Blog by Steve Laug

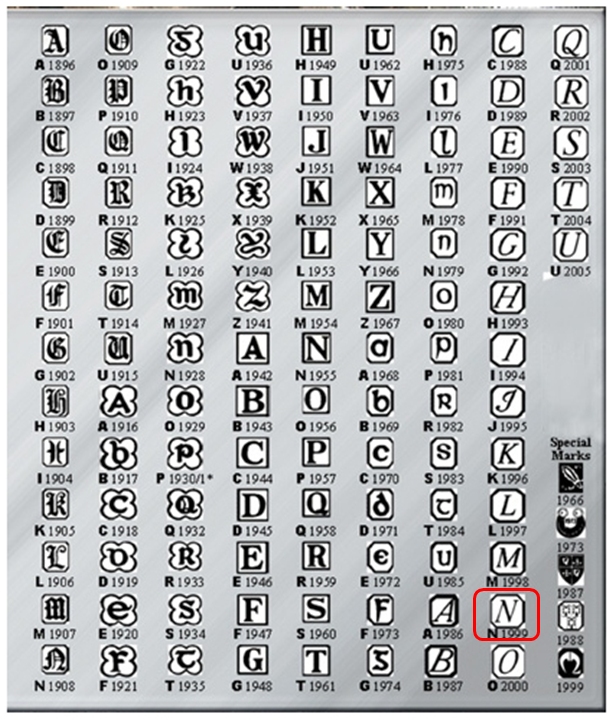

The next pipe on the table came to us from one of Jeff’s pipe hunts not far from where he is located. It is a Comoy’s 409 Bulldog that is in decent condition. It is stamped Comoy’s Christmas 1983 on the top left side of the diamond shank. On the right side it is stamped with the Comoy’s circular COM stamp Made in London in a circle over England. That is followed by the shape number 409. On the right underside it is stamped with the letter E near the stem/shank junction. The stamping is clear and readable. The pipe has a medium brown finish and some amazing grain that the shape follows well. The finish was very dirty with grime ground into the grain around bowl sides. The bowl had a thick cake in the bowl and some lava overflow on the top and the beveled inner edge of the top. There was darkening on the briar around the inner beveled edge of the rim. The stem was dirty, oxidized and calcified. There was light tooth chatter and marks on the stem near the button on both sides. The stem has the inset C logo of Comoy’s on the top left side of the diamond saddle stem. Jeff took photos of the pipe before he cleaned it up.

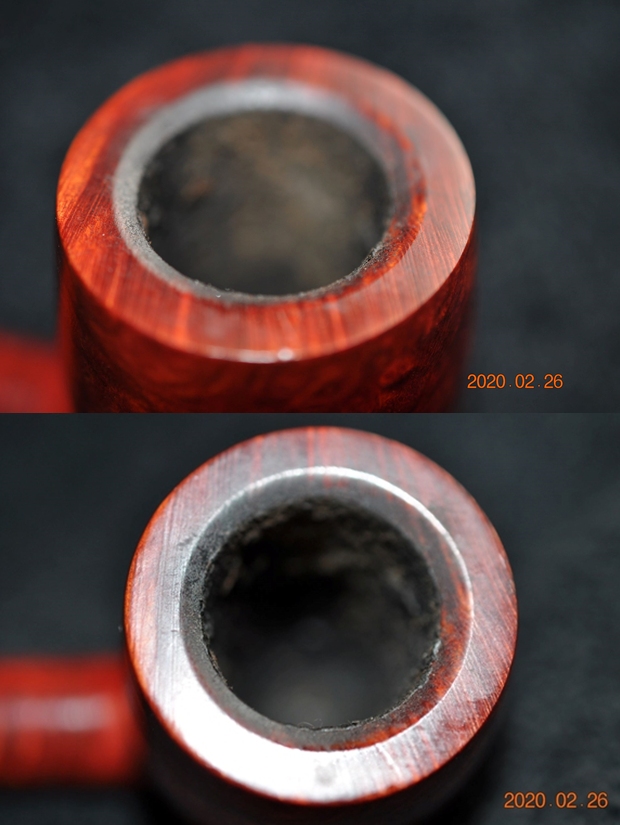

Jeff took photos of the rim top to show the thick cake in the bowl and the lava overflow on the top and beveled inner edge of the rim. The photos show the rim top and bowl from various angles.

