Blog by Dal Stanton

I purchased the Savinelli Capitol in June of this year, at the Hole in the Wall antique store near Zhenski Pazar (Women’s Market) located in downtown Sofia. Steve was visiting Bulgaria from Vancouver in the context of our work and we went to the Hole in the Wall for a mini pipe hunting sortie. I’d remembered on other occasions the vendor producing a 4-pipe pouch that he kept behind the counter and I asked about it and he still had it with pipes intact. The leather bag itself was a find. The 4 pipes revealed after unzipping the bag were a Savinelli Tortuga 628, Danske Club Vario 85 (both occupying a place in my rotation), a Butz-Choquin Rocamar (which became a wedding gift for my new son-in-law), and the Capitol (that I learned was a Savinelli second) now before me. Above, I linked the restorations of the Tortuga and BC Rocamar to their respective postings. Honestly, when I first acquired the Bag of Four, my sights were fixed on the 3 big brothers of the Capitol which I identified as a Prince shape from Pipedia’s shapes chart. Per Bill Burney’s description,

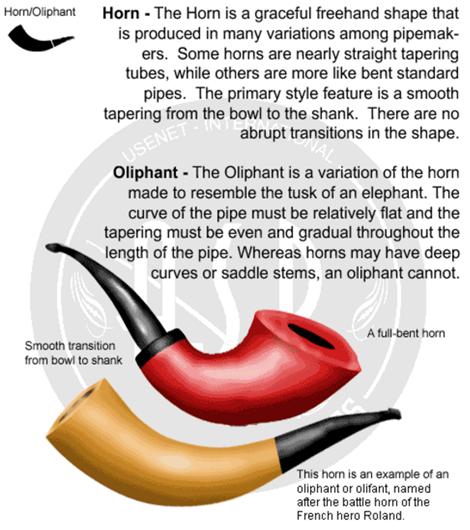

Honestly, when I first acquired the Bag of Four, my sights were fixed on the 3 big brothers of the Capitol which I identified as a Prince shape from Pipedia’s shapes chart. Per Bill Burney’s description,

The prince, named after the Prince of Wales (Prince Albert, later King Edward VII), has a squat, rounded bowl with a long, usually very slightly bent stem and a short shank. Compared to other pipes, the shank and stem are thin and delicate, though not necessarily fragile. This makes for a light and comfortable pipe (Link).

On the internet, I searched high and low through images of Prince Albert (1819-1861) and found no images among the 100s visually linking the prince with the shape now associated with him. The photo below, one could imagine, has his pipe waiting for him just to his right, reluctantly removing it from the eventual public view of the old ‘sit-still’ camera recording the moments. Yet, in my search on the internet, one can find 100s of pictures of happy, confident men smoking their pipes with adoring women looking on. How is this possible? – a man would be quick to ask. Well of course, their pipes are packed with Prince Albert’s tobacco! So, the secret is out – PA not only stands for Prince Albert but also, and more importantly, Pipe Appeal! Good to know as Christmas gift lists are being created for this holiday season! With Christmas music playing in the background the ambiance is perfect. The CAPITOL is stamped on the left side of the shank with no other markings. When I search Pipedia, I discover that Capitol is listed among a robust inventory of other Savinelli made sub-brands, seconds and order productions. At Pipes Website store, I found several Savinelli Capitol shapes for sale. At The Danish Pipe Shop I discovered several Savinelli Capitols listed and a bit pricy at that! So, it would seem, the Capitol line of Savinelli has some depth and quality to it. Unfortunately, I could find no Savinelli listing that brought the entire Capitol line inventory together. This Capitol Prince has an elegant, slim appearance, boasting a length of 5½ inches, a petite bowl width of 1½ inches and a fire chamber diameter of ¾ of an inch. The rim has some clunk dents along the edge and the backside shows darkening from oils and perhaps rear-end tobacco lighting over the edge. The fire chamber has a light cake build up but I will bring it to the briar for a clean, fresh start. I detect a larger fill on the heel of the bowl near the left junction of the shank. The stem is in great shape with minor teeth chatter on the bit. I detect a dent in the vulcanite at the shank junction and note that there is day-light between the junction of shank and stem – the mating is not flush, but a good cleaning may take care of this. Interestingly, I also notice that the stummel is encased in what I call a ‘Candy Apple wrapper’ which I also saw in the Savinelli Tortuga restoration acquired at the same time as the Savinelli Capitol. I didn’t like the Candy Apple wrapper around the Tortuga then and this Capitol Prince’s natural briar will be liberated as was his big brother’s! The following pictures on my work table here in Sofia, Bulgaria, show these areas of need and a very handsome pipe.

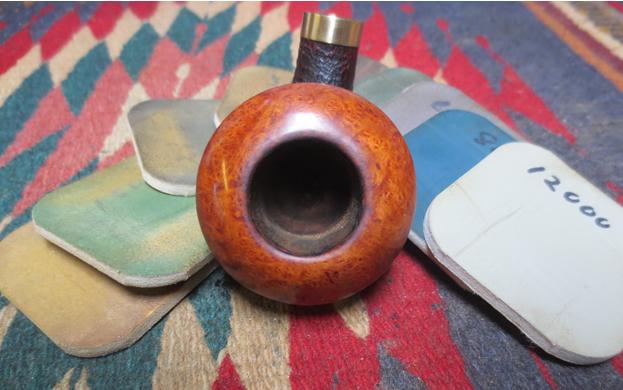

With Christmas music playing in the background the ambiance is perfect. The CAPITOL is stamped on the left side of the shank with no other markings. When I search Pipedia, I discover that Capitol is listed among a robust inventory of other Savinelli made sub-brands, seconds and order productions. At Pipes Website store, I found several Savinelli Capitol shapes for sale. At The Danish Pipe Shop I discovered several Savinelli Capitols listed and a bit pricy at that! So, it would seem, the Capitol line of Savinelli has some depth and quality to it. Unfortunately, I could find no Savinelli listing that brought the entire Capitol line inventory together. This Capitol Prince has an elegant, slim appearance, boasting a length of 5½ inches, a petite bowl width of 1½ inches and a fire chamber diameter of ¾ of an inch. The rim has some clunk dents along the edge and the backside shows darkening from oils and perhaps rear-end tobacco lighting over the edge. The fire chamber has a light cake build up but I will bring it to the briar for a clean, fresh start. I detect a larger fill on the heel of the bowl near the left junction of the shank. The stem is in great shape with minor teeth chatter on the bit. I detect a dent in the vulcanite at the shank junction and note that there is day-light between the junction of shank and stem – the mating is not flush, but a good cleaning may take care of this. Interestingly, I also notice that the stummel is encased in what I call a ‘Candy Apple wrapper’ which I also saw in the Savinelli Tortuga restoration acquired at the same time as the Savinelli Capitol. I didn’t like the Candy Apple wrapper around the Tortuga then and this Capitol Prince’s natural briar will be liberated as was his big brother’s! The following pictures on my work table here in Sofia, Bulgaria, show these areas of need and a very handsome pipe.

