Blog by Paresh Deshpande

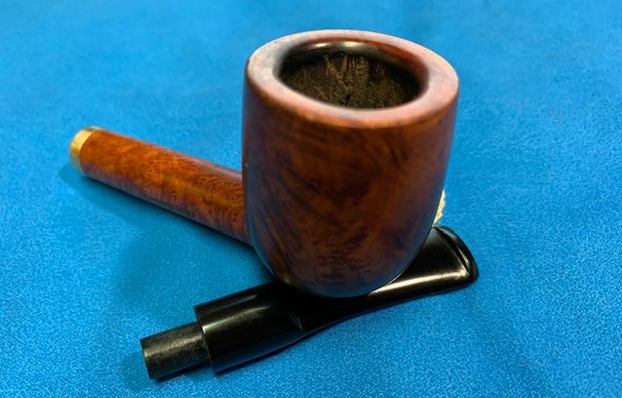

While surfing eBay for estate pipes, I came across this one ‘no name’ pipe with a horn stem and beautiful flowing calabash shape. The beautiful curvy shape apart, the pipe had some really hideous (IMHO) rustication on the stummel surface, a semblance of widely spaced scales with thin vertical lines. The perfect shape and spacing of the scales over the stummel surface points to machined and not hand crafted rustications. Notwithstanding the rustications on the stummel, I fell in love with the pipe and had already chalked out a plan for its transformation even before I had won the auction. As I had expected, there was only a couple of other bids and the pipe soon made its way to me. A month and a half later, the pipe had reached me and now it is on my work table.

As mentioned by the seller, the stummel and the stem are devoid of any stampings and there is absolutely no clue for me to establish the provenance of this beautiful pipe. However, the threaded bone tenon, horn stem and round orifice are indicative of this pipe being from the period 1900s to 1950s. It would be interesting if further light could be shed on this pipe as regards its origin, vintage etc by the esteemed readers of rebornpipes.

Initial Visual Inspection

The first thing one can notice is the lovely shape of the pipe and the second is its ultra light weight. The chamber has been neatly reamed and the rim top surface is devoid of any lava overflow. There is severe charring to the inner edge in 12 o’clock direction. There are a couple of minor tooth indentations in the bite zone of the otherwise pristine stem. The stem is overturned to the right and not in alignment with the shank/ stummel. The stummel is dirty, dull and lifeless to look at. Overall, it is in decent condition as can be seen from the pictures below.

Dimensions Of The Pipe

Dimensions Of The Pipe

(a) Overall length of the pipe: – 5 3/4 inches.

(b) Bowl height: – 1.5 inches.

(c) Inner diameter of chamber: – 0.7 inches

(d) Outer diameter of chamber: – 1.3 inches

Once The Pipe Is On My Work Table……

It appears that an attempt has been made to refurbish this pipe, but for reasons best known to the previous restorer, it was abandoned. Save for a little dust and soot, the chamber is nicely reamed back to the bare briar. The chamber walls, though not very thick, are without any heat fissures or pits and that’s a big relief. The rim top surface is peppered with numerous minor hairline scratches. The inner rim edge shows severe charring at 12 o’clock direction (encircled in yellow) and it extends over more than half way towards the outer edge. There is a smooth band of briar wood below and adjoining the outer rim edge. There are no ghost smells in the chamber. Addressing the charred inner rim edge is going to be tricky as the topping required would be extensive to the extent that the profile of the stummel and pipe as a whole, would be considerably altered. I would top the rim surface well within the limits of the smooth briar band below the outer rim edge and up to the point where I reach solid, albeit darkened briar. I would, thereafter polish it and attempt to blend the darkened areas by a applying a dark stain to the rest of the rim top surface.

The stummel surface is without any damage. There is dust and dirt embedded in to the rusticated nooks and crannies giving the briar an old and lifeless look. The patterned scaled rustications also do not help in the overall appearance of the stummel. The mortise is threaded into which seat the threaded bone tenon of the stem and appears to be clean. I plan on complete rustication of the stummel and thereafter contrast staining with black and brown stains. The only issue I need to keep in mind is that the walls of the stummel are not very thick and thus I need to be cautious least I end up gouging too deep into the chamber wall.

