Frankenpipes are born out of having no more pipes in the refurb box to work on. I have many in transit at the moment but none with which to sit and unwind. That always is a recipe for me to dig in the boxes of parts and see what I can come up with to keep the hands busy. The pipe that follows was born of fiddling with parts in my parts box. The part I started with was an old bowl that I received in a gift box recently that did not have a pipe to go with it. It was a pressure fit bowl that obviously sat on a base of some kind of system pipe. I searched the Metal Pipes website to see if I could find out any information but did not find any likely candidates for this mystery bowl. It had some nice grain on it so it seemed like a shame to just let it sit in the box and wait for a potential pipe for it. I also I had a cut off shank piece that I had made for another purpose, a stem that fit the shank nicely and a block of briar that was too tiny for a pipe. The small block is one that I have been scavenging pieces off of to make plugs for burnout repairs. As I looked at the pieces I had an idea for putting them together into an interesting pipe that had kind of art deco feel to it. Now it was time to bring the pipe together and actualize my vision.  I measured out the drilling areas for the block. I needed to drill the airway large enough to insert the briar shank. I would use the Missouri Meerschaum concept of inserting the shank into the briar block. I started by drilling the first hole in the end of the block. I drilled the mortise area first. I did this in stages as it needed to be big enough for the shank piece to be pressure fit into place. Afterward I drilled the rest of the airway in the block. I decided to drill it all the way through to the other side of the block so that I could put in a funky plug on the front end. I looked around for what I would use and had several ideas. Time would tell which I would choose in the end.

I measured out the drilling areas for the block. I needed to drill the airway large enough to insert the briar shank. I would use the Missouri Meerschaum concept of inserting the shank into the briar block. I started by drilling the first hole in the end of the block. I drilled the mortise area first. I did this in stages as it needed to be big enough for the shank piece to be pressure fit into place. Afterward I drilled the rest of the airway in the block. I decided to drill it all the way through to the other side of the block so that I could put in a funky plug on the front end. I looked around for what I would use and had several ideas. Time would tell which I would choose in the end.  I moved through several drill bits until the bit that was the size of the shank piece. I drilled it deep enough to inset the shank quite deep in the hole.

I moved through several drill bits until the bit that was the size of the shank piece. I drilled it deep enough to inset the shank quite deep in the hole.  I marked the airway exit on the top of the block with a permanent marker and drew a line to show the track of the airway. I marked my drill bit to the depth of the top of the airway and drilled the hole in the top of the block. I wanted the hole to be the size of the nipple on the bottom of the bowl so that it would pressure fit into the hole. I wanted the hole to go through to the top of the airway so that the nipple on the bowl would sit on top and create good airflow from bowl to stem.

I marked the airway exit on the top of the block with a permanent marker and drew a line to show the track of the airway. I marked my drill bit to the depth of the top of the airway and drilled the hole in the top of the block. I wanted the hole to be the size of the nipple on the bottom of the bowl so that it would pressure fit into the hole. I wanted the hole to go through to the top of the airway so that the nipple on the bowl would sit on top and create good airflow from bowl to stem.  I pressure fit the bowl in the top of the block and the shank in the end of the block for the next two photos. I wanted to see if the parts all fit together well. I gave the shank a slight angle upward and would later bend the stem if the look was correct. Everything worked well at this point. For the plug on the end of the block I decided to do something simple. I wanted a plug that would be like a coloured dot on the end of the base. I cut off a piece of knitting needle and inserted it in the airway at the end of the block that is not showing at this point. I glued it in place and used the Dremel to take the overage back flush with the block.

I pressure fit the bowl in the top of the block and the shank in the end of the block for the next two photos. I wanted to see if the parts all fit together well. I gave the shank a slight angle upward and would later bend the stem if the look was correct. Everything worked well at this point. For the plug on the end of the block I decided to do something simple. I wanted a plug that would be like a coloured dot on the end of the base. I cut off a piece of knitting needle and inserted it in the airway at the end of the block that is not showing at this point. I glued it in place and used the Dremel to take the overage back flush with the block.

The height of the block was too much so I wanted to cut it in half. I do not have power tools to do that kind of thing so a bit of sweat equity and a small hack saw did the job. I sliced off the bottom half of the block to be used in making bowl plugs at a later date and now the height was more suitable to this little sitter.

The height of the block was too much so I wanted to cut it in half. I do not have power tools to do that kind of thing so a bit of sweat equity and a small hack saw did the job. I sliced off the bottom half of the block to be used in making bowl plugs at a later date and now the height was more suitable to this little sitter.  I glued the shank into place in the block with epoxy and angled it the way I wanted it to be when I finished the work on the base.

I glued the shank into place in the block with epoxy and angled it the way I wanted it to be when I finished the work on the base.

I used the Dremel and a sanding drum to begin to shape the block into a base for the pipe. I wanted a slope upward to the bowl – the sides would also slope upward. My idea was to have the bowl sitting on top of a volcano like base.

I used the Dremel and a sanding drum to begin to shape the block into a base for the pipe. I wanted a slope upward to the bowl – the sides would also slope upward. My idea was to have the bowl sitting on top of a volcano like base.

It took a lot of sanding to get the shape even close to what I had envisioned and in the process I ran into my first problem. The joint of the block and the shank could not be sanded smooth or the walls would be too thin and the shank would break too easily. I probably should have used a Delrin tenon to connect the two parts but as usual looking back is not overly helpful. So I had to improvise with this one. I had a small brass pressure fitting that would look kind of interesting on this little Frankenpipe so I worked the joint area to accommodate the brass fitting. The photos below show the pipe taking shape with the brass band high on the shank. (At the time of these photos I had not yet glued the band on the shank.)

It took a lot of sanding to get the shape even close to what I had envisioned and in the process I ran into my first problem. The joint of the block and the shank could not be sanded smooth or the walls would be too thin and the shank would break too easily. I probably should have used a Delrin tenon to connect the two parts but as usual looking back is not overly helpful. So I had to improvise with this one. I had a small brass pressure fitting that would look kind of interesting on this little Frankenpipe so I worked the joint area to accommodate the brass fitting. The photos below show the pipe taking shape with the brass band high on the shank. (At the time of these photos I had not yet glued the band on the shank.)

I filled in the openings around the edges of the fitting where the shank joined the block with briar dust and wood glue packed into place with a dental pick. I sanded the ridges on the fitting with 150 grit sandpaper to remove them. I would have to do more work on the look of the band as I worked out the details later. I took the following photos after I had done more shaping of the base and glued the band in place. While the band is not beautiful it certainly strengthens the joint on the shank of the pipe and makes up for my lack of planning!

