Blog by Al Jones

Last week, one of my fellow GBD enthusiasts contacted me about a Cadogan era (post 1982) GBD 549 that was available via a popular online estate seller. I thought it was priced a little high. I thought he could find a better 549 from the pre-Cadogan era, with the brass stem rondel that might be less expensive. I recalled seeing this one on Ebay, but since I have a 549, I didn’t pay much attention to it. I sent him the Ebay link as an example and didn’t even notice that the auction was ending in an hour or so. He messaged me later, saying he had won the auction for considerably less than the other 549. Looking more closely at the auction pictures, I thought that this was a very nice example. The pipe is a “Speciale Standard” and made in France. The owner has purchased several GBD’s from me in the past and I volunteered to clean this one up for him. I’m glad that I had the opportunity to work on this little gem.

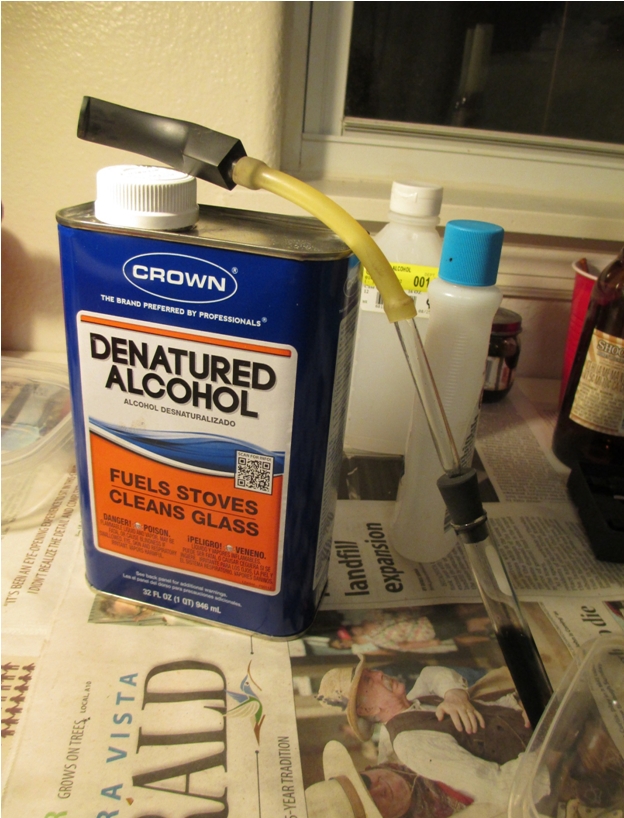

The briar looked outstanding with some nice grain and birdseye. The stem was oxidized, with just a hint of teeth scratches. There was some rim darkening that I hoped could be removed or lessened.

I started on the stem using 600 and then 800 grit wet paper to remove the oxidation. I then moved to 1000, 1500 and 2000 grit paper. I finished with 8000 and 12000 grade micromesh paper. Mounted on the pipe, the stem was then buffed with White Diamond and Red Jewelers rouge.

The rim darkening came off nicely, using a worn piece of 8000 grit micromesh paper. I then lightly buffed the bowl, with White Diamond, while being careful to stay away from the perfect nomenclature. The bowl was then buffed several times with Carnuba wax.

Here is the finished pipe.