Blog by Paresh

The next pipe that I picked up for restoration is a small sized classic straight Dublin shaped pipe that feels ultra light in the hand with a nice and comfortable feel in the mouth when clenched. This pipe came in one of couple of pipe lots that I had purchased on Etsy a few years ago and had been languishing in the lot of about 40- 50 pipes that Abha had done the initial cleaning for me. It languished at the bottom of the pile for no other reason than the fact that it was so nondescript that it did not attract my attention. However, with the continuing lockdown and partial suspension of work by Postal and Customs departments, my tobacco stock is fast depleting and this forced me to search for small bowled pipes. Thus, this pipe has now moved up in the line for restoration.

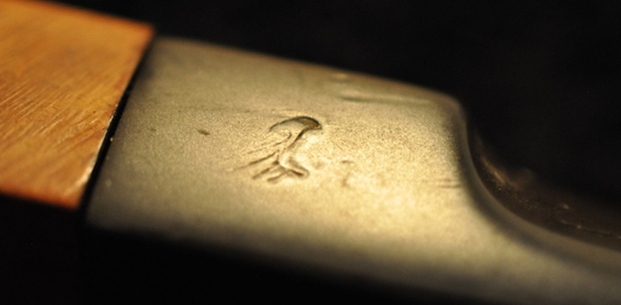

This pipe has a quaint little bowl size with some nice mixed grains. It is stamped on the left side of the shank as “STERNIES” over “LHS” in a diamond over “IMPORTED BRIAR”. The set of stampings on this pipe are all crisp and in block capital letters. The vulcanite stem is devoid of any stampings. While researching any pipe, the first site that I visit is rebornpipes.com since this is one site where I usually find well researched information on any brand that has anything, even remotely related, to pipes!! Now, till the time I got this pipe on my work table, I had not heard or read anything on this pipe brand and now that I have decided to work on it, rebornpipes does have a write up by Steve on this brand. He had thoroughly researched this brand and makes for an interesting read. Here is the link to the write up:-

While researching any pipe, the first site that I visit is rebornpipes.com since this is one site where I usually find well researched information on any brand that has anything, even remotely related, to pipes!! Now, till the time I got this pipe on my work table, I had not heard or read anything on this pipe brand and now that I have decided to work on it, rebornpipes does have a write up by Steve on this brand. He had thoroughly researched this brand and makes for an interesting read. Here is the link to the write up:-

To avoid the proverbial ‘reinventing the wheel’, I urge readers to go through the above write up to get a better feel of the brand. However, only a few relevant excerpts of the information that would help me in establishing the provenance of the pipe are reproduced below.

The L&H Stern Inc. was established by Ludwig Stern (1877-1942) in 1911. His brother Hugo (1872-?) acted as vice-president & secretary. The firm moved to 56 Pearl St. Brooklyn in 1920. It closed down in the 1960s. LHS was one of the main pipe suppliers for US soldiers during WWII.

The brand had 8 pipe grades listed in the 1944 issue of Outdoor Magazine.

Sterncrest Ultrafine $ 10

Sterncrest 14K $ 7.50

Sterncrest Sterling $ 5

Certified Purex $3.50

Select Grain $2.50

Sivercrest $ 2

Superfine Purex $1.50

Sculpted Purex $1.50

In addition to the above grades, a 1944 catalog also listed the following lines and models:

Barrister

Marwyn

Park Lane

Radmanol

Warwick

Additional notes: Some models were made before, during, and after WWII. LHS was one of the main pipe supplier for US soldiers during WWII.

Pre-war pipes were stamped Real Briar Root, or Briar Root. Some war time pipes were made from domestic briar or “American” briar and were void of any briar stampings. Many American pipe makers lost their overseas supply of Mediterranean briar shortly before and during the war. Post war pipes were stamped Imported Briar to assure customers that they were buying premium briar once again.

