Blog by Steve Laug

I first picked this book up at a Chicago Pipe Show at a table where G.L. Hunt’s daughter, K.A. Worth was selling her new book on her father and the Falcon Pipe. I remember sitting and talking with her about the book and the pipe and being fascinated with both the history of the pipe and the man. It is a memory that runs through my mind each time I pick up this book or one of the Falcons that I have in my pipe cupboard. She autographed my copy which only enhances the memory of that day in Chicago.

I first picked this book up at a Chicago Pipe Show at a table where G.L. Hunt’s daughter, K.A. Worth was selling her new book on her father and the Falcon Pipe. I remember sitting and talking with her about the book and the pipe and being fascinated with both the history of the pipe and the man. It is a memory that runs through my mind each time I pick up this book or one of the Falcons that I have in my pipe cupboard. She autographed my copy which only enhances the memory of that day in Chicago.

Her book is divided into two parts. The first section she calls The Pipe People and it covers a little over 100 pages. The second section she calls The Pipes and it covers about 60 pages. I have included a screen shot of the Table of Contents to show how the book is laid out. Prior to the first part she has an Introduction and following the second part is an Epilogue.

The Introduction sets the stage for the book. It starts with the following quote: “It all began in the imagination of an American engineer. Prolific inventor Kenly Bugg of Ft. Wayne, Indiana, put pencil to paper and soon a revolutionary new smoker’s pipe emerged… Bugg patented his Falcon design on August 21, 1945… Enter the genius of G.L. Hunt and his company, Diversey Machine Works – an oft quoted statistic has George Hunt selling some six million Falcons by 1954 in the United States alone.”

The author goes on with a brief survey and concludes the Intro with this quote: “In this volume we will chronicle the development of the Falcon pipe and the Falcon companies, along the way paying tribute to those who ushered the pipe to worldwide renown. Here we will provide what will surely prove the most comprehensive Falcon history to date… Come now… let’s step inside…”

The quote gives the reader the author’s purpose for the book and invites them into the pages of her book. Let’s look at the parts and evaluate whether she fulfilled her purpose.

PART ONE: The Pipe People

“…The Falcon Pipe is the most unique in all the pipe world. I know you are familiar with the tremendous success of the Falcon Pipe here in the States and the success it has enjoyed throughout the Sterling Countries – those people and companies that are associated with Falcon Pipe do become known as “The Pipe People”… George L. Hunt – May 1963.”

This quote is on the header page of the first part of the book. With it the author introduces the man and the process of development of the Falcon. She tells it through her interactions with her grandfather and the archives of material that she read through in preparation for this book. It is a fascinating way to tell the story and is immensely readable and it the method that she uses throughout the book. It is the largest part of the book, Chapters 1-10, and really gives the most clear, readable and concise history of the brand that is available.

In this review, rather than go chapter by chapter and summarize the contents, I will summarize each part of the book and give a more global picture of the book. I am not as concerned to give a view per page as to give the potential purchaser a feel for what is included in the book itself. They can read the details themselves.

PART ONE is the overall history of the brand from when author’s grandfather bought the patents to when the pipe came to be one of the most well-known brands of throughout history. She looks at the pipe from its inception and the connection between the inventor and her grandfather through to its expansion into the British market with a view of the struggles and strains that went with that expansion. Thus she takes the reader on the journey from patent of the Falcon to its manufacture and marketing. She does not skip over all of the glitches and struggles along the way but describes them in a humorous style that makes the reader a part of the discovery process she is on in writing the book. There is also background information given on each of the key individuals in the mix – Kenly Bugg, G.L. Hunt, David E. Morris, Howard Hodgkins and Michael Jim Dixon. Many others are listed and covered as well but these seem to be key players who interact with and cause change in the life and direction of the Falcon brand. The first part ends with a picture of an advertisement for a Falcon Universal Pipe Companion and a brief paragraph bringing the history of the brand to an end.