Jeff took photos of the rim top to show the thick cake in the bowl and the lava overflow on the top and beveled inner edge of the rim. The photos show the rim top and bowl from various angles.

Jeff took some photos of the bowl sides and heel to show the nice grain that was on this bowl. It is a quite beautifully grained pipe.

Jeff took some photos of the bowl sides and heel to show the nice grain that was on this bowl. It is a quite beautifully grained pipe.

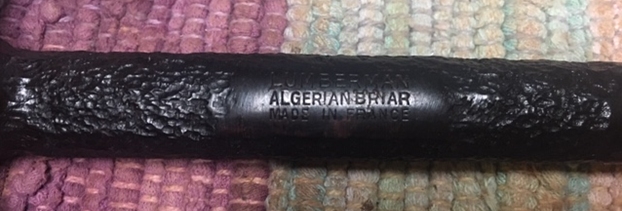

The stamping on each side of the diamond shank is shown in the photos below. They look very good and readable. You can also see the inset C logo on the top left side of the diamond stem.

The stamping on each side of the diamond shank is shown in the photos below. They look very good and readable. You can also see the inset C logo on the top left side of the diamond stem.

The stem was a very good fit to the shank. It was oxidized, calcified and had debris stuck to the surface of the vulcanite. There was tooth chatter and marks on both sides of the stem and on the button surface.

The stem was a very good fit to the shank. It was oxidized, calcified and had debris stuck to the surface of the vulcanite. There was tooth chatter and marks on both sides of the stem and on the button surface.  I knew that I was dealing with a 1983 Comoy’s 409 Bulldog that was specially made as a Christmas Pipe. I turned to work on the pipe itself. Jeff had done a great job cleaning up the pipe as usual. He reamed the pipe with a PipNet reamer and cut back the cake back to the bare briar. He cleaned up the walls with a Savinelli Fitsall Pipe Knife. He scrubbed the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol to remove the tars and oils. He scrubbed the exterior of the pipe with Murphy’s Oil Soap and a tooth brush to remove the grime from the finish. He worked on the rim top lava and darkening with the soap and tooth brush. He scrubbed the inside of the stem with alcohol and pipe cleaners. He scrubbed the exterior with Soft Scrub and then soaked it in Before & After Deoxidizer. He washed it off with warm water to remove the deoxidizer. The pipe looked far better. I took photos of the pipe when I received it before I started working on it.

I knew that I was dealing with a 1983 Comoy’s 409 Bulldog that was specially made as a Christmas Pipe. I turned to work on the pipe itself. Jeff had done a great job cleaning up the pipe as usual. He reamed the pipe with a PipNet reamer and cut back the cake back to the bare briar. He cleaned up the walls with a Savinelli Fitsall Pipe Knife. He scrubbed the interior of the bowl and shank with pipe cleaners, cotton swabs and alcohol to remove the tars and oils. He scrubbed the exterior of the pipe with Murphy’s Oil Soap and a tooth brush to remove the grime from the finish. He worked on the rim top lava and darkening with the soap and tooth brush. He scrubbed the inside of the stem with alcohol and pipe cleaners. He scrubbed the exterior with Soft Scrub and then soaked it in Before & After Deoxidizer. He washed it off with warm water to remove the deoxidizer. The pipe looked far better. I took photos of the pipe when I received it before I started working on it.

I took photos of the bowl and rim top as well as the stem to show how clean they were. You can see the darkening on the inner edge of the rim and the top. The stem looks clean of oxidation and the tooth marks and chatter are very clear in the photos.

