Blog by Kenneth Lieblich

Welcome to my first meerschaum restoration! In fact, it is not just a meerschaum pipe, but it is also a Peterson pipe. This came out of lot of pipes from eBay some months ago, but it took me a while to get to it – I was a bit daunted. Even though it looked rough to start, it ended up as a very handsome pipe. Please read on…

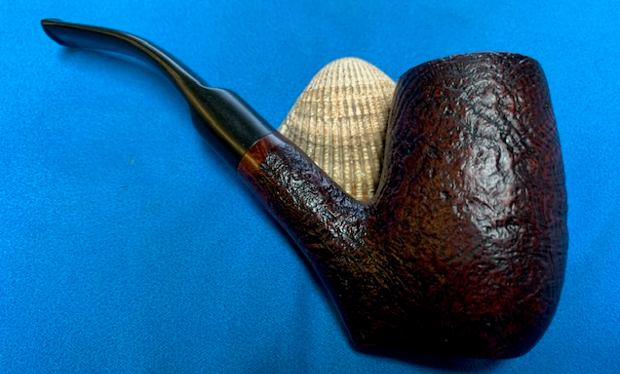

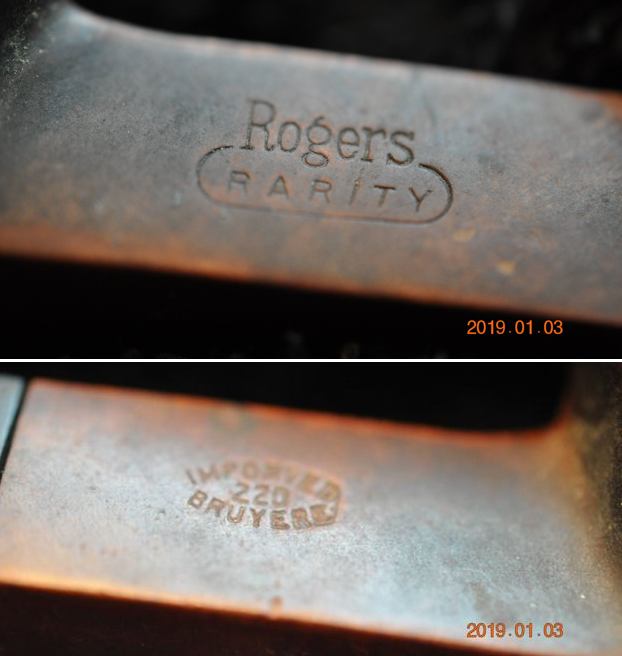

This is a rusticated, African block meerschaum, made on the Isle of Man. The stem has a push-style tenon. Like many of the meerschaum pipes of this era, this one has a factory-stained rim – to give it that sort of ‘broken in’ look. How do I know it is a Peterson? Because it has the distinctive, stylized ‘P’ on the left side of the stem, near the shank. Similar to other pipes that Steve has restored, this one seems likely to have been produced by Laxey Pipes Ltd. on the Isle of Man for Peterson Pipes. Here is the Pipedia article about them (I hasten to add that the various errors below are in the original text and are not mine):

This is a rusticated, African block meerschaum, made on the Isle of Man. The stem has a push-style tenon. Like many of the meerschaum pipes of this era, this one has a factory-stained rim – to give it that sort of ‘broken in’ look. How do I know it is a Peterson? Because it has the distinctive, stylized ‘P’ on the left side of the stem, near the shank. Similar to other pipes that Steve has restored, this one seems likely to have been produced by Laxey Pipes Ltd. on the Isle of Man for Peterson Pipes. Here is the Pipedia article about them (I hasten to add that the various errors below are in the original text and are not mine):

Laxey Pipes Ltd. resided in a historical 19th century four-storey Man stone building at The Quay, Old Laxey, Isle of Man, which thankfully has been preserved.