The stummel surface is without any damage. There is dust and dirt embedded in to the rusticated nooks and crannies giving the briar an old and lifeless look. The patterned scaled rustications also do not help in the overall appearance of the stummel. The mortise is threaded into which seat the threaded bone tenon of the stem and appears to be clean. I plan on complete rustication of the stummel and thereafter contrast staining with black and brown stains. The only issue I need to keep in mind is that the walls of the stummel are not very thick and thus I need to be cautious least I end up gouging too deep into the chamber wall.

The tapered horn stem is clean with no major issues. The upper stem surface has a couple of minor bite marks at the base of the button and also over the button edge. The lower surface has some minor tooth indentations in the bite zone. The button edges on both the surfaces need to be sharpened. The round orifice and the tenon end are clean.

The tapered horn stem is clean with no major issues. The upper stem surface has a couple of minor bite marks at the base of the button and also over the button edge. The lower surface has some minor tooth indentations in the bite zone. The button edges on both the surfaces need to be sharpened. The round orifice and the tenon end are clean. The seating of the stem in to the mortise is overturned to the right by a huge margin and is very loose. This would need something more permanent than the clear nail polish coat application. The following pictures will give the readers a correct perspective of the issue.

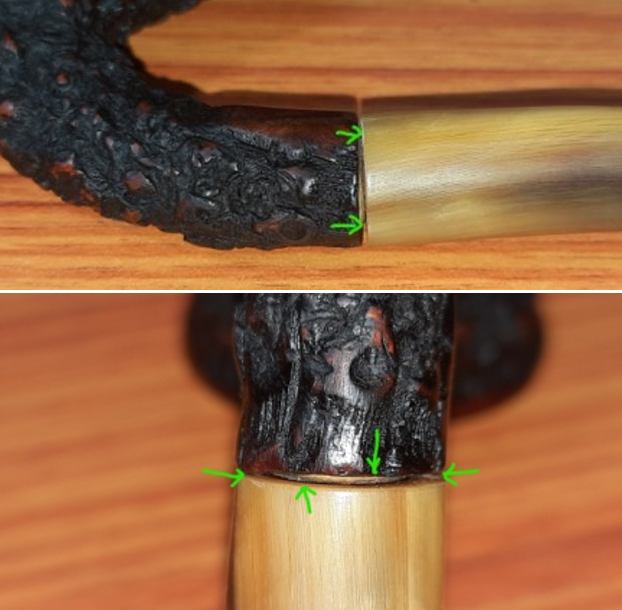

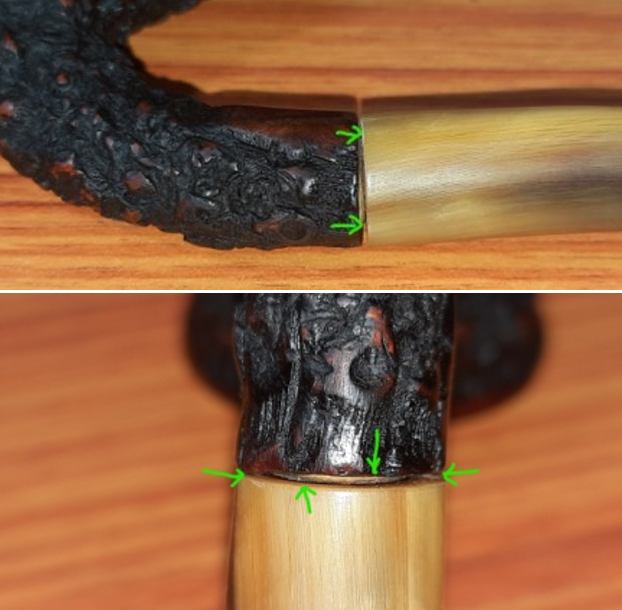

The seating of the stem in to the mortise is overturned to the right by a huge margin and is very loose. This would need something more permanent than the clear nail polish coat application. The following pictures will give the readers a correct perspective of the issue. The Process

