Blog by Steve Laug

Once again in this write up and I will take you through my process of working on each pipe that we purchase. Jeff has set up a spread sheet to track where the pipe came from, the date of purchase and what we paid for it so that we know what we have invested in the pipe before we even work on it. This takes a lot of the guess work out of the process. This particular pipe was purchased on 11/10/2022 from Copenhagen, Denmark from a seller we buy a lot of pipes from. I also want you to understand why we take the photos we do. If you have followed for a while then you will see the familiar pattern of the photos we include both in the before and midstream process of working on a pipe. It is not accidental or chance as the photos have been taken to help me make an assessment of the pipe Jeff sees before he starts his clean up work. We do this to record the condition that the pipe was in when received it and to assess what kind of work will need to be done on. When I look at these photos this is what I see.

Once again in this write up and I will take you through my process of working on each pipe that we purchase. Jeff has set up a spread sheet to track where the pipe came from, the date of purchase and what we paid for it so that we know what we have invested in the pipe before we even work on it. This takes a lot of the guess work out of the process. This particular pipe was purchased on 11/10/2022 from Copenhagen, Denmark from a seller we buy a lot of pipes from. I also want you to understand why we take the photos we do. If you have followed for a while then you will see the familiar pattern of the photos we include both in the before and midstream process of working on a pipe. It is not accidental or chance as the photos have been taken to help me make an assessment of the pipe Jeff sees before he starts his clean up work. We do this to record the condition that the pipe was in when received it and to assess what kind of work will need to be done on. When I look at these photos this is what I see.

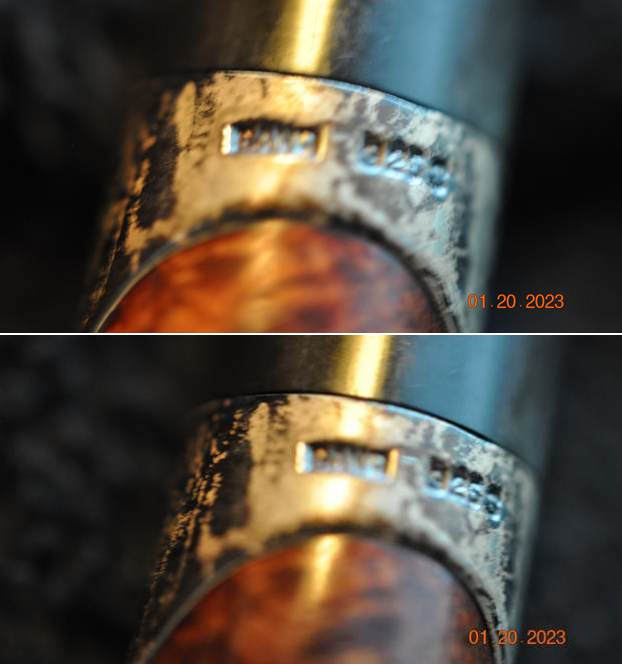

- The first thing I see is a unique Sterling Silver band on the shank that has become familiar from the pipes we have purchased from Copenhagen. Each one is much the same and all were made by S. Bang. I am pretty certain this is one as well. The question is if it is cosmetic like the others have been or does it take care of a crack in the shank. We shall see.

- The finish is dirty and there is oils from the smoker’s hands on both side of the bowl. There is grimed ground into the finish as well but even so there is also some great grain peeking through. From the exterior it does not appear that there is a crack in the shank but when Jeff examines it he will confirm either the presence or absence of a crack.

- The rim top had a thick lava overflow from the cake in the bowl. It was thicker on the back half of the rim top but present all the way around. It is hard to know if there is darkening or damage under the lava. Sometimes the lava protects the rim top and edges and sometime it hides issues. Its is very dirty looking.

- The bowl has a thick cake in it that hides the inner edge of the bowl but once it is clean we will know what the edges look like. The outer edges look good and there does not appear to be any obvious burn damage to the top or bowl edges.

- The vulcanite saddle stem is in good condition – dirty, lightly oxidized and has light tooth chatter on both sides. There does not appear to be a CP logo on the stem but the fit to the shank end is well done. It is hard to know with certainty if it is an original stem or a replacement.

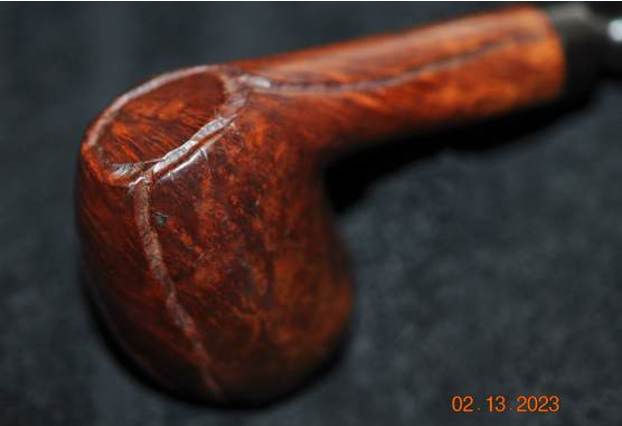

Overall my impressions of this pipe is that it is a beauty that once cleaned up will look pretty amazing. The oxidized S. Bang fancy Sterling Silver Band adds a touch bling even though tarnished that does not detract from the beauty of the pipe. The exterior of the bowl does not show any hot spots or darkening. The pipe is very English looking and is a classic Lovat that has the distinctive cut of a Charatan. The photos below confirm the assessment above. Jeff took close up photos so that I could have a clearer picture of the condition of the bowl, rim edges and top. The rim top photos confirm my assessment above. The cake in the bowl is quite thick and the rim top has lava and debris on it. You can also see the condition of the outer edge but the inner edge is a bit of a mystery at this point. This is what I look for when assessing a pipe. While there is lava and darkening there is no visible burn damage at this point. The bowl is still fairly round.

