While searching the web for information on Bakelite I came across this very interesting article on vulcanite, Bakelite and Casein that were all used at some point in history in making pipes and pipe stems. The link for the article, that includes the photos used to illustrate the various pipes are included is shown below: http://pipeacademy.org/pdf/publications/AIP%20Publication%20PDFS/2001%20Pipe%20Year%20Book,%20de%20Haan%20searchable.pdf

I have edited the article and posted it here without the photos that were used in the original piece. I have not found this concise a description of the materials anywhere else. Thank you Ronald J. de Haan for your excellent research.

This article is an attempt to draw attention to a very interesting field within the area of smoking collectibles. Many collectors of tobacco articles know something about many smoking accessories made out of synthetic material, like ashtrays, match-holders and cigar-cases.

In general though, there is very little knowledge about pipes made out of synthetic material, like hard rubber and other early plastics. Pipes (bowl and stem) that are completely made out of synthetic material are quite rare. This is not surprising, because synthetic material is less heat resistant during smoking, than traditional materials such as meerschaum, clay or briar.

The use of hard rubber for the production of pipes did not come as the result of long research; but is the result of the discovery of vulcanisation in 1839, which increased the applications for rubber enormously.

The introduction of rubber

Rubber is a natural product extracted from the rubber tree, Hevea brasiliensis. The bark of the tree is cut in a controlled way, as not to disrupt the flow of sap so the tree will survive. The milk-like, syrupy substance is known under several names. In the Amazon area the inland name for rubber tree is Cahucha (weeping tree). This word lives on in the French Caoutchouc and the German Kautschuk, both meaning rubber. The name rubber dates from the mid 18th century and was introduced by the famous British theologian and scientist Joseph Priestly.

The story of rubber in the western world begins at the end of the 15th century. On his second journey to America, Christopher Columbus visited the island of Haiti and saw children playing with elastic balls. The material was introduced in Europe as a toy. For the next centuries its application was limited.

In 1731 the French Charles de la Condamine, during a surveyor-expedition in Peru discovered that the local inhabitants used rubber to make their clothing waterproof. They also made shoes and bottles by pulling the material around moulds and letting the rubber harden in the sun or above a fireplace.

The British Thomas Hancock experimented in 1820 with forming rubber by mechanical power after heating the material, which resulted in the first waterproof rain clothes, made by Charles Mackintosh. It was the American Charles Goodyear who patented in 1839 the process of stabilising rubber with the help of sulfur, which is called the vulcanization process.

The vulcanization process

By vulcanising the rubber for a longer time and by adding a larger percentage of sulfur (up to 50%) the product became harder. The result was a new material. It was the first half synthetic plastic made out of a natural product changed by a controlled chemical process.

This new material is known by several names, depending on the production or the appearance: ebonite, because it looks like ebony; vulcanite because of the process of heating, referring to the Roman god Vulcan; hard rubber, which speaks for itself.

One of the first patents by Goodyear states that the new material was used in the production of pipe stems, an application that proved to be very suitable because the material was easy to mould. This hard rubber, though not the most suitable material for pipe-bowls, was used for the production of complete pipes until the 20th century, undoubtedly because of the ease of doing the detailed work. In order to prevent the bowls from melting or burning away, it was necessary to place inserts of meerschaum, briar or clay in the bowl of the tobacco pipe. Cigar and cigarette holders however, were produced without an insert because it was not necessary.

Two other synthetic materials have to be mentioned in this article, because they have been used extensively in the production of pipes, sometimes in combination with hard rubber. These two materials are casein and Bakelite.

Casein

Casein, in full casein-formaldehyde, consists as the name suggests of an important part of the milk protein. Casein can be extracted from skimmed milk with a specific enzyme. By exposing the kneadable doughy substance to the liquid formaldehyde for days or even weeks a new material emerges, which will not melt, even at high temperatures.

It is a so-called thermosetting synthetic material, like rubber (semi-synthetic). The patent for the production of this material dates from 1899 and belonged to the Germans Krische and Spitteler. They called the new material Galalith. Later it became known also as Erinoid, Ameroid and Kasolid. Casein can be coloured easily. A drawback of the material is its sensitiveness to liquid. Long-term exposure to liquid makes the material crack.

