Blog by Dal Stanton

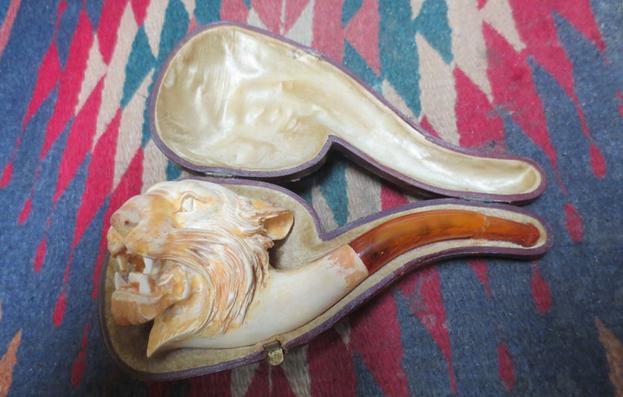

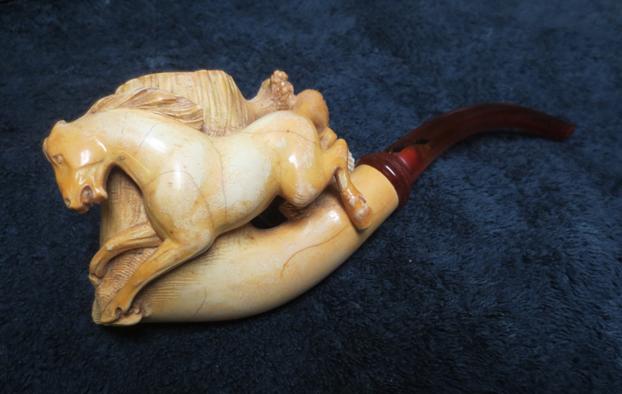

A pipe man’s dream scenario: His daughter and son-in-law, who live in Denver, give him the perfect birthday gift – a budget enabling him to land a special, coveted pipe on eBay! It doesn’t get much better than that – there is the hunt, the find, the anticipation, the bid, the stress, and finally, the victory (hopefully)! I started the hunt looking for a meerschaum to add to my growing briar collection, but when I saw the McLardy Calabash and it’s perfectly shaped and colored gourd – the quint-essential Sherlock Holmes pipe, decked out with silver cap and ferrule, it cried out to me and resistance was futile. The eBay seller was in Manchester, UK, and his description of the Calabash was very helpful with silver hallmarks which dated the pipe in 1907 – the first year that the Chicago Cubs won the World Series followed by a second series win in 1908 over the Tigers. They would not win again until this year, 2016. 1907 also saw Theodore Roosevelt as the 26th president of the US, the first electric washing machine, Albert Einstein beginning to apply laws of gravity to the Theory of Relativity, and Ford’s Model R is produced. My grandmother, who died at 102, would not be cradled for another 3 years, in 1910. 1907 also gave us the pipe in these eBay pictures of the birthday gift now with me in Sofia, Bulgaria.

Truly an antique, I was anxious to explore the silver hallmarks and to verify the seller’s information – not that I doubted it, but this Gourd Calabash afforded me the opportunity to learn about the age-old practice of marking silver, not only to establish its authenticity, but also the provenance of the pipe that has been adorned with the sterling. The ferrule and cap hallmarks were identical except that the triangular ‘Maker’s Mark’ was over the hallmarks on the ferrule and to the left on the cap (compared above).

Truly an antique, I was anxious to explore the silver hallmarks and to verify the seller’s information – not that I doubted it, but this Gourd Calabash afforded me the opportunity to learn about the age-old practice of marking silver, not only to establish its authenticity, but also the provenance of the pipe that has been adorned with the sterling. The ferrule and cap hallmarks were identical except that the triangular ‘Maker’s Mark’ was over the hallmarks on the ferrule and to the left on the cap (compared above). The Maker’s Mark points to Samuel McLardy & Co. as referenced here at HALLMARKS OF ENGLISH SILVER MAKER’S MARK IDENTIFICATION – ILLUSTRATED LISTING. The story is fascinating.

The Maker’s Mark points to Samuel McLardy & Co. as referenced here at HALLMARKS OF ENGLISH SILVER MAKER’S MARK IDENTIFICATION – ILLUSTRATED LISTING. The story is fascinating.

In January of 2015, The Dutch Pipe Smoker wrote a blog regarding the Samuel McLardy & Co. summarizing an extensive article by Don Duco called, Pipes Samuel McLardy from Manchester – an excellent article helping me to grasp the geo-political realities of the time.

In January of 2015, The Dutch Pipe Smoker wrote a blog regarding the Samuel McLardy & Co. summarizing an extensive article by Don Duco called, Pipes Samuel McLardy from Manchester – an excellent article helping me to grasp the geo-political realities of the time.

From The Dutch Pipe Smoker:

The McLardy company thanks its existence to the entrepreneurial spirit of 1 person: Samuel McLardy, born in Glasgow in 1842. He was the son of a tobacconist who also produced his own clay pipes. In the paternal shop he must have learned the profession of pipe-maker. Shortly after his 20th birthday he decided to move to Manchester to start his own company. There is remarkably little known about the history of the factory. On an old advertisement it says “established 1865” so since then there must have been a steady growth. Within a couple of decades there was a massive production of clay pipes. Around 1895 the factory owned over 500 moulds which meant yearly production was around 5 million pipes! Similar to that of Dutch factory P. Goedewaagen & Zoon in that period. Over time we find Samuel McLardy at different locations. Before 1880 that was Miller Street number 16 in Manchester and it is there where the shop grew to the size of a factory. In 1890 the company moved to Shudehill number 67 where it remained active until after 1910.

The production of clay pipes was a large part of the McLardy operation and this interesting Pipe Manufacturers Catalogue shows several clay models displayed for sale. Duco’s article, referenced above, examines the historical realities impacting the Samuel McLardy Co., (typical of other UK pipe companies) by navigating through relatively prosperous years leading up to the turn of the century, the decline of interest in clay pipes, diversification of other product lines to cope with falling revenues, WWI, the growing economic bubble of the 20s leading ultimately to the collapse of the McLardy, Co., soon after the stock market crashes in September (for UK) and October (for US), 1929. I found this last statement regarding the Samuel McLardy, Co., as a matter of public record published in archives of The London Gazette regarding the liquidation of the company. Reflective of the times, there were several companies listed in the Gazette which were being “wound up”:

The Companies Act, 1929.