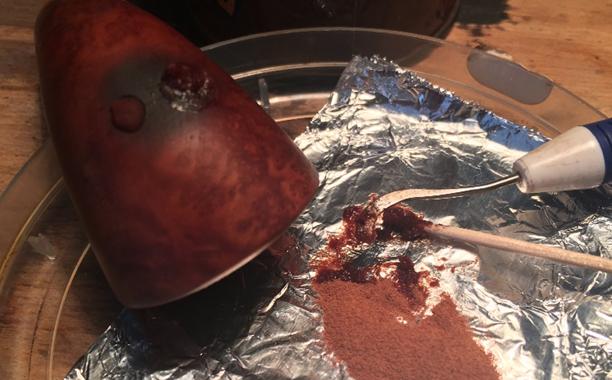

With the stem showing no oxidation, I skip the Oxiclean bath which may be a first for me! The twisty stinger extending from the tenon is extracted unceremoniously and added to the Lonely Stingers Bottle and is officially retired from active service. I give my initial focus to the stummel clean-up starting with reaming the bowl. I use the Pipnet reaming kit camped over a paper towel which enables me to quickly catch and dispose of the powdered carbon – this makes my wife happier as my work table shares our bedroom space in our 10th floor flat! Often, I go out onto the balcony to do this dirty work but winter has come in Bulgaria. I use the two smallest reaming blades and I do not use them aggressively – I do not want to dig into the briar. I follow the reaming blades with the Savinelli pipe knife to scrape and fine tune the cleaning of the cake residue. I remove what appears as dried dottle at the floor of the bowl. I finish by using 240 grit paper wrapped around a dowel rod and my index finger to clean and smooth the wall. Finally, I take a cotton pad with alcohol and wipe the bowl removing the carbon dust. The pictures show the progress.

With the stem showing no oxidation, I skip the Oxiclean bath which may be a first for me! The twisty stinger extending from the tenon is extracted unceremoniously and added to the Lonely Stingers Bottle and is officially retired from active service. I give my initial focus to the stummel clean-up starting with reaming the bowl. I use the Pipnet reaming kit camped over a paper towel which enables me to quickly catch and dispose of the powdered carbon – this makes my wife happier as my work table shares our bedroom space in our 10th floor flat! Often, I go out onto the balcony to do this dirty work but winter has come in Bulgaria. I use the two smallest reaming blades and I do not use them aggressively – I do not want to dig into the briar. I follow the reaming blades with the Savinelli pipe knife to scrape and fine tune the cleaning of the cake residue. I remove what appears as dried dottle at the floor of the bowl. I finish by using 240 grit paper wrapped around a dowel rod and my index finger to clean and smooth the wall. Finally, I take a cotton pad with alcohol and wipe the bowl removing the carbon dust. The pictures show the progress.

With the isopropyl 95% on the work table, I clean the internals of the stummel. Using pipe cleaners (bristled and smooth) and Q-tips I go to work. Dental probes are also helpful to reach into the mortise and scrape the surface dislodging muck. It was dirtier than I expected, but finally Q-tips start re-emerging ever whiter from the mortise plunges. Done. Now, I take the stem and go to work on its airway with pipe cleaners. I discover very quickly that a reason for lack of cleaning on this stem is that I am not able to move a pipe cleaner through the airway. The button airhole is too tight and needs to be enlarged to accommodate pipe cleaners. No one likes fighting with pipe cleaners that refuse to pass through cramped quarters. I take a round, pointed needle file and begin gradually to enlarge the button airhole. My method is to insert the file point into the airhole but only as far as the expanding file diameter will allow to enable me to move the file back and forth easily, gradually removing the upper and lower button airhole surfaces. If I jam the needle file down the airhole too aggressively, not only will it get jammed, it will also damage the vulcanite contours around the airhole. After some time, the airhole gradually expands allowing the needle file to file more deeply opening the airway. After some time and testing, pipe cleaners are able successfully to navigate the passage and the stem airway cleans up very quickly. When I work on the teeth chatter later, I’ll smooth out this work with 240 grit paper. The pictures show the cleaning and button airhole enlargement processes.

With the isopropyl 95% on the work table, I clean the internals of the stummel. Using pipe cleaners (bristled and smooth) and Q-tips I go to work. Dental probes are also helpful to reach into the mortise and scrape the surface dislodging muck. It was dirtier than I expected, but finally Q-tips start re-emerging ever whiter from the mortise plunges. Done. Now, I take the stem and go to work on its airway with pipe cleaners. I discover very quickly that a reason for lack of cleaning on this stem is that I am not able to move a pipe cleaner through the airway. The button airhole is too tight and needs to be enlarged to accommodate pipe cleaners. No one likes fighting with pipe cleaners that refuse to pass through cramped quarters. I take a round, pointed needle file and begin gradually to enlarge the button airhole. My method is to insert the file point into the airhole but only as far as the expanding file diameter will allow to enable me to move the file back and forth easily, gradually removing the upper and lower button airhole surfaces. If I jam the needle file down the airhole too aggressively, not only will it get jammed, it will also damage the vulcanite contours around the airhole. After some time, the airhole gradually expands allowing the needle file to file more deeply opening the airway. After some time and testing, pipe cleaners are able successfully to navigate the passage and the stem airway cleans up very quickly. When I work on the teeth chatter later, I’ll smooth out this work with 240 grit paper. The pictures show the cleaning and button airhole enlargement processes.

I love working on clean pipes! With internals clean I know shift my attention to the stummel surface. I first attack the Candy Apple varnish-like surface. I start conservatively by first using cotton pads with undiluted Murphy’s Oil Soap to work on the rim and bowl surface. With the aid of a brass brush, the Murphy’s Soap does a good job cleaning the rim, but it is probable that the surface is an acrylic finish which is difficult to remove. Next, I use acetone with cotton pads to attack the Candy Apple surface. As I scrub, and I scrub a good while, it gives me time to study the briar grain on this stummel and on the heel, I find what looks like a spider pattern – beautiful. I’m ever amazed at God’s gift to us in the design and intricacy of this piece of briar – a ragged bush of a plant that would be called scrub if you saw it on the side of the road as you passed. As the pictures below reveal, even after acetone scrubbing the shine of the acrylic is still very visible. To see if I can soften it, I plop the stummel into an acetone bath. The pictures show the progress.

