Blog by Steve Laug

I have been working on a lot of different estate pipes and selling them for different families. Once in a while it is good to change things up a bit. Alex came by and went through the Malaga pipes I have awaiting restoration. He also brought other pipes to add to his box. I have a box of pipes from Alex that I am always working away at. He periodically drops more Malaga pipes into his box. There are quite a few of them to work on so I decided work on a few of them. The next one of these was another Malaga pipe. It is a beautiful oval shank Rusticated Canadian that has a very tight pattern of rustication. It also has a long striated grey/silver/black acrylic stem. The Malaga Canadian that Alex picked up from EBay. It had been mislabeled a Hungarian and the price was right. The pipe was dirty and caked when arrived. The rusticated rim top has a little lava filled but otherwise looked good. The bowl had a thin cake in it that was hard and dense. The exterior of the bowl and shank are very dirty with grime and oils from prolonged use. The stamping on the left side of the shank was in a smooth band on the thin shank. It read MALAGA. There was a thin band of smooth briar around the shank end. The acrylic stem was had tooth chatter on the top and the underside of the stem. I took photos of the pipe before I started the cleanup work.

I took close up photos of the bowl and rim to capture the condition of the pipe before I started my cleanup work. The rim top had some lava embedded in the rusticated finish and was heavier on the back side. The outer and inner edges of the bowl were not too bad. The inside edge was clean and the outside looked very good. Other than being so dirty that it was in great condition. The stem was dirty and there was tooth chatter on the top and underside near the button and on the flat surfaces of the stem.

I took close up photos of the bowl and rim to capture the condition of the pipe before I started my cleanup work. The rim top had some lava embedded in the rusticated finish and was heavier on the back side. The outer and inner edges of the bowl were not too bad. The inside edge was clean and the outside looked very good. Other than being so dirty that it was in great condition. The stem was dirty and there was tooth chatter on the top and underside near the button and on the flat surfaces of the stem. I took a photo to capture the stamping on a smooth panel on the left side of the shank near the stem/shank joint. The photo shows the stamping MALAGA on the left side of the shank is very readable.

I took a photo to capture the stamping on a smooth panel on the left side of the shank near the stem/shank joint. The photo shows the stamping MALAGA on the left side of the shank is very readable.

If this is the first of the Malaga restorations that you have read about then you should know the backstory of the brand. I am including the link to a blog that I wrote that gives some of the history of the Malaga brand and the Malaga Pipe Shop in Royal Oak, Michigan in the USA. I have written an earlier blog to give a little history of the Malaga Brand and the pipemaker, George Khoubesser. Here is the link – https://rebornpipes.com/tag/malaga-pipes/.That blog also includes links to a catalogue and the history of the pipemaker George Khoubesser. Follow the link to get a feel for the brand and the pipemaker.

If this is the first of the Malaga restorations that you have read about then you should know the backstory of the brand. I am including the link to a blog that I wrote that gives some of the history of the Malaga brand and the Malaga Pipe Shop in Royal Oak, Michigan in the USA. I have written an earlier blog to give a little history of the Malaga Brand and the pipemaker, George Khoubesser. Here is the link – https://rebornpipes.com/tag/malaga-pipes/.That blog also includes links to a catalogue and the history of the pipemaker George Khoubesser. Follow the link to get a feel for the brand and the pipemaker.

I followed our regular regimen for cleaning estates. I reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake.  I scraped out the dried tars and oils with a pen knife and then scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners.

I scraped out the dried tars and oils with a pen knife and then scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. I scrubbed the briar with Before & After Briar Cleaner. I rubbed it into the surface of the briar with my finger tips and let it sit for about 10 minutes then rinsed it off with running water. I dried it off with a soft cloth.

I scrubbed the briar with Before & After Briar Cleaner. I rubbed it into the surface of the briar with my finger tips and let it sit for about 10 minutes then rinsed it off with running water. I dried it off with a soft cloth.

I touched up the edges of the rim with a walnut stain pen to take care of the damage there. Then I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I touched up the edges of the rim with a walnut stain pen to take care of the damage there. Then I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

The stem was in excellent condition but there was some light tooth chatter and no deep marks. It was well cut stem and had a great look and feel. I sanded out the tooth chatter with 220 grit sand paper and polished it with 400 wet dry sand paper. Once it was finished it began to shine.