Jeff took close up photos so that I could have a clearer picture of the condition of the bowl, rim edges and top. The rim top photos confirm my assessment above. The cake in the bowl is quite thick and the rim top has lava and debris on it. You can also see the condition of the outer edge but the inner edge is a bit of a mystery at this point. This is what I look for when assessing a pipe. While there is lava and darkening there is no visible burn damage at this point. The bowl is still fairly round.  The photos of the stem surface from various angles confirmed my assessment of its condition. You can see the oxidation and the fit against the tarnished silver band on the shank end. The stem surface though dirty does not appear to have tooth marks – chatter yes, but no deep marks. The stem is quite dirty but otherwise undamaged.

The photos of the stem surface from various angles confirmed my assessment of its condition. You can see the oxidation and the fit against the tarnished silver band on the shank end. The stem surface though dirty does not appear to have tooth marks – chatter yes, but no deep marks. The stem is quite dirty but otherwise undamaged.

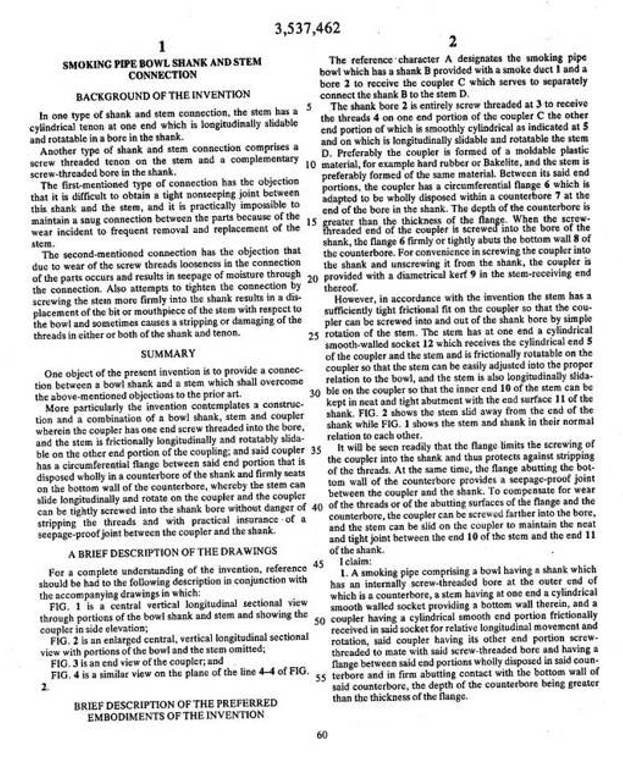

The next photos show the amazing grain around the heel and the sides of the bowl. Tell me what you see? Are there any visible problems that stand out to you? Are the cracks or scratches? Are there visible flaws or fissures in the briar? What kind of grain stands out around the bowl and heel? Any visible issues on the heel of the bowl? Even the questions should help you to see what I am looking for when I see these photos.

The next photos show the amazing grain around the heel and the sides of the bowl. Tell me what you see? Are there any visible problems that stand out to you? Are the cracks or scratches? Are there visible flaws or fissures in the briar? What kind of grain stands out around the bowl and heel? Any visible issues on the heel of the bowl? Even the questions should help you to see what I am looking for when I see these photos.

You have read it a few times now in the previous blogs. What am I looking for when I look at the shank stamp? In this case it is stamped on the left side and reads Charatan’s Make[over] London England [over] Belvedere in three lines. How does the stamping look to you? Is it clear and readable? Is it faint in spots or is it uniform? I know you are looking at photos but so do I at this point in the process. The right side is also stamped and reads 1014 which is the shape number. The same questions apply here as well.

