard and you can see the tooth marks and chatter on the stem surface. It is also clear that it does not fit well against the side of the band.

I also took some close up photos of the stems on both pipes to show the state of the stem. The first two photos show the stem on the Prince. You can see the damage of the broken area on the side of the button and the cut off button. You can also see the groove or divot that had been cut in the stem to make the pipe useable. The third and fourth photos show the stem on the Billiard and you can see the tooth marks and chatter on the stem surface. It is also clear that it does not fit well against the side of the band.

I decided to restem the Prince so I found a stem in my can of stems that was the same diameter as the shank and slightly longer than the broken stem to account for the missing button. I turned the tenon with a sanding drum on a Dremel to get a close fit and then hand sanded until it push snuggly into the mortise.

I decided to restem the Prince so I found a stem in my can of stems that was the same diameter as the shank and slightly longer than the broken stem to account for the missing button. I turned the tenon with a sanding drum on a Dremel to get a close fit and then hand sanded until it push snuggly into the mortise. To deal with the badly fit shank band I cleaned the area with a dental pick and then pressed briar dust into the groove just ahead of the band. I dripped clear super glue into the briar dust and then as it settled add more glue and more briar dust. I wanted the transition between the shank and the band to be smooth. I sanded the repair with a folded piece of 220 grit sandpaper and then with a medium and a fine grit sanding sponge to smooth out the scratches in the surface.

To deal with the badly fit shank band I cleaned the area with a dental pick and then pressed briar dust into the groove just ahead of the band. I dripped clear super glue into the briar dust and then as it settled add more glue and more briar dust. I wanted the transition between the shank and the band to be smooth. I sanded the repair with a folded piece of 220 grit sandpaper and then with a medium and a fine grit sanding sponge to smooth out the scratches in the surface. I reamed both bowls back to bare wood with a PipNet reamer. I sanded the beveled rim on the Prince to clean off the oils and lava and to show the bevel. More work would need to be done on both rims.

I reamed both bowls back to bare wood with a PipNet reamer. I sanded the beveled rim on the Prince to clean off the oils and lava and to show the bevel. More work would need to be done on both rims.

I worked on the bevel of the rims with 220 grit sandpaper to remove the buildup and also to smooth out the bevel. It took quite a bit of sanding on both rims to get the angle consistent all the way around the bowl and also to remove the burn damage on the inner edge of both. I sanded both with a medium and fine grit sanding sponge to finish the cleanup.

I worked on the bevel of the rims with 220 grit sandpaper to remove the buildup and also to smooth out the bevel. It took quite a bit of sanding on both rims to get the angle consistent all the way around the bowl and also to remove the burn damage on the inner edge of both. I sanded both with a medium and fine grit sanding sponge to finish the cleanup. I stained the newly cleaned surfaces of the rim with a light brown stain pen to approximate the colour on the smooth portions on the bowl sides and bottom of the shank.

I stained the newly cleaned surfaces of the rim with a light brown stain pen to approximate the colour on the smooth portions on the bowl sides and bottom of the shank. I sanded them both with 400 grit wet dry sandpaper to smooth out the remaining scratches that showed up with the stain. It also lightened the stain enough that the match was perfect.

I sanded them both with 400 grit wet dry sandpaper to smooth out the remaining scratches that showed up with the stain. It also lightened the stain enough that the match was perfect.

With the rims finished it was time to scrub the rustication. I used Murphy’s Oil Soap and a tooth brush to scour the rustication pattern on both bowls. I scrubbed them and then rinsed them under warm running water.

With the rims finished it was time to scrub the rustication. I used Murphy’s Oil Soap and a tooth brush to scour the rustication pattern on both bowls. I scrubbed them and then rinsed them under warm running water.

To address the difference in diameter of the stem and the band on the shank on the Billiard I used a Dremel and sanding drum to take down the top, bottom and right side of the saddle stem. I repeatedly checked the fit until I had it very close then I finished adjusting the fit by hand with 220 grit sandpaper. I sanded the stem on the Prince with 220 grit sandpaper to remove the oxidation and the calcification on the end of the stem.

To address the difference in diameter of the stem and the band on the shank on the Billiard I used a Dremel and sanding drum to take down the top, bottom and right side of the saddle stem. I repeatedly checked the fit until I had it very close then I finished adjusting the fit by hand with 220 grit sandpaper. I sanded the stem on the Prince with 220 grit sandpaper to remove the oxidation and the calcification on the end of the stem.

With the fit finished on the stems it was time to clean out the internals of the stems and shanks. I used alcohol, cotton swabs and pipe cleaners to scrub the insides until they were clean.

With the fit finished on the stems it was time to clean out the internals of the stems and shanks. I used alcohol, cotton swabs and pipe cleaners to scrub the insides until they were clean.

I wet sanded the stem and the brass with a 1500 grit micromesh sanding pad for the first round of sanding on both. It worked to remove many of the scratches and marks in the brass and the vulcanite.

I wet sanded the stem and the brass with a 1500 grit micromesh sanding pad for the first round of sanding on both. It worked to remove many of the scratches and marks in the brass and the vulcanite. I worked on the stem with the micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three pads. When I finished sanding with the 12000 grit pad I let the oil dry on the stem.

I worked on the stem with the micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil between each set of three pads. When I finished sanding with the 12000 grit pad I let the oil dry on the stem.

In the final sanding I sanded the brass and it carried over onto the top portion of each stem giving it a bit of a brown look in the next photo. This all came off when I buffed the stem with red Tripoli and White Diamond.

In the final sanding I sanded the brass and it carried over onto the top portion of each stem giving it a bit of a brown look in the next photo. This all came off when I buffed the stem with red Tripoli and White Diamond. I heated the stem on the Prince and gave it a slight bend to give it a more finished looked. I buffed the stems and rims with White Diamond and Blue Diamond and then gave them multiple coats of carnauba wax. I also waxed the smooth portions on the bowl sides, shank bottoms and the rims. I buffed these with Blue Diamond as well. I wiped the rustication down with a light coat of olive oil to bring some life back to the briar. The finished sisters are shown below.

I heated the stem on the Prince and gave it a slight bend to give it a more finished looked. I buffed the stems and rims with White Diamond and Blue Diamond and then gave them multiple coats of carnauba wax. I also waxed the smooth portions on the bowl sides, shank bottoms and the rims. I buffed these with Blue Diamond as well. I wiped the rustication down with a light coat of olive oil to bring some life back to the briar. The finished sisters are shown below.

Thanks for looking. Does anyone have any information about this brand? It would be great to be able to get a little information. Please post anything you know in the comments below. Thanks.

Thanks for looking. Does anyone have any information about this brand? It would be great to be able to get a little information. Please post anything you know in the comments below. Thanks.