Blog by Mike Leverette

As a pipe refurbisher who has worked on and restored many older Peterson pipes over the years and a researcher who likes to understand the brands of pipes I work on I have always been amazed at how little there is on the history of the brand. When I was working on one of the first Peterson pipes that came my way I remember writing then calling Mike Leverette and seeking his help in dating the little Pre-Republic pipe I had in hand. Mike directed me to this article of his on Pipelore.net and later sent me a copy of the piece he had written. It became my go to piece when seeking information on Petersons. Mike and some of his colleagues created the well-known ‘Peterson Pipe Project’ web site. Mike died in 2009, following a long battle with cancer. His work has been taken up by Mark Irwin and Gary Malmberg who are currently working on a book on entitled, The History of the Kapp & Peterson Company and their system pipes. According to the Briar Books Press website the book’s release has been pushed back to Christmas 2015. While we all wait for the publication of this work I am posting the article that Mike sent me many years ago now and dedicate it respectfully to my good friend Mike’s memory. Without further ado here is Mike’s article.

This guide first appeared in pipelore.net on August 26, 2006 by: Mike Leverette.

Introduction

The history of Ireland is an old and honourable one; steeped in warfare, family, racial and religious traditions. No other country can compete in comparison. However, the first couple of millennia of Irish history have no relevance to this dating guide. Should you wish to read more on the history of the Irish, I recommend “The Story of the Irish Race” by Seamus MacManus who gives a very vivid, and near as we can tell an accurate portrayal of their history.

History pertinent to our purposes began in the year 1865; the year Charles Peterson opened a small tobacco shop in Dublin. Later in 1875, Charles Peterson approached the Kapp brothers, Fredrich and Heinrich, with a new pipe design and with this, a very long-lived partnership was formed, Kapp & Peterson. This new pipe design is the now famous Peterson Patented System Smoking Pipe. By 1890, Kapp & Peterson was the most respected pipe and tobacco manufacturer in Ireland and rapidly gaining followers in England and America. In 1898 another of Peterson’s remarkable inventions became available, the Peterson-Lip (P-Lip) mouthpiece, also known as the Steck mouthpiece. So for the purpose of this dating guide, we will study Irish history, relevant to our pipe dating needs, from 1870s until now.

Before we start with this Peterson dating guide, an observation; the Kapp Brothers were making pipes as early as the 1850s and in many of the shapes we now associate with Peterson since the Kapp Brothers simply took their existing shapes and incorporated Charles Peterson’ s patented design into them. From their inception, Kapp & Peterson’s goal was to make a good smoking pipe that the ordinary, common working man could afford and we believe they have, very admirably, lived up to this.

Explanation of Title

The vagaries of Peterson’s processes do not allow for an accurate dating guide so this guide is a ‘rule-of-thumb’ guide only. For example; Peterson did not take up the old Country of Manufacture stamps as new ones were issued so depending on which one the various workers happen to pick up, the stamps can and do cross over the boundaries of the various Eras. Some of the pipes of the Sherlock Holmes Series of the 1980s have pre-Republic stamps, as well as other pipes produced in 2000. However, there will not be too many of these missed stamped pipes. For silver anomalies, see the section on silver marks.

Stamping of Bowls

During the years of Kapp and Peterson’s business operations, the country of Ireland has undergone several name changes and K&P’s stamping on their pipes reflects these changes. Knowing these changes, a Peterson pipe can be roughly dated and placed in “eras.”

• The Patent Era was between the years of K&P’s formation until the expiration of the patent; 1875 through approximately 1910. Though for our purposes we will list this era as 1875 through 1922. Peterson pipes made during the majority of this period had no “Country of Manufacture” (COM) stamped on them. However, later in this period, say around 1915/16, Peterson began stamping their pipes “Made in Ireland” in a block format.