Special Resolution of SAMUEL McLARDY & CO. Limited.

Passed 13th January, 1930.

AT an Extraordinary General Meeting of the Members of the above named Company, duly convened, and held at No. 20, Swan-street, Manchester, on the 13th day of January, 1930, the following Resolution was duly passed as a Special Resolution: –

” That the Company be wound up voluntarily; and that Mr. George Elder, Chartered Accountant, of Edwin Collier & Co., 3, York-street, Manchester, be appointed Liquidator for the purposes of such winding-up.”

Dated this day 13th January 1930

SAMUEL McLARDY

Source: The London Gazette – 17th January 1930 With a greater appreciation for the man and his company in time, I turn again to the hallmarks on the McLardy Calabash’s ferrule (above) which reveal the pipe’s origins. The hallmark to the left is the city mark for cities of United Kingdom. The anchor is the mark of Birmingham from 1773 to the present (See: Online Encyclopedia of Silver Marks, Hallmarks & Makers’ Marks – British Marks) referenced below.

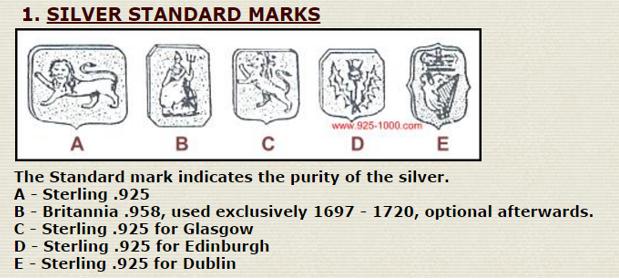

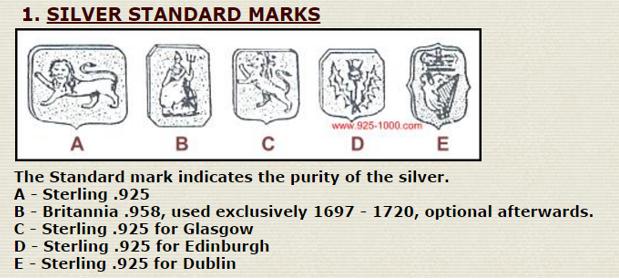

With a greater appreciation for the man and his company in time, I turn again to the hallmarks on the McLardy Calabash’s ferrule (above) which reveal the pipe’s origins. The hallmark to the left is the city mark for cities of United Kingdom. The anchor is the mark of Birmingham from 1773 to the present (See: Online Encyclopedia of Silver Marks, Hallmarks & Makers’ Marks – British Marks) referenced below.  The Lion hallmark in the middle ferrule stamping above is the Standard mark indicating the quality or purity of the silver. As referenced below from the same helpful website, ‘A’ represents a sterling rating of .925.

