Blog by Steve Laug

Jeff and I cannot remember where we picked up the next pipe and have no idea where we found it or what the condition was when we found it. I know that Jeff cleaned it before it ended up here but we cannot put a finger on the pre-cleanup photos or even where we got it. So I decided to just write about it as it looks today before I start the cleanup work and describe the work that I did on the pipe. It is stamped on the left side of the shank and reads Pipe of the Month in script. On the underside of the shank it reads Imported Briar while on the right it reads Wally Frank LTD. The pipe is uniquely shaped and I was tempted to call it a drunken poker (in fact I did in the title of the blog). It must have been a good smoking pipe from the condition of the cleaned bowl. The rim top and edges of the bowl are all damaged. It looked like the pipe had been knocked out on hard surfaces and reamed with a knife. The stem was in good condition once I received it with light tooth marks and chatter on both sides. The majority of my work would be done in reshaping and reworking the rim top.

Jeff had cleaned up the pipe with his usual penchant for thoroughness. He reamed the pipe with a PipNet Pipe Reamer and cleaned up the remnants with a Savinelli Fitsall Pipe Knife. He scrubbed the bowl with undiluted Murphy’s Oil Soap with a tooth brush. He rinsed it under running warm water to remove the soap and grime. He cleaned out the inside of the shank and the airway in the stem with alcohol, cotton swabs and pipe cleaners. He soaked the stem in Before & After Deoxidizer and rinsed it off with warm water. I took photos of the pipe before I started my work.

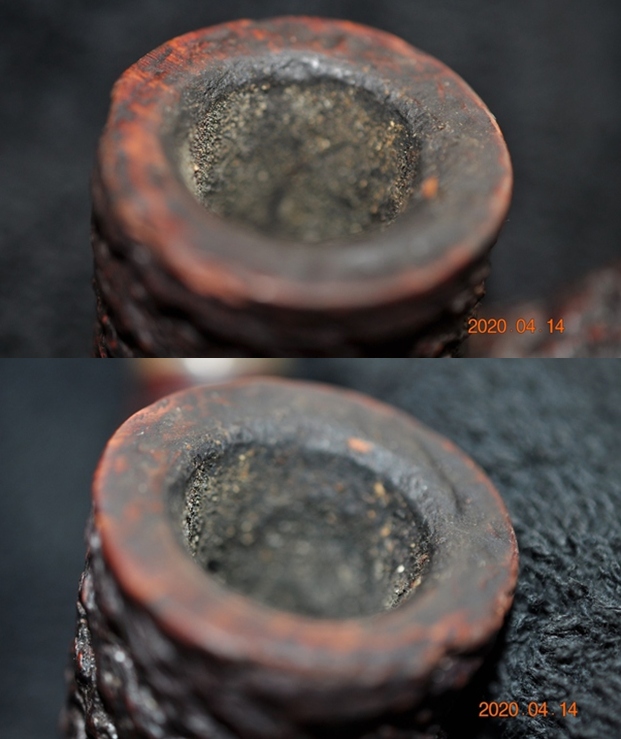

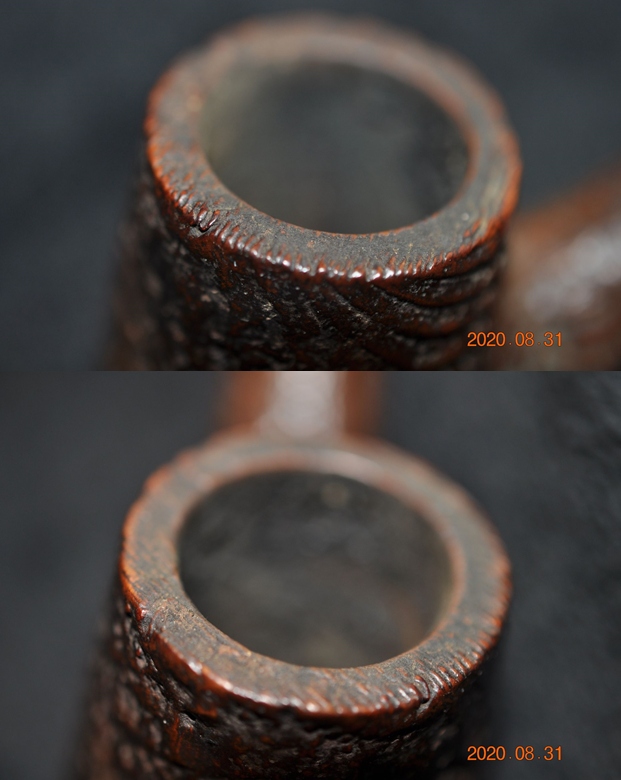

The rim top and edges of the rim looked rough with damage all around. The outer edge was rough and the inner edge was notched with what looked like knife marks. The rim top was also nicked and dented. The stem surface looked very good with some remaining oxidation and tooth marks and chatter on both sides near the button.

