Blog by Steve Laug

To me there is nothing quite like the thrill of a pipe hunt to get my blood running. The anticipation of finding something that I had not found or seen before is always a prologue to the actual hunt itself. When I walk through the door of the “hunting ground” there is a new anticipation – what lies in store for me in the aisles and booths of the shop. I have found that some shops/malls are organized and have all of the tobacciana in one spot in the shop but the majority are not that systematized. Something about walking through a large or small shop with a focused objective makes the pleasure even more intense. When I find pipes – be it just a few or a box full – I get a solid rush as I work my way through the box and see if anything special is hidden in the lot. I have found Dunhill’s hidden in cans of junk pipes so I always work through the lot individually. I have to tell you that there are very few times that I come home from a hunt empty handed.

On Friday evening my brother Jeff called me from Montana. He and his wife had driven there to visit her parents. Along the way they had of course stopped at several antique shops and looked for pipes. In one of the shops he struck “gold”, the shop had a motherlode of pipes. He had talked with the owner and she told him she bought a box of pipes. He bought a few of them from her and then went back to the hotel and gave me a call. He showed me the pipes he had picked up and they were old ones. He had some nice pipes. He then told me the story and an idea he had.

His idea was brilliant really and quite simple. We both have iPads and use FaceTime to chat back and forth about pipes that he is looking at. He thought, why not bring the iPad to the antique shop and take me on the pipe hunt with him. That way we could look through the many pipes that were available in the shop and it would be like I was present experiencing the discovery of each one. We made a plan and set the time for the hunt. I was looking forward to checking out the place.

The next day after lunch my iPad showed that Jeff was calling on Facetime. I answered and in a moment I was inside the antique shop with him. We walked over to the corner of the shop where the display case was. The owner opened the case and Jeff brought out a rack of pipes at a time. He brought them to the counter where the iPad was sitting. He took each pipe out of the rack and we looked at the stamping on the shank and the condition of the mouthpiece and bowl. We looked at the stem material and determined what it was made of. We guessed the age as best as we could, given the brand and the style of the bowl and stem. We went through over forty pipes that way and spent the better part of an hour and a half.

He captured two photos of the iniside of the shop that showed what we saw when we were on FaceTime. They show a display case and the area where the pipes were in the store from two different angles.

He gathered the pipes together and took them to his hotel room. He spread out the pipes on the bed and took some photos of the lot. There really are some unique pipes in the lot. I can’t wait to get them in Vancouver and work them over. There were many CPF pipes in the bunch that are different from others I have worked. The first is a photo that gives a big picture of the pipes we picked out from the shop.

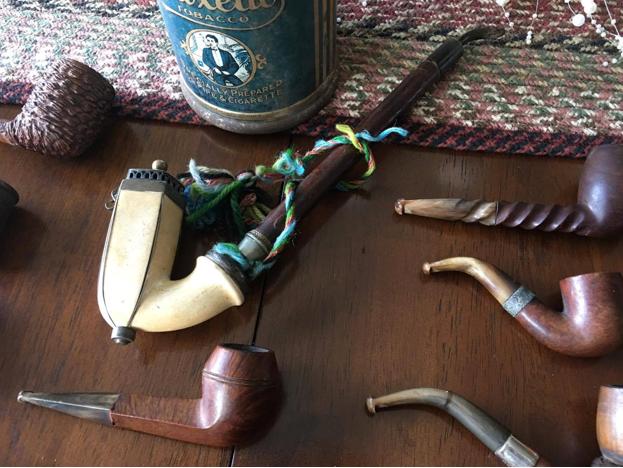

He gathered the pipes together and took them to his hotel room. He spread out the pipes on the bed and took some photos of the lot. There really are some unique pipes in the lot. I can’t wait to get them in Vancouver and work them over. There were many CPF pipes in the bunch that are different from others I have worked. The first is a photo that gives a big picture of the pipes we picked out from the shop. He also took some close up photos of sections of the lot. Here are those photos. They give you an idea of some of the unique pieces we found at the shop.

He also took some close up photos of sections of the lot. Here are those photos. They give you an idea of some of the unique pieces we found at the shop. The next two photos is a close up of the pipes on the left toward the top of the first photo.

The next two photos is a close up of the pipes on the left toward the top of the first photo.

The next two photos show closer looks at the pipes in the middle and on the right side of the first photo.

The next two photos show closer looks at the pipes in the middle and on the right side of the first photo.