The pipe-making industry used the material widely till after the Second World War for the production of cigarette pipes (pipettes), as it could easily be pierced, turned or modeled. The long Charleston cigarette pipes of the 1920’s are made of casein.

Bakelite

Bakelite, officially phenol-formaldehyde, is regarded as the first fully synthetic material. The Belgian born Leo Baekeland invented it in the United States. He succeeded in controlling the long known heavy chemical reaction between phenol and formaldehyde. Controlled high temperature and high-pressure, formed the basis for his patent which he obtained in 1907. The result of the chemical reaction is an amber-coloured resin. Mixed with filling material like sawdust, asbestos or textile fibres the result, after pressing, is a hard thermosetting synthetic material. The most important qualities of this material are its insulation for electricity, its solidity and the possibility of use in mass production.

These qualities made Bakelite the most successful synthetic material in the first half of the 20th century. From 1928 it was also produced as moulded resin. Both the pressed and the moulded forms were suitable for the pipe making industry. Pipes were made from Bakelite and moulded phenol-resin. Complete pipes of Bakelite are very rare because of its lack of heat resistance. Phenol-resin however was frequently used for pipe mouthpieces and cigarette holders because it imitated amber.

Literature

Cool, Patrick and Sessor, Catherine, Bakeliet, Helmond 1993

Engelen, Jos, De Meerschuimpijp, in: Pijpologische Kring Nederland, 20″c jaargang nr, 80 (1988), page 998

Katz, Sylvia, Early Plastics, Shire Publication nr, 168 (1986)

Perree, Rob, Bakelite, Amsterdam 1996

Tymstra, Fred, Bakelieten pijpen met stenen potje, in: Pijpelogische Kring Nederland, 16° jaargang nr, 63, page 566-572 (1993)

Woshner, Mike, India-Rubber and Gutta Percha in the Civil War Era, z.pl., z.j.

Catalogues

Smokers Articles and Walking Canes and Miscellaneous Goods, The Novelty Rubber Co., New York 1877

Price Current, Goodyear’s Rubber MFG Co. And Goodyear’s I.R. Clove MFG Co., New York 1880

Pipes and smokers Articles, Zorn & Co

George, Philadelpia 1892 (reprint by Paul Jung Jr., 1989)

Catalogue General, Bessard-Pignol Gustave, Clermont Ferrand 1894

With special thanks to:

Richard Schoevaart, Amsterdam, Karelloeff, Laren, Jacques Bergmans, Weert.

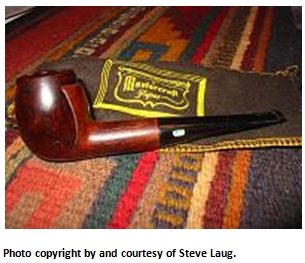

The pipe was in remarkable shape for its age. It was not caked up and the pipe was nice and clean, ready to smoke. All I did was go over it very lightly with some 2500 grit and 000 steel wool over the banding lightly. Then I applied some light buffing and a new coat of wax. The pipe was too original to mess with much .The stem has a gorgeous red color that was bought out with a little brown and then white Tripoli before waxing.

The pipe was in remarkable shape for its age. It was not caked up and the pipe was nice and clean, ready to smoke. All I did was go over it very lightly with some 2500 grit and 000 steel wool over the banding lightly. Then I applied some light buffing and a new coat of wax. The pipe was too original to mess with much .The stem has a gorgeous red color that was bought out with a little brown and then white Tripoli before waxing.

The stampings are very nice for a 100 year old pipe. As you can see it looks like it was repaired once. The repair looks quite old in person and don’t think it was done anytime recently.

The stampings are very nice for a 100 year old pipe. As you can see it looks like it was repaired once. The repair looks quite old in person and don’t think it was done anytime recently.

It’s a smaller poker. It is in between the size of a Medico Poker and a Dr.Grabow 85 Poker. It’s around 4 11/16 inch long with a 1 1/2 tall bowl. I will probably dedicate it to my new favorite flake tobacco.

It’s a smaller poker. It is in between the size of a Medico Poker and a Dr.Grabow 85 Poker. It’s around 4 11/16 inch long with a 1 1/2 tall bowl. I will probably dedicate it to my new favorite flake tobacco.