Great information here Charles. There is also a one dot green that is on early pipes made by the grandfather… I have one of those old timers and have been in correspondence with them regarding it. Well done on this pipe – it is a beauty!

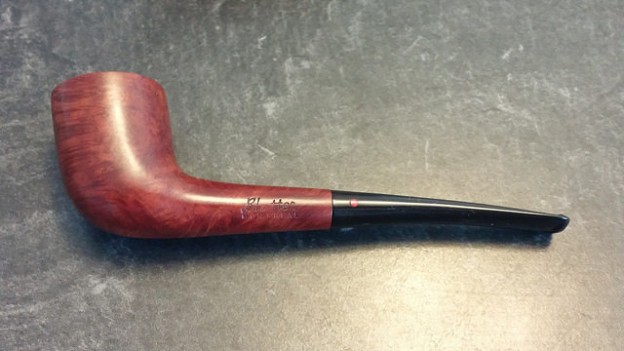

I was recently sent a box of six pipes for refurbishment from a gentleman in Iqaluit, Nunavut. All six pipes were made by Blatter & Blatter, Inc of Montreal, known at one point in the firm’s 100 year history as Blatter Bros.

Established in Montreal in 1907, Blatter & Blatter has remained, by choice, a small, family-owned pipe producer, currently putting out about 300 pipes annually. The company website is very short on details – I believe that the Quebec advertising laws restrict the firm from posting pictures and pricing – but as far as grading of Blatter pipes goes, Pipephil.eu can help.

Blatter pipes are marked with one or two dots on the side of the stem. One red dot indicates a machine-made pipe in a classic shape; two red dots mark a completely hand made pipe, usually in the freehand style. A few pipes are marked with one…

View original post 781 more words