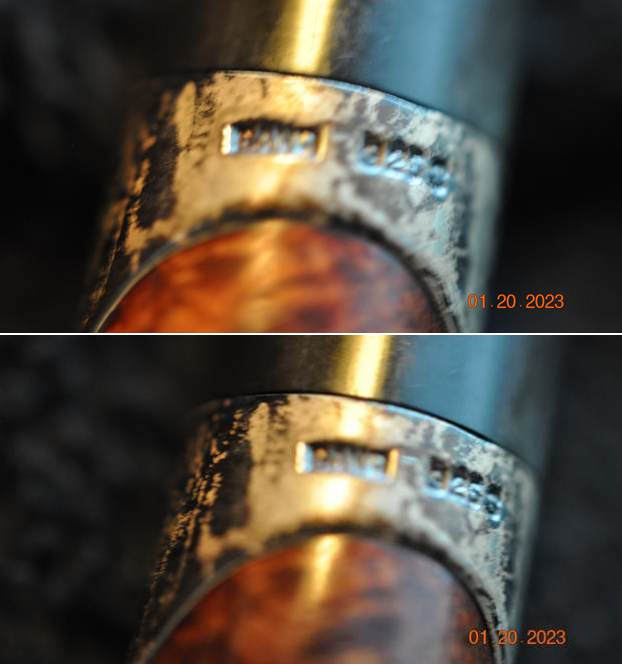

You have read it a few times now in the previous blogs. What am I looking for when I look at the shank stamp? In this case it is stamped on the left side and reads Charatan’s Make[over] London England [over] Belvedere in three lines. How does the stamping look to you? Is it clear and readable? Is it faint in spots or is it uniform? I know you are looking at photos but so do I at this point in the process. The right side is also stamped and reads 1014 which is the shape number. The same questions apply here as well.  The next photos show where London Meets Copenhagen. The stamping on the stylized silver band are simply BANG in one box and 325S in the second box. I love this kind of backstory on a pipe. How did an English made pipe from London connect with an S.Bang Sterling Silver Band? I know it happened in Copenhagen as that is where we bought the pipe. We asked the seller the story on it and he said that the older gentleman who owned this pipe took it along with several others from his collection to the S. Bang workshop and had them add bands to his pipes. They were not necessary as the shank was not cracked but the old pipeman just wanted some decorative bands on his pipes (he may well have been my age so old is such a relative term). However that happened it is a great story of the meeting of this London pipe with a Danish silvermaker. I have to say that I really like the result!

The next photos show where London Meets Copenhagen. The stamping on the stylized silver band are simply BANG in one box and 325S in the second box. I love this kind of backstory on a pipe. How did an English made pipe from London connect with an S.Bang Sterling Silver Band? I know it happened in Copenhagen as that is where we bought the pipe. We asked the seller the story on it and he said that the older gentleman who owned this pipe took it along with several others from his collection to the S. Bang workshop and had them add bands to his pipes. They were not necessary as the shank was not cracked but the old pipeman just wanted some decorative bands on his pipes (he may well have been my age so old is such a relative term). However that happened it is a great story of the meeting of this London pipe with a Danish silvermaker. I have to say that I really like the result! An added part of pipe restoration for me is to try to gather as much background on a brand and maker as I can find. With Charatan that is an enjoyable web to untangle. There is a lot of information and it can lead to understanding what era a pipe was made in. To try to figure out the era of the Charatan’s pipe I was working on I turned to the Pipephil website, Logos and Stampings (http://www.pipephil.eu/logos/en/logo-charatan.html). There is some really helpful information on each of the lines of Charatan’s Make pipes that entered the market. There is an alphabetical listing of the lines but the Belvedere they showed had a stem made for a 9mm filter while the one I have is a nonfiltered pipe. The site did give a short history of the brand. I quote the portion that is most pertinent.

An added part of pipe restoration for me is to try to gather as much background on a brand and maker as I can find. With Charatan that is an enjoyable web to untangle. There is a lot of information and it can lead to understanding what era a pipe was made in. To try to figure out the era of the Charatan’s pipe I was working on I turned to the Pipephil website, Logos and Stampings (http://www.pipephil.eu/logos/en/logo-charatan.html). There is some really helpful information on each of the lines of Charatan’s Make pipes that entered the market. There is an alphabetical listing of the lines but the Belvedere they showed had a stem made for a 9mm filter while the one I have is a nonfiltered pipe. The site did give a short history of the brand. I quote the portion that is most pertinent.

The brand was founded in 1863 by Frederik Charatan. When his father retired in 1910, Reuben Charatan took over the family business. All the pipes were handmade until 1973. The brand name has been overtaken by Dunhill in 1978 and sold in 1988 to James B. Russell Inc.(NJ, USA). During the period 1988-2002 Charatans were crafted by Butz Choquin in St Claude (France). Dunhill re-purchased Charatan brand name in 2002 and Colin Fromm (Invicta Briars, Castleford) followed up on freehand production.

Next I turned to Pipedia to see if I could find more information on the brand and possibly a link to the Belvedere line (https://pipedia.org/wiki/Charatan) but once again in the general article it was not listed. It did give a little more historical information. I quote the pertinent parts and have highlighted in red the sections that give information on this particular pipe.

In 1863 Frederick Charatan, a Russian/Jewish immigrant, opened a shop in Mansell Street, located in the borough of Tower Hamlets, London E1, where he began to carve Meerschaum pipes. These pipes got very popular soon, and thus Charatan moved to a bigger workshop in Prescot Street, just around the corner. Here he began to make briar pipes which should make the name famous the world over. Charatan was the first brand to make entirely hand-made briars from the rough block to the finished pipe including the stems. The nomenclature “Charatan’s Make” refers to this method of production and was meant to differentiate Charatan from other brands who “assembled” pipes from pre-drilled bowls and delivered mouthpieces.

Being the undisputed No. 1 in English pipemaking, Charatan was approached by Alfred Dunhill who was unsatisfied with the quality of the pipes he imported from France. During 1908 – 1910 Dunhill bought pipes from Charatan paying exorbitant prices to ensure he had some of the very best pipes for sale in England. In 1910 he lured away Joel Sasieni, one of Charatan’s best carvers, and opened his own small pipe workshop on 28 Duke Street. On the retirement of his father in 1910 Reuben Charatan took over the family business…

…The pre-Lane period (prior to 1955) and the Lane era pipes (1955 to until sometime between 1979 – 1984) are of primary interest the collector. The Lane era is often quoted as beginning about 1950… Charatan records are almost non-existent before Lane due to a factory fire, making it difficult to date pre-Lane pipes. Charatan used 4 basic grades prior to 1950: Supreme, Selected, Executive, and Belvedere. After 1950 Herman Lane’s influence began, and the grades started to expand. In 1955 Lane took over sole distributorship of Charatan in the US. In 1957 he introduced the Supreme S. Most of his other introductions were from the 60’s and early 70’s…

From this I am fairly certain I am dealing with a pre-Lane pipe made prior to 1955 and because of the Belvedere stamp it could potentially go back as far as before 1950. There are none of the expected Lane stampings on the pipe which also supports this.