I took photos of the bowl and rim top as well as the stem to show how clean they were. You can see the darkening on the inner edge of the rim and the top. The stem looks clean of oxidation and the tooth marks and chatter are very clear in the photos. I took photos of the stamping on the sides of the shank. The stamping is clear and readable as noted above.

I took photos of the stamping on the sides of the shank. The stamping is clear and readable as noted above.  I took a photo of the pipe with the stem removed to show the overall look of stem, tenon and profile of the pipe.

I took a photo of the pipe with the stem removed to show the overall look of stem, tenon and profile of the pipe. I decided to start my work on the pipe by addressing the darkening on the rim top and beveled inner edge. I used a folded piece of 220 grit sandpaper to work on the finish to remove the darkening on both. It took a bit of work but I was able to remove the majority of it and the end product looked much better.

I decided to start my work on the pipe by addressing the darkening on the rim top and beveled inner edge. I used a folded piece of 220 grit sandpaper to work on the finish to remove the darkening on both. It took a bit of work but I was able to remove the majority of it and the end product looked much better.  I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the bowl down with a damp cloth after each pad.

I polished the briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping the bowl down with a damp cloth after each pad.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes while I worked on the stem. After the time passed I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the briar with my fingertips. The product works to clean, enliven and preserve the briar. I let it sit for 10 minutes while I worked on the stem. After the time passed I buffed it with a cotton cloth to deepen the shine. The briar really comes alive with the balm.

I set the bowl aside and turned my attention to the stem. Some of the tooth marks were deep – fortunately small but deep on both sides. I filled in the divots with clear super glue and set the stem aside to dry while I took my dog for a walk. When I got back I used a needle file to sharpen the edge of the button and flatten the repairs.

I set the bowl aside and turned my attention to the stem. Some of the tooth marks were deep – fortunately small but deep on both sides. I filled in the divots with clear super glue and set the stem aside to dry while I took my dog for a walk. When I got back I used a needle file to sharpen the edge of the button and flatten the repairs.

I sanded out the repairs on both sides of the button surface and stem with 220 grit sandpaper to blend them into the surface. I began polishing the stem with 400 grit wet dry sandpaper.

I sanded out the repairs on both sides of the button surface and stem with 220 grit sandpaper to blend them into the surface. I began polishing the stem with 400 grit wet dry sandpaper. I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

This Comoy’s Christmas 1983 Bulldog is a real beauty. The Medium Brown stain highlights some great grain around the bowl sides and the heel. The finish on the pipe is in excellent condition and the contrasting stains work well to highlight the grain on the pipe. The polished black vulcanite saddle stem adds to the mix. With the grime and debris gone from the finish and the bowl it was a beauty and is eye-catching. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Bent Bulldog 409 is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. I can only tell you that like the other pipes I am working that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 5 ¼ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. Thanks for walking through the restoration with me as I worked over another beautiful pipe. This pipe will be added to the British Pipe Makers section of the rebornpipes store soon. If you want to add it to your collection send me an email or a message! Thanks for your time.

This Comoy’s Christmas 1983 Bulldog is a real beauty. The Medium Brown stain highlights some great grain around the bowl sides and the heel. The finish on the pipe is in excellent condition and the contrasting stains work well to highlight the grain on the pipe. The polished black vulcanite saddle stem adds to the mix. With the grime and debris gone from the finish and the bowl it was a beauty and is eye-catching. I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Bent Bulldog 409 is quite nice and feels great in the hand. Give the finished pipe a look in the photos below. I can only tell you that like the other pipes I am working that it is much prettier in person than the photos capture. The dimensions of the pipe are Length: 5 ¼ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. Thanks for walking through the restoration with me as I worked over another beautiful pipe. This pipe will be added to the British Pipe Makers section of the rebornpipes store soon. If you want to add it to your collection send me an email or a message! Thanks for your time.