I love working on clean pipes! With internals clean I know shift my attention to the stummel surface. I first attack the Candy Apple varnish-like surface. I start conservatively by first using cotton pads with undiluted Murphy’s Oil Soap to work on the rim and bowl surface. With the aid of a brass brush, the Murphy’s Soap does a good job cleaning the rim, but it is probable that the surface is an acrylic finish which is difficult to remove. Next, I use acetone with cotton pads to attack the Candy Apple surface. As I scrub, and I scrub a good while, it gives me time to study the briar grain on this stummel and on the heel, I find what looks like a spider pattern – beautiful. I’m ever amazed at God’s gift to us in the design and intricacy of this piece of briar – a ragged bush of a plant that would be called scrub if you saw it on the side of the road as you passed. As the pictures below reveal, even after acetone scrubbing the shine of the acrylic is still very visible. To see if I can soften it, I plop the stummel into an acetone bath. The pictures show the progress.

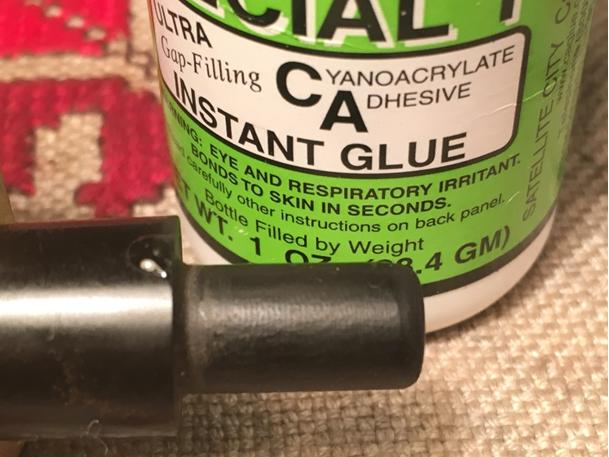

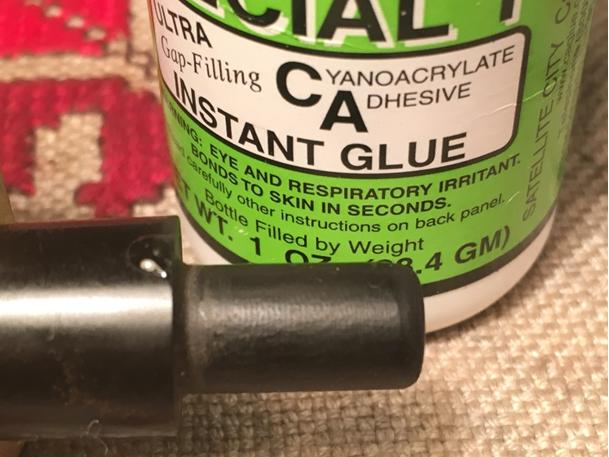

With the stummel in the acetone bath, I return to the stem and take 240 grit sanding paper and work on the teeth chatter on the lower and upper bit. I also sand the button airhole to remove file markings and to smooth the surface. Then I apply a dot of Hot Stuff “T” CA glue to the small dent on the shank-side edge of the stem. I like to use the “T” for thicker, because it beads up on the divot and doesn’t run. I wait for the superglue to cure before proceeding with more work on the stem. The pictures show the progress.

With the stummel in the acetone bath, I return to the stem and take 240 grit sanding paper and work on the teeth chatter on the lower and upper bit. I also sand the button airhole to remove file markings and to smooth the surface. Then I apply a dot of Hot Stuff “T” CA glue to the small dent on the shank-side edge of the stem. I like to use the “T” for thicker, because it beads up on the divot and doesn’t run. I wait for the superglue to cure before proceeding with more work on the stem. The pictures show the progress.

Taking the stummel out of the acetone bath after about 6 hours, I place it on the desk and as the acetone evaporates I can see that the bath will need help. With the surface softened by the acetone bath, I take 0000 steel wool and dip a small portion in the acetone and rub the steel wool over the shiny surfaces. This finally does the job of bringing the natural briar to the surface. Now I can see the true condition of the surface and where I may need to sand and repair.

Taking the stummel out of the acetone bath after about 6 hours, I place it on the desk and as the acetone evaporates I can see that the bath will need help. With the surface softened by the acetone bath, I take 0000 steel wool and dip a small portion in the acetone and rub the steel wool over the shiny surfaces. This finally does the job of bringing the natural briar to the surface. Now I can see the true condition of the surface and where I may need to sand and repair. I examine the stummel and invert it looking more closely at the large fill I identified earlier. I picked at it with a sharp dental probe and dig out the loose fill. I will need to mix a briar dust and superglue putty to refill this pitting as well as ‘top-off’ some smaller pits around the area. The heel of the stummel is banged up good and I need to sand those out after applying the briar dust putty patches and after they cure. I flip the stummel and study the rim. The briar in this Capitol Prince will be beautiful at the end of the restoration because it already is! I decide to first take a coarse 120 grit paper rolled up tightly to cut a bevel on the inner rim. I do this to remove the damaged areas along the edge but also the Prince will look even classier with a gentle bevel enhancing an already handsome bowl. I follow this initial cut of the bevel with 240 grit paper to smooth the surface further. I want to apply a very gentle topping to the rim with 600 grit paper. I take the chopping block out and place a sheet of 600 grit paper, with rim down, in a circular motion, gently I rotate the stummel over the surface. I check the rim as I proceed to make sure I only take enough surface off to give a clean fresh look and remove minor nicks. I follow the topping by using rolled up 600 grit paper to finish the bevel matching the smoothness of the rim. The pictures show the progress. I’m pleased with the look of the rim.

I examine the stummel and invert it looking more closely at the large fill I identified earlier. I picked at it with a sharp dental probe and dig out the loose fill. I will need to mix a briar dust and superglue putty to refill this pitting as well as ‘top-off’ some smaller pits around the area. The heel of the stummel is banged up good and I need to sand those out after applying the briar dust putty patches and after they cure. I flip the stummel and study the rim. The briar in this Capitol Prince will be beautiful at the end of the restoration because it already is! I decide to first take a coarse 120 grit paper rolled up tightly to cut a bevel on the inner rim. I do this to remove the damaged areas along the edge but also the Prince will look even classier with a gentle bevel enhancing an already handsome bowl. I follow this initial cut of the bevel with 240 grit paper to smooth the surface further. I want to apply a very gentle topping to the rim with 600 grit paper. I take the chopping block out and place a sheet of 600 grit paper, with rim down, in a circular motion, gently I rotate the stummel over the surface. I check the rim as I proceed to make sure I only take enough surface off to give a clean fresh look and remove minor nicks. I follow the topping by using rolled up 600 grit paper to finish the bevel matching the smoothness of the rim. The pictures show the progress. I’m pleased with the look of the rim.