You can see from the photos that there are some interesting pieces that we found. I could not believe that we picked up 30 pipes and one case. There were 11 unique CPF brand pipes, 1 Manhattan, 1 Twisted shank horn stem, 1 Borlum, 1 Superior, 1 Hilson, 2 WDC, 1 Kaywoodie All Briar, 1 Imperial, 2 Italian Briar, 1 Hooker, 1 Stanwell Majestic, 1 London Thorn Drucquer pipe, 2 Meerschaums, 1 carved bulldog, 1 Seville, 1 Frank Bakelite and a RBC empty pipe case. He sent me a list of the brands on the pipes. I have grouped together to give a sense of what was present in the lot.

You can see from the photos that there are some interesting pieces that we found. I could not believe that we picked up 30 pipes and one case. There were 11 unique CPF brand pipes, 1 Manhattan, 1 Twisted shank horn stem, 1 Borlum, 1 Superior, 1 Hilson, 2 WDC, 1 Kaywoodie All Briar, 1 Imperial, 2 Italian Briar, 1 Hooker, 1 Stanwell Majestic, 1 London Thorn Drucquer pipe, 2 Meerschaums, 1 carved bulldog, 1 Seville, 1 Frank Bakelite and a RBC empty pipe case. He sent me a list of the brands on the pipes. I have grouped together to give a sense of what was present in the lot.

- CPF military mount Oom Paul

- CPF The Remington, French Briar, (Miliatary mount)

- CPF French Briar with Hallmarked band and horn stem. Filigree carving around bowl

- CPF Pullman with Horn Stem

- CPF Siamese with twin horizontal stems

- CPF Cromwell with twin vertical stems

- CPF Briar Bowl Sitting on Petals- Horn Stem

- CPF French Briar Bulldog with Horn Stem

- CPF French Briar with tarnished metal band and a Horn Stem (looks like mini-Wellington)

- CPF French Briar Horn Shaped Pipe with metal band and Horn Stem

- CPF Colon French Briar with Black Meer Bowl and Amber stem

- Briar pipe with twisted shank going into a twisted horn stem

- Borlum Italian Briar (Unbreakable Bit)

- Hilson Bolero, Made in Belgium, #8

- Superior with filigree metal band around shank and bowl- red bakelite stem

- Manhattan with Horn Stem

- WDC Monitor

- WDC Campaign with Briar unscrewable bowl

- Kaywoodie AllBriar 50B (All-imported Briar)- chewed off wood stem

- Imperial De Luxe, Made in London England (Mini-churchwarden)

- Italian Briar bulldog with red dot on stem

- The Hooker- with screw cap next to bowl on top of shank- Patented May 17,1910- Horn Stem

- Stanwell Majestic 64, Made in Denmark

- London Thorn, Drucquer & Sons, Berkeley

- Carved bulldog with yellow Bakelite stem

- Seville Filter, Imported Briar Italy

- Heavily Rusticated Italian Briar with wrong stem

- No-name Meerschaum Bowl and shank without stem- with spikes on bowl and shank, brown to black

- Large Meerschaum Capped Pipe with horn stem and cherry wood shank

- Frank Bakelite (EP Silver)

- RBC Genuine French Briar , Red-lined small Black Case

When Jeff returned home, he removed the stickers and tags from the pipe and laid them out on his kitchen table. The photos below give another look at the pipes – sans price stickers and tags.

I would say we had a good day pipe hunting. I have never seen that many CPF pipes in one spot and the number of pipes of that age is unique as well. I think we will have to do some more of these virtual pipe hunts because it transcends borders and space and gives the experience in real time. The only thing missing to me was the actual handling of the pipes in person. The experience was really good and I was able to feel like I was in the shop itself as we looked at each pipe and discussed the pros and cons before buying them. You might consider this kind of pipe hunt if you have a good friend who enjoys the hunt as much as you do and has an iPhone or iPad. If you happen to try it out or have already done so in the past post a comment below. Thanks for looking.

I would say we had a good day pipe hunting. I have never seen that many CPF pipes in one spot and the number of pipes of that age is unique as well. I think we will have to do some more of these virtual pipe hunts because it transcends borders and space and gives the experience in real time. The only thing missing to me was the actual handling of the pipes in person. The experience was really good and I was able to feel like I was in the shop itself as we looked at each pipe and discussed the pros and cons before buying them. You might consider this kind of pipe hunt if you have a good friend who enjoys the hunt as much as you do and has an iPhone or iPad. If you happen to try it out or have already done so in the past post a comment below. Thanks for looking.