The company specialised in the production of meerschaum pipes using the Meerschaum mined by the Tanganyika Meerschaum Corporation in the Amboseli basin in Tanganyika (since 1964 part of the United Republic of Tanzania).

Please note: you may often find names like “Manx Pipes Ltd.”, “Man Pipe Co.” and others more, but there is no indication of another Isle of Man pipe producer other than Laxey Pipe Ltd. at any time!

Laxey Pipes Ltd. marketed own brands like “Manxpipe”, “Manxman”, “Manxland” e.c. Names like “John Bull”, “White Knight” (unwaxed), “Domino” (black, or lined) indicated some shapes / colours of Laxey’s own series. The stems either showed the astronomical sign for “male” or “man” (circle + arrow), or the crest of the Isle of Man, the 3-legged X in a circle. Manxpipes and Laxey’s other brands were available through pipe retailers in general, but also were sold (mainly) to tourists through their own shop in Laxey.

Furthermore Laxey Pipes Ltd. manufactured the meer bowls for Peterson, Barling, Nørding and others from the later 1960’s until 2001. Man Pipe e.g. was a brand distibuted by Comoy’s. The bowls usually showed no nomenclature indicating the orderer. “Genuine Block Meerschaum” was engraved frequently. Often, just the stems were different, while bowls were the same.

Supply of meerschaum from East Africa run out (Kenya / Tanzania exhausted, Somalia inaccessible), and thus the last Laxey meers were supplied to trade in May, 2001. Laxey Pipes Ltd. tried to survive continuing with briar pipes – mainly in the Danish style -, but to no success. It closed down business in July, 2002.

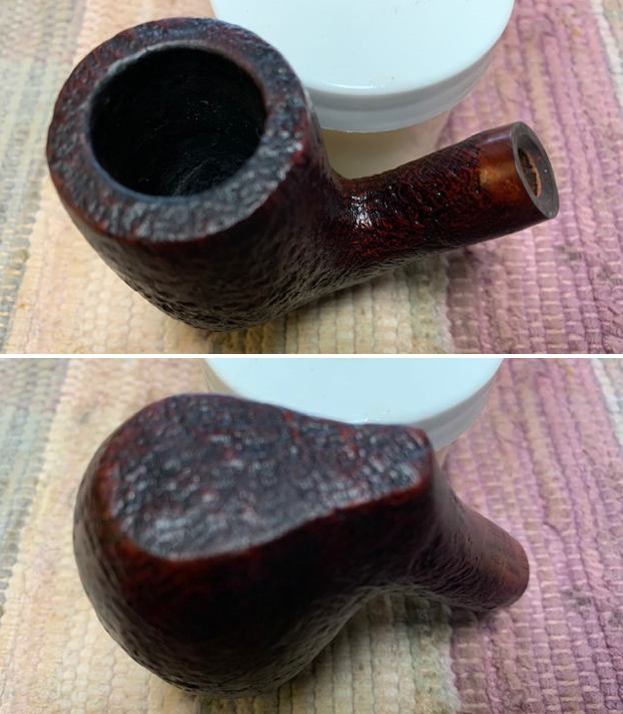

Anyway, on to the pipe – and what a mess it was. The stummel had the following problems: a nasty ghost, filth embedded in the rustication, a creepy and unnatural yellow tinge to the meerschaum, lots of lava on the rim, lots of cake in the bowl, and – worst of all – chunks missing from the rim. Meanwhile, the stem had its own set of problems: the ‘P’ logo was nearly obliterated, heavy oxidation and calcification, and tooth marks and dents. In fact, even my wife commented that this pipe might be the proverbial ‘bridge too far’ – but, like the stereotypical, stubborn husband, I was not to be deterred!