Time to mix briarwood dust and superglue to make a putty to apply patches to the hole and pits on heel of the stummel. I take my briar dust can and with a pipe nail, scoop out some dust placing it in a little pile. Using regular clear super glue, I put a little puddle next to the briar dust. Using a toothpick, I start adding some briar dust to the glue until it gradually reaches a putty/toothpaste-like consistency and then I apply a small dollop over the fill area. I mash it down to make a tight patch and I leave some excess over the areas to sand down later.

Time to mix briarwood dust and superglue to make a putty to apply patches to the hole and pits on heel of the stummel. I take my briar dust can and with a pipe nail, scoop out some dust placing it in a little pile. Using regular clear super glue, I put a little puddle next to the briar dust. Using a toothpick, I start adding some briar dust to the glue until it gradually reaches a putty/toothpaste-like consistency and then I apply a small dollop over the fill area. I mash it down to make a tight patch and I leave some excess over the areas to sand down later.  With the stummel now out of action for the night, I turn to the stem again taking the flat needle file and freshen the button – upper and lower. I then flip the stem and again taking the flat needle file I remove the excess superglue from the patch I did on the edge of the stem – shank-side. When the filing brings the excess superglue nearly to the surface level of the vulcanite, I use 240 grit sanding paper to blend the patch further with the vulcanite. I follow the 240 with 600 grit paper doing the same. I complete the patch repair by using 0000 steel wool to smooth the patch area as well as the entire stem in preparation of the micromesh polishing process. The pictures show the progress.

With the stummel now out of action for the night, I turn to the stem again taking the flat needle file and freshen the button – upper and lower. I then flip the stem and again taking the flat needle file I remove the excess superglue from the patch I did on the edge of the stem – shank-side. When the filing brings the excess superglue nearly to the surface level of the vulcanite, I use 240 grit sanding paper to blend the patch further with the vulcanite. I follow the 240 with 600 grit paper doing the same. I complete the patch repair by using 0000 steel wool to smooth the patch area as well as the entire stem in preparation of the micromesh polishing process. The pictures show the progress.

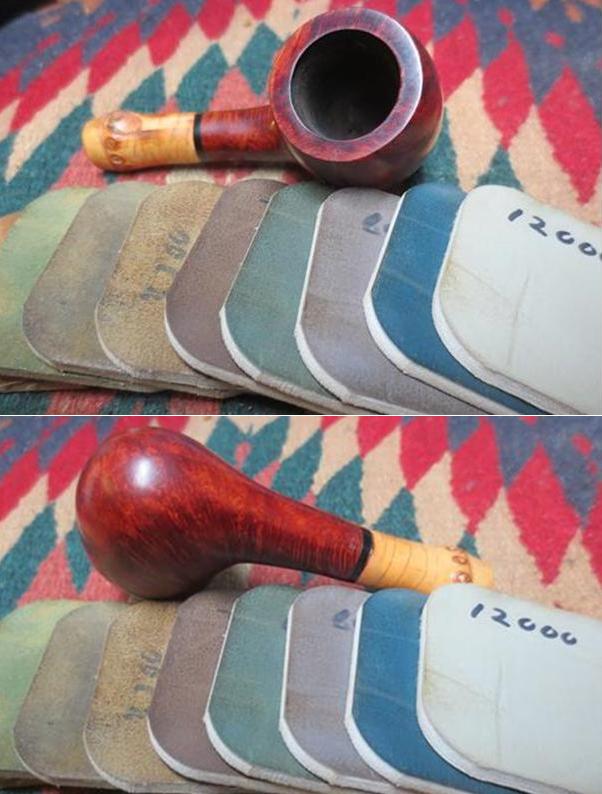

Now for the micromesh phase, using pads 1500 to 2400 I wet sand the stem and follow with an application of Obsidian Oil to rejuvenate the vulcanite. Following this, I dry sand using pad 3200 to 4000, followed by pads 6000 to 12000. After each set of 3, I apply an additional coat of Obsidian Oil. The stem looks good. I put it aside to dry and call it a day. The pictures show the micromesh phase.

Now for the micromesh phase, using pads 1500 to 2400 I wet sand the stem and follow with an application of Obsidian Oil to rejuvenate the vulcanite. Following this, I dry sand using pad 3200 to 4000, followed by pads 6000 to 12000. After each set of 3, I apply an additional coat of Obsidian Oil. The stem looks good. I put it aside to dry and call it a day. The pictures show the micromesh phase.

Early the next morning before heading to work, I want to work on the briar dust patch applied the night before. The superglue dust putty has cured. I take a flat needle file and start filing on the excess mound of cured putty. I’m careful to file down on the patch footprint only and not wander. I take a picture illustrating the idea (#2 below). The idea is that I gradually file the putty excess and ‘sneak up’ on the briar below the patch. I take the filing down to the briar surface, within the patch footprint. At this stage, I apply much less pressure to the file, moving the flat file more in a circular motion lightly over the patch footprint. I want to blend the patched area now with the uncovered briar surface. The aim is to remove the putty excess not take away briar. Picture #3 shows the completion of the flat needle file’s service. I then continue the blending with 240 grit paper expanding the area a bit outside the footprint area (picture #4). I’m not too concerned about this because I know I have sanding to do to eradicate the numerous dents next to the patch.

Early the next morning before heading to work, I want to work on the briar dust patch applied the night before. The superglue dust putty has cured. I take a flat needle file and start filing on the excess mound of cured putty. I’m careful to file down on the patch footprint only and not wander. I take a picture illustrating the idea (#2 below). The idea is that I gradually file the putty excess and ‘sneak up’ on the briar below the patch. I take the filing down to the briar surface, within the patch footprint. At this stage, I apply much less pressure to the file, moving the flat file more in a circular motion lightly over the patch footprint. I want to blend the patched area now with the uncovered briar surface. The aim is to remove the putty excess not take away briar. Picture #3 shows the completion of the flat needle file’s service. I then continue the blending with 240 grit paper expanding the area a bit outside the footprint area (picture #4). I’m not too concerned about this because I know I have sanding to do to eradicate the numerous dents next to the patch.