• The Irish Free State was formed on 15 January 1922. So the Free State Era will be from 1922 through 1937. Peterson followed with a COM stamp of “Irish Free State” in either one or two lines, either parallel or perpendicular to the shanks axis and extremely close to the stem.

• Eire was formed on 29 December 1937. The Made in Eire Era will be from 1938 through roughly 1940? or 1941?. For dates with ?’s, see below. Peterson now stamped their pipes with “Made in Eire” in a circle format with “Made” and “Eire” in a circle with the “in” located in the center of the circle. This COM was used during the years of 1938 – 1940?/41?. Later they stamped their pipes with “Made in Ireland” in a circle format (1945?-1947?) and still later with “Made in Ireland” in a block format (1947?-1949). The “Made in Ireland” block format came in either one line or two lines.

• The Republic Era is from 1949 until the present. The Republic of Ireland was formed on 17 April 1949. From 1949 to present the stamp for this era is “Made in the Republic of Ireland” in a block format generally in three lines but two lines have been used with or without Republic being abbreviated.

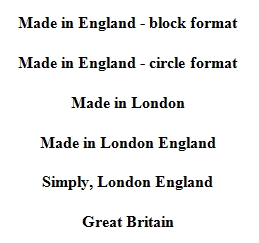

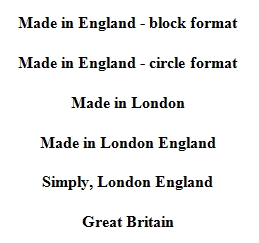

• English made Peterson pipes actually spans between the pre-Republic and Republic eras. In 1895, Peterson opened a shop in London England that lasted until the late 1950s or early 1960s. So the English Era, for a simplified date, will be from 1895 through 1959. The stamps Peterson used in London and that we have seen are:

Though there are a couple of more, the above will give one the general idea. We believe the earliest stamp of this era was the “Made in England” in a block format since Peterson was using the “Made in Ireland” block format at about the same time on their Irish production pipes. The “Made in England” circle format was used during the same time frame as the “Made in Eire” and “Made in Ireland” circle formats.

As one can see this is pretty straightforward but there have been inconsistencies within this method of stamping. Peterson was never very energetic in removing their old stamps from the work stations so the older stamps can and did cross-over into the newer Era’s.

The explanation for the question marks in the 1940’s dates is, during the Second World War briar was hard to come by for obvious reasons, so no one can say for sure what years Peterson produced briar pipes and how many briar pipes were produced in those years. Why the switch from “Made in Eire” to “Made in Ireland” is anyone’s guess since the country was still technically Eire until 1949. As a point of interest and due to the shortage of briar, Peterson did make clay and Bog Oak pipes during the war years though they had ceased clay pipe production in the Patent Era and Bog Oak production back in the early 1930s.

The “Made in Ireland” block format (above) can be another headache in dating Peterson pipes since this stamp was used in the late Patent Era as well as the late 1940s. So for a guide we must take into consideration the style of lettering Peterson used on their pipes. From the start of the Patent Era until somewhere in the early 1930s, Peterson used the “Old Style” lettering that used a forked tail “P” in Peterson.

The “Made in Ireland” block format (above) can be another headache in dating Peterson pipes since this stamp was used in the late Patent Era as well as the late 1940s. So for a guide we must take into consideration the style of lettering Peterson used on their pipes. From the start of the Patent Era until somewhere in the early 1930s, Peterson used the “Old Style” lettering that used a forked tail “P” in Peterson.

From then until now, Peterson used the more familiar script “P” (above) intermixed with a plain block letter “P.” Later in the 1970s, Peterson began production of “commemorative” pipes, often referred to as “replica” or “retro” pipes and these will also have the old style lettering but according to the pipes that we own and have seen, most of these will have a small difference in the original forked tail “P”. Again, there appears to be a cross-over with the old style forked tail and the later forked tail P’s (below). However, these commemorative pipes generally have a silver band with hallmarks so one can date these pipes by the hallmark.