The Process

The process of transforming this pipe began with cleaning the chamber that had been reamed and cleaned before it reached me. With my fabricated knife, I completely removed the dust and little residual carbon from the walls of the chamber. I further cleaned the walls with a folded piece of 220 grit sand paper to completely remove the carbon from the walls and wiped the chamber with a cotton pad and alcohol. The charred surface at the inner rim edge was also gently scraped with the knife and sandpaper to remove the burnt briar till I reached solid briar underneath.

Next, I cleaned the mortise and shank with regular and bristled pipe cleaners dipped in alcohol. At first I just could not get the pipe cleaner to pass through the mortise and out through the draught hole. I then inserted the pipe cleaner through the draught hole and with some efforts; it came out through the mortise dislodging some dried gunk from the air way as it came out. Other than the stuck dried gunk, the mortise was clean and just a couple of pipe cleaners were put to use. I was particularly deliberate in cleaning the threads in the mortise in preparation of further repairs to improve the seating of the threaded tenon, the process for which will be covered subsequently.

Next, I cleaned the mortise and shank with regular and bristled pipe cleaners dipped in alcohol. At first I just could not get the pipe cleaner to pass through the mortise and out through the draught hole. I then inserted the pipe cleaner through the draught hole and with some efforts; it came out through the mortise dislodging some dried gunk from the air way as it came out. Other than the stuck dried gunk, the mortise was clean and just a couple of pipe cleaners were put to use. I was particularly deliberate in cleaning the threads in the mortise in preparation of further repairs to improve the seating of the threaded tenon, the process for which will be covered subsequently. After I was done with the internal cleaning of the stummel, I cleaned the external surface. I generously applied Murphy’s oil soap with a hard bristled tooth brush and scrubbed the stummel and rim top with the soap. I washed the stummel under running warm water with anti oil dish washing detergent and brass wired brush till the stummel surface was clean and dried it using paper towels and soft cotton cloth. The rim top surface was deliberately cleaned with a Scotch Brite pad to further remove the charred wood from the rim edge. I simultaneously cleaned the shank internals with the detergent and hard bristled shank brush. The stummel surface has cleaned up nicely with the scaly and thin lined rustication plainly visible. Truth be told, the stummel now appear more dull and unattractive to my eyes!

After I was done with the internal cleaning of the stummel, I cleaned the external surface. I generously applied Murphy’s oil soap with a hard bristled tooth brush and scrubbed the stummel and rim top with the soap. I washed the stummel under running warm water with anti oil dish washing detergent and brass wired brush till the stummel surface was clean and dried it using paper towels and soft cotton cloth. The rim top surface was deliberately cleaned with a Scotch Brite pad to further remove the charred wood from the rim edge. I simultaneously cleaned the shank internals with the detergent and hard bristled shank brush. The stummel surface has cleaned up nicely with the scaly and thin lined rustication plainly visible. Truth be told, the stummel now appear more dull and unattractive to my eyes!

Once the internals and the external surface of the stummel had been cleaned, I progress to rusticating the stummel. To rusticate, I firmly held the stummel in my left hand and using my right hand began gouging out the briar with my fabricated rusticating tool. The technique is to firmly press the pointed four prongs of the modified Philips screwdriver into the surface, rotate and gouge out the removed chunk of briar. I worked diligently till I was satisfied with the rustications and the appearance of the stummel. I was careful to avoid gouging too deep as the walls are not very thick and I feared that deep rustications will lead to further thinning of the walls and subsequent burn out. As I reviewed the rusticated stummel, the rustication is prominent while the thickness of the wall is not compromised at all. I am very pleased with the progress thus far.