The grade “STERNIES”, as seen on the pipe on my work table, finds no mention in the 8 grades of pipe that have been listed in the 1944 catalogue. Also the fact that the stem bears no logo of two dots is a mystery (or has it been completely buffed off?). That fact apart, the stamping “IMPORTED BRIAR” points to post WW II production.

Thus, the LHS pipe currently on my work table is from the period 1945 to 1960s when LHS closed shop!!

Initial Visual Inspection

As I have mentioned above, this pipe was initially handled by Abha and she is not in a habit of taking many pictures as she works on each piece of briar. There are not many pictures to give the readers an idea about the condition of the pipe before she had worked her magic and presented me with a nice clean canvas to carry forward my repair and refurbishing tasks. I have included a description of the initial condition of the pipe as documented by her.

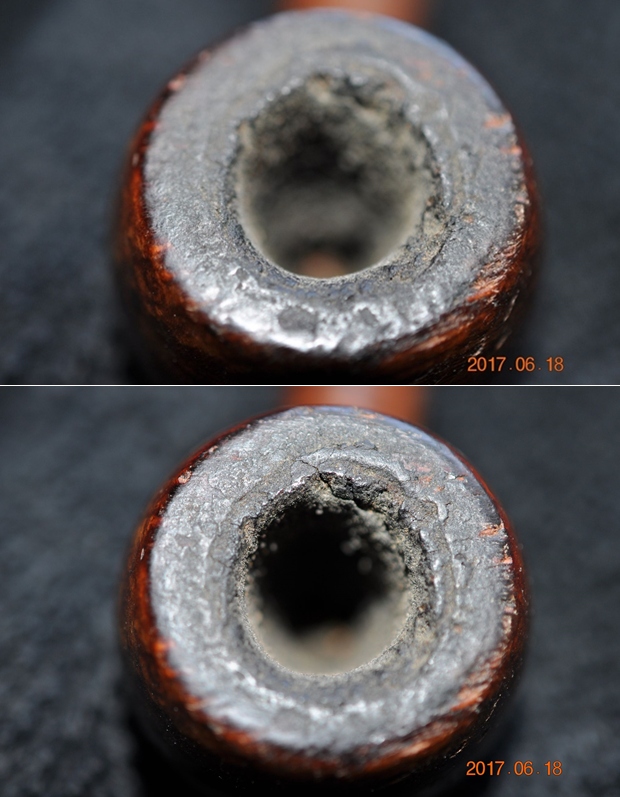

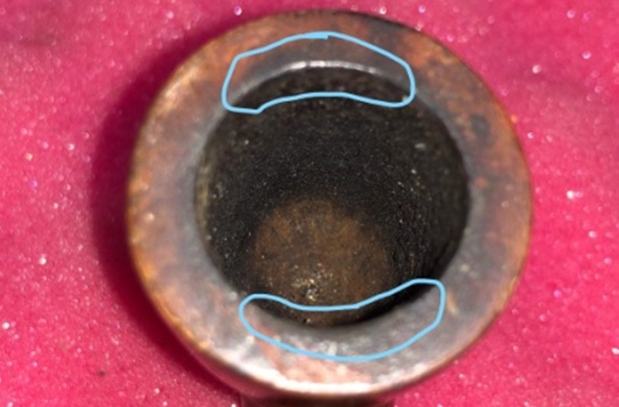

This pipe has a rather small bowl in a classic Dublin shape and has a chamber depth of about 1.1 inches. The chamber had an even layer of dry flaky cake which is not very thick. The condition of the inner walls of the chamber can be commented upon after the cake has been taken down to the bare briar. The rim top surface was covered in overflowing lava. The inner rim edge has minor charring in 6 o’clock and 11 o’clock directions (encircled in pastel blue) with some minor dings all along the edge. The outer rim edge is mysteriously darkened in the 12 o’clock direction. The draught hole is clogged and restricts the free flow of air through it. The ghost smells in the chamber are very mild.