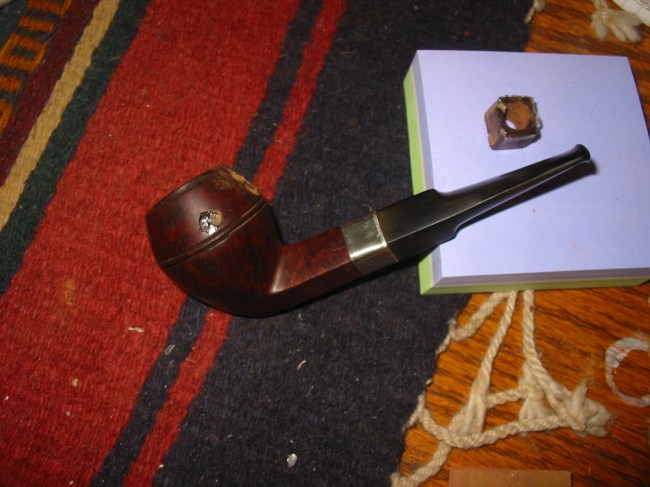

I filled in the openings around the edges of the fitting where the shank joined the block with briar dust and wood glue packed into place with a dental pick. I sanded the ridges on the fitting with 150 grit sandpaper to remove them. I would have to do more work on the look of the band as I worked out the details later. I took the following photos after I had done more shaping of the base and glued the band in place. While the band is not beautiful it certainly strengthens the joint on the shank of the pipe and makes up for my lack of planning!

The photo below shows the base with the bowl removed. You can get a clear picture of the base without the bowl and how the bowl looks from the bottom. The hole in the base is the same size as the nipple on the bowl.

The photo below shows the base with the bowl removed. You can get a clear picture of the base without the bowl and how the bowl looks from the bottom. The hole in the base is the same size as the nipple on the bowl.  I sanded it for another hour before calling it a night and then wiped it down with some light olive oil to get an idea where the scratches were that I needed to do more work on and also to see the grain. The next four photos show the pipe at this point in the process. There is still more sanding to do on the base and shank as well as some minor shaping. The idea though is clear – and the pipe is smokeable. The draw is very good and there are no leaks around the joint where the bowl presses into the base. So far so good.

I sanded it for another hour before calling it a night and then wiped it down with some light olive oil to get an idea where the scratches were that I needed to do more work on and also to see the grain. The next four photos show the pipe at this point in the process. There is still more sanding to do on the base and shank as well as some minor shaping. The idea though is clear – and the pipe is smokeable. The draw is very good and there are no leaks around the joint where the bowl presses into the base. So far so good.

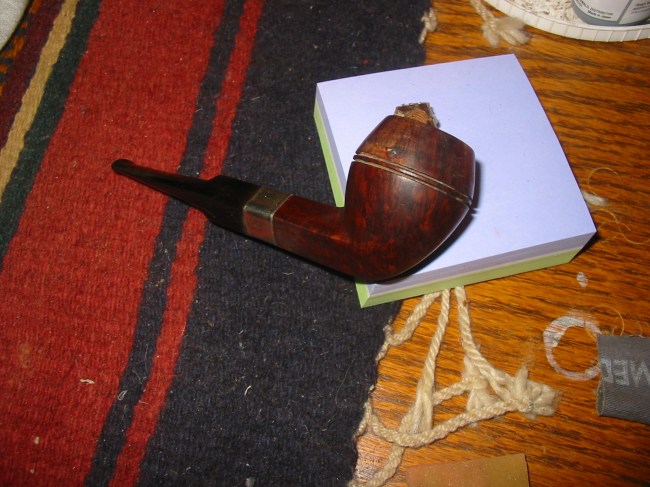

I set up a heat gun and bent the stem over the rounded handle of the heat gun to get a slight bend in it. I set the bend with cool water. With the bend the pipe is a sitter. The bend pulls the weight backward and the pip sits nicely on the button and the flat bottom of the base.

I set up a heat gun and bent the stem over the rounded handle of the heat gun to get a slight bend in it. I set the bend with cool water. With the bend the pipe is a sitter. The bend pulls the weight backward and the pip sits nicely on the button and the flat bottom of the base.

I did quite a bit more sanding and shaping of the base with 150 and 220 grit sandpaper. Once I had the shape to where I wanted it I sanded it with medium and fine grit sanding sponges. I gave the bowl and shank a wipe down with a cloth that was dampened with olive oil. Other than that the bowl and shank are not stained.

I did quite a bit more sanding and shaping of the base with 150 and 220 grit sandpaper. Once I had the shape to where I wanted it I sanded it with medium and fine grit sanding sponges. I gave the bowl and shank a wipe down with a cloth that was dampened with olive oil. Other than that the bowl and shank are not stained.

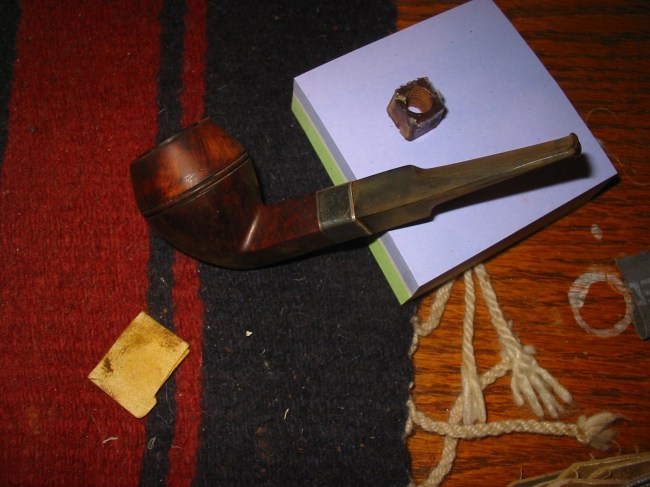

While the shaping was finished there was still a lot of sanding to do to remove the scratches that remain in the briar. I also want to do some sanding on the band to remove scratches and polish it as well. The vulcanite stem also needs sanding and polishing. I took the pipe apart and sanded all the pieces with micromesh sanding pads. I sanded all of them with 1500-2400 grit pads and then finished sanding them with a 6000 grit pad. I buffed the parts with red Tripoli and then White Diamond and gave each part of the bowl and base multiple coats of carnauba wax.

While the shaping was finished there was still a lot of sanding to do to remove the scratches that remain in the briar. I also want to do some sanding on the band to remove scratches and polish it as well. The vulcanite stem also needs sanding and polishing. I took the pipe apart and sanded all the pieces with micromesh sanding pads. I sanded all of them with 1500-2400 grit pads and then finished sanding them with a 6000 grit pad. I buffed the parts with red Tripoli and then White Diamond and gave each part of the bowl and base multiple coats of carnauba wax.  I sanded the stem with a fine grit sanding sponge and then with the various grits of micromesh sanding pads. I wet sanded with 1500-2400 grit pads and dry sanded with 3200-12,000 grit pads. I buffed the stem with White Diamond, rubbed it down with Obsidian Oil and finished by giving it a buff with carnauba wax.