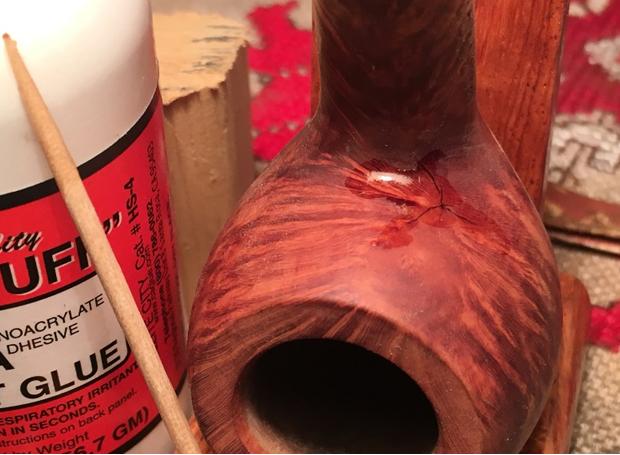

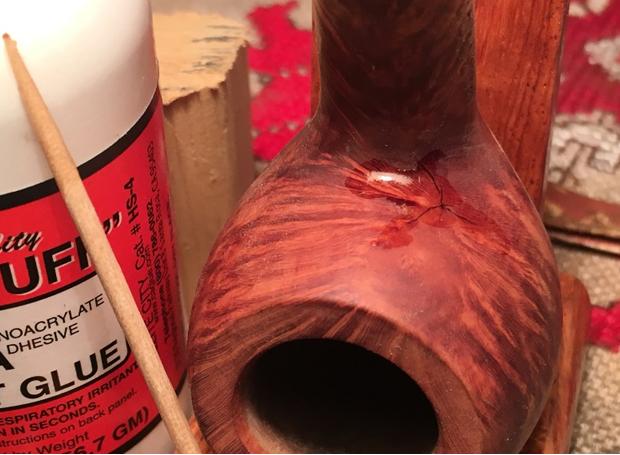

As my wife was admiring the stummel and the briar patterns over my shoulder as I worked, she exclaimed about the face of the kitty revealed in the briar! Raising my eyebrows to refocus my attention to the area captivating her, I see the pattern which is recorded in the picture immediately below. She describes the two eyes, the whiskers and the forehead, probably in need of a little scratch, I thought! So, the Savinelli Capitol Prince has a kitty, too. Then my wife said, with not as much excitement, isn’t that a crack in the middle of the kitty’s face? I had seen it before but it was small and it followed the contours of the grain pattern. Yet, her question raised questions in my mind. I believe the crack is not growing but I elect to apply Hot Stuff CA Glue to the crack just to be on the safe side. This CA glue’s viscosity is extremely thin and perfect for shoring up cracks as it seeps into to a crack’s crevice in a way that thicker glue is unable. However, the problem with this thin glue is that it can absolutely take off like a rabbit scampering over the briar surface not in need of CA glue. To minimize this, I only dabble a bit on a toothpick trying to hold only a small drop at the point of the toothpick. Then, strategically apply it to the center of the crack which spokes outwardly in four separate veins. I find that the glue is running off the end of the toothpick because of its liquidity. I’m finally able to capture a droplet on the toothpick and apply it to the center. The glue spreads a bit, but I change the pitch of the stummel and use gravity to my favor. I also use the tip of the toothpick and paint the glue over the spoking cracks by drawing the glue from the center. The pictures show the progress of shoring up kitty’s nose and whiskers.

As my wife was admiring the stummel and the briar patterns over my shoulder as I worked, she exclaimed about the face of the kitty revealed in the briar! Raising my eyebrows to refocus my attention to the area captivating her, I see the pattern which is recorded in the picture immediately below. She describes the two eyes, the whiskers and the forehead, probably in need of a little scratch, I thought! So, the Savinelli Capitol Prince has a kitty, too. Then my wife said, with not as much excitement, isn’t that a crack in the middle of the kitty’s face? I had seen it before but it was small and it followed the contours of the grain pattern. Yet, her question raised questions in my mind. I believe the crack is not growing but I elect to apply Hot Stuff CA Glue to the crack just to be on the safe side. This CA glue’s viscosity is extremely thin and perfect for shoring up cracks as it seeps into to a crack’s crevice in a way that thicker glue is unable. However, the problem with this thin glue is that it can absolutely take off like a rabbit scampering over the briar surface not in need of CA glue. To minimize this, I only dabble a bit on a toothpick trying to hold only a small drop at the point of the toothpick. Then, strategically apply it to the center of the crack which spokes outwardly in four separate veins. I find that the glue is running off the end of the toothpick because of its liquidity. I’m finally able to capture a droplet on the toothpick and apply it to the center. The glue spreads a bit, but I change the pitch of the stummel and use gravity to my favor. I also use the tip of the toothpick and paint the glue over the spoking cracks by drawing the glue from the center. The pictures show the progress of shoring up kitty’s nose and whiskers.

After the CA Glue cures, I take a small piece of 240 grit paper rolled so that it presents a more solid surface. I then take the 240 roll and strategically sand the crack fix. I keep the roll within the shiny patch footprint with a view of removing glue off the surface and to avoid losing briar as collateral activity. I then take a medium grade sanding sponge and work the patch areas (crack and fill) as well as the multitude of dents on the stummel, but especially on the heel of the stummel. As I work on bringing out the imperfections set in the briar, the thought surfaces in my mind that I had adopted an approach to this pipe, it’s shape and demeanor, going for of a more pristine look – the look of a pipe that is the favorite of royals. A pipe having a quietly, self-confident posture, but elegant and humble. It has a kitty, too! Some pipes seem more of a rugged disposition and seem to beg for some imperfections as badges of past challenges in life – this Savinelli Capitol Prince says, “Please, put a crease in my trousers” – or, as it seems to me! The pictures show the progress.

After the CA Glue cures, I take a small piece of 240 grit paper rolled so that it presents a more solid surface. I then take the 240 roll and strategically sand the crack fix. I keep the roll within the shiny patch footprint with a view of removing glue off the surface and to avoid losing briar as collateral activity. I then take a medium grade sanding sponge and work the patch areas (crack and fill) as well as the multitude of dents on the stummel, but especially on the heel of the stummel. As I work on bringing out the imperfections set in the briar, the thought surfaces in my mind that I had adopted an approach to this pipe, it’s shape and demeanor, going for of a more pristine look – the look of a pipe that is the favorite of royals. A pipe having a quietly, self-confident posture, but elegant and humble. It has a kitty, too! Some pipes seem more of a rugged disposition and seem to beg for some imperfections as badges of past challenges in life – this Savinelli Capitol Prince says, “Please, put a crease in my trousers” – or, as it seems to me! The pictures show the progress.

With the primary patches completed and dents smoothed and blended, I take micromesh pads 1500 to 2400 and wet sand the stummel. I wet sand with the first set of three because it seems the effect of the water on the briar would soften it a bit, and it seems to give the micromesh pads more bite. This helps removing any imperfections/dents left over from all the previous sanding. The latter pads serve to polish what is there more than address imperfections. Well, I was just thinking about smartly pressed trousers when I finish sanding with the first set of micromesh pads, set to take a picture, when I see that the kitty’s eye had changed. He appears to be winking at me! I discover whatever was in the eye before (a small fill?) was no longer there and I am looking at a new royal pit. The latter micromesh cycles must wait as I apply a new ‘T’ Glue patch on the new pit and wait for it to cure and sand and blend it. So, now the kitty has a black eye. The pictures show the pause in progress.