Once the internals and the external surface of the stummel had been cleaned, I progress to rusticating the stummel. To rusticate, I firmly held the stummel in my left hand and using my right hand began gouging out the briar with my fabricated rusticating tool. The technique is to firmly press the pointed four prongs of the modified Philips screwdriver into the surface, rotate and gouge out the removed chunk of briar. I worked diligently till I was satisfied with the rustications and the appearance of the stummel. I was careful to avoid gouging too deep as the walls are not very thick and I feared that deep rustications will lead to further thinning of the walls and subsequent burn out. As I reviewed the rusticated stummel, the rustication is prominent while the thickness of the wall is not compromised at all. I am very pleased with the progress thus far.

I cleaned the stummel surface with a brass wired wheel brush mounted on a handheld rotary tool. While cleaning the surface of all the debris, this rotating brass brush wheel also creates subtle patterns of its own and this adds an additional dimension to the appearance of the stummel.

I cleaned the stummel surface with a brass wired wheel brush mounted on a handheld rotary tool. While cleaning the surface of all the debris, this rotating brass brush wheel also creates subtle patterns of its own and this adds an additional dimension to the appearance of the stummel.

I sanded down the jagged high points in the rustication to a smooth and even surface using a worn out piece of 150 grit sand paper without compromising on the tactile feel to the hand.

I sanded down the jagged high points in the rustication to a smooth and even surface using a worn out piece of 150 grit sand paper without compromising on the tactile feel to the hand.

Next I decided to work on the damage to the rim top and inner rim edge. I topped the rim on a piece of 220 grit sand paper, checking frequently till I was satisfied that the darkened surface is addressed to an acceptable extent without compromising on the stummel profile and the rim top surface is nice, smooth and even. The darkened rim is still evident but the briar in this area is nice and solid and so I shall leave it be.

Next I decided to work on the damage to the rim top and inner rim edge. I topped the rim on a piece of 220 grit sand paper, checking frequently till I was satisfied that the darkened surface is addressed to an acceptable extent without compromising on the stummel profile and the rim top surface is nice, smooth and even. The darkened rim is still evident but the briar in this area is nice and solid and so I shall leave it be.  All this while that I was working on the stummel, Abha quietly worked on the stem. She cleaned the stem internals with regular and bristled pipe cleaners dipped in alcohol. It didn’t take many pipe cleaners to get the stem air way clean.

All this while that I was working on the stummel, Abha quietly worked on the stem. She cleaned the stem internals with regular and bristled pipe cleaners dipped in alcohol. It didn’t take many pipe cleaners to get the stem air way clean. Next she sanded the stem surface with a 320 grit paper. This addressed the minor tooth indentations and bite marks on either surface in the bite zone. She progressively moved to polishing the stem through 400, 600, 800 and 1000 grit sand paper. She finished the stem refurbishing by wet sanding the stem with 1500 to 12000 grit micromesh pads. She rubbed a little Extra Virgin Olive oil into the stem surface to hydrate it and set it aside to be absorbed into the bone.

Next she sanded the stem surface with a 320 grit paper. This addressed the minor tooth indentations and bite marks on either surface in the bite zone. She progressively moved to polishing the stem through 400, 600, 800 and 1000 grit sand paper. She finished the stem refurbishing by wet sanding the stem with 1500 to 12000 grit micromesh pads. She rubbed a little Extra Virgin Olive oil into the stem surface to hydrate it and set it aside to be absorbed into the bone.

Next I polished the rim top and the high spots in the rustication using micromesh pads, wet sanding with 1500 to 12000 grit pads. I wiped the bowl with a moist cloth after each pad to clean the surface. I am happy with the appearance of the stummel at this point in the restoration. The stummel is now ready for a fresh coat of stain.