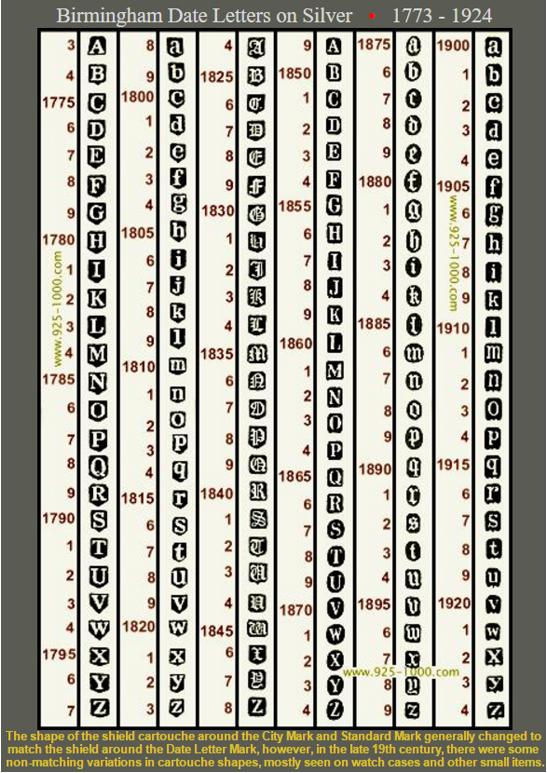

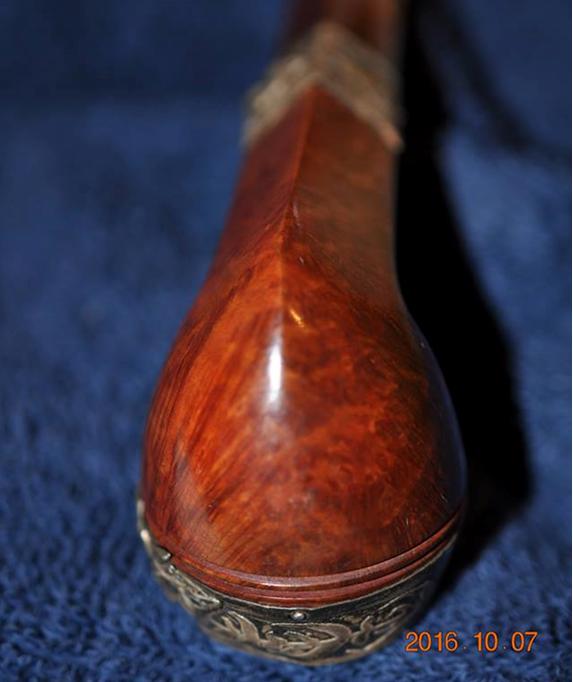

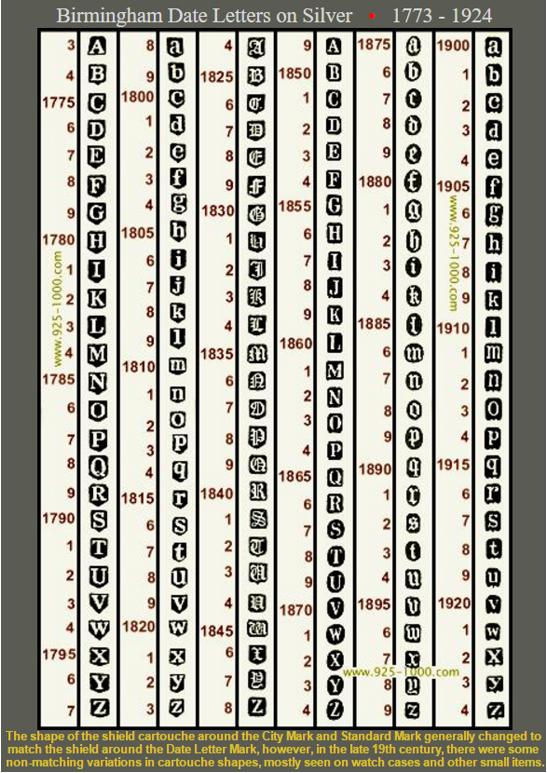

The Lion hallmark in the middle ferrule stamping above is the Standard mark indicating the quality or purity of the silver. As referenced below from the same helpful website, ‘A’ represents a sterling rating of .925. Finally, the hallmark on the far right, the ‘h’ ensconced in a scroll-like cartouche, represents the dating letter. The Birmingham Date Letters on Silver 1773-1924 chart below references the letter system specifically for Birmingham, England. The far-right column points to the dating of this McLardy Gourd Calabash which stands at a ripe old age of 109 years, coming out of the Manchester factory located on Shudehill number 67 – the factory depicted on the cover above (Today, on Google maps street view, the address continues but appears to be a parking garage.). It has not gone unnoticed by me that the eBay seller of the Calabash also resides in Manchester. The question that comes to mind is whether this McLardy vestige has wandered away from home at all? If he could only tell his story….

Finally, the hallmark on the far right, the ‘h’ ensconced in a scroll-like cartouche, represents the dating letter. The Birmingham Date Letters on Silver 1773-1924 chart below references the letter system specifically for Birmingham, England. The far-right column points to the dating of this McLardy Gourd Calabash which stands at a ripe old age of 109 years, coming out of the Manchester factory located on Shudehill number 67 – the factory depicted on the cover above (Today, on Google maps street view, the address continues but appears to be a parking garage.). It has not gone unnoticed by me that the eBay seller of the Calabash also resides in Manchester. The question that comes to mind is whether this McLardy vestige has wandered away from home at all? If he could only tell his story….  There is but one more bit my curious mind wishes to discover – from whence comes the gourd that has become the cherished Calabash, made famous by Arthur Conan Doyle’s Sherlock Holmes? As quaint as it may sound, it is likely the gourd which became the McLardy Calabash before me did not come from a cozy English garden on the outskirts of Manchester – images of Downton Abbey. Most likely, the gourd came from southern Africa. In his newsletter, ‘Save the Calabash’, Thomas Martin provides some good research regarding this question of the Calabash gourd. He wrote:

There is but one more bit my curious mind wishes to discover – from whence comes the gourd that has become the cherished Calabash, made famous by Arthur Conan Doyle’s Sherlock Holmes? As quaint as it may sound, it is likely the gourd which became the McLardy Calabash before me did not come from a cozy English garden on the outskirts of Manchester – images of Downton Abbey. Most likely, the gourd came from southern Africa. In his newsletter, ‘Save the Calabash’, Thomas Martin provides some good research regarding this question of the Calabash gourd. He wrote:

Calabash has come to represent a shape not a gourd

Nobody would expect an apple shaped pipe to be made from an apple. Like “calabash” the name represents the shape not the material. The Calabash pipe used to actually be made from a gourd (Lageneria vulgaris). To my knowledge, there are no makers of real Calabash pipes in the United States and so I decided to make it my goal to give it a try. Having made a handful or two of briar pipes, I learned that finding good briar is the challenge that Rainer Barbi calls “the dance.” I can tell you, finding a Calabash gourd although not impossible, is far more difficult.

Current wisdom suggests that acceptable gourds can only be grown in the Ladismith region of South Africa. When Calabash proliferated they were cultivated for the specific purpose of becoming a pipe. Presently, if you can find a farmer that grows the gourd he doesn’t grow it or shape it to be a pipe. In North America they are grown mostly for crafters. In Africa they are grown for crafters and for more utilitarian use.

If you want to know more about gourds, the making of a Calabash, different kinds of Calabash pipes and Hollywood’s contribution to the mystique, take a look at http://calabashpipe.com/. I make no apologies admitting that I approach the clean-up and restoration of the 1907 McLardy Gourd Calabash with a bit of fear and trepidation. I have read the blogs of several former restorations of gourd Calabashes and I have assimilated various practices – it’s difficult to say “best” practices because compared to briar pipe restorations, gourd Calabash restorations are far and few between. I’m thankful for Steve’s consultations via email mainly regarding how to approach the bowl which the eBay seller maintained is Meerschaum, but Steve’s counsel to tread carefully is well-taken – he indicated that he has seen Calabashes this age with bowls made of clay or asbestos as well. With the Samuel McLardy Co. doing so much trade with clay pipes, I’m wondering if the bowl capped in this gourd might just be clay. We’ll see. This question, became the ‘pre-restoration’ question that had to be resolved. I sent these pictures to Steve after his counsel to take a real close look at the gaps just below the silver bowl cap that reveal the bowl material. Is it meerschaum as advertised by the seller? Is it clay? Or, is it asbestos material? Steve’s email described that if it was an asbestos material, it would be better not to smoke this pipe, but to turn it into a display icon – better this than sucking down airborne asbestos! His instructions were to examine the scraped area at the rim and see if it was fibrous. If so, then it probably was made of an asbestos material. If clay, it would be more porous. Thankfully, with a sharp dental probe in hand under a large magnifying glass, I scraped the light material pictured below to discover that it was pretty solid – no fibers detected. We’re in agreement that the material is most likely clay, but I’m not sure how to conclusively determine one or the other at this point. Can anyone tell by looking at this?