This pipe has a rather small bowl in a classic Dublin shape and has a chamber depth of about 1.1 inches. The chamber had an even layer of dry flaky cake which is not very thick. The condition of the inner walls of the chamber can be commented upon after the cake has been taken down to the bare briar. The rim top surface was covered in overflowing lava. The inner rim edge has minor charring in 6 o’clock and 11 o’clock directions (encircled in pastel blue) with some minor dings all along the edge. The outer rim edge is mysteriously darkened in the 12 o’clock direction. The draught hole is clogged and restricts the free flow of air through it. The ghost smells in the chamber are very mild.

The smooth stummel surface has some very beautiful grain patterns and has a coat of lacquer that has worn off at a number of places giving the surface a blotched appearance. The stummel shows signs of vintage in the form of many scratches, dents and dings that it has acquired over a period of time. There a couple of fills over the stummel surface and are easily noticeable (encircled in yellow). The briar has accumulated a lot of grime and dust imparting the stummel a lifeless and bone dry appearance. The shank end has an aluminum spacer ring separating the shank end from the stem end when threaded in. On closer observation, it can be seen that a portion of this spacer extends into the mortise and is threaded which matches with the stinger threads.

The smooth stummel surface has some very beautiful grain patterns and has a coat of lacquer that has worn off at a number of places giving the surface a blotched appearance. The stummel shows signs of vintage in the form of many scratches, dents and dings that it has acquired over a period of time. There a couple of fills over the stummel surface and are easily noticeable (encircled in yellow). The briar has accumulated a lot of grime and dust imparting the stummel a lifeless and bone dry appearance. The shank end has an aluminum spacer ring separating the shank end from the stem end when threaded in. On closer observation, it can be seen that a portion of this spacer extends into the mortise and is threaded which matches with the stinger threads.

The vulcanite stem was lightly oxidized. Some minor tooth chatter and tooth indentations are seen on both the upper and lower stem surfaces in the bite zone and at the bottom of the button edge. The threaded aluminum stinger tenon end had accumulated ash and oils/ tars that had dried out on the inside as well as on the outside. The horizontal slot has dried gunk embedded in to it which will have to be addressed.

The vulcanite stem was lightly oxidized. Some minor tooth chatter and tooth indentations are seen on both the upper and lower stem surfaces in the bite zone and at the bottom of the button edge. The threaded aluminum stinger tenon end had accumulated ash and oils/ tars that had dried out on the inside as well as on the outside. The horizontal slot has dried gunk embedded in to it which will have to be addressed. Initial Cleaning By Abha…

Initial Cleaning By Abha…

Abha, my wife, reamed out the complete cake and further smoothed out the chamber walls with a folded piece of 220 grit sand paper and scrapped out the entire lava overflow from over the rim top surface. She further cleaned out the internals of the shank with pipe cleaners and alcohol and cotton buds. She followed the internal cleaning of the shank with external cleaning of the stummel using Murphy’s Oil soap and hard bristled tooth brush and dried it with paper napkins and cotton cloth.

Next she cleaned out the internals of the stem air way using hard and regular pipe cleaners dipped in isopropyl alcohol. She cleaned the stem surface under running warm water and scrubbed the surface oxidation from the stem using Scotch Brite pad and dish washing soap. The aluminum stinger was also similarly cleaned. She further removed the oxidation by scrubbing the stem with 0000 grade steel wool and applied a little olive oil to rehydrate the stem.

Next she cleaned out the internals of the stem air way using hard and regular pipe cleaners dipped in isopropyl alcohol. She cleaned the stem surface under running warm water and scrubbed the surface oxidation from the stem using Scotch Brite pad and dish washing soap. The aluminum stinger was also similarly cleaned. She further removed the oxidation by scrubbing the stem with 0000 grade steel wool and applied a little olive oil to rehydrate the stem.  Once The Pipe Is On My Work Table…

Once The Pipe Is On My Work Table…

The cleaned up pipes presents a very clear picture of what needs to be done to restore this pipe to a decent and smokable condition. I really cannot thank Abha, my wife, enough for all the help and support that she extends me in my pursuance of this hobby. I proceed to carry out my appreciation of the work that needs to be done on this pipe to restore it.

