By Al Jones

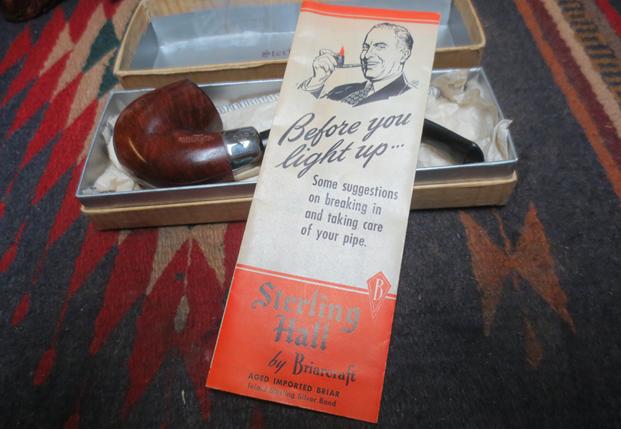

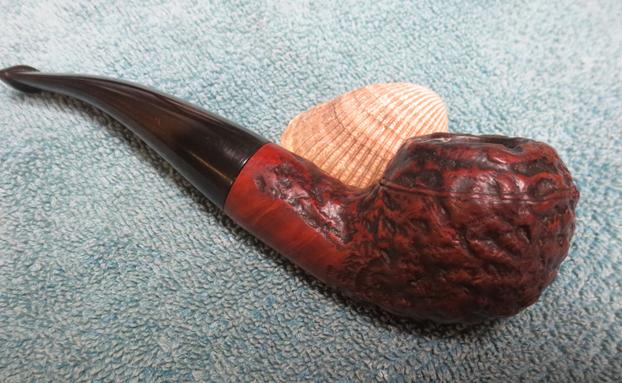

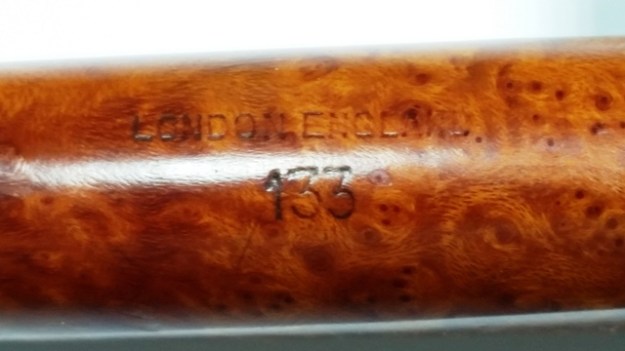

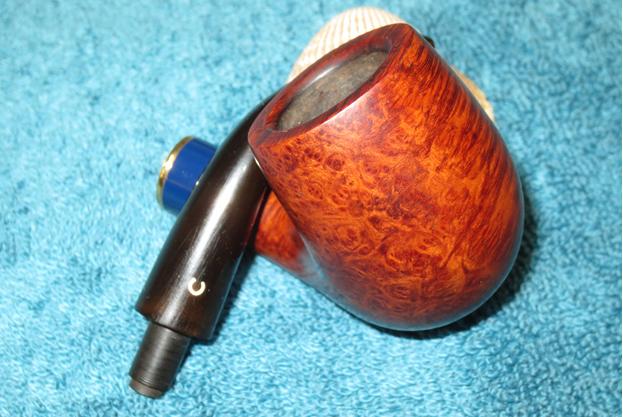

When I spied this pipe, I wasn’t familiar with the Sashar line or that it was a Sasieni 2nd’s line. The shape and style spoke to me as Sasieni and sure enough, the nomenclature read “London Made By Sasieni”. Upon receipt of the pipe, which came via England, I could see the stem also had a Sasieni feel. The pipe is rusticated, but with a texture and detail that I’ve not seen before. The rustication on Sasieni Rustic pipes is lovely, but I think this method may have a nicer hand feel. I’m familiar with the other Sasieni 2nd’s: Mayfair, Fantail and Olde English but Sashar was new to me. The pipe was stamped with the shape 959R. It is similar to the Viscount Lascelles, but on a slightly smaller scale. The nomenclature was lightly stamped, but completely visible. I didn’t capture it well on my photo below, but it reads:

959R

Sashar

London Made

By Sasieni

Made in England (straight line)

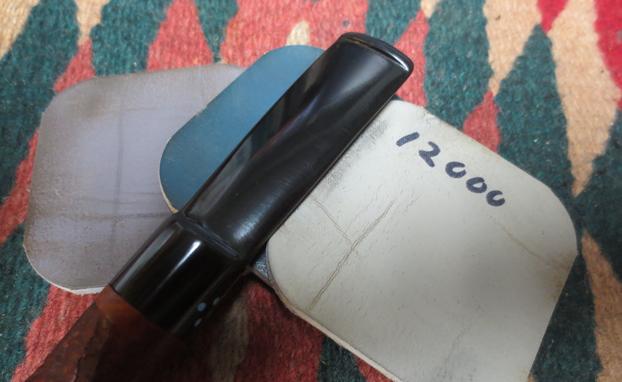

The pipe had a badly oxidized stem and some wear marks on the polished bowl top. The “S” stem logo imprint was still visible.

I reamed the slight cake from the bowl and found an interior in excellent condition. The bowl was soaked with sea salt and alcohol. The stem was soaked for several hours in a mild solution of Oxy-Clean, with a dab of grease on the logo.

I smoothed the nicks on the bowl top with some 800 grit, then 1000 and 2000 grade wet papers. The bowl top was buffed with White diamond and several coats of Carnuba wax.

The stem was mounted and heavy layer of oxidation removed with 800 grade paper, followed by 1000 and 2000 grades. That was followed with micro-mesh sheets in 8,000 and 12,000 grades. The stem logo was brightened with a dab of white Acrylic paint. After it started to harden, I wiped it off leaving paint in the recess. It was set aside to dry overnight. The stem was then buffed with White Diamond and Meguiars Plastic polish.

Below is the finished pipe. To my eye, the tapered stem Bent Billiard epitomizes the British briar pipe. I reluctantly packed up the pipe. It was sold and is now heading to a new owner on the Greek island of Corfu.