I make no apologies admitting that I approach the clean-up and restoration of the 1907 McLardy Gourd Calabash with a bit of fear and trepidation. I have read the blogs of several former restorations of gourd Calabashes and I have assimilated various practices – it’s difficult to say “best” practices because compared to briar pipe restorations, gourd Calabash restorations are far and few between. I’m thankful for Steve’s consultations via email mainly regarding how to approach the bowl which the eBay seller maintained is Meerschaum, but Steve’s counsel to tread carefully is well-taken – he indicated that he has seen Calabashes this age with bowls made of clay or asbestos as well. With the Samuel McLardy Co. doing so much trade with clay pipes, I’m wondering if the bowl capped in this gourd might just be clay. We’ll see. This question, became the ‘pre-restoration’ question that had to be resolved. I sent these pictures to Steve after his counsel to take a real close look at the gaps just below the silver bowl cap that reveal the bowl material. Is it meerschaum as advertised by the seller? Is it clay? Or, is it asbestos material? Steve’s email described that if it was an asbestos material, it would be better not to smoke this pipe, but to turn it into a display icon – better this than sucking down airborne asbestos! His instructions were to examine the scraped area at the rim and see if it was fibrous. If so, then it probably was made of an asbestos material. If clay, it would be more porous. Thankfully, with a sharp dental probe in hand under a large magnifying glass, I scraped the light material pictured below to discover that it was pretty solid – no fibers detected. We’re in agreement that the material is most likely clay, but I’m not sure how to conclusively determine one or the other at this point. Can anyone tell by looking at this?

The next ‘pre-restoration’ question that had to be answered as well was, what was the dark material in the bowl? One of the normal restoration practices is to clean out the fire chamber and at first I was thinking that the bowl of the Calabash would need to be sanded, but it became clear that it was not carbon cake staring up at me, but it looked more like a pipe mud coating over the clay/meerschaum bowl. In the next picture, angling the light I capture the view down to the draft hole showing the coating material and it appears pretty thin. With a pipe this age, the resulting plan is to be conservative – if it’s not too broken, why fix it? I decide to leave well enough alone – I will make more pipe mud and close the gaps around the upper chamber next to the silver cap. I will not sand the bowl, nor will I attempt to take the cap off to gain greater access to the interior of the gourd for cleaning.

The next ‘pre-restoration’ question that had to be answered as well was, what was the dark material in the bowl? One of the normal restoration practices is to clean out the fire chamber and at first I was thinking that the bowl of the Calabash would need to be sanded, but it became clear that it was not carbon cake staring up at me, but it looked more like a pipe mud coating over the clay/meerschaum bowl. In the next picture, angling the light I capture the view down to the draft hole showing the coating material and it appears pretty thin. With a pipe this age, the resulting plan is to be conservative – if it’s not too broken, why fix it? I decide to leave well enough alone – I will make more pipe mud and close the gaps around the upper chamber next to the silver cap. I will not sand the bowl, nor will I attempt to take the cap off to gain greater access to the interior of the gourd for cleaning.  With the 1907 McLardy Gourd Calabash on my work table, I take additional pictures of the areas in need and to get a better look at things – moving from ‘pre-restoration’ questions to cleaning up this Calabash and recommissioning him for service! Preparing for a new application of pipe mud in the gaps around the rim, below the cap, I want to clean the overflow black coating on the inside rim of the silver cap. The gourd is in good shape but there are some residue marks on the upper front side of the gourd – at this point, I don’t know if it has irrevocably stained the gourd or if it can be removed with a general cleaning. Both silver cap and ferule have dents and bumps from years of use and being passed from hand to hand. I won’t deal with the dents, but bringing a new shine to the sterling silver is a priority. The stem is in very good condition with mild oxidation and almost non-existent tooth chatter, but I do detect a dent in the upper button. There is also a divot in the vulcanite on the shank-side of the stem that needs attention. The bone tenon needs to be cleaned – it is the only access point to the interior of the gourd – I’ll clean what I can from that angle, but my assumption is that the interior of the gourd is dry and possibly somewhat fragile. I’ll be satisfied with a gentle clean in and around the bone tenon. One last thing that has caught my attention – the stem is a bit overclocked or rotated. I’m not sure now if it’s something to be concerned about.

With the 1907 McLardy Gourd Calabash on my work table, I take additional pictures of the areas in need and to get a better look at things – moving from ‘pre-restoration’ questions to cleaning up this Calabash and recommissioning him for service! Preparing for a new application of pipe mud in the gaps around the rim, below the cap, I want to clean the overflow black coating on the inside rim of the silver cap. The gourd is in good shape but there are some residue marks on the upper front side of the gourd – at this point, I don’t know if it has irrevocably stained the gourd or if it can be removed with a general cleaning. Both silver cap and ferule have dents and bumps from years of use and being passed from hand to hand. I won’t deal with the dents, but bringing a new shine to the sterling silver is a priority. The stem is in very good condition with mild oxidation and almost non-existent tooth chatter, but I do detect a dent in the upper button. There is also a divot in the vulcanite on the shank-side of the stem that needs attention. The bone tenon needs to be cleaned – it is the only access point to the interior of the gourd – I’ll clean what I can from that angle, but my assumption is that the interior of the gourd is dry and possibly somewhat fragile. I’ll be satisfied with a gentle clean in and around the bone tenon. One last thing that has caught my attention – the stem is a bit overclocked or rotated. I’m not sure now if it’s something to be concerned about.

Well, I put the word out to my friend and colleague, Gary, who lives in Plovdiv, Bulgaria, for some fresh cigar ash to make a fresh mixture of ash and water for pipe mud. While I wait for his reply, I remove the stem from the Calabash, stick a pipe cleaner in the airway and plop it in Oxyclean to raise the light oxidation from the stem. I also want to clean the inside of the silver cap in anticipation of a final shine but also to provide a clean line to apply the needed pipe mud in the gaps. I use God’s provided tools in fingernails and a bit of spittle – not much! I slowly and carefully, move around the inside of the silver cap with my index finger, scraping the old, perhaps ancient, not sure, pipe mud from the silver-plated surface. I don’t want to use a metal tool on the silver surface because I definitely don’t want a new scratch to add blemish. I then drag my thumb nail over the edge, with a bit of spittle, and hang it over the inner edge of silver cap and scrape additional hard caked stuff off. That actually worked really well!