I continued digging further into the dating of the pipe, but what I had found above was a good start for me. If some of you would like to try your hand at dating it more accurately as to the time period it came out you might want to check out the article on Pipedia on Dating Charatans (https://pipedia.org/wiki/Dating_of_Charatans).

I also reread the article on Pipedia by the Italian fellow who contributed some really helpful information on the brand (https://pipedia.org/wiki/Charatan_-_Milan_2014). I quote the section on the Second period: Reuben Charatan 1910 – c. 1962. I have highlighted a portion of the section on the shank in red to point out some more helpful dating information.

– In 1962 Herman Lane took over the business from the Charatan family, although he had already influenced production from the 1950s.

– The pipes were mostly larger than the previous ones and corresponded in size to Dunhill group 5. These are slightly less rare, but still difficult to find.

– Stem: Usually in ebonite, saddle shaped or tapered, bearing a fine “CP” stamp, underbore system (see below) used when necessary.

– Shank: The shape code is stamped on it together with the nomenclature “CHARATAN’S MAKE LONDON ENGLAND” arranged in two lines. From 1955 onwards on the models marketed for the USA there is also a serif and circled capital “L” (but not all models bear this) which resembles the pound sterling symbol. The “L” is for Lane, the importer.

From 1958, Lane changed the nomenclature for models marketed for the US to clarify the message: “MADE BY HAND”. In this period the underbore was introduced. Its manufacturing period ranged between 1920 and c.1930. This model was equipped with a duralumin plunger trap fitted in the stem, which served to clean the residue more easily. This particular model bore a special stamp on the stem, and also had its own catalogue…

QUALITY GRADES…The stem did not only display the stamps mentioned above. Another stamp that can help dating is the one referring to the quality of the pipe. Until Herman Lane arrived on the scene there were four quality grades. Starting with the lowest: Belvedere, Executive, Selected, and Supreme. Lane went on to add higher grades from time to time: Supreme S, Supreme S100, S150, S200, S250, S300, Coronation, Royal Achievement, Crown Achievement, and Summa Cum Laude; these last three are extremely rare and almost impossible to find. He also invented other, different grades, even changing the previous pipe classification standards. We will not go into detail here, but it means that if we find an S100 or Coronation the pipe was manufactured following Herman Lane’s acquisition. In particular, the FH mark, or Freehand pipe was commissioned to the famous Danish craftsman, Preben Holm.

Now I knew I was working on a pre-Lane pipe which actually means it was made before 1955 as shown by the stamping. I wanted to now see if I could find any information the shape 1014 number as it was not listed in any shape charts I could find.

I did a Google search of the Charatan’s Make London England Belvedere 1014 and was taken to one link. Interestingly it was on smokingpipes.com US website and it is the exact pipe I am working on sans the Bang band on the shank. The stamping the shape of the stem and all parts even the stain matches the one that I have in hand. I am also including a screen capture of the pipe (https://www.smokingpipes.com/pipes/estate/england/moreinfo.cfm?product_id=314515). I am sure many of you will shake your head and ask maybe even out loud, “Why is he including this again?” However, please remember that the point of these blogs is not to wow your with the work or make you shake your heads but I want you to know the details of the work we do so you can do your own. Back in 2020 Jeff wrote a blog about his cleaning process. I am including a link to that now so you can see what I mean about his process. Do not skip it! Give it a read (https://rebornpipes.com/2020/01/20/got-a-filthy-estate-pipe-that-you-need-to-clean/). Here is the introduction to that blog and it is very true even to this day.

I am sure many of you will shake your head and ask maybe even out loud, “Why is he including this again?” However, please remember that the point of these blogs is not to wow your with the work or make you shake your heads but I want you to know the details of the work we do so you can do your own. Back in 2020 Jeff wrote a blog about his cleaning process. I am including a link to that now so you can see what I mean about his process. Do not skip it! Give it a read (https://rebornpipes.com/2020/01/20/got-a-filthy-estate-pipe-that-you-need-to-clean/). Here is the introduction to that blog and it is very true even to this day.

Several have asked about Jeff’s cleaning regimen as I generally summarize it in the blogs that I post rather than give a detailed procedure. I have had the question asked enough that I asked Jeff to put together this blog so that you can get a clear picture of the process he uses. Like everything else in our hobby, people have different methods they swear by. Some may question the method and that is fine. But it works very well for us and has for many years. Some of his steps may surprise you but I know that when I get the pipes from him for my part of the restoration they are impeccably clean and sanitized. I have come to appreciate the thoroughness of the process he has developed because I really like working on clean pipe!

For the benefit of some of you who may be unfamiliar with some of the products he uses I have included photos of three of the items that Jeff mentions in his list. This will make it easier for recognition. These three are definitely North American Products so you will need to find suitable replacements or order these directly on Amazon. The makeup pads are fairly universal as we were able to pick some up in India when we were with Paresh and his family.

In the blog itself he breaks his process down into two parts – cleaning the stem and cleaning the bowl. Each one has a large number of steps that he methodically does every time. I know because I have watched him do the work and I have seen the pipes after his work on them. He followed this process step by step and when the pipe got to me it was spotlessly clean and ready for my work. The inside of the stem, shank and bowl were clean and to me that is an amazing gift as it means that my work on this end is with a clean pipe! I cannot tell you how much difference that makes for my work.