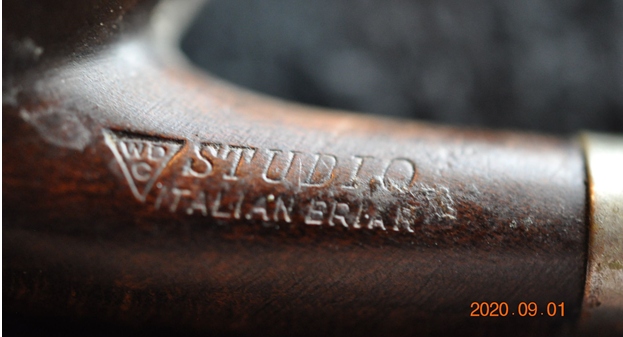

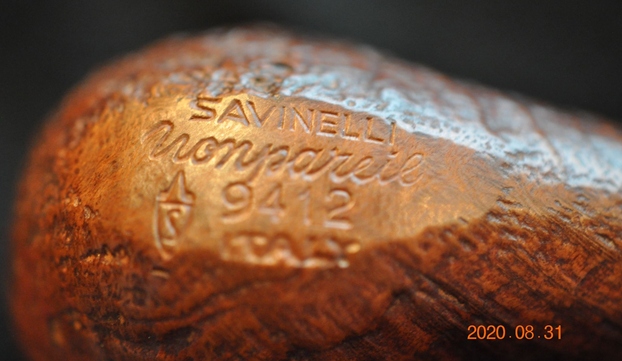

The rim top and edges of the rim looked rough with damage all around. The outer edge was rough and the inner edge was notched with what looked like knife marks. The rim top was also nicked and dented. The stem surface looked very good with some remaining oxidation and tooth marks and chatter on both sides near the button.  I took photos of the stamping on the sides of the shank. It is clear and readable as noted above.

I took photos of the stamping on the sides of the shank. It is clear and readable as noted above.  I removed the stem and took a photo of the pipe to give a sense of the whole. The bowl has a definitely tilt to it and the heel is rounded. The saddle stem is tapered with a slight bend that follows the flow of the pipe.

I removed the stem and took a photo of the pipe to give a sense of the whole. The bowl has a definitely tilt to it and the heel is rounded. The saddle stem is tapered with a slight bend that follows the flow of the pipe.  I turned to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-w1.html) and looked up the section on Wally Frank Pipes. I have included a screen capture of the section on The Pipe of the Month.

I turned to Pipephil’s site (http://www.pipephil.eu/logos/en/logo-w1.html) and looked up the section on Wally Frank Pipes. I have included a screen capture of the section on The Pipe of the Month. Each member of Wally Frank’s “The Pipe of the Month Club” received a brand new pipe in the mail once a month.

Each member of Wally Frank’s “The Pipe of the Month Club” received a brand new pipe in the mail once a month.

There was also a link to the Pipe of the Month Order form that was on the site. I have included that below for your viewing. Now it was time to work on the pipe. To take care of the significant damage to the rim top and edges I started my work by gently topping the bowl to minimize the damaged areas. I gave the inner edge of the bowl a bevel to reduce the burned areas. I also sanded the outer edge and smoothed out the damage.

Now it was time to work on the pipe. To take care of the significant damage to the rim top and edges I started my work by gently topping the bowl to minimize the damaged areas. I gave the inner edge of the bowl a bevel to reduce the burned areas. I also sanded the outer edge and smoothed out the damage.

I wiped the bowl down with acetone to remove the spotty varnish coat and to get the bowl free of the shininess so I could blend in the rim top more carefully. There was some nice looking grain under the varnish. Removing varnish always gives me pause because it can often reveal things I would have rather left hidden. However in this case it was not true.

I wiped the bowl down with acetone to remove the spotty varnish coat and to get the bowl free of the shininess so I could blend in the rim top more carefully. There was some nice looking grain under the varnish. Removing varnish always gives me pause because it can often reveal things I would have rather left hidden. However in this case it was not true.

I polished the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth to remove the sanding dust. The bowl really began to take on a shine.

I polished the briar with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the bowl down after each pad with a damp cloth to remove the sanding dust. The bowl really began to take on a shine.