Well, I put the word out to my friend and colleague, Gary, who lives in Plovdiv, Bulgaria, for some fresh cigar ash to make a fresh mixture of ash and water for pipe mud. While I wait for his reply, I remove the stem from the Calabash, stick a pipe cleaner in the airway and plop it in Oxyclean to raise the light oxidation from the stem. I also want to clean the inside of the silver cap in anticipation of a final shine but also to provide a clean line to apply the needed pipe mud in the gaps. I use God’s provided tools in fingernails and a bit of spittle – not much! I slowly and carefully, move around the inside of the silver cap with my index finger, scraping the old, perhaps ancient, not sure, pipe mud from the silver-plated surface. I don’t want to use a metal tool on the silver surface because I definitely don’t want a new scratch to add blemish. I then drag my thumb nail over the edge, with a bit of spittle, and hang it over the inner edge of silver cap and scrape additional hard caked stuff off. That actually worked really well!

Earlier I mentioned that I have read several posts dealing with cleaning up Gourd Calabashes with questions about the gourd surface itself. Steve’s post was helpful (See: Restoring an old CPF Gourd Calabash Pipe). To clean the gourd surface getting rid of the oils and dirt that collects on the gourd surface, I use undiluted Murphy’s Oil Soap on a cotton pad and scrub the surface, then remove it with another cotton pad – not using water which may wet the gourd surface too much. The gourd below the cap shows what appear to be residue from what I’m guessing was someone’s attempt to reattach the cap to the gourd – it appears to be glue runovers. I can’t tell if it has damaged the gourd surface or if the old glue is resting on the surface. As I scrub the gourd with undiluted Murphy’s Oil Soap, I concentrate on these areas. I take a 2400 grade micromesh pad and lightly sand the area – just testing very gently what effect the pad would have on the gourd surface – I’ve not worked with gourd before so easy does it! I discover that the gourd surface is resilient and the combination of Murphy’s Oil Soap and the micromesh pad lightly addressing the trouble areas proves to work very well! The glue was on the surface and very gradually, I clean the gourd surface. Nice! The pictures show the progress.

Earlier I mentioned that I have read several posts dealing with cleaning up Gourd Calabashes with questions about the gourd surface itself. Steve’s post was helpful (See: Restoring an old CPF Gourd Calabash Pipe). To clean the gourd surface getting rid of the oils and dirt that collects on the gourd surface, I use undiluted Murphy’s Oil Soap on a cotton pad and scrub the surface, then remove it with another cotton pad – not using water which may wet the gourd surface too much. The gourd below the cap shows what appear to be residue from what I’m guessing was someone’s attempt to reattach the cap to the gourd – it appears to be glue runovers. I can’t tell if it has damaged the gourd surface or if the old glue is resting on the surface. As I scrub the gourd with undiluted Murphy’s Oil Soap, I concentrate on these areas. I take a 2400 grade micromesh pad and lightly sand the area – just testing very gently what effect the pad would have on the gourd surface – I’ve not worked with gourd before so easy does it! I discover that the gourd surface is resilient and the combination of Murphy’s Oil Soap and the micromesh pad lightly addressing the trouble areas proves to work very well! The glue was on the surface and very gradually, I clean the gourd surface. Nice! The pictures show the progress.

With the gourd clean and looking better than I expected, I move down to the bone tenon extending from the mortise of the 1907 McLardy Calabash and clean the externals with Q-tips dipped in isopropyl 95%. I use the dental probe to dig into the threads of the tenon where compacted crud awaits. The bone tenon cleans up without too much effort. The pictures show the progress.

With the gourd clean and looking better than I expected, I move down to the bone tenon extending from the mortise of the 1907 McLardy Calabash and clean the externals with Q-tips dipped in isopropyl 95%. I use the dental probe to dig into the threads of the tenon where compacted crud awaits. The bone tenon cleans up without too much effort. The pictures show the progress. I set the gourd aside and fish the stem out of the Oxiclean bath. I wet sand the stem using 600 grit sand paper to address the oxidation that the Oxiclean bath raised from the vulcanite stem. Following the 600 grit paper I use steel wool 0000 over the stem to complete the initial stage of cleaning the stem externals. From the externals, I dive into cleaning the internal airway and stem threads using pipe cleaners and Q-tips dipped in isopropyl 95%. There was more gunk in the screw-in area than I expected and it put up some resistance. The pictures show the progress.

I set the gourd aside and fish the stem out of the Oxiclean bath. I wet sand the stem using 600 grit sand paper to address the oxidation that the Oxiclean bath raised from the vulcanite stem. Following the 600 grit paper I use steel wool 0000 over the stem to complete the initial stage of cleaning the stem externals. From the externals, I dive into cleaning the internal airway and stem threads using pipe cleaners and Q-tips dipped in isopropyl 95%. There was more gunk in the screw-in area than I expected and it put up some resistance. The pictures show the progress.

I turn my attention to the upper button in need of repair for a bite or dent that took out the right corner of the button lip. As I’m looking at this button, I suddenly realize that in my small, but growing collection of pipes, I have no other pipes with this style of button – and I know that it has a specific name which takes a few minutes of searching to recall – orific button meaning round. Another novice was asking about orific stems in a thread on Pipesmagazine.com called Orific/orifice button/stem query where I quickly learned that this button was used primarily at the end of the 1800s and beginning of the 1900s. By the 1920s the design pretty much had become a thing of the past. I also found an interesting reflection on buttons that Steve did a few years back called, A View from the End of Stem. There was also a divot on the edge of the stem next to the shank that needed attention. Taking activated charcoal and Special ‘T’ CA Glue (‘T’ for ‘thick’) I mix them together gradually creating a charcoal putty that I apply to the button with a toothpick acting as a trowel. I put more than needed to allow later sanding and shaping with a file and paper after the charcoal glue cures. I also apply a dab of the mix on the divot on the other end of the stem. I’m making progress on this orific stem! The pictures show the progress.

I turn my attention to the upper button in need of repair for a bite or dent that took out the right corner of the button lip. As I’m looking at this button, I suddenly realize that in my small, but growing collection of pipes, I have no other pipes with this style of button – and I know that it has a specific name which takes a few minutes of searching to recall – orific button meaning round. Another novice was asking about orific stems in a thread on Pipesmagazine.com called Orific/orifice button/stem query where I quickly learned that this button was used primarily at the end of the 1800s and beginning of the 1900s. By the 1920s the design pretty much had become a thing of the past. I also found an interesting reflection on buttons that Steve did a few years back called, A View from the End of Stem. There was also a divot on the edge of the stem next to the shank that needed attention. Taking activated charcoal and Special ‘T’ CA Glue (‘T’ for ‘thick’) I mix them together gradually creating a charcoal putty that I apply to the button with a toothpick acting as a trowel. I put more than needed to allow later sanding and shaping with a file and paper after the charcoal glue cures. I also apply a dab of the mix on the divot on the other end of the stem. I’m making progress on this orific stem! The pictures show the progress.