I decided to start on them stem, as I still was not sure how to resolve the chunks missing from the rim. I broke out the isopropyl alcohol and pipe cleaners, and got to work on the inside of the stem. Predictably, it was pretty dirty and I went through a good number of pipe cleaners in order to clean it up. Then I had to tackle the overwhelming oxidation and calcification – yuck. I took a blade (an old butter knife, actually) and began gently scraping at all that build-up. Obviously, I took it easy, as I did not want to damage the stem’s vulcanite any further. The butter knife worked quite well and I got a good amount loose. I followed that up with some lemon-infused isopropyl alcohol on some cotton rounds to try and scrub the rest away. This worked quite well and I noted some improvement.

I decided to start on them stem, as I still was not sure how to resolve the chunks missing from the rim. I broke out the isopropyl alcohol and pipe cleaners, and got to work on the inside of the stem. Predictably, it was pretty dirty and I went through a good number of pipe cleaners in order to clean it up. Then I had to tackle the overwhelming oxidation and calcification – yuck. I took a blade (an old butter knife, actually) and began gently scraping at all that build-up. Obviously, I took it easy, as I did not want to damage the stem’s vulcanite any further. The butter knife worked quite well and I got a good amount loose. I followed that up with some lemon-infused isopropyl alcohol on some cotton rounds to try and scrub the rest away. This worked quite well and I noted some improvement.

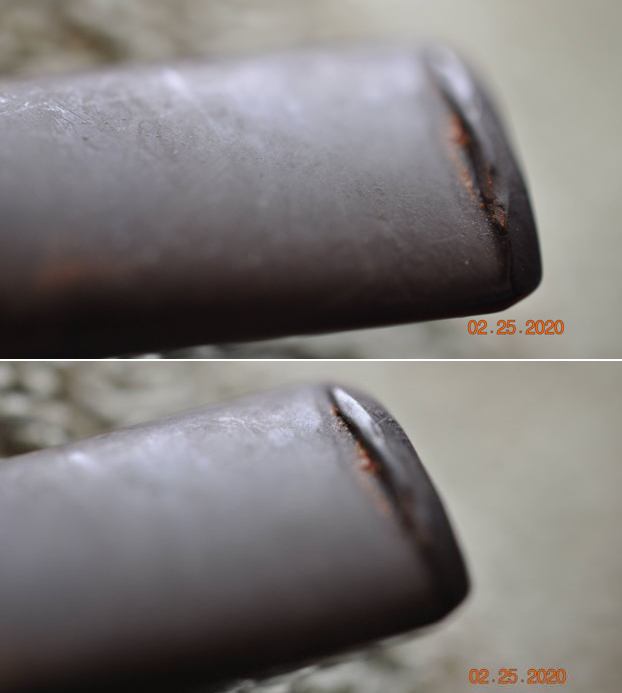

There were quite a few dents in the stem. Some were obviously tooth marks, but other dents looked like blunt force trauma! Time to break out the BIC lighter to see if it could raise some of these dents. Quite frankly, it did not do much – this repair was going to require some considerable sanding etc. Before that, however, the stem went for an overnight soak in the Before & After Hard Rubber Deoxidizer. The following day, I cleaned all of the de-oxidizing sludge off with alcohol, pipe cleaners, et cetera. The oxidation had migrated to the surface and would be fairly straightforward to remove. I scrubbed vigorously with SoftScrub to remove the leftover oxidation.

There were quite a few dents in the stem. Some were obviously tooth marks, but other dents looked like blunt force trauma! Time to break out the BIC lighter to see if it could raise some of these dents. Quite frankly, it did not do much – this repair was going to require some considerable sanding etc. Before that, however, the stem went for an overnight soak in the Before & After Hard Rubber Deoxidizer. The following day, I cleaned all of the de-oxidizing sludge off with alcohol, pipe cleaners, et cetera. The oxidation had migrated to the surface and would be fairly straightforward to remove. I scrubbed vigorously with SoftScrub to remove the leftover oxidation. Before I moved on to the Micromesh pads, I built up the dent damage on the stem with cyanoacrylate adhesive and let it fully cure. It turned out that this was not as straightforward as I had hoped. It took more than one application of adhesive to sort this problem out. I then sanded it down with 220-, 400-, and 600-grit sandpapers to make the stem look normal. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing.