The rim top was slightly lighter than the rest of the bowl so I touched it up with an Oak stain pen to match the rest of the pipe.

The rim top was slightly lighter than the rest of the bowl so I touched it up with an Oak stain pen to match the rest of the pipe. With the rim cleaned up the bowl was in good condition. I rubbed it down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. The product works to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

With the rim cleaned up the bowl was in good condition. I rubbed it down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips. The product works to clean, enliven and protect the briar. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine.

I set the bowl aside and turned to work on the stem. I “painted” the stem with the flame of a lighter to lift the tooth marks. The majority of them disappeared with the heat of the flame. Those that remained I filled in with clear super glue. Once the repairs had cured I sanded them smooth with 220 grit sandpaper. I started polishing the stem with 400 grit wet dry sandpaper.

I set the bowl aside and turned to work on the stem. I “painted” the stem with the flame of a lighter to lift the tooth marks. The majority of them disappeared with the heat of the flame. Those that remained I filled in with clear super glue. Once the repairs had cured I sanded them smooth with 220 grit sandpaper. I started polishing the stem with 400 grit wet dry sandpaper.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad. I used Before & After Pipe Polish – both Fine and Extra Fine to further polish the stem.

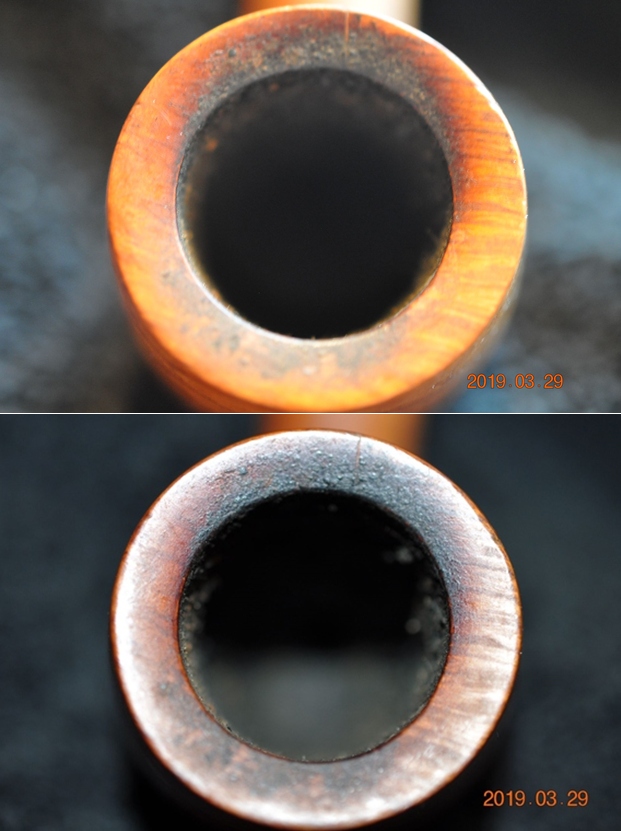

Before I put the stem back on the shank I checked out the shank end and the edges. I was surprised when I saw a small crack on the top of the shank toward the right that was obviously there before but only now after polishing could I see it. I circled the cracked area in red in the two photos below.

Before I put the stem back on the shank I checked out the shank end and the edges. I was surprised when I saw a small crack on the top of the shank toward the right that was obviously there before but only now after polishing could I see it. I circled the cracked area in red in the two photos below.  I glued the crack with a dribble of super glue and then pressed a thin brass band on the shank end. I really like these thin bands as they do not cover the stamping on the shank – which in this case was on three sides. I like the finished look of the pipe with the band.

I glued the crack with a dribble of super glue and then pressed a thin brass band on the shank end. I really like these thin bands as they do not cover the stamping on the shank – which in this case was on three sides. I like the finished look of the pipe with the band.

This Wally Frank Pipe of the Month Drunken Poker with a vulcanite saddle stem is a great looking pipe now that it has been restored. The smooth finish and unique grain look and feel great in the hand and should only feel better as the pipe is smoked. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel to give a shine. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Drunken Poker fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¼ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 25gr/.88oz. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This Wally Frank Pipe of the Month Drunken Poker with a vulcanite saddle stem is a great looking pipe now that it has been restored. The smooth finish and unique grain look and feel great in the hand and should only feel better as the pipe is smoked. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel to give a shine. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Drunken Poker fits nicely in the hand and feels great. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 ¼ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 25gr/.88oz. If you are interested in adding this pipe to your collection send me a message or an email. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!