I received word from Gary that cigar ash is not in stock, but another recipe like Pipe Mud (a bowl coating mixture) arrived from Steve – taking powdered charcoal and mixing it with either plain yogurt or sour cream will create a paste to apply for the bowl gaps as planned. Steve assured me that this brew would turn dark and not stand out. So, with Bulgarian kiselo mlyako (sour crème) in hand I mix with activated charcoal gradually forming a paste. It turns black immediately with the charcoal and it thickens. I use a dental spatula and take small dollops and apply it to the gaps under the silver cap where the clay bowl is exposed – I’m going with clay and not meerschaum. While the paste is still wet and malleable, I scrape the edge to clean the cap and create a bowl line. I agree with Steve – this stuff looks like the protective layer covering the rest of the bowl. The patch looks good. The pictures show the progress.

I received word from Gary that cigar ash is not in stock, but another recipe like Pipe Mud (a bowl coating mixture) arrived from Steve – taking powdered charcoal and mixing it with either plain yogurt or sour cream will create a paste to apply for the bowl gaps as planned. Steve assured me that this brew would turn dark and not stand out. So, with Bulgarian kiselo mlyako (sour crème) in hand I mix with activated charcoal gradually forming a paste. It turns black immediately with the charcoal and it thickens. I use a dental spatula and take small dollops and apply it to the gaps under the silver cap where the clay bowl is exposed – I’m going with clay and not meerschaum. While the paste is still wet and malleable, I scrape the edge to clean the cap and create a bowl line. I agree with Steve – this stuff looks like the protective layer covering the rest of the bowl. The patch looks good. The pictures show the progress.

With the Charcoal/Sour Cream Patch curing, I put the gourd aside and retrieve the orific stem. Using a flat needle file I sand down and shape the now cured, charcoal superglue to rebuild the missing hunk of lip. I use the flat edge of the needle file first working on the backside or bowl side of the lip to establish a flush surface with the patch and native lip. I take a picture with the file in place to illustrate this – it’s not easy taking pictures when you need both hands to hold things! After the flat lip edge is established, I round off the patch to match the orific pattern. I use 600 grit paper to do this (rather than the file or 240 grit) because I want to remove the excess patch slowly – almost allowing it to sneak up on the native vulcanite surrounding the patch. After some slow, intentionally patient effort, the new button is looking very good. I use 240 grit paper on the bit to erase file marks left over. I also use 600 grit paper on the small patch on the other end of the stem. I finish the patch and button rebuild by working the entire stem with 0000 steel wool, prepping the stem for the micromesh process that follows. I’m pleased with the rebuild I see! The pictures tell the story!

With the Charcoal/Sour Cream Patch curing, I put the gourd aside and retrieve the orific stem. Using a flat needle file I sand down and shape the now cured, charcoal superglue to rebuild the missing hunk of lip. I use the flat edge of the needle file first working on the backside or bowl side of the lip to establish a flush surface with the patch and native lip. I take a picture with the file in place to illustrate this – it’s not easy taking pictures when you need both hands to hold things! After the flat lip edge is established, I round off the patch to match the orific pattern. I use 600 grit paper to do this (rather than the file or 240 grit) because I want to remove the excess patch slowly – almost allowing it to sneak up on the native vulcanite surrounding the patch. After some slow, intentionally patient effort, the new button is looking very good. I use 240 grit paper on the bit to erase file marks left over. I also use 600 grit paper on the small patch on the other end of the stem. I finish the patch and button rebuild by working the entire stem with 0000 steel wool, prepping the stem for the micromesh process that follows. I’m pleased with the rebuild I see! The pictures tell the story!

Continuing with the stem restoration, with micromesh pads 1500 to 2400 I wet sand followed by an application of Obsidian Oil. With micromesh pads 3200 to 4000 and 6000 to 12000 I dry sand and follow each set with an additional coating of Obsidian Oil to rejuvenate the vulcanite stem. The pictures show the progress.

Continuing with the stem restoration, with micromesh pads 1500 to 2400 I wet sand followed by an application of Obsidian Oil. With micromesh pads 3200 to 4000 and 6000 to 12000 I dry sand and follow each set with an additional coating of Obsidian Oil to rejuvenate the vulcanite stem. The pictures show the progress.

I reattach the stem to the gourd to get a fresh look at the stem alignment. Over time the bone tenon has worn down a bit. Earlier I noted that the old stem was over-clocked a few degrees and I didn’t know yet if I would try to correct it. I experimented with the feel and placement of the stem as I drew it to my mouth – giving me a sense of what would be most comfortable. After all, it is my birthday gift! I decide to attempt to reestablish alignment – or at least give it a shot. Steve’s earlier email described painting the tenon with clear finger nail polish or super glue, allowing it to cure about 24 hours and then gently rethreading the stem. Emphasis on the ‘gently’ because too much torque applied could break the tenon. Borrowing my wife’s polish, I paint a thin layer on the tenon and put it aside to cure.

I reattach the stem to the gourd to get a fresh look at the stem alignment. Over time the bone tenon has worn down a bit. Earlier I noted that the old stem was over-clocked a few degrees and I didn’t know yet if I would try to correct it. I experimented with the feel and placement of the stem as I drew it to my mouth – giving me a sense of what would be most comfortable. After all, it is my birthday gift! I decide to attempt to reestablish alignment – or at least give it a shot. Steve’s earlier email described painting the tenon with clear finger nail polish or super glue, allowing it to cure about 24 hours and then gently rethreading the stem. Emphasis on the ‘gently’ because too much torque applied could break the tenon. Borrowing my wife’s polish, I paint a thin layer on the tenon and put it aside to cure.