From then until now, Peterson used the more familiar script “P” (above) intermixed with a plain block letter “P.” Later in the 1970s, Peterson began production of “commemorative” pipes, often referred to as “replica” or “retro” pipes and these will also have the old style lettering but according to the pipes that we own and have seen, most of these will have a small difference in the original forked tail “P”. Again, there appears to be a cross-over with the old style forked tail and the later forked tail P’s (below). However, these commemorative pipes generally have a silver band with hallmarks so one can date these pipes by the hallmark.

Also, we must address the stamp “A Peterson Product.” During the last few years of the Pre-Republic era and throughout the Republic era, Peterson began stamping their other lines, such as Shamrocks and Killarneys, with “A Peterson Product” over the COM stamp. So a pipe stamped thusly will have been made say from 1948 to the present with the COM stamp identifying it as a pre-Republic or a Republic pipe.

Also, we must address the stamp “A Peterson Product.” During the last few years of the Pre-Republic era and throughout the Republic era, Peterson began stamping their other lines, such as Shamrocks and Killarneys, with “A Peterson Product” over the COM stamp. So a pipe stamped thusly will have been made say from 1948 to the present with the COM stamp identifying it as a pre-Republic or a Republic pipe.

Silver Band Dating

Silver hallmarks are placed on the silver after an assay office, in Peterson’s case, the Dublin Assay Office, has verified that the silver content is indeed sterling, in other words 925 parts of silver per 1000 parts of the metal. The silver hallmarks on Peterson pipes are a group of three marks, each in an escutcheon; the first is a seated Hibernia denoting Dublin Ireland, the second is a harp denoting the silver fineness, and the third is a letter denoting the year. The style of letter and the shape of the escutcheon the letter is in, will determine the year in which the assay office stamped the metal band and not necessarily the year the pipe was made. Peterson orders these bands by the thousands and sends them to the assay office for hallmarking. The assay office will stamp the date of the year in which they received the bands and it may be a year or two or three before Peterson’s employees happen to place one of these bands on a pipe though generally the bands are placed on a pipe in the year they were stamped. The Dublin hallmarks can be found in any book on silver markings or on one of several web sites.

For the one year, 1987, the Dublin Assay Office added a fourth mark to commemorate the City of Dublin’s founding in 988. However, the Peterson pipes we have and have seen with silver dates of 1987 and 1988 generally do not have this fourth mark.

Here again, we must add a “maybe” to the above hallmarks. On 1 June 1976, certain countries attended an international conference on silver markings and decided to adopt an entirely different mark for sterling silver. This mark is an Arabian numeral, 925, located between the scales of a balance beam and in Peterson’s case may or may not have the Hibernia and Harp marks to either side. These particular pipes can only be said to date between 1976 and the present, and were stamped as such for shipment to the different countries involved in the conference. For pipes shipped to all other countries, Peterson still uses the old style hallmarks. Peterson pipes with a sterling silver band that does not have hallmarks could have been made for the United States market since the United States only requires sterling silver to be stamped “sterling silver” or “sterling.”

Before we close this section on silver hallmarks, we must address the marks that many people refer to as hallmarks. Peterson uses three marks on some of their pipes that are not silver hallmarks but are rather another Peterson logo (below). These marks are:

• A Shamrock for the many shamrocks found in Ireland

• A Prone Fox representing the famous fox hunts in Ireland’s history, and

• A Stone Tower for the many hundreds of stone towers spotted throughout Ireland

Again these are not genuine silver hallmarks:  Also many of the newer pipe smokers think that Kapp & Peterson’s official logo of “K&P,” each in a shield shaped escutcheon, are hallmarks but, of course, they are not. They are simply Kapp & Peterson’s initials.

Also many of the newer pipe smokers think that Kapp & Peterson’s official logo of “K&P,” each in a shield shaped escutcheon, are hallmarks but, of course, they are not. They are simply Kapp & Peterson’s initials.