I sanded the stem with a fine grit sanding sponge and then with the various grits of micromesh sanding pads. I wet sanded with 1500-2400 grit pads and dry sanded with 3200-12,000 grit pads. I buffed the stem with White Diamond, rubbed it down with Obsidian Oil and finished by giving it a buff with carnauba wax.

I sanded the brass band with the micromesh pads to polish it as well. When I had finished I gave the pipe a final buff with White Diamond and then applied carnauba wax to each part. I buffed them with a soft flannel buff to finish the shine.

I sanded the brass band with the micromesh pads to polish it as well. When I had finished I gave the pipe a final buff with White Diamond and then applied carnauba wax to each part. I buffed them with a soft flannel buff to finish the shine.

The final photo is of the front of the pipe. The knitting needle plug that I used is a bright reddish orange circle that sits at the base of the pipe on the front. The colour of the pipe is the red of the previous four finished photos. The last photo was taken with my cell phone and is a bit washed out.

The final photo is of the front of the pipe. The knitting needle plug that I used is a bright reddish orange circle that sits at the base of the pipe on the front. The colour of the pipe is the red of the previous four finished photos. The last photo was taken with my cell phone and is a bit washed out.

Tag Archives: pressure fitting a band

Custom Made Billiard Back into Service

The next pipe in the lot that I refurbished was the top pipe in the centre column in the photo below. It was a Custom Bilt like billiard. It is stamped on the left side of the shank Custom Made and on the right side of the shank Imported Briar. That stamping tells me that it is an American Made Pipe. I cannot find any information on the stamping on the internet but will continue to look and see what I can find.

The pipe was dirty. The bowl was badly caked – meaning that the cake was very crumbly and uneven. The bowl was out of round as can be seen in the photo below. I would need to ream it out completely to reshape the bowl. The finish was dirty in all of the worm trail carving that is found in these old rustic pipes. It looks a lot like a Mincer Custombilt but I am not sure. The rim surface is tarry with build up and the front inner edge of the bowl is burned. The shank looks good in these photos but there is a divot out of the briar on the left side where it will meet the stem. It did not have a stem when I picked it up on Ebay. I will need to make some decisions about what to do with the new stem and the match at the shank.

The pipe was dirty. The bowl was badly caked – meaning that the cake was very crumbly and uneven. The bowl was out of round as can be seen in the photo below. I would need to ream it out completely to reshape the bowl. The finish was dirty in all of the worm trail carving that is found in these old rustic pipes. It looks a lot like a Mincer Custombilt but I am not sure. The rim surface is tarry with build up and the front inner edge of the bowl is burned. The shank looks good in these photos but there is a divot out of the briar on the left side where it will meet the stem. It did not have a stem when I picked it up on Ebay. I will need to make some decisions about what to do with the new stem and the match at the shank.

I went through my box of stems to find one that would fit the shank with little adjustment. I had just the stem there. The fit would be great as it was the same diameter as the shank. The stem was oxidized and dirty inside but there were no tooth marks. There was also a calcification on the stem near the button that would have to be dealt with when I got the stem fit to the shank. The next five photos show the “new” stem. I had to hand sand the tenon to get it to fit snugly in the mortise. The third photo below shows the sanded tenon. I used emery paper to sand the tenon back until it fit in the shank. The fourth and fifth pictures show the fit of the stem to the shank. The divot is visible in the fourth photo. It is mid shank on the left side of the pipe. No amount of fitting the stem would make that disappear. I could sand down the shank at that point to make a cleaner fit but I was not sure that is what I wanted to do. To do the sanding would change the chunky appearance of the pipe. So I decided not to sand the shank. I went on and cleaned the inside of the pipe before I made the final decision on the shank.

While I was prepping to ream the bowl I took out a nickel band to see what it would look like on the shank. I liked the overall look. I left it on the shank while I reamed the bowl. I used a PipNet reamer – a T handle with various cutting heads to ream the bowl. I started with the one that fit the easiest and then worked up to the third head which was the same diameter as the bowl. I reamed it back to bare wood (Photos 1 and 2). I then heated the band with the heat gun and pressed on the shank to give me a smooth transition between the stem and the shank (Photos 3 and 4).

I worked on the inner rim with a folded piece of 220 grit sandpaper. I sanded the top of the bowl with the same sandpaper and the fine grit sanding sponge to remove the build up on the rim (Photos 1 and 2). The third photo below shows the inner edge of the rim after the sanding with the 220 grit sandpaper. I was able to get the bowl close to round. I also used the sanding drum on the Dremel to even things out so the third photo shows the finished repair to the inner rim edge.

I wiped the exterior of the bowl down with acetone on cotton pads. I wanted to clean out the buildup in the crevices of the trails on the bowl. The dirt and finish that came off is visible in the two photos below. Two obvious fills also showed up in the bowl. These would need to be taken care of to hide them under the new stain once I was finished.

With the finish removed it was time to clean out the shank and airway of the pipe. I used pipe cleaners, cotton swabs and also the drill bit from the KleenReem Pipe reamer to remove the tars and oils that had built up in the shank. I probably could have used a retort but the shank did not smell sour or rank. It smelled like Virginia tobaccos had been smoked in this so I just used a lot of pipe cleaners and cotton swabs dipped in Everclear until they came out spotless. I wiped down the tenon on the “new” stem as well with the Everclear.

Once the insides were clean I inserted the stem in the shank to see if I still had a snug fit. Sometimes when the grime is removed the fit is not as good as it was before cleaning. I have learned the hard way to leave the stem tight and when it is cleaned the fit will be perfect. I sanded the stem with fine grit emery paper to remove the calcified buildup and the oxidation on the stem. The next three photos show the stem after the sanding with the emery paper.

I then sanded the stem with 220 grit sandpaper to remove more of the oxidation and also the scratches left behind by the emery paper. The next series of three photos show the stem after sanding with the sandpaper.

I went back and cleaned the stem with pipe cleaners and Everclear. I should have done that when I was cleaning the shank but honestly I forgot to do so. Never too late however so I did it next. The next four photos show the pile of pipe cleaners that it took to clean the stem. I also wiped the bowl and shank down with Everclear on a cotton pad to prepare it for staining.

I restained the pipe with a dark brown aniline stain. I thinned the stain with 1 part alcohol to 2 parts stain to get the brown I wanted for a colour. I wanted it dark enough that the fills would blend into the finish but also transparent enough to show the grain through the stain. I used a black permanent marker, called a Sharpie here in Canada to give the fills a dark top coat before applying the stain. I have learned that this method makes the fills blend into the bowl better on these rusticated bowls. I applied the stain with a cotton swab, flamed it with my lighter and reapplied it and flamed it again. It took three applications of the stain to give good coverage to the bowl. The next three photos show the unstained pipe (Photo 1) and the newly stained pipe (Photos 2 and 3).