A day later arriving home from work, I’m anxious to reattach the stem to the bone tenon to find out if the fingernail polish works to tighten the stem – to ‘unclock’ the turn of the stem only a few degrees. I screwed the stem slowly on to the bone tenon and at first, I detected no difference in the pressure. When the stem started to arrive at the critical point I felt the tightening – requiring a bit more torque. I did not force the stem but reverse the turn a bit, then re-torque a bit more, then back off again, re-torque, then finally it tightened sufficiently. Steve’s warning about not forcing things came from his own experience of unexpectedly cracking a brittle bone tenon in a Gourd Calabash restortation. I could not believe it – it actually worked! The stem is now perfectly lined up with the gourd stummel. Amazing! The picture tells the story!

A day later arriving home from work, I’m anxious to reattach the stem to the bone tenon to find out if the fingernail polish works to tighten the stem – to ‘unclock’ the turn of the stem only a few degrees. I screwed the stem slowly on to the bone tenon and at first, I detected no difference in the pressure. When the stem started to arrive at the critical point I felt the tightening – requiring a bit more torque. I did not force the stem but reverse the turn a bit, then re-torque a bit more, then back off again, re-torque, then finally it tightened sufficiently. Steve’s warning about not forcing things came from his own experience of unexpectedly cracking a brittle bone tenon in a Gourd Calabash restortation. I could not believe it – it actually worked! The stem is now perfectly lined up with the gourd stummel. Amazing! The picture tells the story! We’re now in the home-stretch and my mind has started wondering about which tobacco I will use to inaugurate the next life of this venerable 109-year-old Gourd Calabash. Suggestions?? Taking cues from Charles Lemon’s post, Freshening an Andreas Bauer gourd Calabash, I take three unused Chinese purchased Dremel cotton wheels for use on the Calabash’s gourd and stem. I use the first to lightly apply White Diamond to the gourd surface. For you who use a Dremel for polishing, I discover that the Dremel techniques I use (See Dremel Tutorial) with briar works quite well with the gourd. Putting the Dremel on the lowest RPM setting, I apply the White Diamond, keeping the cotton (not felt!) wheel moving over the surface while I rotate the gourd keeping the sheen of the lamp in focus on the gourd surface. This sheen acts as my ‘headlight’ enabling me to see the rippling movement of the compound across the gourd’s surface – the same way as with briar. As I methodically move over the gourd surface in this way, I also catch blemishes or marks in the surface that I address directly, yet lightly with the Dremel’s cotton wheel. With my wife’s help, after the first picture showing the tools employed, pictures 2 and 3 illustrate the ‘sheen technique’ that has worked very well for me. I am careful to avoid the silver cap and ferrule as I apply the compound.

We’re now in the home-stretch and my mind has started wondering about which tobacco I will use to inaugurate the next life of this venerable 109-year-old Gourd Calabash. Suggestions?? Taking cues from Charles Lemon’s post, Freshening an Andreas Bauer gourd Calabash, I take three unused Chinese purchased Dremel cotton wheels for use on the Calabash’s gourd and stem. I use the first to lightly apply White Diamond to the gourd surface. For you who use a Dremel for polishing, I discover that the Dremel techniques I use (See Dremel Tutorial) with briar works quite well with the gourd. Putting the Dremel on the lowest RPM setting, I apply the White Diamond, keeping the cotton (not felt!) wheel moving over the surface while I rotate the gourd keeping the sheen of the lamp in focus on the gourd surface. This sheen acts as my ‘headlight’ enabling me to see the rippling movement of the compound across the gourd’s surface – the same way as with briar. As I methodically move over the gourd surface in this way, I also catch blemishes or marks in the surface that I address directly, yet lightly with the Dremel’s cotton wheel. With my wife’s help, after the first picture showing the tools employed, pictures 2 and 3 illustrate the ‘sheen technique’ that has worked very well for me. I am careful to avoid the silver cap and ferrule as I apply the compound.

After completing the White Diamond application, I wipe down the gourd with a clean cotton cloth to remove the left-over compound powder. I now mount in the Dremel’s hand-held extender another clean cotton wheel and apply a number of coats (3) of carnauba wax to both the gourd and stem surfaces. With briar, I increase the RPM’s of the Dremel by one number to assist in liquefying the wax and spreading it over the surface. I’ll try this on the gourd to see how it behaves. It went well. In fact, the gourd seems to ‘drink up’ the carnauba wax and I find that I am reloading the wheel more often than with briar. And, “Oh my!” I didn’t expect the luster that gradually reflects back at me as the wheel travels over the surface! What struck me was that the Calabash almost started taking on the appearance of a porcelain display piece. Completing the carnauba wax for both gourd and stem, I carefully shine the silver cap and ferrule with my wife’s Weinman Silver Polish – not spreading it to the other surfaces. I completed this restoration with a brisk buffing of the entire pipe using a microfiber cloth carefully! I had images of the pipe slipping out of my grasp and skidding along the floor…. Thankfully, this did not happen! This buff brings out the depth of the shine by blending the gourd, silver and orific vulcanite stem.

After completing the White Diamond application, I wipe down the gourd with a clean cotton cloth to remove the left-over compound powder. I now mount in the Dremel’s hand-held extender another clean cotton wheel and apply a number of coats (3) of carnauba wax to both the gourd and stem surfaces. With briar, I increase the RPM’s of the Dremel by one number to assist in liquefying the wax and spreading it over the surface. I’ll try this on the gourd to see how it behaves. It went well. In fact, the gourd seems to ‘drink up’ the carnauba wax and I find that I am reloading the wheel more often than with briar. And, “Oh my!” I didn’t expect the luster that gradually reflects back at me as the wheel travels over the surface! What struck me was that the Calabash almost started taking on the appearance of a porcelain display piece. Completing the carnauba wax for both gourd and stem, I carefully shine the silver cap and ferrule with my wife’s Weinman Silver Polish – not spreading it to the other surfaces. I completed this restoration with a brisk buffing of the entire pipe using a microfiber cloth carefully! I had images of the pipe slipping out of my grasp and skidding along the floor…. Thankfully, this did not happen! This buff brings out the depth of the shine by blending the gourd, silver and orific vulcanite stem.