Dating by Series

Dating by series or numbers is an area in which we are having a difficult time of establishing. For instance, the 300 series are all shapes used during the Patent Era and we believe Peterson started using this number system when the original patent expired. In the case of the 300 series and without looking at the COM stamp or silver hallmark, one can only say that they were made between 1910 and today. The 300 series was not in Peterson’s 1905 catalogue.

Though we are still trying to find the start dates of many series, here are some that we are pretty positive about:

• Centennial Edition – 1975 (for K&P’s Centennial)

• Great Explorers Series – 2002

• Harp Series – 2002

• Mark Twain Numbered Edition – 1979 (numbered 1 through 400)

• Mark Twain 2nd Numbered Edition – 1981 (numbered 1 through 1000) Mark Twain Un-numbered Edition – 1983 to c1989 (There must be a fourth production of Mark Twain pipes for there a couple of men who own Mark Twain pipes with a silver date of 1998; we are still trying to pin down the dates of this fourth production.)

• Emerald – c1985 to 2003

• Millennium Edition – 1988 (for the City of Dublin’s founding)

• Sherlock Holmes Series – 1987 to c1989

• Return of Sherlock Holmes Series – c1991

• Sherlock Holmes Meerschaums – 2006

Peterson Clay, Bog Oak and Cherry Wood Pipes

Peterson Clay, Bog Oak and Cherry Wood pipes were offered in the Patent Era with or without a formed case, as also offered with their briar and meerschaum pipes.

Peterson made clay pipes during the Patent Era with only two shapes being offered and depicted in their 1905 catalogue. During this period their clay pipes were stamped/moulded “Peterson Patent” and could be purchased with either a silver or nickel band. How long and in what years Peterson made these clays is not known but as stated above two shapes were offered in their 1905 catalogue. Then during World War II, Peterson again made clay pipes due to the understandable shortage of briar. The clays of this period are stamped “Peterson System” and were only offered with nickel bands. This later production of clay pipes ended with the closing of Peterson’s London Shop in the late 1950s or early 1960s.

Also during World War II, Peterson again made bog oak pipes and again, this was due to the shortage of briar. They had previously ceased production of bog oak pipes in the 1930s during the Irish Free State Era. On the subject of bog oak pipes, Peterson’s bog oaks will always have a metal band with either amber (early production only) or vulcanite stems and will have the appropriate COM stamp. As with their clay pipes, Peterson offered a silver or nickel band on their early bog oak pipes of the Patent Era and just a nickel band on their WWII bog oak pipes.

Peterson made pipes of cherry wood during their Patent Era in both the smooth finish and the bark-left-on finish; and as with their clay pipes, Peterson used both amber and vulcanite stems and choice of silver or nickel bands. And like their clay pipes of the Patent Era, the introduction and termination dates are not known. Peterson Cherry Wood pipes were offered with or without a meerschaum lining.

Metal Ferrules of Military Mounted Pipes

As pipes get older, wear will, with all the handling, cleaning and polishing, take its toll on the nomenclature which will eventually disappear, thus, making it harder to determine the age of your Peterson. A good thorough cleaning of old hand oils, dirt and ash will sometimes bring out a faint outline of the nomenclature but sometimes the nomenclature has completely worn away and even this cleaning will not bring it back. So where do we go from here to determine the pipe’s age? The shape of the metal ferrule on Peterson pipes with the military mount will give you some hint though not a precise date.

During the Patent Era, the metal ferrules of Peterson military mounts will have a more ‘acorn-ish’ shape, that is, the bend will have a larger radius as it turns down to meet the stem. This larger radius gradually (?) changes to a smaller radius, more abrupt bend, during the Irish Free State Era and even more abruptly after World War Two when the bend takes on the modern day shape.

The metal ferrules on Peterson clay pipes during the Patent Era are angular while their clay pipes of World War Two will have the bend shape as do most of the Peterson pipes from then until now.