Once the stain was dry I hand buffed it with a shoe brush to see if I needed to add any more stain to some of the spots on the bowl and rim (Photo 1). The next three photos show the buffed bowl and the finished colour. The coverage was good so I buffed it by hand and then went back to work on the stem.

The next series of six photos show the progressive polishing of the stem with micromesh sanding pads from 1500-12,000 grit.

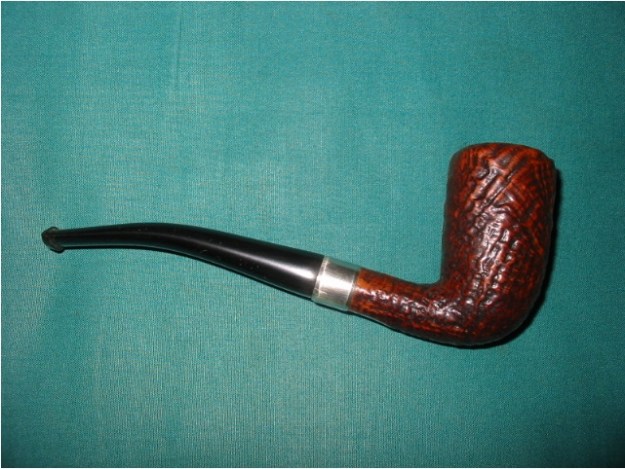

I took the pipe to the buffer and buffed the stem with White Diamond and then rubbed it down with Obsidian Oil to preserve it. I gave the bowl a coat of Halcyon II wax and the stem several coats of carnauba wax to prevent oxidation. I buffed the entire pipe lightly with a soft flannel buff. The finished pipe is pictured in the last four photos.

Finding a Hidden Gem Underneath all the Grit and Grime

I went to work on the third pipe down in the far right column. It was one that I almost bypassed because of the shape it was in, but decided to take a chance and see what was underneath all of the mess. The stamping was long ago worn away by buffing. It had originally had a ferrule on the shank and that was missing. The bowl was badly caked and it was out of round from overzealous reaming. The finish was shot with thick black grime impregnated into the bowl finish all the way around. Underneath there appeared to be some nice grain. The missing ferrule left behind remnants of the glue that had held it in place. In the shank where the ferrule was missing were several fills – the only ones in the pipe. The size of the pipe is about a group 2 – kind of the classic size of an older billiard. The stem was missing so it would need to have one made to fit.

The next series of photos shows the build up on the outside of the bowl. Not only was it badly caked it also was covered with a grey/black grime that would be challenging.

I used acetone and cotton pads to remove the external grime on the bowl (Photos 1 – 2 below). There was actually some nice grain underneath all the grime. I reamed the bowl with a PipNet reamer starting with the smallest cutting head and working my way up to the largest that would fit the bowl. I wanted to ream it back to bare wood so that I could work on the damaged inner rim (Photo 3 below). I topped the bowl to remove the damage to the top of the rim and clean up the outer edges of the rim. I used my normal method of a piece of sandpaper on a flat surface and pushing the bowl into the sandpaper and rotating it to remove the damaged briar (Photo 4 – 5). I also push a nickel band onto the shank part way. I would later need to heat it to get a pressure fit deep on the shank. This band would both strengthen the thin walls of the mortise at the end and also cover the only fills present on the pipe.

I used a Dremel with a sanding drum to work on the roundness of the bowl. I worked to even out the distance between the inner edge of the rim and the outer edge. Once this was completed I used sandpaper to smooth out the edge and give it a slight bevel (Photo 1). I wiped down the bowl and rim with acetone on a cotton pad to clean off the last of the dust and grime from the reaming and sanding (Photos 2 – 3).

I set up the heat gun and turned it to the high setting. I held the band over the heat and rotated it to evenly heat the entire band (Photo 1). Once it was heated (just a few minutes) I then took it to the work table and pressed the band in place on a metal plate I use for setting the bands. Sometimes this takes several trips between the heat and the plate but this time one trip was all it took and the band was set (Photos 2 – 3).

I used a PIMO tenon turning tool to turn the tenon to fit the mortise. I generally turn it until it is close and then finish the fit by hand with sandpaper (Photo 1). After sanding the stem fit quite well in terms of the tenon. It was snug and flush against the shank – no light showing through (Photos 2 -3). I used the Dremel with a sanding drum to remove the excess vulcanite on the stem and to shape it to match the diameter of the shank. I sand carefully with the sanding drum to bring it as close as possible to the size I want. You have to be careful and steady so that you do not nick the shank or the band while doing this. The finishing fit is done by hand with files and sandpaper (Photos 4 – 5).

The next series of seven photos show the shaping process. I begin with a medium grit emery paper and sand out the scratches left behind by the Dremel. I shape the stem with this paper to the point where the flow and fit of the stem is what I am looking for (Photos 1 – 2). I then move on to 220 grit sandpaper and continue to remove the scratches and shape the stem (Photos 3 – 4). It then finish this shaping with a fine grit sanding sponge and polish out more of the scratches. Each grit of paper brings the stem closer to the finished shape (Photos 5 – 7).

I apologize for the graininess of the next two photos but they show the bowl after I had stained it. I used a dark brown aniline stain thinned with one part alcohol. I wanted a rich reddish brown colour on this old timer so I thinned the stain to match the colour I wanted. I applied it to the bowl and rim, flamed it, reapplied it and flamed it again.

I worked on the stem with micromesh sanding pads. I also sanded the nickel band to bring out a polish to it as well. The next series of seven photos shows the progressive shine that comes to the stem with each successive grit of micromesh from 1500-12,000 grit. I wet sanded with the 1500-2400 grit and then dry sanded with the remaining grits.

I sanded the bowl with the higher grits of micromesh and then buffed the pipe with White Diamond to give the entirety a rich shine. I applied several coats of carnauba wax and buffed it with a soft flannel buff. The stain really highlights some of the beautiful grain on this pipe. I am glad I took the risk to bring this one back to life.