When the pipe arrives here in Vancouver I have a clean pipe and I go over it keeping in mind my assessment shared in the opening paragraph above. Now that I have it in hand I am looking for confirmation of what I saw in the photos as well as any significant structural changes in the bowl and finish as I go over it.

- I was correct in my thoughts that the band was a Bang. It is clearly stamped Bang along with the 325S silver quality designation. It is for cosmetic purpose only as there are no visible cracks in the shank as I go over the exterior and the internal end of the shank. IT is clear and it is a beauty. The oxidation is gone and the band looks very good.

- The finish is very clean and darkening from oils on the bowl sides is gone. The grain stands out on the surface of the clean briar. There are no cracks showing up in the grain lines or in the flaws under the grime. It is sound on the outside. I will need to polish the briar and buff it to bring back the shine.

- The rim top is clean of the lava but there is still some darkening on the top and edges of the bowl. The inner edge is ragged and shows both burn damage and also some previous reaming damage. It is still fairly round but not smooth. The good news for me is that there are no cracks showing up in the rim top. The rim top and edges were sound.

- The bowl was very clean and smelled clean. The clean walls did not show evidence of checking or cracking. There were no hot spots or damage on the walls or around the entrance of the airway into the bowl. It was clean and smooth which is great news for me. Both the shank and the bowl were very clean showing no debris on a clean pipe clean run through them. I would need to give it a final cleaning with pipe cleaners and alcohol once I had finished with the external work to remove the debris that may have collected there in the process.

- The vulcanite saddle stem is in good condition – it cleaned up very well. All oxidation is gone. It is a little rough to the touch and the light chatter is not deep at all. There is not a CP logo on the stem but the fit to the shank end is well done. It is hard to know with certainty if it is an original stem or a replacement.

Hopefully the steps above show you both what I look for when I go over the pipe when I bring it to the work table and also what I see when I look at the pipe in my hands. They also clearly spell out a restoration plan in short form. My work is clear and addressing it will be the next steps. I took photos of the whole pipe to give you a picture of what I see when I have it on the table. This is important to me in that it also shows that there was no damage done during the clean up work or the transit of the pipe from Idaho to here in Vancouver.

I carefully went over the bowl and rim top to get a sense of what is happening there. In this case once the lava was removed damage to the edge and top was revealed. Originally I thought it looked like reaming damage but I don’t think so as I examine it closely. I think it is actually burn damage to the edge that extends around the inner edge though it is heavier at the front and back of the bowl. The rim top also shows some damage. It is clean but will need to be worked on to bring it back to normal. I also go over the stem carefully. There were no tooth marks or dents in the stem. I could not see any sign of remaining CP stamping on the stem so no real clue as to whether it is original or a replacement. I took photos of the rim top and stem sides to show as best as I can what I see when I look at them.

I carefully went over the bowl and rim top to get a sense of what is happening there. In this case once the lava was removed damage to the edge and top was revealed. Originally I thought it looked like reaming damage but I don’t think so as I examine it closely. I think it is actually burn damage to the edge that extends around the inner edge though it is heavier at the front and back of the bowl. The rim top also shows some damage. It is clean but will need to be worked on to bring it back to normal. I also go over the stem carefully. There were no tooth marks or dents in the stem. I could not see any sign of remaining CP stamping on the stem so no real clue as to whether it is original or a replacement. I took photos of the rim top and stem sides to show as best as I can what I see when I look at them. I always check to make sure that the clean up work did not damage the stamping on the shank in any way. It looks very good still. I also took a photo of the silver. I always appreciate the handiwork of the carvers at Charatan who turn a piece raw briar into a beautiful pipe. I love just looking at the beauty of the lay of the pipe with the grain and the proportion of the hand made pipes. I like to remove the stem from the shank to get a sense of what was in the mind of the pipe maker when he crafted the pipe. It is a beauty in flow and shape.

I always check to make sure that the clean up work did not damage the stamping on the shank in any way. It looks very good still. I also took a photo of the silver. I always appreciate the handiwork of the carvers at Charatan who turn a piece raw briar into a beautiful pipe. I love just looking at the beauty of the lay of the pipe with the grain and the proportion of the hand made pipes. I like to remove the stem from the shank to get a sense of what was in the mind of the pipe maker when he crafted the pipe. It is a beauty in flow and shape.

By this time you should know that I almost always start with the bowl in my restoration because I truly do not like the tedious work of stem repairs and polishing. I always leave that until last even though I know that it needs to be done. For me the encouragement of seeing a rejuvenated bowl is the impetus I need to attack the stem work.

By this time you should know that I almost always start with the bowl in my restoration because I truly do not like the tedious work of stem repairs and polishing. I always leave that until last even though I know that it needs to be done. For me the encouragement of seeing a rejuvenated bowl is the impetus I need to attack the stem work.

Today I started working on this pipe by turning to the bowl. I chose to deal with the darkening and burn damage on the rim edges and top. I used a folded piece of 220 grit sandpaper to reshape and remove the rim top and damage. It took a little work but I was able to remove all of the darkening. It is a beautiful piece of briar with some great grain. Once rim top was reshaped and reworked I needed to blend them into the rest of the briar. I polished the briar with micromesh sanding pads. I choose to dry sand the briar rather than wet sand it. Again it is a matter of personal preference. I prefer to use the pads dry and find they work very well on the briar. I sand with each pad (9 in total) and group them by threes for ease of reference. I also work over the plateau areas at the same time. I wipe the bowl down after each pad with a damp cloth to remove the sanding debris and check the briar. I love seeing the developing shine on the briar as I move through the pads which is why I include so many photos of this step.