As with everything pertaining to the dating of Peterson pipes, this method can only give us a hint to the age of the pipe but it is better than nothing at all. The years of these changes in the metal ferrule shape are, we are sure, lost to the ages. However, someone with a larger number of Peterson pipes than we may be able to check the silver dates for more precise age boundaries. Well, this is a very short dating guide and we hope that you will be able to date more accurately your favourite Peterson with this information.

Oh, I beseech you; do believe me when I confess that before doing so I attempted to cover up my evil act with multiple layers of yellow and orange marker ink and Super Glue, which surgery proved fruitless, as all can see from this hideous disfigurement committed by yours truly. I can now only plead that in my Godforsaken state of pride and arrogance I believed I could re-animate that which I knew was dead. Thus the poor monster appeared before the sparkling eyes of the master, Chuck. To my great combination of horror and expectation, he seemed amused, and so I chose to have the satisfaction of describing the facts as I imagined them before he could state them himself.

Oh, I beseech you; do believe me when I confess that before doing so I attempted to cover up my evil act with multiple layers of yellow and orange marker ink and Super Glue, which surgery proved fruitless, as all can see from this hideous disfigurement committed by yours truly. I can now only plead that in my Godforsaken state of pride and arrogance I believed I could re-animate that which I knew was dead. Thus the poor monster appeared before the sparkling eyes of the master, Chuck. To my great combination of horror and expectation, he seemed amused, and so I chose to have the satisfaction of describing the facts as I imagined them before he could state them himself.

No doubt the Reader can see the many reasons why this hunk of briar, despite its likely latent lineage, might not be conducive to preparation for the average pipe smoker’s, or, dare I say it, even restorer’s viewing without extreme measures. Yet just such extremities did I have in mind to make this once fair Hilson born of a line of solid stock starting in Germany and traveling to Belgium and lately found in Denmark under another owner.

No doubt the Reader can see the many reasons why this hunk of briar, despite its likely latent lineage, might not be conducive to preparation for the average pipe smoker’s, or, dare I say it, even restorer’s viewing without extreme measures. Yet just such extremities did I have in mind to make this once fair Hilson born of a line of solid stock starting in Germany and traveling to Belgium and lately found in Denmark under another owner.

Alas, the mishmash of grains still shone through. I have made a few attempts with pipes that had far less reason to conceal the visages of their fearsome, uncomely wood entirely with black stain, all of which met with disaster due to various problems, most of them being the necessity for a baby smooth surface. This time, however, I had overcome that hindrance and set out to try again, with satisfactory results. The only difference was that I mixed equal parts of black and maroon stains, then re-buffed, to this initial end.

Alas, the mishmash of grains still shone through. I have made a few attempts with pipes that had far less reason to conceal the visages of their fearsome, uncomely wood entirely with black stain, all of which met with disaster due to various problems, most of them being the necessity for a baby smooth surface. This time, however, I had overcome that hindrance and set out to try again, with satisfactory results. The only difference was that I mixed equal parts of black and maroon stains, then re-buffed, to this initial end.

True, this was a far cry better than where I started, but not quite what I was looking for. I was deathly afraid of taking the next step in trepidation of doing something I have already done enough to know better: taking one step beyond the edge and ending up ass over teakettle. So call me what you will – a madman, a reckless fool, yes, sling whatever epithets you will at me, but I did what my conscience bade me and gave the bowl a whirl of Red Tripoli with another, light coat of carnauba.

True, this was a far cry better than where I started, but not quite what I was looking for. I was deathly afraid of taking the next step in trepidation of doing something I have already done enough to know better: taking one step beyond the edge and ending up ass over teakettle. So call me what you will – a madman, a reckless fool, yes, sling whatever epithets you will at me, but I did what my conscience bade me and gave the bowl a whirl of Red Tripoli with another, light coat of carnauba.