Since my wife and I will be going to the home of our daughter and son-in-law in Denver for Christmas, the benefactors of this amazing birthday gift, I will hold off the inaugural smoke of this restored 1907 McLardy Gourd Calabash treasure until I can share it with them. Indeed, he is a venerable, distinguished pipe and I’m privileged to be entrusted as the current steward, but of course, not the last. My next project is to figure out an adequate stand that will handle this calabash! Thank you for joining me!

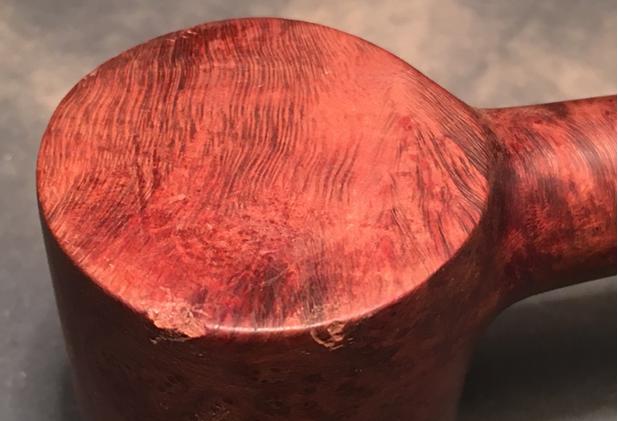

The next two photos show the two sides of the bowl. The left side of the bowl is a beautiful tight sandblast finish. The rim is also sandblasted as is the entire shank. The right side of the bowl is a smooth medium brown patch of briar that is on all of the Antique line of Stanwell pipes that I have seen.

The next two photos show the two sides of the bowl. The left side of the bowl is a beautiful tight sandblast finish. The rim is also sandblasted as is the entire shank. The right side of the bowl is a smooth medium brown patch of briar that is on all of the Antique line of Stanwell pipes that I have seen. The photo of the rim shows the condition and the thin cake in the bowl. The pipe was well cared for and did not need to have a lot of work done to bring it back.

The photo of the rim shows the condition and the thin cake in the bowl. The pipe was well cared for and did not need to have a lot of work done to bring it back. The next photo shows the underside of the shank and the stamping. You can read the Stanwell stamping even though it is a bit faint on the left side. The Antique stamping is also light but the shape number is clear and deep.

The next photo shows the underside of the shank and the stamping. You can read the Stanwell stamping even though it is a bit faint on the left side. The Antique stamping is also light but the shape number is clear and deep. The last two photos show the condition of the stem and the light oxidation and tooth chatter on the top side near the button. The Crown S stamping on the stem is in perfect condition.

The last two photos show the condition of the stem and the light oxidation and tooth chatter on the top side near the button. The Crown S stamping on the stem is in perfect condition. The next four photos show the condition of the pipe when it arrived in Vancouver. I took the photos to show what the pipe looked like before I began the cleanup.

The next four photos show the condition of the pipe when it arrived in Vancouver. I took the photos to show what the pipe looked like before I began the cleanup.

I took a close-up photo of the rim and the shank extension to show the contrast in colours and the condition of the rim at the point I received the pipe.

I took a close-up photo of the rim and the shank extension to show the contrast in colours and the condition of the rim at the point I received the pipe. I also took some close up photos of the stem to show the oxidation and the light tooth chatter on both sides of the stem.

I also took some close up photos of the stem to show the oxidation and the light tooth chatter on both sides of the stem. I gave the bowl and shank several coats of Conservator’s Wax and hand buffed the pipe with a shoe brush and then a microfibre cloth to raise and deepen the shine on the briar. I ran a pipe cleaner through the airway and the mortise and it came out clean.

I gave the bowl and shank several coats of Conservator’s Wax and hand buffed the pipe with a shoe brush and then a microfibre cloth to raise and deepen the shine on the briar. I ran a pipe cleaner through the airway and the mortise and it came out clean.

The stem was lightly oxidized so I decided to only use micromesh sanding pads to clean it up. I wet sanded it with 1500-2400 grit sanding pads and gave it a coat of Obsidian Oil. I dry sanded it with 3200-12000 grit pads and gave it a rub down with Obsidian Oil after each set of three pads. I set it aside after the final set of pads to dry.

The stem was lightly oxidized so I decided to only use micromesh sanding pads to clean it up. I wet sanded it with 1500-2400 grit sanding pads and gave it a coat of Obsidian Oil. I dry sanded it with 3200-12000 grit pads and gave it a rub down with Obsidian Oil after each set of three pads. I set it aside after the final set of pads to dry.

I buffed the pipe with Blue Diamond on the buffing wheel to polish it. I gave the bowl several coats of Conservator’s Wax and buffed it with a clean buffing pad. I gave the stem multiple coats of carnauba wax and buffed it with a clean buffing pad. I hand buffed the pipe with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. The complexity of the contrast of dark and medium browns as well as a hint of black gives a dimensionality to this pipe that is quite stunning. It did not take a lot of work to bring it back but it was a pleasure to work on it. Thanks for walking with me through the process.

I buffed the pipe with Blue Diamond on the buffing wheel to polish it. I gave the bowl several coats of Conservator’s Wax and buffed it with a clean buffing pad. I gave the stem multiple coats of carnauba wax and buffed it with a clean buffing pad. I hand buffed the pipe with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. The complexity of the contrast of dark and medium browns as well as a hint of black gives a dimensionality to this pipe that is quite stunning. It did not take a lot of work to bring it back but it was a pleasure to work on it. Thanks for walking with me through the process.

It was now time to start cleaning the internals of both the stem and stummel.

It was now time to start cleaning the internals of both the stem and stummel. Needless to say, the pile of cotton swabs and pipe cleaners were only a representative sample of what it took to get the stem clean. And the well/mortise and airway of the pipe was equally nasty’ I really hadn’t expected this given the maintained cake in the bowl. I stuffed a cotton ball in the bowl and a cotton swab in the air hole, filled the bowl with alcohol and left it to sit over night. I completed cleaning inside the stem before going to bed.

Needless to say, the pile of cotton swabs and pipe cleaners were only a representative sample of what it took to get the stem clean. And the well/mortise and airway of the pipe was equally nasty’ I really hadn’t expected this given the maintained cake in the bowl. I stuffed a cotton ball in the bowl and a cotton swab in the air hole, filled the bowl with alcohol and left it to sit over night. I completed cleaning inside the stem before going to bed.