Once rim top was reshaped and reworked I needed to blend them into the rest of the briar. I polished the briar with micromesh sanding pads. I choose to dry sand the briar rather than wet sand it. Again it is a matter of personal preference. I prefer to use the pads dry and find they work very well on the briar. I sand with each pad (9 in total) and group them by threes for ease of reference. I also work over the plateau areas at the same time. I wipe the bowl down after each pad with a damp cloth to remove the sanding debris and check the briar. I love seeing the developing shine on the briar as I move through the pads which is why I include so many photos of this step.

For the past few years now I have been using a product developed by Mark Hoover called Before & After Restoration Balm. It is a paste/balm that is rubbed into the surface of the briar and the plateau. The product works to deep clean the nooks and crannies of finish, enliven and protect the briar. I worked it into the briar with my finger tips and let it sit for 10 minutes to do its work. I wiped it off with a soft cloth then buffed it with a cotton cloth. The briar really began to have a deep shine in the briar and the grain shone through. The photos I took of the bowl at this point mark the progress in the restoration. It is a gorgeous pipe.

For the past few years now I have been using a product developed by Mark Hoover called Before & After Restoration Balm. It is a paste/balm that is rubbed into the surface of the briar and the plateau. The product works to deep clean the nooks and crannies of finish, enliven and protect the briar. I worked it into the briar with my finger tips and let it sit for 10 minutes to do its work. I wiped it off with a soft cloth then buffed it with a cotton cloth. The briar really began to have a deep shine in the briar and the grain shone through. The photos I took of the bowl at this point mark the progress in the restoration. It is a gorgeous pipe.

Now it was time to address the part of the restoration I leave until last. I set the bowl aside and turned my attention to the stem. The stem was in good nick other than the light oxidation on the top side. There were no tooth marks or chatter so it was simply a matter of polishing the stem and bring back a shine. I use micromesh sanding pads and water to wet sand the stem with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil on a cotton rag after each sanding pad as I find it does two things – first it protects the vulcanite and second it give the sanding pads bite in the polishing process.

Now it was time to address the part of the restoration I leave until last. I set the bowl aside and turned my attention to the stem. The stem was in good nick other than the light oxidation on the top side. There were no tooth marks or chatter so it was simply a matter of polishing the stem and bring back a shine. I use micromesh sanding pads and water to wet sand the stem with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil on a cotton rag after each sanding pad as I find it does two things – first it protects the vulcanite and second it give the sanding pads bite in the polishing process.

After finishing with the micromesh pads I rub the stem down with Before & After Fine and Extra Fine stem polish as it seems to really remove the fine scratches in the vulcanite. I rub the Fine Polish on the stem and wipe it off with a paper towel and then repeat the process with the extra fine polish. I finish the polishing of the stem down with a final coat of Obsidian Oil and set the stem aside to let the oil absorb. This process gives the stem a shine and also a bit of protection from oxidizing quickly.

After finishing with the micromesh pads I rub the stem down with Before & After Fine and Extra Fine stem polish as it seems to really remove the fine scratches in the vulcanite. I rub the Fine Polish on the stem and wipe it off with a paper towel and then repeat the process with the extra fine polish. I finish the polishing of the stem down with a final coat of Obsidian Oil and set the stem aside to let the oil absorb. This process gives the stem a shine and also a bit of protection from oxidizing quickly. The final steps in my process involve using the buffer. I first buff the stem and the briar with Blue Diamond on the buffing wheel. Blue Diamond is a plastic polish but I find that it works very well to polish out the light scratches in the vulcanite and the briar. I work the pipe over on the wheel with my finger or thumb in the bowl to keep it from becoming airborne. It works well and I am able to carefully move forward with the buffing. The briar and stem just shone!

The final steps in my process involve using the buffer. I first buff the stem and the briar with Blue Diamond on the buffing wheel. Blue Diamond is a plastic polish but I find that it works very well to polish out the light scratches in the vulcanite and the briar. I work the pipe over on the wheel with my finger or thumb in the bowl to keep it from becoming airborne. It works well and I am able to carefully move forward with the buffing. The briar and stem just shone!

I finished with the Blue Diamond and moved on to buffing with carnauba wax. Once I have a good shine in the briar and vulcanite I always give the bowl and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I following up the wax buff with a clean buffing pad. It works to raise the shine and then I follow that up with a hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished vulcanite stem. It really is a beautiful pipe. The smooth finish around the bowl sides and shank show the grain shining through the rich brown stains of this Charatan’s Make London England Belvedere 1014 Lovat with an S. Bang Silver Band. The finished pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.31 ounces/37 grams. It is a beautiful pipe and one that I will be putting on the rebornpipes store in the British Pipe Maker section.

I finished with the Blue Diamond and moved on to buffing with carnauba wax. Once I have a good shine in the briar and vulcanite I always give the bowl and the stem multiple coats of carnauba wax. I have found that I can get a deeper shine if I following up the wax buff with a clean buffing pad. It works to raise the shine and then I follow that up with a hand buff with a microfiber cloth to deepen the shine. It is always fun for me to see what the polished bowl looks like with the polished vulcanite stem. It really is a beautiful pipe. The smooth finish around the bowl sides and shank show the grain shining through the rich brown stains of this Charatan’s Make London England Belvedere 1014 Lovat with an S. Bang Silver Band. The finished pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.31 ounces/37 grams. It is a beautiful pipe and one that I will be putting on the rebornpipes store in the British Pipe Maker section.