Restemming and Reclaiming an Old, Unsmoked Rex Bulldog

This is the second of the old unsmoked pipe bowls I picked up on EBay. It is one that I can find absolutely no information on anywhere. Some have thought it was a Barclay Rex but I can find nothing that would link it to that shop in NYC. It is stamped Rex in cursive script on the right side of the shank and also stamped Rex over Sterling on the band. It has the look and feel of an older English-made pipe. But I am not sure. The seller said it was from the late 1800’s but all attempts to contact them on the source of that information have remained unanswered. So it remains a bit of a mystery to me. It is one though that I will continue to hunt down until I can come up with something. This shape is what is called in some of the older catalogues a Bulldog. I personally am not sure what to call it. It has the shape of a bulldog on the bowl and the double ring separating the bottom of the bowl from the cap. The shank however, is oval. It has a factory installed band on it that is also stamped Rex. The script on the shank is in gold leaf. The bowl is very clean. There was a small crack in the shank on the shank at about one o’clock looking toward the bowl. This may have been the reason for the band or the band may have been decorative. There was no stem with this pipe so I was not sure of the length of the stem to make for it. The drilling is very interesting. It is drilled like some of the calabash bowls or bowls that were screwed onto Bakelite shank and bases in the late 1800s. It is directly in the bottom of the bowl and seems to have a small hollow chamber under the hole. The airway meets it directly underneath. I have not seen this drilling on briar pipes of newer eras. The bowl is smooth inside and almost polished. The briar is quite nice and sports mixed grains from cross grain to birdseye to flame around the bowl. The double cut rings are clean and are not clogged with wax or dirt. There appears to be a thin coat of shellac on the outside of the bowl to give it a shine as it shines with or without the application of wax. The silver band is interestingly shaped as well. It is somewhat conical – wider toward the bowl side and narrower on the stem side. There is also a stepped down lip on both sides of the band. Where it is on the bowl is stepped down to a small ring around the shank. On the stem side it is also stepped down. This would make fitting a stem to the shank a challenge. It was not too badly oxidized so it would clean up very easily. The first series of five photos are those taken by the Ebay seller and give a good idea of the look and condition of the pipe. The one thing not clear to me was the size of the pipe. I took a chance on it as the apparent age and the assumed age stated by the seller made the likelihood of it being smaller was very high. When it arrived it was indeed quite small. The bowl and shank are roughly 3 inches long without the stem. The height of the bowl is 1 5/8 inches. The inside diameter of the bowl is ¾ inches and the outside diameter is 1 ¼ inches.

Once I started working on it the first decision that needed to be made was on the type and length of the stem to be used. I fitted several oval stems to the bowl – a standard length billiard type stem, a thicker and a thinner oval Canadian stem and a Lovat style saddle stem. The longer stem did not work well with the longer shank on the pipe. The thicker Canadian stem also made the stem look quite chunky and large as did the saddle stem of the Lovat. The stem I settled on was the thinner Canadian oval. Even this one would require considerable thinning to make for a proper fit against the bevel of the band. The first photo below shows the two Canadian taper style oval stems. I chose the bottom stem in the photo.

I used the PIMO tenon turning tool to turn the tenon so that it would fit in the shank. The next three photos show the initial fit of the stem. You will note in the photos the gap where the bevel of the band lies. I had to make a decision to either leave the gap or work on the stem size so that it fit against the bevel and thus was slightly thinner than the shank prior to the band.

I decided to thin the stem to fit against the bevel. I used the Dremel with a sanding drum to bring it close to the finished size. I then sanded it with medium grit emery paper to smooth out the scratches and grooves from the Dremel. Once I had most of the scratches removed I sanded it with a medium grit sanding sponge to further shape the stem and remove excess material. The next series of three photos show the fit of the stem after it was sanded with the sanding sponge (pink square in the photos).

At this point in the process I had to take it back and sand off some more material with 340 grit sandpaper. It still was too thick to fit well. I also had to finesse the fit against the band with needle files as in some places it was not quite straight. When I had it fitting well I moved on to sanding with a 1500 grit micromesh sanding pad (the next two photos). I also did a small repair on the crack in the top of the shank. I pried it open slightly and dripped some clear super glue into the crack. It did not go all the way through into the shank which was interesting. It seemed to be a surface crack. The repair worked well. I polished that portion of the shank with the 1500 grit micromesh sanding pad as well to remove the slight excess of glue left behind (third photo below).

After the repair I continued sanding and polishing the stem with 1800-12,000 grit micromesh sanding pads. The next four photos highlight the sanding/polishing process. Notice the slight hip on the stem at the band edge. In the photos this appears to be more drastic than it is in actual life. The fit is more of a pinched look.

The final series of four photos show the finished pipe. I buffed it with White Diamond and then gave it multiple coats of carnauba wax. I really like the stem and fit against this long shanked “Bulldog” bowl. The pipe glows with an age and patina that calls out to be smoked. This is yet another who will soon fulfill the purpose for which it was made.

Reclaiming an EPW Bulldog – Restoring it Twice

Blog by Steve Laug

This old time long shanked bulldog was a mess when I got it. At first glance it looks pretty good. But it was not. The shank had previously been banded and that band was lost. It was a deep band and filigreed so it left marks. There were also two large cracks in the shank that extended about an inch into the length. The rim was clean but the top portion of the bulldog shape – above the double rings was also stained and filled with holes from the nails that had held the decorated rim cap in place. There were four holes – back, front and both sides. There were also deep gouges where the decorative border had cut into the briar. The stamping was faint and read EPW in an oval. There was no stem with this one either so it would need to have one made. The overall finish on the bowl was not too bad in that it was not dented or burned or damaged on the sides and undersides of the bowl. I decided to try banding the shank and see what I could do about the cracks on the top right side of the shank and the lower left side of the shank. They would in all likelihood be an issue. I did not have a deep band so I tried with a narrower band (about ½ inch deep). I shaped a round band with a flat blade screwdriver and a hammer until it was the right shape to fit the shank. I heated the band and pressed it into place.

The next three photos show the band in place. If you look close in the photos below you can see the crack on the top of the right side shank. The one on the left underside of the shank did not come out in the photos. You can also see the nail holes in the bowl above the double rings.

The next series of three photos shows the fitting of a new tenon. I drilled the stem and then used a tap to thread the stem so that I could screw in the new tenon. In the photos below you can see the tap in the stem and the new threaded tenon just above the bowl at the centre of the picture. The third photo shows the hole in the stem threaded and ready for the new tenon.

Once the stem was ready I dripped a little superglue on the tenon and screwed it into the stem. The next two photos show the tenon in place. I still needed to turn it with the Pimo tenon turner to reduce the size to fit the shank of the pipe.

I used the tenon turner and reduce the diameter of the tenon until it was close to fitting and then hand sanded it until it fit correctly. With the cracked shank the fit was critical. I did not want the tenon too big as it would open the cracks. The two photos below show the tenon after turning. It still needed a bit more hand sanding to make a perfect fit.

The next four photos below show the restemmed pipe. The stem fit perfectly against the band and the look was exactly what I was aiming for. The issue that remained was the two cracks that extended further than the band.

The next three photos show the work of patching the nail holes and the cracks with briar dust and superglue. I packed in the briar dust with my dental pick until they were filled and then I dripped the superglue into the spots. Once they were dry I sanded them down to remove the excess and blend them into the surrounding bowl. I wanted them to be less visible and be able to be blended in with the stain when I got around to staining it.

With the nail holes filled on the front and back of the bowl I was finished with the patching for now. I still was bothered by the ones on the sides of the bowl but would deal with them later. I sanded down the patches one more time with a fine grit sanding sponge and then wiped the bowl and shank down with an alcohol dampened cotton pad to remove the dust and remaining finish. The next series of eight photos shows that process as I prepared the bowl to be restained.