With the primary patches completed and dents smoothed and blended, I take micromesh pads 1500 to 2400 and wet sand the stummel. I wet sand with the first set of three because it seems the effect of the water on the briar would soften it a bit, and it seems to give the micromesh pads more bite. This helps removing any imperfections/dents left over from all the previous sanding. The latter pads serve to polish what is there more than address imperfections. Well, I was just thinking about smartly pressed trousers when I finish sanding with the first set of micromesh pads, set to take a picture, when I see that the kitty’s eye had changed. He appears to be winking at me! I discover whatever was in the eye before (a small fill?) was no longer there and I am looking at a new royal pit. The latter micromesh cycles must wait as I apply a new ‘T’ Glue patch on the new pit and wait for it to cure and sand and blend it. So, now the kitty has a black eye. The pictures show the pause in progress.

When the CA Thick glue cured, I filed it down with a half-circle needle file to the surface and fine-tuned it with 240 grit paper. I follow this by addressing the patch area with 600 grit paper then 0000 steel wool.

When the CA Thick glue cured, I filed it down with a half-circle needle file to the surface and fine-tuned it with 240 grit paper. I follow this by addressing the patch area with 600 grit paper then 0000 steel wool.

To catch up this patch area with the rest of the stummel, I use micromesh pads 1500-2400. At this point I return to the micromesh process with pads 3200 to 4000. I notice the initial fill patch on the heel of the stummel with the micromesh polishing had lightened a bit. I take a dark walnut stain stick and dab it in the fill patches then I use a cotton pad with some alcohol and press it a few times to blend and lighten the stain stick application. It looks better now. I finish with micromesh pads 6000-12000 to further blend the stain stick patch as well as the micromesh phase. The pictures show the progress. The grain is looking very good.

To catch up this patch area with the rest of the stummel, I use micromesh pads 1500-2400. At this point I return to the micromesh process with pads 3200 to 4000. I notice the initial fill patch on the heel of the stummel with the micromesh polishing had lightened a bit. I take a dark walnut stain stick and dab it in the fill patches then I use a cotton pad with some alcohol and press it a few times to blend and lighten the stain stick application. It looks better now. I finish with micromesh pads 6000-12000 to further blend the stain stick patch as well as the micromesh phase. The pictures show the progress. The grain is looking very good.

Time to decide. I have yet to decide upon the next steps – whether to move forward with the natural briar or to apply a stain. This question I put off to the conclusion of the micromesh phase so I can evaluate the briar’s presentation and the pipe’s personality. I rejoin the stummel and stem to get a look at the big picture. Decision made. Using Fiebing’s Light Brown Leather Dye I mix 1 part dye to about 4 parts isopropyl 95% in a shot glass – aiming for a lighter cast. I detach the stem and mount the stummel on a cork to handle the stummel. After wiping the stummel with a cotton pad and alcohol, I heat the stummel with my wife’s hair dryer to expand and open the briar to the dye application. Using a folded over soft pipe cleaner I coat the stummel with the 1 to 4 dye mixture liberally and immediately flame it with a lit candle waiting for that use. The alcohol burns off very quickly setting the dye in the grain. In about 4 or 5 minutes, I repeat the process and set the stummel aside for the night to rest – I as well as the newly stained stummel. The pictures show the progress.

Time to decide. I have yet to decide upon the next steps – whether to move forward with the natural briar or to apply a stain. This question I put off to the conclusion of the micromesh phase so I can evaluate the briar’s presentation and the pipe’s personality. I rejoin the stummel and stem to get a look at the big picture. Decision made. Using Fiebing’s Light Brown Leather Dye I mix 1 part dye to about 4 parts isopropyl 95% in a shot glass – aiming for a lighter cast. I detach the stem and mount the stummel on a cork to handle the stummel. After wiping the stummel with a cotton pad and alcohol, I heat the stummel with my wife’s hair dryer to expand and open the briar to the dye application. Using a folded over soft pipe cleaner I coat the stummel with the 1 to 4 dye mixture liberally and immediately flame it with a lit candle waiting for that use. The alcohol burns off very quickly setting the dye in the grain. In about 4 or 5 minutes, I repeat the process and set the stummel aside for the night to rest – I as well as the newly stained stummel. The pictures show the progress. The next morning, anxious to see the results of the newly stained stummel. Taking the Dremel with the attached hand-held extender, I mount a new felt wheel on the extender, set the Dremel on the lowest RPM setting, and apply Tripoli compound to remove the flamed dye crust to expose the surface. I’m liking the color a lot and the grain has responded very well. As I move through the Tripoli process I identify an eye-sore – at least to me. Circling the outer rim edge is a black ring which the felt wheel charged with Tripoli is not removing. The second picture I take after focusing the Tripoli wheel for some time on the ring itself, hoping to lighten and blend the black ring. To me, the ring is unattractive and detracts from the overall appearance of the pipe. The thoughts floating in my mind at this point are, that it is simply darkened stain at that point that a wipe of alcohol might lighten. Another, less appealing thought is that this ring was produced by the flaming and perhaps scorched this most vulnerable part of the rim. I’m thinking that it wasn’t the dye on the rim itself which burned off, but the overflow of dye on the cork that also had burned off did the deed. I’ll need to check into this with Steve! My methodology needs a revamp if this is the case. The pictures show the issue. The final picture shows the beginning of my corrective approach. With an approach moving from conservative to less so, I spend more time focusing on the rim with the Tripoli felt wheel buff. When this did not achieve the desired results, I take a cotton pad with some alcohol in it and wipe strategically around the outer edge of the rim, hanging over the outside slightly. I do a few cycles around the circumference of the rim with the alcohol then follow again with the Tripoli buff to do a follow-up blending. When this did not achieve the desired results, I tightly roll a piece of 240 grit paper and lightly make a quasi-bevel cut on the outer edge of the rim to remove the scorched briar. The results of this are pictured below. Not pictured is the rest of the process. I followed the 240 grit with a rolled piece of 600 grit paper – as with 240 bevel, staying directly on the edge. Then, I jump to mid-range micromesh pads 4000 to 12000, and smooth, polish and blend the outer rim area. While the tendency for perfectionism would have me try something else, the rim looks much, much better and if I didn’t record this excursion here, 99% of onlookers would not see an issue!