Before I moved on to the Micromesh pads, I built up the dent damage on the stem with cyanoacrylate adhesive and let it fully cure. It turned out that this was not as straightforward as I had hoped. It took more than one application of adhesive to sort this problem out. I then sanded it down with 220-, 400-, and 600-grit sandpapers to make the stem look normal. I then used all nine Micromesh pads (1,500 through 12,000 grit) to bring out the lovely black lustre on the stem. I also used Obsidian Pipe Stem Oil in between each pad scrubbing.

The stummel was next, and the usual cleaning procedures were in order for this pipe. I used both the PipNet Reamer and the KleenReem to remove the built-up cake and followed that with 220-grit sandpaper to remove as much as I could. The meerschaum cannot take the usual de-ghosting process of soaking cotton balls in isopropyl alcohol, so sanding was a way to reduce the old ghost in the pipe. I also wanted to ensure there were no hidden flaws in the interior walls of the meerschaum. Fortunately, there were none. Truth be told, I actually also tried to use a bit of ground coffee in the bowl to remove the ghost, but that was not very successful. I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and isopropyl alcohol. There was quite a bit of nastiness inside this stummel – it took a lot of pipe cleaners etc. to sort that out. I then moved on to cleaning the outside of the stummel with Murphy’s Oil Soap and some cotton pads. That worked very well at removing any latent dirt and that weird yellow tinge that I mentioned earlier. I followed that up by quickly cleaning the insides with some dish soap and tube brushes. The meerschaum cannot be left wet for long – it will turn to mush otherwise. Before & After Restoration Balm does not make the same kind of difference on meerschaum as it does on briar, but it still works – so light coating was applied, followed by my horsehair shoe-brush.

I then proceeded to clean out the insides of the shank with Q-tips, pipe cleaners, and isopropyl alcohol. There was quite a bit of nastiness inside this stummel – it took a lot of pipe cleaners etc. to sort that out. I then moved on to cleaning the outside of the stummel with Murphy’s Oil Soap and some cotton pads. That worked very well at removing any latent dirt and that weird yellow tinge that I mentioned earlier. I followed that up by quickly cleaning the insides with some dish soap and tube brushes. The meerschaum cannot be left wet for long – it will turn to mush otherwise. Before & After Restoration Balm does not make the same kind of difference on meerschaum as it does on briar, but it still works – so light coating was applied, followed by my horsehair shoe-brush.

On to the inevitable repairs: this is where the nightmares begin. Honestly, it was not immediately clear to me how I was going to make the stummel look decent. Sure, I had cleaned it, etc., but what about the obvious chunks missing from the side? I considered sanding it all down, but I feared this would alter the shape of the pipe beyond reason and repair. I figured that, at very least, this pipe needed to be topped. That is to say, the rim had to be inverted and sanded down on a piece of 220-grit sandpaper. By doing this, it would remove some of the lighter damage altogether and would improve the state of the heavier damage. But the old problem remained: how was I going to repair the chunks of missing meerschaum on this pipe?

On to the inevitable repairs: this is where the nightmares begin. Honestly, it was not immediately clear to me how I was going to make the stummel look decent. Sure, I had cleaned it, etc., but what about the obvious chunks missing from the side? I considered sanding it all down, but I feared this would alter the shape of the pipe beyond reason and repair. I figured that, at very least, this pipe needed to be topped. That is to say, the rim had to be inverted and sanded down on a piece of 220-grit sandpaper. By doing this, it would remove some of the lighter damage altogether and would improve the state of the heavier damage. But the old problem remained: how was I going to repair the chunks of missing meerschaum on this pipe? I then realized that the solution was as obvious as the nose on my face: I would take a piece of meerschaum from another pipe and fashion a repair. I grabbed one of my sacrificial meerschaum pipes (a dreadfully ugly horse’s head) and used a pair of end-cutting nippers to break off a couple of pieces. Having done that, I used cyanoacrylate adhesive to fix them in place on the stummel. I was feeling pretty good about this solution, but knew that there was still a long row to hoe. Obviously, I needed to sand down and shape the new pieces of meerschaum, but I also needed to make the rim as rusticated as the rest of the stummel. Enter the Dremel (with accompanying angelic voices). Yes, I first used a sanding drum on the Dremel to remove excess material from the repair (but not too much), then I used a high-speed engraving cutter to rough up the surface of both the rim and the repair.