PART TWO: The Pipe

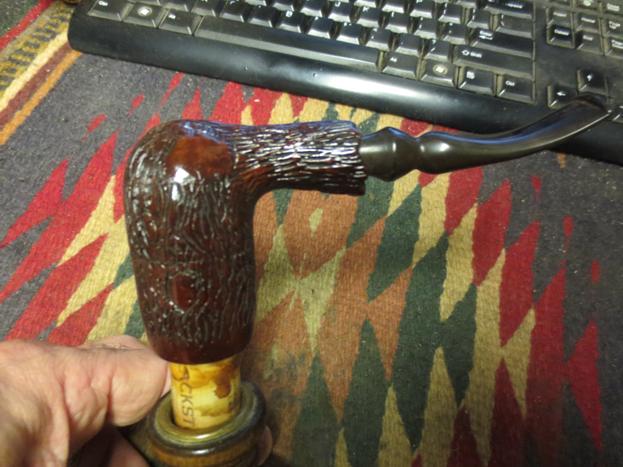

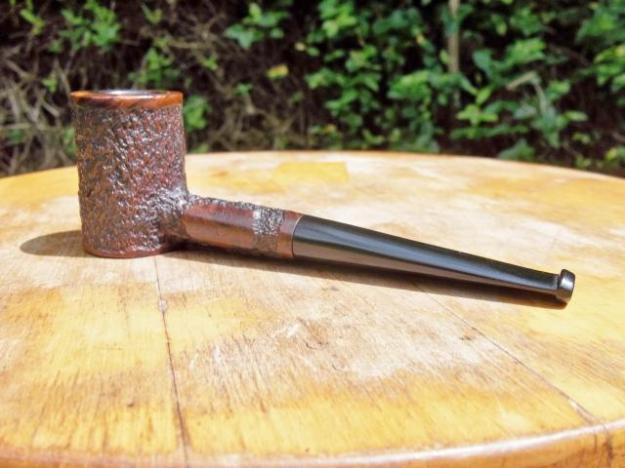

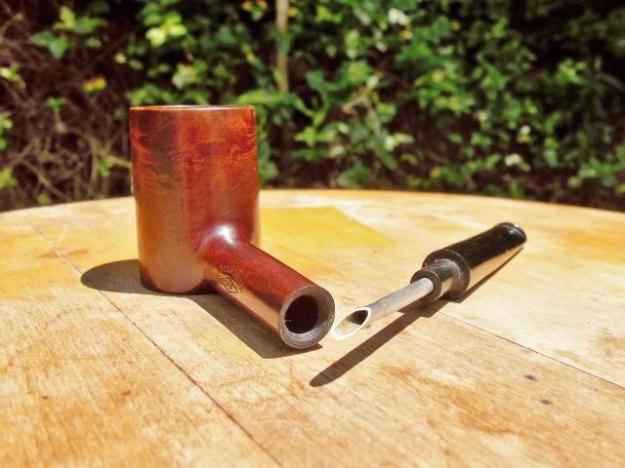

This part of the book gives the reader an in-depth look at the pipe itself. The author includes quite a few photos of different bowls and stems as well as a variety of advertizing brochures and pamphlets issued by Falcon. Even flipping through the photos gives the reader a good idea of the variety and scope of the Falcon pipe and its enthusiasts. It is an amazing collection of photos and pamphlets/brochures.

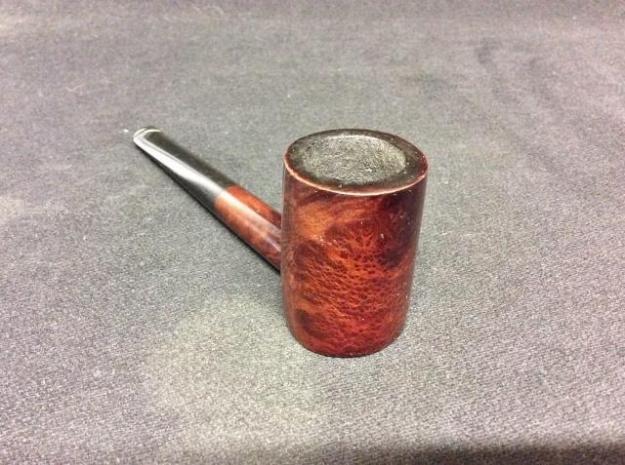

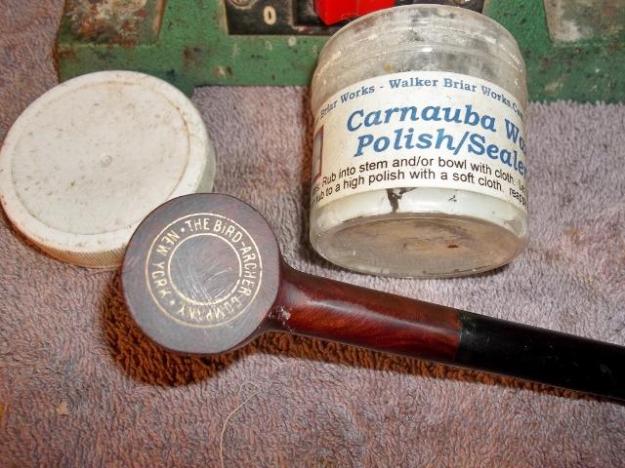

The Part begins with a brief description of the harvesting and curing of briar for the Falcon bowls. There are also production drawings and outcomes of the number of bowls that were turned in a given year. There is even a photo of a meerschaum lined briar bowl (that is one that I have never seen anywhere). The next section covers the manufacture of the base and stem for the pipe. It is a fascinating read and the pictures of the bases and the stamping is helpful in making sense of the various bases that I have. There are many different examples of Falcon bowls and bases throughout the section.

There is a section on the variations on the British scene in terms of Falcon shapes and sizes. Again the author includes many advertisements and photos. Also there is information on the Alco line and the Brentford line. I had heard about Falcon making the Alco pipes but I was unfamiliar with the Brentfords. There is information on the development of the coloured bowls and bases and the Shillelagh line coming out of Ireland. Several other Falcon lines that I was unfamiliar with end Part Two. Falcon produced a pipe with a pyrolitic graphite lined bowl, a filter version of the pipe and finally a line of pipe related products for the pipe smoker. These included finger pipe tampers (look like thimbles), dry rings for wet smokers, Falcon pipe spray pipe cleaner, matches, mix and match bowls, tobacco blends and much more.

Part Two is by far my favourite part of the book because it takes a lot of the various Falcon pipes that I have had in the shop and gives the background and rationale of the variations. The pictures and drawings as well as flyers etc. give a clear picture of the brand at its height.

The book ends with an Epilogue that pulls together all of the final pieces of the history of the company and the pipe.

It is a well written easy to read book. I would unhesitatingly recommend it to anyone wanting to know about the history and the variety of Falcon pipes and also those who may want a quick introduction before purchasing and enjoying a pipe. Well worth a read and many rereads. I refer to my copy whenever I am working on a Falcon to get a better idea of where it fits into the chronology of the brand. Buy it! You will not regret this great addition to pipe history.