Next I polished the rim top and the high spots in the rustication using micromesh pads, wet sanding with 1500 to 12000 grit pads. I wiped the bowl with a moist cloth after each pad to clean the surface. I am happy with the appearance of the stummel at this point in the restoration. The stummel is now ready for a fresh coat of stain. I wanted to highlight the difference between the rusticated and the smooth stummel surface. I decided to stain the rusticated surface with a black dye which would contrast beautifully with the browns of the rim top and the raised knobs of the rustications. I heated the rusticated portion of the stummel surface with my heat gun to open up the pores on the stummel so that the stain is well absorbed. I used Fiebing’s Black Leather dye and liberally applied it over the heated surface, flaming it with a lighter as I went ahead to different self designated zones on the surface. This helps in the setting of the stain in the grain of the briar. I ensured that every inch of the rusticated surface is coated with the dye. I immediately followed it by wiping the raised portions of the rustication with cotton pad and alcohol to lighten the knobs. Once polished, these will contrast with the black of the rest of the stummel surface. I set the stummel aside overnight for the dye to set into the briar surface.

I wanted to highlight the difference between the rusticated and the smooth stummel surface. I decided to stain the rusticated surface with a black dye which would contrast beautifully with the browns of the rim top and the raised knobs of the rustications. I heated the rusticated portion of the stummel surface with my heat gun to open up the pores on the stummel so that the stain is well absorbed. I used Fiebing’s Black Leather dye and liberally applied it over the heated surface, flaming it with a lighter as I went ahead to different self designated zones on the surface. This helps in the setting of the stain in the grain of the briar. I ensured that every inch of the rusticated surface is coated with the dye. I immediately followed it by wiping the raised portions of the rustication with cotton pad and alcohol to lighten the knobs. Once polished, these will contrast with the black of the rest of the stummel surface. I set the stummel aside overnight for the dye to set into the briar surface.  The following day, I again wiped the stummel with a cotton swab and alcohol to remove any excess stain and followed it up by sanding the raised rustication with a folded piece of 320 grit sand paper. This was followed up by careful dry sanding of the entire stummel, especially the raised rustications with 1500 to 12000 grit micromesh pads. This lightens and highlights the high spots in the rustications. Next, I rubbed a small quantity of “Before and After Restoration Balm” in to the briar with my finger tips, working it deep into the rustications and let it rest for a few minutes. The balm almost immediately works its magic and the briar now has a nice vibrant appearance over the smooth surface with the beautiful rusticated patterns on full display. I further buffed it with a horse hair shoe brush.

The following day, I again wiped the stummel with a cotton swab and alcohol to remove any excess stain and followed it up by sanding the raised rustication with a folded piece of 320 grit sand paper. This was followed up by careful dry sanding of the entire stummel, especially the raised rustications with 1500 to 12000 grit micromesh pads. This lightens and highlights the high spots in the rustications. Next, I rubbed a small quantity of “Before and After Restoration Balm” in to the briar with my finger tips, working it deep into the rustications and let it rest for a few minutes. The balm almost immediately works its magic and the briar now has a nice vibrant appearance over the smooth surface with the beautiful rusticated patterns on full display. I further buffed it with a horse hair shoe brush.

The only issue that remains unaddressed at this stage is the issue of loose and overturned seating of the stem into the mortise. I had the option of using the clear nail polish to tighten the seating but that would have been a temporary solution as the threaded bone tenon was way too loose fitting in to the mortise and no amount of smoking would have tightened the mortise to the required extent and hence was dropped. I decided on using CA superglue for the purpose. I applied a coat of superglue over the threads of both the mortise and tenon and let it set for a few seconds. Thereafter, I threaded the tenon in to the mortise till the stem was perfectly aligned and again held it in place for a few seconds for the superglue to take the shape of the threads. I repeated the process once over and achieved a perfectly aligned and snug seating of the stem in to mortise.

The only issue that remains unaddressed at this stage is the issue of loose and overturned seating of the stem into the mortise. I had the option of using the clear nail polish to tighten the seating but that would have been a temporary solution as the threaded bone tenon was way too loose fitting in to the mortise and no amount of smoking would have tightened the mortise to the required extent and hence was dropped. I decided on using CA superglue for the purpose. I applied a coat of superglue over the threads of both the mortise and tenon and let it set for a few seconds. Thereafter, I threaded the tenon in to the mortise till the stem was perfectly aligned and again held it in place for a few seconds for the superglue to take the shape of the threads. I repeated the process once over and achieved a perfectly aligned and snug seating of the stem in to mortise.  It was at this juncture that a new issue came to the fore as I was taking pictures of the stem and shank junction under magnification. The green arrows tell the story!