I restained the pipe with an oxblood aniline stain. The next series of four photos shows the pipe after staining. The nail holes and small holes on both sides of the bowl really bothered me. The cracks, while well bonded stood out clearly and made me wonder about how well they would hold up. I laid the pipe aside for a couple days to think about some solutions to the problem. I mulled over whether I should order a deeper band for the shank or whether I should cut down the shank and make it a normal sized bulldog. I did nothing to the pipe for two days and then on the third evening I came home and went to my work table to see what I could do to deal with the damage on the old pipe.

I decided to cut off the shank at the inside edge of the nickel band. I wanted to use the nickel band as the straight edge for the saw. I have seen too many pipes where the cut off shank was poorly cut and at an angle. So I used a hacksaw that has a perfect blade for working with briar. The teeth are fine so they do not chip the wood as they cut it. The cut when completed is clean and smooth with no chips. The next three photos show the set up for cutting and the cutting process itself. (I apologize for the second photo – it is hard to saw and take a photo!) But you can get the idea. The third photo below shows the finished cut.

I took the two pieces back to my work table and removed the cut off piece of briar shank from the band. When they fell out they were in two pieces. I cleaned up the band and straightened out the angles to make sure it would fit the shortened shank. It was just a bit too deep and when in place would cover the W of the stamping but it would do a good job on the cracks. With the piece cut off the cracked shank had two very small cracks left that would easily be repaired by the band. I smoothed out the cut end with a piece of emery paper. In the second photo below you can see the cut off shank piece. It is cracked all the way through and in two pieces. Note also that the mortise was threaded for the older original screw tenon.

I put the band in place on the end of the shank. It was a good tight fit but would not slide all the way in place. So I set up my heat gun and heated the band (Photo 1 below). I then pressed it into place on the shank by squarely pushing the shank and band on a metal plate (Photo 2 below). The final three photos below show the shank with the newly fitted band in place. The shank is ready to be drilled deeper to fit the tenon.

I matched the drill bit to the mortise in the cut off piece of shank. I used a drill bit one size lower and drilled the mortise to the depth of the tenon. I then used the proper sized drill bit and drilled it a bit larger. Once I had the drilling down I sanded down the tenon with some emery cloth to make a clean tight fit and inserted the stem. Once the stem fit well I decided to rework the nail holes and holes in the sides of the top half of the bowl above the double rings. I packed in briar dust and dripped super glue in to them. The next two photos show the repaired/filled holes.

The glue and briar dust dried quickly so I sanded them with 320 grit sandpaper to smooth them out to the surface of the briar. The next four photos show the sanded patches and also the sanded stem. I used the same sandpaper to sand off the oxidation on the stem and clean up the surface of the stem so that I could work on it with the micromesh to bring out a deep black shine. (In the background of the photos I left the piece of cut off shank for a sense of the size of the piece I removed from the length of the pipe.)

At this point in the process I was ready to work the stem with micromesh sanding pads to remove all of the scratches and bring back the deep black. The shorter stem gave the pipe a great look in my opinion. The finished length is 5 inches as opposed to 5 ½ inches but it looks more balanced to me. The loss is the long shanked look of the original bulldog. The gain is a more solid pipe with less chance for the breakage to continue and render the pipe irreparable.

The next series of photos show the progress of sanding with the micromesh pads from 1500 – 12,000 grit. The first four photos show the stem after I wet sanded with the 1500, 1800 and 2400 grit micromesh. After wet sanding I polished the stem with some Maguiar’s Scratch X2.0 and then took it to the buffer and buffed the stem with Tripoli and White Diamond.

I then dry sanded with 3200 -12,000 grit micromesh sanding pads. The next series of seven photos show the progress of the developing shine on the stem. Once I finished with the 12,000 grit pad I wiped down the stem with Obsidian Oil and when dry buffed it with White Diamond for a final time. The only thing remaining was a final buff with carnauba wax.

The final four photos below show the finished pipe. I applied several coats of carnauba wax and buffed the pipe and stem with a soft flannel buff to give it the final shine. When I started on this pipe I would have never guessed that I would refurbish it twice, band it twice, stain it twice, work the stem twice, and on goes the list of second times on this one. But the end product speaks for itself. I like the look of the shortened shank and tight band. This one will outlast me in its service to pipemen in the days ahead.

New Life for a Wally Frank Super Delicious Billiard

Blog by Steve Laug

I have become familiar with many of the Wally Frank lines of pipes but this was one I had not heard of before. It almost sounds like something to eat rather than smoke. It is stamped Wally Frank Ltd on the left side of the shank and on the right Super Delicious – interesting stamping indeed. The pipe was one of the bowls that I had in my box needing to be restemmed. It also had a cracked shank that was present before I matched a stem to it. Often a shank will crack like this if a tenon that is oversized is forced into the shank. That obviously had happened to this old pipe sometime in its life. I found a stem that fit the shank and inserted it enough to show the crack in the shank for the first photo below. The crack approximately ½ inch long and was in a portion of the shank where it was thinner than the other side. One of the challenges in restemming these older pipes is the fact that the shank is very often out of round and the stem has to be shaped to match it accordingly. The bowl has some nice grain on it and was well worth restoring. The remaining three photos in the first group of four show the grain and shape of the pipe. Note that rim was not only darkened but was worn on the front edge of the outer rim.

I reamed out the bowl and removed the cake that was present only in the top half of the bowl. It seemed that the lower portion of the bowl was not even broken in. The top of the bowl needed to be topped to even out the flat top of the bowl. The way the angle was after the tars and grime were removed was d a slight slant toward the front of the bowl and the front edge was rounded from tapping out the bowl repeatedly on a hard surface. I used the board and sandpaper to top the bowl and even out the top. I also made certain that the bowl was held against the board to even out the angle and make the top smooth and flat. The first photo below shows how out of round the shank is in proportion to the mortise. Notice the difference in thickness all around the shank diameter. The crack in the shank is at about 3 o’clock on the shank. The next two photos show the bowl after it has been topped and is even with no slant toward the back or front of the bowl.

After I had topped the bowl and evened things out I wiped the entirety of the bowl down with acetone on a soft cotton pad to remove the grime and the remaining finish on the bowl. It came off almost black when I was finished cleaning it. I then needed to band the crack shank. I opened it with the stem and then dripped a bit of superglue in the crack before pressure fitting the band in place. The first photo below shows the shape of the shank and makes the thin area very clear. This would require quite a bit of shaping to make the stem fit the shank correctly. The next two photos show the banded stem and how it fits on the shank. I kind of like the look of the band against the natural colour of the briar.