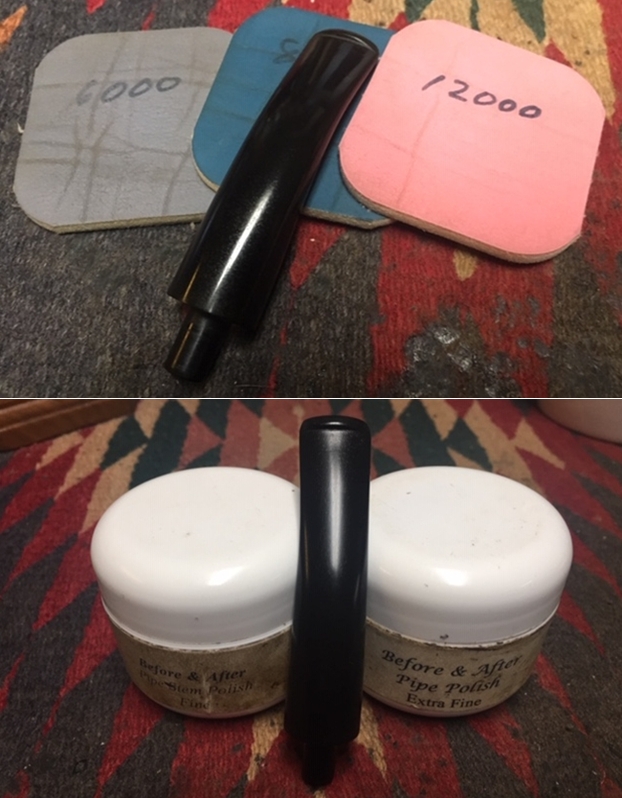

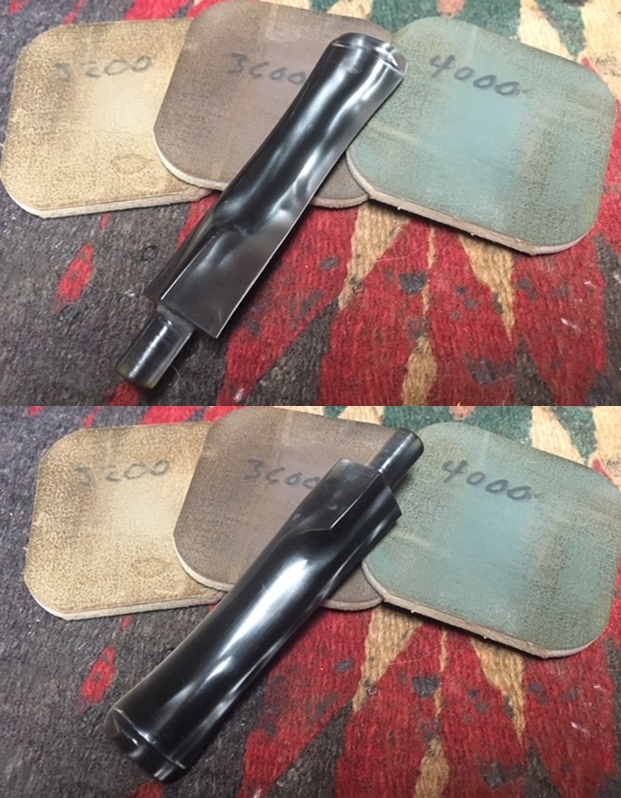

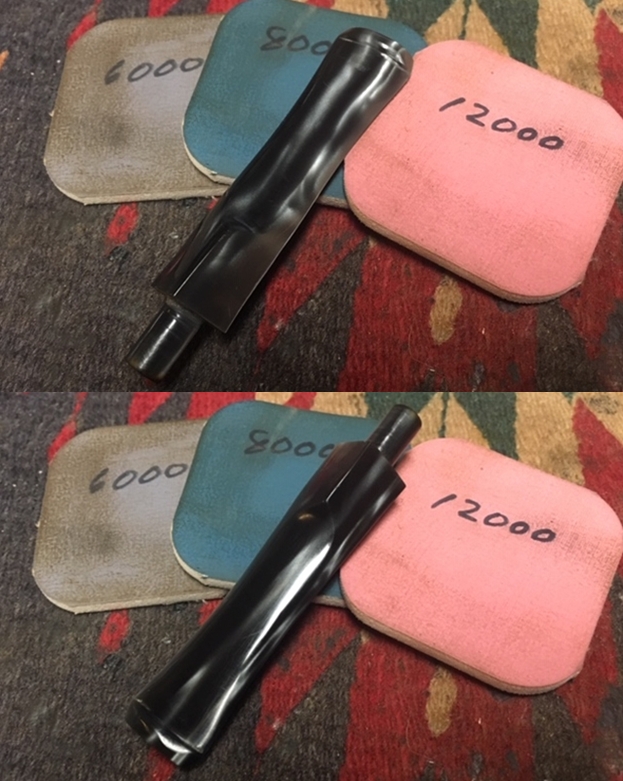

The stem was in excellent condition but there was some light tooth chatter and no deep marks. It was well cut stem and had a great look and feel. I sanded out the tooth chatter with 220 grit sand paper and polished it with 400 wet dry sand paper. Once it was finished it began to shine. I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with a damp cloth. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with a damp cloth. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a cotton cloth.

This is a beautiful Malaga Rusticated Canadian with a variegated grey/black/silver acrylic stem. It has a great look and feel. The rustication is very tactile but also the pattern is well done and a tight pattern. It is a beauty. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rustication took on life with the buffing. The rich brown colours work well with the polished acrylic stem. The finished pipe has a rich look that is quite catching. Have a look at it with the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 7 inches, Height: 1 7/8 inches, Outside diameter of the bowl: 1 3/8 inches, Chamber diameter: 3/4 of an inch. I will be adding the pipe to the finished Malaga pipes that I have set aside for Alex. This will be a great addition to his collection of Malaga pipe. Thanks for walking through the restoration with me as I worked over another Malaga.

This is a beautiful Malaga Rusticated Canadian with a variegated grey/black/silver acrylic stem. It has a great look and feel. The rustication is very tactile but also the pattern is well done and a tight pattern. It is a beauty. I polished stem and the bowl with Blue Diamond polish on the buffing wheel. I gave the bowl multiple coats of Conservator’s Wax and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The rustication took on life with the buffing. The rich brown colours work well with the polished acrylic stem. The finished pipe has a rich look that is quite catching. Have a look at it with the photos below. The shape, finish and flow of the pipe and stem are very well done. The dimensions are Length: 7 inches, Height: 1 7/8 inches, Outside diameter of the bowl: 1 3/8 inches, Chamber diameter: 3/4 of an inch. I will be adding the pipe to the finished Malaga pipes that I have set aside for Alex. This will be a great addition to his collection of Malaga pipe. Thanks for walking through the restoration with me as I worked over another Malaga.