It was at this juncture that a new issue came to the fore as I was taking pictures of the stem and shank junction under magnification. The green arrows tell the story! Closer inspection revealed that the cause of this gap was the uneven shank end and the tenon was not flush with the stem face (which by the way is also not perfectly shaped). The gap was more on the lower surface than the upper. To address these issues, I firstly topped the shank face on a piece of 220 grit sandpaper till it was even. I was extremely careful while topping so that there was minimum loss of briar as the tenon was already slightly long and I had no desire to increase this gap any further. Secondly, I bridged the gap between the shank face and stem by using a brass band. This also added a nice touch of bling to the entire pipe. I like the way the pipe has shaped up.

Closer inspection revealed that the cause of this gap was the uneven shank end and the tenon was not flush with the stem face (which by the way is also not perfectly shaped). The gap was more on the lower surface than the upper. To address these issues, I firstly topped the shank face on a piece of 220 grit sandpaper till it was even. I was extremely careful while topping so that there was minimum loss of briar as the tenon was already slightly long and I had no desire to increase this gap any further. Secondly, I bridged the gap between the shank face and stem by using a brass band. This also added a nice touch of bling to the entire pipe. I like the way the pipe has shaped up.

To complete the restoration, I first mounted a cotton cloth buffing wheel that is dedicated for use with Blue Diamond, onto my hand held rotary tool. I set the speed at about half of the full power and polished the stem. The Blue Diamond compound helps to erase the minor scratches that are left behind even after micromesh polishing cycle and followed it by applying several coats of carnauba wax with a cotton cloth buffing wheel dedicated to Carnauba Wax. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to deepen the shine further. The finished pipe looks amazingly beautiful and has undergone quite a transformation. With its perfectly balanced weight, a nice full bent shape and light weight, this is a perfect pipe for clenching while working. This is one pipe that will I feel will not disappoint either aesthetically or functionally. In case this beauty calls out to you, please let me know and we shall work out a mutually beneficial deal.

To complete the restoration, I first mounted a cotton cloth buffing wheel that is dedicated for use with Blue Diamond, onto my hand held rotary tool. I set the speed at about half of the full power and polished the stem. The Blue Diamond compound helps to erase the minor scratches that are left behind even after micromesh polishing cycle and followed it by applying several coats of carnauba wax with a cotton cloth buffing wheel dedicated to Carnauba Wax. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to deepen the shine further. The finished pipe looks amazingly beautiful and has undergone quite a transformation. With its perfectly balanced weight, a nice full bent shape and light weight, this is a perfect pipe for clenching while working. This is one pipe that will I feel will not disappoint either aesthetically or functionally. In case this beauty calls out to you, please let me know and we shall work out a mutually beneficial deal.

I wish to thank our esteemed readers for sparing their valuable time to read through and any input or advice is always welcome. And how can I not thank Abha, my wife for her patient efforts in imparting glass like finish to the stem and rim top surface!

I wish to thank our esteemed readers for sparing their valuable time to read through and any input or advice is always welcome. And how can I not thank Abha, my wife for her patient efforts in imparting glass like finish to the stem and rim top surface!

Praying for the safety and well being of you and yours…stay home, stay safe and get your vaccines please.

In the photo of the poured out bag on my desk top I have circled the pipe that is next on the table. This was a lightly smoked Bent Billiard shaped pipe with a smooth finish that was dirty. The rim top had some light lava but there was minimal cake in the bowl. This little Bent Billiard really intrigued me, so it was next.