The next two photos below show the stem shape after I had removed much of the material at the top left corner of the picture. The stem is round at this point but the tenon is no longer in the center of the stem. It is proportionately toward the top left of the picture and on the top bottom when it is in place in the shank.

At this point in the process I restained the bowl with a dark brown aniline stain that I thinned with isopropyl alcohol so that it would match the colour of the bowl. My goal was to match the rim that I had topped and was raw briar to the natural patina of the bowl and shank. I mixed the stain until it was the colour I was aiming for and then stained the entire bowl with multiple applications of the stain to the rim. I flamed the stain and reapplied it to the rim, flamed it again and then took the pipe to the buffer. I buffed the bowl and stem with Tripoli and White Diamond. Once I was done with that I buffed the bowl and shank with multiple coats of carnauba wax to bring depth to the shine and also to blend the rim and bowl together.

I then worked on the oxidation of the stem. I had shaped it to fit the shank with my Dremel and when it fit well I sanded the stem from front to button with 280 grit sandpaper and then 400 and 600 grit wet dry sandpaper to remove the oxidation and scratch marks from the Dremel. Once it was smooth I progressed through the micromesh sanding pads from 1500-12,000 grit. In between 4000 and 6000 grits I polished the stem with Maguiar’s Scratch X 2.0 and then finished sanding with the micromesh. I finished the stem with a coat of Obsidian Oil and then multiple coats of carnauba wax to give it shine. The next series of four photos show the finished pipe. It is shined and ready to smoke.

Reworking an Imperial Treble Zulu – Stainless Steel Tenon

I picked up this older Imperial Tobacco Co pipe – a Zulu shape number 354. The shape number makes me wonder if the pipe was made by Comoy’s. Maybe someone here knows for sure. The number is missing on the Comoy’s shape number chart on Pipedia. The pipe is interesting to me for several reasons. It is the third in a group of three pipes by Imperial that came to me in an EBay lot. The first two were Two-Points and this one a Treble. I had not heard or seen this line before these came my way. The other reason is that several pipes in this lot had stainless steel tenons! The Treble has one and at first I thought it was original – the stem did not fit well as the tenon was stuck in the bowl and the stem would not seat all the way to the shank. The bowl was in pretty nasty shape. With lots of darkening and the grain virtually obscured under dirt. The rim was caked and tarred. The bowl was full of broken cake and cobwebs. The stem was gnawed with deep bite marks, the button destroyed and the tenon stuck in the shank.

I was able to remove the tenon from shank with a big pair of channel locks and some serious twisting and turning. I filed the end of the tenon and cut grooves in it so that the epoxy would have something to bite into when I pushed it into the stem. I then slid a pipe cleaner into the stem and threaded the tenon on the cleaner. When I got down to the stem I mixed some epoxy (two part mix) and painted it on the tenon. I let it set for a few moments and then pushed it into the stem. I wiped off the excess around the stem and tenon junction. I set it aside and worked on the bowl.

I reamed the bowl and cleaned both it and the shank. Then I used a fine grit sanding pad that I have here to work on the lava on the top of the bowl. Once that was done I wiped down the bowl with isopropyl alcohol to remove the grime and the finish. The next photos show the bowl after the initial cleanup. From there I put it in the alcohol bath and went back to work on the stem.

The next series of two photos show the bite marks on the stem and the state of the button. The bite marks were very deep and some were actually cuts in the stem material rather than just dents. I used my heat gun to raise the dents as much as possible but honestly they did not come up very much at all. This one would be a bit of a challenge. I used sanded the stem around the button and the dents with 240 grit sandpaper to get the oxidation off that area. I was going to use the superglue to repair these bite marks and needed a clean surface to work with. Once I had sanded the area clean I used a dental pick to pick away the brown left in the dents. I wanted to clean out the dents as much as possible and roughen the surface in the dent for a good bond with the glue. The first picture shows the top of the stem, the second shows the bottom.

Once they were clean and ready I washed the area down with some isopropyl alcohol to remove any remaining sanding dust. Then I put drops of superglue in the holes on the underside of the stem first. Once they were dry I did the same with the dents on the top side of the stem. The three photos below show the glue in place – they appear as shiny black spots in the photos.

I set the pipe stem aside to thoroughly dry and took the bowl out of the alcohol bath. I dried it off and then sanded the top of the bowl with the fine grit sanding pads that I have. The top is showing some nice grain and the tars are coming off nicely.

I wiped down the bowl and rim with acetone (fingernail polish remover) to remove the remaining finish and grime. The white cotton pads in the background of the next three photos show what still remained on the bowl after the alcohol wash. I wanted to get the bowl down to bare briar so that I could refinish it and then give it a new coat of stain. My goal was to highlight the beautiful grain on this one.

I guess I must get a bit bored doing the same thing or something, because I went back to the stem to sand the patches that I had made. I used emery cloth to get the patches even with the surface of the stem. The next series of three photos show the progress on cleaning up the stem and evening out the stem surface. The patches are beginning to fade and blend into the stem.

After sanding the stem I cleaned out the stem and the shank. It was a dirty process. The first picture below shows just a few of the many pipe cleaners and cotton swabs. I dip them in the cap filled with isopropyl that is pictured in the photos and swab out the stem and shank with them.

I reinserted the stem in the shank and wiped the entirety down with an alcohol soaked cotton pad. I wanted to see where I was at with the stem and the bowl. You will notice the addition of a band in the photos below. Once I refit the stem I could see that the stainless tenon was indeed a replacement and that it was misdrilled – it was set in the stem too high making the match at the tenon impossible. I decided to work on the shank rather than pull the tenon, redrill the hole in the stem and reinsert a bigger tenon. I could still do that should I desire. I sanded the shank a little to reduce the gap between the stem and shank. Then I pressure fit a band on it to guide the stem to the proper fit. It worked well actually and the stem lines up nicely now.

I took the next two photos to show the state of the stem patches at this point in the repair process. You can see that they are virtually invisible on the top of the stem and just slightly visible on the underside. At this point I continued to sand the stem and work at the area around the button to redefine it and to blend in the patches. I used a fine grit sanding pad and an extra fine grit pad to remove the scratches and to make the button area more defined. I then worked over the stem with the usual list of micromesh pads from 1500-6000 grit.

I restained the bowl with an oxblood stain and buffed the entirety with White Diamond and then gave the pipe several coats of carnauba wax and buffed with a soft flannel buff to bring out the shine to the pipe. You can see from the profile shots that the button is more clearly defined and the flow of the stem looks correct from the bowl to the button. The patches on the stem have blended quite well and though still visible if you look closely are smooth and black.