I then realized that the solution was as obvious as the nose on my face: I would take a piece of meerschaum from another pipe and fashion a repair. I grabbed one of my sacrificial meerschaum pipes (a dreadfully ugly horse’s head) and used a pair of end-cutting nippers to break off a couple of pieces. Having done that, I used cyanoacrylate adhesive to fix them in place on the stummel. I was feeling pretty good about this solution, but knew that there was still a long row to hoe. Obviously, I needed to sand down and shape the new pieces of meerschaum, but I also needed to make the rim as rusticated as the rest of the stummel. Enter the Dremel (with accompanying angelic voices). Yes, I first used a sanding drum on the Dremel to remove excess material from the repair (but not too much), then I used a high-speed engraving cutter to rough up the surface of both the rim and the repair.

So far, so good. The engraving cutter had worked – to a point – but it had not really resulted in the sort of rustication I was looking for. My solution came from the Dremel again, but only indirectly. Steve reminded me of his trick of using an old Philips-head screwdriver as a rustication device (you can read about that here). Whereas Steve used Dremel grinding stones to make his rustication device, I used a metal cutting disc on the Dremel. As you can see, my screwdriver came out looking quite good and the stummel came out looking even better.

So far, so good. The engraving cutter had worked – to a point – but it had not really resulted in the sort of rustication I was looking for. My solution came from the Dremel again, but only indirectly. Steve reminded me of his trick of using an old Philips-head screwdriver as a rustication device (you can read about that here). Whereas Steve used Dremel grinding stones to make his rustication device, I used a metal cutting disc on the Dremel. As you can see, my screwdriver came out looking quite good and the stummel came out looking even better.

I was definitely pleased with the roughened surface of the stummel, but I next needed to address the lack of colour. This, of course, was a direct result of my topping of the rim – it removed the patina. The solution must have come to me in the mid-afternoon: tea. Yes, I used black tea to provide a beautiful stain to the meerschaum that gave it a really good look. I went and added some more Before & After Restoration Balm and, once again, used my horsehair shoe-brush to work it in.

I was definitely pleased with the roughened surface of the stummel, but I next needed to address the lack of colour. This, of course, was a direct result of my topping of the rim – it removed the patina. The solution must have come to me in the mid-afternoon: tea. Yes, I used black tea to provide a beautiful stain to the meerschaum that gave it a really good look. I went and added some more Before & After Restoration Balm and, once again, used my horsehair shoe-brush to work it in. Meerschaum does not really do well on a high-speed buffer, so I used a microfibre cloth to achieve the same effect. I did, however, take the stem to the buffer, where I applied White Diamond and some wax to give it that lovely shine.

Meerschaum does not really do well on a high-speed buffer, so I used a microfibre cloth to achieve the same effect. I did, however, take the stem to the buffer, where I applied White Diamond and some wax to give it that lovely shine.

In the end, what a beauty this pipe is! It is back to its old glory and ready to be enjoyed again by the next owner. I am pleased to announce that this pipe is for sale! If you are interested in acquiring it for your collection, please have a look in the ‘Irish’ pipe section of the store here on Steve’s website. You can also email me directly at kenneth@knightsofthepipe.com. The approximate dimensions of the pipe are as follows: length 154 mm; height 47 mm; bowl diameter 34 mm; chamber diameter 20 mm. The mass of the pipe is 40 grams. Thank you very much for reading and, as always, I welcome and encourage your comments.