In the photo of the poured out bag on my desk top I have circled the pipe that is next on the table. This was a lightly smoked Bent Billiard shaped pipe with a smooth finish that was dirty. The rim top had some light lava but there was minimal cake in the bowl. This little Bent Billiard really intrigued me, so it was next.  The Bent Billiard was stamped in gold on the left side of the shank and read Real Briar [at an angle over] Made in France. The brass/nickel shank band was oxidized but still in decent condition. The bowl was lightly smoked and dusty but there was no cake. There was light lava on rim top toward the backside. The inner and outer edges looked good. The finish was dirty and the varnish top coat was spotty and peeling. The pipe had a Bakelite or Amberoid stem that was in good condition. There was one chip on the top near the shank joint. There were some light tooth marks and chatter on the stem. The button was orific – a round hole in the button end. The button had some wear and darkening but was in good condition. It has a push tenon that appears to be a synthetic material as well. Here are a few photos of the pipe before I did anything to it.

The Bent Billiard was stamped in gold on the left side of the shank and read Real Briar [at an angle over] Made in France. The brass/nickel shank band was oxidized but still in decent condition. The bowl was lightly smoked and dusty but there was no cake. There was light lava on rim top toward the backside. The inner and outer edges looked good. The finish was dirty and the varnish top coat was spotty and peeling. The pipe had a Bakelite or Amberoid stem that was in good condition. There was one chip on the top near the shank joint. There were some light tooth marks and chatter on the stem. The button was orific – a round hole in the button end. The button had some wear and darkening but was in good condition. It has a push tenon that appears to be a synthetic material as well. Here are a few photos of the pipe before I did anything to it.

I took photos of the bowl and stem. You can see the condition of the bowl. It is lightly cake and there is slight lava coat on the rim top. The edges look to be in good condition. The drilling is centered in the bottom of the bowl. It is a good sized bowl. The interior walls of the pipe are smooth and do not have drilling marks or checks or chips. The Bakelite/Amberoid stem is in good condition and has a push tenon and an orific button. There is a small chip in the Bakelite stem near the shank band and there are tooth marks on both sides near the button.

I took photos of the bowl and stem. You can see the condition of the bowl. It is lightly cake and there is slight lava coat on the rim top. The edges look to be in good condition. The drilling is centered in the bottom of the bowl. It is a good sized bowl. The interior walls of the pipe are smooth and do not have drilling marks or checks or chips. The Bakelite/Amberoid stem is in good condition and has a push tenon and an orific button. There is a small chip in the Bakelite stem near the shank band and there are tooth marks on both sides near the button. I took a photo of the stamping on the left side of the shank. It reads as noted above.

I took a photo of the stamping on the left side of the shank. It reads as noted above.  I removed the stem from the shank. You can see the brand new threaded bone tenon in the photo below. The proportions of this pipe are well done. The grain around the bowl is very nice.

I removed the stem from the shank. You can see the brand new threaded bone tenon in the photo below. The proportions of this pipe are well done. The grain around the bowl is very nice.  I knew from work on other older pipes that had the same stamp as this- Real Briar Made in France that there was not any clear cut information on that stamping on any of the usual sites. I also knew that the C.P.F. (Colossus Pipe Factory) that I had worked on bore this same stamp. My guess is that the pipe may have been made by them but I could not be sure.

I knew from work on other older pipes that had the same stamp as this- Real Briar Made in France that there was not any clear cut information on that stamping on any of the usual sites. I also knew that the C.P.F. (Colossus Pipe Factory) that I had worked on bore this same stamp. My guess is that the pipe may have been made by them but I could not be sure. I wiped down the bowl with 99% Isopropyl alcohol on a cotton pad to remove the peeling varnish coat and grime on the finish of the bowl sides. Wiping it down revealed some great grain around the bowl and shank sides.

I wiped down the bowl with 99% Isopropyl alcohol on a cotton pad to remove the peeling varnish coat and grime on the finish of the bowl sides. Wiping it down revealed some great grain around the bowl and shank sides.

I polished the briar and the nickel plated band with micromesh sanding pads. I dry sanded with 1500-12000 grit pads and wiped the bowl down with a damp cloth after each sanding pad. The briar began to really come alive.