Hopefully the shape writing this blog is helpful to you in some way. In it I wanted to show both what I am looking for and how I move forward in addressing what I see when work on a pipe. Let me know if it is helpful to you. It is probably the most straightforward detailed description of my work process that I have done. As always I encourage your questions and comments as you read the blog. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of those who follow us.

Let’s have a closer look. This Peterson 307 pipe has the classic “System” look: bent shape, nickel mount, and tapered, army-style stem. Of course, it also had the traditional Peterson P-lip stem. The markings on the left side of the shank are Peterson’s [over] System [over] Standard. The right side of the shank showed Made in the [over] Republic [over] of Ireland [over] 307. The nickel mount on the shank had K&P [over] Petersons. There were no markings on the stem.

Let’s have a closer look. This Peterson 307 pipe has the classic “System” look: bent shape, nickel mount, and tapered, army-style stem. Of course, it also had the traditional Peterson P-lip stem. The markings on the left side of the shank are Peterson’s [over] System [over] Standard. The right side of the shank showed Made in the [over] Republic [over] of Ireland [over] 307. The nickel mount on the shank had K&P [over] Petersons. There were no markings on the stem.

The Peterson System pipes are well-storied among Peterson collectors/admirers. I took the opportunity to read the article on Pipedia, specifically about the System pipes, by Jim Lilley. There is lots of good information there and I encourage you to read it: https://pipedia.org/wiki/A_closer_look_at_the_famous_Peterson_Standard_System_Pipe

The Peterson System pipes are well-storied among Peterson collectors/admirers. I took the opportunity to read the article on Pipedia, specifically about the System pipes, by Jim Lilley. There is lots of good information there and I encourage you to read it: https://pipedia.org/wiki/A_closer_look_at_the_famous_Peterson_Standard_System_Pipe On to the pipe itself: the stem was in average condition – not especially dirty, but it had been well used. It had some notable dents, though. There was some damage to the top side of the P-lip and a tooth dent on the underside of the mouthpiece. I also noticed (but failed to photograph) that there were significant scratches at the shank-end of the stem, where I assume the stem had rubbed against the nickel mount on the shank. The bowl was moderately dirty and had quite a bit of lava which concealed some burn marks, and there was plenty of cake. Aside from some small fills, the outside of the bowl was fine. The nickel mount was in good shape – no dents or scratches of note – but it was dull and needed some polishing.

On to the pipe itself: the stem was in average condition – not especially dirty, but it had been well used. It had some notable dents, though. There was some damage to the top side of the P-lip and a tooth dent on the underside of the mouthpiece. I also noticed (but failed to photograph) that there were significant scratches at the shank-end of the stem, where I assume the stem had rubbed against the nickel mount on the shank. The bowl was moderately dirty and had quite a bit of lava which concealed some burn marks, and there was plenty of cake. Aside from some small fills, the outside of the bowl was fine. The nickel mount was in good shape – no dents or scratches of note – but it was dull and needed some polishing.

To work! The stem was first on my list. I wiped the outside down with Murphy’s Oil Soap on some cotton pads. I also took a BIC lighter and ‘painted’ the stem with its flame to lift the few bite marks and dents. Sadly, however, this did not do much. Then I cleaned out the inside with pipe cleaners and isopropyl alcohol.

To work! The stem was first on my list. I wiped the outside down with Murphy’s Oil Soap on some cotton pads. I also took a BIC lighter and ‘painted’ the stem with its flame to lift the few bite marks and dents. Sadly, however, this did not do much. Then I cleaned out the inside with pipe cleaners and isopropyl alcohol.

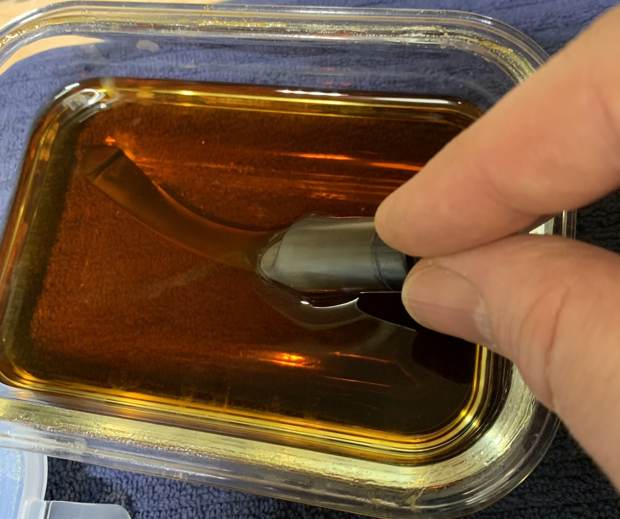

I used some SoftScrub on the outside of the stem to remove some oxidation. Then, the stem went for an overnight soak in the Pipe Stem Oxidation Remover. The following day, I cleaned the de-oxidizing mess off with alcohol, pipe cleaners, et cetera. The oxidation had migrated to the surface and would be fairly straightforward to remove. I scrubbed again with SoftScrub on some cotton pads to remove the leftover oxidation.