The next morning, anxious to see the results of the newly stained stummel. Taking the Dremel with the attached hand-held extender, I mount a new felt wheel on the extender, set the Dremel on the lowest RPM setting, and apply Tripoli compound to remove the flamed dye crust to expose the surface. I’m liking the color a lot and the grain has responded very well. As I move through the Tripoli process I identify an eye-sore – at least to me. Circling the outer rim edge is a black ring which the felt wheel charged with Tripoli is not removing. The second picture I take after focusing the Tripoli wheel for some time on the ring itself, hoping to lighten and blend the black ring. To me, the ring is unattractive and detracts from the overall appearance of the pipe. The thoughts floating in my mind at this point are, that it is simply darkened stain at that point that a wipe of alcohol might lighten. Another, less appealing thought is that this ring was produced by the flaming and perhaps scorched this most vulnerable part of the rim. I’m thinking that it wasn’t the dye on the rim itself which burned off, but the overflow of dye on the cork that also had burned off did the deed. I’ll need to check into this with Steve! My methodology needs a revamp if this is the case. The pictures show the issue. The final picture shows the beginning of my corrective approach. With an approach moving from conservative to less so, I spend more time focusing on the rim with the Tripoli felt wheel buff. When this did not achieve the desired results, I take a cotton pad with some alcohol in it and wipe strategically around the outer edge of the rim, hanging over the outside slightly. I do a few cycles around the circumference of the rim with the alcohol then follow again with the Tripoli buff to do a follow-up blending. When this did not achieve the desired results, I tightly roll a piece of 240 grit paper and lightly make a quasi-bevel cut on the outer edge of the rim to remove the scorched briar. The results of this are pictured below. Not pictured is the rest of the process. I followed the 240 grit with a rolled piece of 600 grit paper – as with 240 bevel, staying directly on the edge. Then, I jump to mid-range micromesh pads 4000 to 12000, and smooth, polish and blend the outer rim area. While the tendency for perfectionism would have me try something else, the rim looks much, much better and if I didn’t record this excursion here, 99% of onlookers would not see an issue!

I move on to complete the polishing process by attaching the Blue Diamond felt wheel to the Dremel hand-extender and working this lesser abrasive compound over the briar surface. Completing the compounds, I wipe/buff the stummel with a cotton cloth to remove left-over compound dust before moving to apply the wax. I reunite the stem and stummel of the Savinelli Capitol Prince. After mounting a cotton wheel to the Dremel, I increase the RPMs to the next number and apply several coats of carnauba wax to the stummel and stem. After the carnauba wax application, I mount a clean cotton wheel with the same RPM setting on the Dremel as with the carnauba and provide a clean wheel buff to the entire pipe. Finally, I give the pipe a rigorous hand-buffing with a micro-fiber cloth to deepen the 3-dimensional-appearing gloss already shining through this happy piece of briar.

I move on to complete the polishing process by attaching the Blue Diamond felt wheel to the Dremel hand-extender and working this lesser abrasive compound over the briar surface. Completing the compounds, I wipe/buff the stummel with a cotton cloth to remove left-over compound dust before moving to apply the wax. I reunite the stem and stummel of the Savinelli Capitol Prince. After mounting a cotton wheel to the Dremel, I increase the RPMs to the next number and apply several coats of carnauba wax to the stummel and stem. After the carnauba wax application, I mount a clean cotton wheel with the same RPM setting on the Dremel as with the carnauba and provide a clean wheel buff to the entire pipe. Finally, I give the pipe a rigorous hand-buffing with a micro-fiber cloth to deepen the 3-dimensional-appearing gloss already shining through this happy piece of briar.

The grain on this small Prince bowl is captivating with larger bird’s eye on the front, splaying fans on the heel, and of course, a kitty with whiskers fanning out as he gazes up the shank and stem at his steward – or should I add, stewardess! The diminutive size of the bowl along with the longer-than-expected sleek shank and stem, would make this Savinelli Capitol Prince – a preferred shape to at least one royal, a wonderful addition to any pipeman’s or pipelady’s collection. Thank you for joining me!

Those of you who have gone pipe hunting enough know the rush that goes with opening an old leather covered pipe case like this and finding the Churchwarden that the case was made for still resident inside. There are a lot of empty pipe cases selling on eBay daily that give witness to the fact that the case and the pipe that should be inside often have parted company. In this case though when he opened the case I think he was surprised. I certainly was when he sent me a text with the photo. Inside was a smooth block meerschaum pipe with a long stem that was in relatively decent shape. The stem was intact and there were no large nicks or bumps on the bowl sides or shank. The stem aligned correctly with the shank and the whole thing appeared to be functional. These are the kinds of finds right up there with finding that illusive $10 Dunhill that keep me always looking inside cans, boxes and even pipe cases to see if something has been overlooked. You never know what kind of treasure might be hidden awaiting your discovery.

Those of you who have gone pipe hunting enough know the rush that goes with opening an old leather covered pipe case like this and finding the Churchwarden that the case was made for still resident inside. There are a lot of empty pipe cases selling on eBay daily that give witness to the fact that the case and the pipe that should be inside often have parted company. In this case though when he opened the case I think he was surprised. I certainly was when he sent me a text with the photo. Inside was a smooth block meerschaum pipe with a long stem that was in relatively decent shape. The stem was intact and there were no large nicks or bumps on the bowl sides or shank. The stem aligned correctly with the shank and the whole thing appeared to be functional. These are the kinds of finds right up there with finding that illusive $10 Dunhill that keep me always looking inside cans, boxes and even pipe cases to see if something has been overlooked. You never know what kind of treasure might be hidden awaiting your discovery. The leather (probably a leather like vinyl) covered case was in great shape. The exterior was not even worn. The polished brass hinges and clasps looked good with the shiny leather. The front of the case had two clasps and next to the left one is the tag reading Made in Turkey. On the back side there are two hinges that are hidden beneath the leather. Four small brass brads hold each hinge in place. The hinges are not sprung or damaged in any way.

The leather (probably a leather like vinyl) covered case was in great shape. The exterior was not even worn. The polished brass hinges and clasps looked good with the shiny leather. The front of the case had two clasps and next to the left one is the tag reading Made in Turkey. On the back side there are two hinges that are hidden beneath the leather. Four small brass brads hold each hinge in place. The hinges are not sprung or damaged in any way. My brother took a few photos of the pipe in the case to give an idea of what he saw when he opened the lid. The inside was lined with a rich golden coloured soft fabric that protected the meerschaum and held the pipe firmly in place. In the inside top cover there was the SMS logo that reads Handcarved Block Meerschaum Turkey around the stylised SMS. On the left side of the stem is the same logo inset in clear acrylic in the vulcanite.

My brother took a few photos of the pipe in the case to give an idea of what he saw when he opened the lid. The inside was lined with a rich golden coloured soft fabric that protected the meerschaum and held the pipe firmly in place. In the inside top cover there was the SMS logo that reads Handcarved Block Meerschaum Turkey around the stylised SMS. On the left side of the stem is the same logo inset in clear acrylic in the vulcanite.

He removed the pipe from the case and you can see the beauty and simplicity of the shape. The shank and the rim edge are starting show some colour with a faint brown hue.

He removed the pipe from the case and you can see the beauty and simplicity of the shape. The shank and the rim edge are starting show some colour with a faint brown hue. He took some close up photos to show the condition of the rim. The bowl had a cake developing in it that went about half way down the bowl sides. The tars had darkened the rim on the back side and the outer edges of the rim had a few nicks and scratches. It would be interesting to see how much of this was surface damage once I had the pipe in hand in Vancouver.