Restoring a unique Peterson 10

I picked up this old Peterson shape number 10 at a flea market for about $12. This one needed cleaning inside and out as well as reaming. The finish was quite good. I just used a soft bristle tooth brush to get into the crevices. The shank had a crack in it so I banded it with a silver band. The bowl was caked and very narrow. I used a battery terminal brush and an old adjustable reamer to get inside of it. The stem on it was obviously not the original but a smaller diameter replacement stem that did not fit well. The shank had been sanded smooth but was not tapered to meet the misfit stem but it was perfect for setting the band. Before doing that I used some super glue to squeeze the crack in the shank together. I held it until it was dry. I then heated the band with my heat gun and pressure fit it on the shank. I flattened the bottom edge of the band to match the flat bottom where the stamping is. I fit and shaped a new stem. Once it was fit I bent it to a comfortable fit for the mouth. Then I sanded and polished it with my usual regimen of micromesh pads from 1500-6000 grit.

Barling Garnet Grain Small Bent Billiard 2034 Given New Life

Blog by Steve Laug

I picked up this little Barling (transition era pipe so the Barling stamping is missing the “s” and is a script) in a lot I bought on EBay. It had a broken stem that was also chewed through on the end and not repairable. The tenon was still in the shank and was exceptionally tight. I put the bowl in the freezer for about 30 minutes and then used a screw to remove the broken piece from the shank. The key here is to not screw in the screw too much or you can crack the shank. I was able to easily pull it out as can be seen in picture 3. The finish on the bowl was rough on the top with tars and some denting. The sides of the bowl also had some denting. I cleaned the top of the bowl and removed the tars. I steamed the dents out of the top and bowl sides.

I wiped down the bowl with acetone to remove the grime and the waxes that were on the finish. When I had finished I inspected the shank area because the drilling was off a bit in the shank and the walls were thin near the top left. There were small hairline cracks that went through several places and spidered up to about a 1/8 inch into the length of the shank. I glued those and pressure fit a nickel band on the shank.

I turned the tenon on a recycled stem I had here and fit it on the pipe. I used my Dremel to remove the excess material where the diameter of the stem was greater than that of the pipe. I kept the broken stem near at hand to match the diameter, the flow of the stem and the shape. I used it as a bit of a template to shape the new stem. The three pictures below show the process of shaping the stem from Dremel to hand sanding with 240 grit sandpaper.

In the picture below I have finished the initial shaping with the sandpaper and have a good fit. You will notice the lightening of the shank below the band – that is part of the process of sanding to fit the band to the shank. I place the original stem below the pipe in the picture for comparison sake. It is a bit thinner in profile than the new one in this photo. I continued to sand the stem with 400 and 600 grit wet dry sandpaper and water to remove the remaining scratches and grooves that the 240 grit sandpaper left. Once I had them removed I proceeded to use the micromesh pads – 1500, 1800 and 2400 grit to sand the stem smooth. When I finished with those I buffed the stem with Tripoli and White Diamond and finished by returning to the micromesh pads -3200, 4000 and 6000 to polish it. One more trip to the buffer with White Diamond finished the polishing. I gave the stem a coat of Obsidian Oil and removed it and set it aside. It was time to work on the finish of the bowl.

I used an oxblood aniline stain to match the stain to the original Garnet Grain colour. I have done this in the past and compared it to a very nice original Garnet Grain and the colour is a perfect match. Before staining I polished the bowl with the 3200 and 4000 micromesh pads avoiding the stamping on the pipe. I applied the stain with a cotton swab and then wiped it off, applied and wiped it off until I got the colour I wanted. I then flamed it and set it aside to dry. Once it was dry I put the stem on it and took it to the buffer and gave it a buff with White Diamond and carnauba wax.

In the first picture below I put the original stem in to show the damage to the underside near the button. I also put a 1 cent piece, a penny in to give perspective on the size of this diminutive billiard. I am very pleased with the overall look of the pipe. The finish came out as a perfect match to the original Garnet Grain colour.

A Barling’s Frustration

I had this old bowl in my box that just looked like a Barlings. I took it out and studied under bright light and a loop. It had the arched Barlings over Make. The other side was stamped EL and Made in England (I believe). It had a serious crack in the shank so I superglued it and banded it. This little pipe became the definition of frustration for me. It was a beautiful and I was incredibly hopeful when I cleaned it up and prepared it for the new stem I had cut for it. The grain was very nice and to find that it was an older Pre-transition Barling’s pipe was exciting. The bowl cleaned up very well. The shank and new band looked great. All that remained was to finish working over the stem for it.

About that time my wife came down to the basement where I was working on it and we decided to go for our Saturday morning walk about. We had planned to take the bus down to an area we like to visit and check out the antique shops. This is something that we both enjoy so I put the little Barling’s my pocket and brought along some sand paper to work on it while sitting and waiting for the bus. We had a good morning, went to the Vancouver Flea Market and even found a couple of older Peterson pipes that I picked up. We decided to have some lunch before going home so we walked over to a nearby Korean BBQ and ordered a nice lunch.

While we were waiting for our lunch I guess the pipe fell out of my pocket. I did not notice until the waiter stepped on something and I heard a crack. Well the long and short of it is when we sat down to lunch it had fallen out of my pocket and when the waiter stepped on it the shank cracked off just ahead of the band. I had a sick feeling as I picked up the pieces of the broken old timer. My visions of a nice older Barling’s Pot shape were pretty much crunched. I put the pieces on the table and looked them over as we continue to wait for the meal and I grumbled about my stupidity in not zipping the coat pocket and also about bringing it with me in the first place.

Once we had finished eating and headed home I had calmed down enough to think about what I would do with the pipe. I took the pieces to the basement work table and turned on a bright overhead light so that I could examine the damages. As I looked at the broken shank I could see that the wood was darkened, almost burned around the crack. It was almost as if the heat in the shank had found a flaw in the briar and followed it outward to the surface. It had not gotten all the way to the surface but was just under the outer layer of the finish. So it appeared that the crack was worse than I had imagined.

That helped me to get over being incredibly frustrated and disappointed in the broken shank. So I spent some time looking it over and decided I could work with it. I decided to turn it into a nose warmer. The saddle stem I had made was too small in diameter to fit so I had to cut another stem. I cut off the ragged edges of the break and used a piece of sandpaper on a solid board to face the shank again. I also drilled out the shank and opened it up enough to accept the new tenon. The tenon is a bit shorter than normal 5/8″ to allow a little difference between the opening in the bowl wall and the mortise. I re-banded the shank for a second time to strengthen the shank after the previous break. I fit the stem to the pipe and sanded and polished it to a shine. Then I buffed and waxed the “new” little pipe. I made it such that I can one day put a church warden stem on the bowl should I desire to do so. For now though it is a nose warmer with a short taper stem. Total length is 4 3/4 inches.

Here are some pictures of the finished pipe. I had pictures of the pipe before and after the break but somehow they were erased so this is all I have left to show. I hope you can imagine what it looked like with the new saddle stem before it broke. But if not, you can see the new version. I am also ordering a churchwarden stem for it so I can fit one of those to it as well. Should look great that way as well.