I polished the briar and the nickel plated band with micromesh sanding pads. I dry sanded with 1500-12000 grit pads and wiped the bowl down with a damp cloth after each sanding pad. The briar began to really come alive.

I touched up the stain on the rim top using a Mahogany stain pen and used a Black Sharpie Pen on the fills that became evident on the back of the bowl. I was able to blend the stain and pen into the surrounding briar and it looked very good.

I touched up the stain on the rim top using a Mahogany stain pen and used a Black Sharpie Pen on the fills that became evident on the back of the bowl. I was able to blend the stain and pen into the surrounding briar and it looked very good. I used alcohol and cotton swabs to clean out the shank of any debris that may have gotten in from the reaming of the bowl. It was still quite clean.

I used alcohol and cotton swabs to clean out the shank of any debris that may have gotten in from the reaming of the bowl. It was still quite clean. I rubbed the briar down with Before & After Restoration Balm. I worked it into the finish with my fingertips. The product works to clean, enliven and protect briar finished. I let it sit for 10 minutes then buffed it off with a cotton cloth. The grain on the bowl really came alive with the buffing. It is really a beautiful pipe.

I rubbed the briar down with Before & After Restoration Balm. I worked it into the finish with my fingertips. The product works to clean, enliven and protect briar finished. I let it sit for 10 minutes then buffed it off with a cotton cloth. The grain on the bowl really came alive with the buffing. It is really a beautiful pipe.

While working on the bowl the band came off the shank. It was loose so while it was off I polished it with a jewelers cloth to remove the oxidation and protect the finish on it. I used a tooth pick to put all purpose glue on the inside of the band and pressed it back in place on the shank.

While working on the bowl the band came off the shank. It was loose so while it was off I polished it with a jewelers cloth to remove the oxidation and protect the finish on it. I used a tooth pick to put all purpose glue on the inside of the band and pressed it back in place on the shank. I set the bowl aside and filled in the chip on the top shank end edge and the tooth mark on the top and underside of the stem near the button. I used clear CA glue. Once it cured I polished it with micromesh sanding pads.

I set the bowl aside and filled in the chip on the top shank end edge and the tooth mark on the top and underside of the stem near the button. I used clear CA glue. Once it cured I polished it with micromesh sanding pads. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped the stem down after each pad with Obsidian Oil to protect and enliven the stem. I finished the polishing with Before & After Pipe Stem polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to dry.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped the stem down after each pad with Obsidian Oil to protect and enliven the stem. I finished the polishing with Before & After Pipe Stem polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil and set it aside to dry.

This another interesting older pipe – Real Briar Made in France Bent Billiard turned out really well and it is a great looking pipe with a great shape to it. Once the varnish coat was removed the grain on the briar and the sheen on the stem really popped when the pipe was buffed with blue diamond on the buffing wheel. The brass/nickel band also took on a sheen. I gave the bowl and stem multiple coats of carnauba wax and buffed it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished French Made Real Briar Bent Billiard is comfortable to hold and is quite distinguished looking. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 inches, Chamber diameter: 5/8 of an inch. The weight of the pipe is 34 grams/1.20 ounces. It is a really beautiful pipe that I will be putting on the rebornpipes store in the French Pipe Makers section if you want to add it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. Keep an eye out on the blog as I have several other older pipes that I will be working on.

This another interesting older pipe – Real Briar Made in France Bent Billiard turned out really well and it is a great looking pipe with a great shape to it. Once the varnish coat was removed the grain on the briar and the sheen on the stem really popped when the pipe was buffed with blue diamond on the buffing wheel. The brass/nickel band also took on a sheen. I gave the bowl and stem multiple coats of carnauba wax and buffed it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished French Made Real Briar Bent Billiard is comfortable to hold and is quite distinguished looking. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 inches, Chamber diameter: 5/8 of an inch. The weight of the pipe is 34 grams/1.20 ounces. It is a really beautiful pipe that I will be putting on the rebornpipes store in the French Pipe Makers section if you want to add it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. Keep an eye out on the blog as I have several other older pipes that I will be working on.