He took some close up photos to show the condition of the rim. The bowl had a cake developing in it that went about half way down the bowl sides. The tars had darkened the rim on the back side and the outer edges of the rim had a few nicks and scratches. It would be interesting to see how much of this was surface damage once I had the pipe in hand in Vancouver. He took photos of the underside of the bowl and the sides as well to show some of the spotty dirt and debris that were there. It was hard to tell from the photos if these were merely on the surface or had penetrated the surface and left scratches on the bowl sides and bottom. I would see once I had it in hand.

He took photos of the underside of the bowl and the sides as well to show some of the spotty dirt and debris that were there. It was hard to tell from the photos if these were merely on the surface or had penetrated the surface and left scratches on the bowl sides and bottom. I would see once I had it in hand.

The stem appeared to be in pretty decent shape but the first inch on both sides of the stem at the button had some tooth marks, chatter and calcification. It appeared that the previous owner had smoked the pipe with a Softee Bit to protect the stem from his bite but even that had not kept all the tooth marks off the stem. Perhaps he or she had smoked it, seen the damage and put the rubber Softee on to protect it from further damage.

The stem appeared to be in pretty decent shape but the first inch on both sides of the stem at the button had some tooth marks, chatter and calcification. It appeared that the previous owner had smoked the pipe with a Softee Bit to protect the stem from his bite but even that had not kept all the tooth marks off the stem. Perhaps he or she had smoked it, seen the damage and put the rubber Softee on to protect it from further damage. My brother did a great clean up on the stem and shank internals and cleaned out the cake in the bowl with his Savinelli Fitsall Knife. He had removed some of the tars and oils on the top of the bowl and scrubbed the exterior with a soft cloth and Murphy’s Oil Soap. When it arrived in Vancouver it looked far better than it had in the earlier photos. I took the next five photos to record my first look at the pipe as I opened the case and removed it from its nest.

My brother did a great clean up on the stem and shank internals and cleaned out the cake in the bowl with his Savinelli Fitsall Knife. He had removed some of the tars and oils on the top of the bowl and scrubbed the exterior with a soft cloth and Murphy’s Oil Soap. When it arrived in Vancouver it looked far better than it had in the earlier photos. I took the next five photos to record my first look at the pipe as I opened the case and removed it from its nest.

I took some close up photos of the bowl, rim and stem to show what it looked like after my brother’s work on it. He had been able to get a lot of the tars and oils off the rim top and had cleaned the sides of the bowl. The second photo shows the SMS logo in acrylic on the left side. The stem showed some oxidation spots and a spot where obviously a label had been glued. He had been able to get the calcification off the stem at the button and also had managed to lift out some of the tooth chatter. The top edge of the button on both sides showed some wear.

I took some close up photos of the bowl, rim and stem to show what it looked like after my brother’s work on it. He had been able to get a lot of the tars and oils off the rim top and had cleaned the sides of the bowl. The second photo shows the SMS logo in acrylic on the left side. The stem showed some oxidation spots and a spot where obviously a label had been glued. He had been able to get the calcification off the stem at the button and also had managed to lift out some of the tooth chatter. The top edge of the button on both sides showed some wear.

I started cleaning the exterior of bowl and stem with a green nylon scrubber. It is a great tool that I learned the use of through Troy (one of the contributors to the blog). I scrubbed the exterior of the stem and was able to remove much of the oxidation. I also used it to scrub the rim. I wet the scrubber with tap water to help with the scrubbing and it did a great job on the rim and stem.

I started cleaning the exterior of bowl and stem with a green nylon scrubber. It is a great tool that I learned the use of through Troy (one of the contributors to the blog). I scrubbed the exterior of the stem and was able to remove much of the oxidation. I also used it to scrub the rim. I wet the scrubber with tap water to help with the scrubbing and it did a great job on the rim and stem. I continued to scrub the rim with the pad and then shifted to polishing the bowl and rim with micromesh sanding pads. I wet sanded the entirety of the pipe with 1500-2400 grit sanding pads and dry sanded it with 3200-12000 grit pads. The finished bowl and rim are shown in the next four photos. I was able to remove the tars and the scratches from the bowl and rim and leave behind a polished bowl that still maintained the patina that had begun to develop.

I continued to scrub the rim with the pad and then shifted to polishing the bowl and rim with micromesh sanding pads. I wet sanded the entirety of the pipe with 1500-2400 grit sanding pads and dry sanded it with 3200-12000 grit pads. The finished bowl and rim are shown in the next four photos. I was able to remove the tars and the scratches from the bowl and rim and leave behind a polished bowl that still maintained the patina that had begun to develop.

I ran a pipe cleaner with alcohol through the stem and the shank of the pipe and as usual my brother had done a thorough job removing the oils and tars from those places.

I ran a pipe cleaner with alcohol through the stem and the shank of the pipe and as usual my brother had done a thorough job removing the oils and tars from those places. I sanded the tooth marks and chatter on both sides of the stem at the button with 220 grit sandpaper to remove the damaged areas. I was fortunate that none of the tooth marks were deep enough to warrant repairs. I removed all of them by sanding the stem.

I sanded the tooth marks and chatter on both sides of the stem at the button with 220 grit sandpaper to remove the damaged areas. I was fortunate that none of the tooth marks were deep enough to warrant repairs. I removed all of them by sanding the stem. I wet sanded the stem with 1500-2400 grit micromesh sanding pads and dry sanded it with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil after each set of three pads. After the final rub down I set the stem aside to dry.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and dry sanded it with 3200-12000 grit pads. I rubbed the stem down with Obsidian Oil after each set of three pads. After the final rub down I set the stem aside to dry.

I buffed the bowl and stem with Blue Diamond on the buffing wheel and gave the stem several coats of carnauba wax. I gave the bowl a few coats of Clapham’s Beeswax Polish (a white beeswax polish) and buffed bowl and stem with a clean buffing pad. I hand buffed the pipe with a microfibre cloth to put the final touches on it. The finished pipe is shown in the photos below. It really is a nicely made meerschaum and the fact that it is a Churchwarden is bonus. The weight of the pipe and the feel of it in the hand will make this pipe a winner. Thanks for looking.

I buffed the bowl and stem with Blue Diamond on the buffing wheel and gave the stem several coats of carnauba wax. I gave the bowl a few coats of Clapham’s Beeswax Polish (a white beeswax polish) and buffed bowl and stem with a clean buffing pad. I hand buffed the pipe with a microfibre cloth to put the final touches on it. The finished pipe is shown in the photos below. It really is a nicely made meerschaum and the fact that it is a Churchwarden is bonus. The weight of the pipe and the feel of it in the hand will make this pipe a winner. Thanks for looking.