I used some SoftScrub on the outside of the stem to remove some oxidation. Then, the stem went for an overnight soak in the Pipe Stem Oxidation Remover. The following day, I cleaned the de-oxidizing mess off with alcohol, pipe cleaners, et cetera. The oxidation had migrated to the surface and would be fairly straightforward to remove. I scrubbed again with SoftScrub on some cotton pads to remove the leftover oxidation.

I built up the dents on the stem with black cyanoacrylate adhesive and let them cure. I then sanded the adhesive down – first with a small file – then with 220-, 400-, and 600-grit sandpapers to meld seamlessly into the stem. I then used all nine Micromesh pads (1,500 through 12,000 grit) to polish it and highlight the black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing.

I built up the dents on the stem with black cyanoacrylate adhesive and let them cure. I then sanded the adhesive down – first with a small file – then with 220-, 400-, and 600-grit sandpapers to meld seamlessly into the stem. I then used all nine Micromesh pads (1,500 through 12,000 grit) to polish it and highlight the black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing.

Moving on to the stummel, I first decided to ream out the bowl. I used both the PipNet Reamer and the KleenReem to remove the built-up cake and followed that with 220-grit sandpaper taped to a dowel to eliminate as much as possible. I took the chamber down to bare briar to ensure there were no hidden flaws in the wall. Fortunately, there were none.

Moving on to the stummel, I first decided to ream out the bowl. I used both the PipNet Reamer and the KleenReem to remove the built-up cake and followed that with 220-grit sandpaper taped to a dowel to eliminate as much as possible. I took the chamber down to bare briar to ensure there were no hidden flaws in the wall. Fortunately, there were none.  I used cotton rounds and some Murphy’s Oil Soap to scrub the outside of the stummel and a toothbrush with Murphy’s for the lava on the pipe’s rim.

I used cotton rounds and some Murphy’s Oil Soap to scrub the outside of the stummel and a toothbrush with Murphy’s for the lava on the pipe’s rim. I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and lemon-infused isopropyl alcohol. There was quite a bit of filth inside this stummel, and it took a fair amount of cotton to get it clean. I followed that up by cleaning the insides with some dish soap and tube brushes.

I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and lemon-infused isopropyl alcohol. There was quite a bit of filth inside this stummel, and it took a fair amount of cotton to get it clean. I followed that up by cleaning the insides with some dish soap and tube brushes.  Now I could address the burn on the rim. I used a piece of tool steel to gently scrape away the burn residue, but I didn’t get the results I hoped for. So, I “topped” the pipe – that is, I gently and evenly sanded the rim on a piece of 220-grit sandpaper. This effectively removed the damage without altering the look of the pipe.

Now I could address the burn on the rim. I used a piece of tool steel to gently scrape away the burn residue, but I didn’t get the results I hoped for. So, I “topped” the pipe – that is, I gently and evenly sanded the rim on a piece of 220-grit sandpaper. This effectively removed the damage without altering the look of the pipe.

I decided to de-ghost the pipe in order to remove any lingering smells of the past. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton. The bowl was nice and clean after this.

I decided to de-ghost the pipe in order to remove any lingering smells of the past. I thrust cotton balls into the bowl and the shank and saturated them with 99% isopropyl alcohol. I let the stummel sit overnight. This caused any remaining oils, tars and smells to leach out into the cotton. The bowl was nice and clean after this.

Now it was time to address the tiny fills on the bowl. I repaired them with a mixture of briar dust and cyanoacrylate adhesive. This ensures a strong repair and one that looks similar to the surrounding wood. As you can see, I made a mess to begin with, but I sanded the repair down with a file and 200- and 400-grit sandpaper until it was level with the surrounding briar. Then, I used all nine Micromesh pads (1,500 through 12,000 grit) on the stummel to finish it off. This included buffing up the nickel mount to a beautiful shine!

Now it was time to address the tiny fills on the bowl. I repaired them with a mixture of briar dust and cyanoacrylate adhesive. This ensures a strong repair and one that looks similar to the surrounding wood. As you can see, I made a mess to begin with, but I sanded the repair down with a file and 200- and 400-grit sandpaper until it was level with the surrounding briar. Then, I used all nine Micromesh pads (1,500 through 12,000 grit) on the stummel to finish it off. This included buffing up the nickel mount to a beautiful shine!

Off to the bench polisher! A dose of White Diamond and a few coats of carnauba wax were just what this pipe needed. Boy-oh-boy, this is one good-looking pipe! I’m pleased with the results.

Off to the bench polisher! A dose of White Diamond and a few coats of carnauba wax were just what this pipe needed. Boy-oh-boy, this is one good-looking pipe! I’m pleased with the results. This Peterson Standard System 307 looks fantastic again and is ready to be enjoyed by its next owner. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the Ireland pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 6¼ in. (158 mm); height 2 in. (51 mm); bowl diameter 1⅝ in. (41 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 2½ oz. (72 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.

This Peterson Standard System 307 looks fantastic again and is ready to be enjoyed by its next owner. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the Ireland pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 6¼ in. (158 mm); height 2 in. (51 mm); bowl diameter 1⅝ in. (41 mm); chamber diameter ¾ in. (20 mm). The weight of the pipe is 2½ oz. (72 g). I hope you enjoyed reading the story of this pipe’s restoration as much as I did restoring it. If you are interested in more of my work, please follow me here on Steve’s website or send me an email. Thank you very much for reading and, as always, I welcome and encourage your comments.