As with all the cleaned pipes that Abha packs, there was a note in the zip lock pouch with issues that she had observed in the pipe. The first point was that she had not dunked the stem in to “Before and After Deoxidizer” solution because of the metal stinger. The next issue that she pointed out was of the rim top surface not being even and the darkening of the inner rim edge. The third issue she pointed out was that the stummel surface had not cleaned up the way it usually does. Here are the pictures of the pipe as I had received.

To be honest, the pipe had cleaned up nicely. What she thought was unclean stummel was in fact the old lacquer coat that had come off in patches. The two fills, encircled in yellow, are now plainly visible. The right side of the stummel shows a few dents/ dings. The aluminum spacer ring at the shank end is greatly oxidized and would need to be polished to a nice shine. The mortise is nice and clean. Sanding the stummel surface with a piece of 220 grit sand paper should address the issue of dings to a great extent. Once the stummel has been completely scrubbed and free of the old lacquer, I shall refresh the fills with a mix of briar dust and superglue. A vigorous scrub with Scotch Brit pad and Murphy’s Oil soap should suffice to remove the old peeling lacquer coat. In case this does not work, a wipe with pure Acetone on a cotton swab will definitely address this issue. After the aluminum spacer ring has been polished, it will provide a nice bling to the overall appearance of the pipe.

To be honest, the pipe had cleaned up nicely. What she thought was unclean stummel was in fact the old lacquer coat that had come off in patches. The two fills, encircled in yellow, are now plainly visible. The right side of the stummel shows a few dents/ dings. The aluminum spacer ring at the shank end is greatly oxidized and would need to be polished to a nice shine. The mortise is nice and clean. Sanding the stummel surface with a piece of 220 grit sand paper should address the issue of dings to a great extent. Once the stummel has been completely scrubbed and free of the old lacquer, I shall refresh the fills with a mix of briar dust and superglue. A vigorous scrub with Scotch Brit pad and Murphy’s Oil soap should suffice to remove the old peeling lacquer coat. In case this does not work, a wipe with pure Acetone on a cotton swab will definitely address this issue. After the aluminum spacer ring has been polished, it will provide a nice bling to the overall appearance of the pipe.

The chamber walls are sans any damage. The inner rim edge is in good condition save for light charring (encircled in green) and a chip (encircled in blue). The outer rim edge shows just a hint of darkening in 1 o’clock direction, but otherwise in excellent condition. The rim top surface is uneven to the touch. The draught hole is dead center and at the bottom of the heel and this construction geometry should make this pipe a fantastic smoker. Topping the rim surface should address the issues of uneven rim top, the charred outer rim edge while greatly reducing the inner rim edge damage. I shall, if need be, create a bevel to the inner edge to completely address the rim damage.

The chamber walls are sans any damage. The inner rim edge is in good condition save for light charring (encircled in green) and a chip (encircled in blue). The outer rim edge shows just a hint of darkening in 1 o’clock direction, but otherwise in excellent condition. The rim top surface is uneven to the touch. The draught hole is dead center and at the bottom of the heel and this construction geometry should make this pipe a fantastic smoker. Topping the rim surface should address the issues of uneven rim top, the charred outer rim edge while greatly reducing the inner rim edge damage. I shall, if need be, create a bevel to the inner edge to completely address the rim damage.

The moment I saw and held the stem in my hands, I was not sure if the stem was vulcanite or made of some plastic derivative. It was very light weight and considerably harder than vulcanite. It was lightly oxidized and had minor tooth chatter on either surface in the bite zone. The button edges on either surface are slightly deformed with tooth indentations. I shall not risk heating the bite zone with the flame of a lighter to raise the tooth chatter but would rather try and sand it out. In case required, I shall further use charcoal and superglue mix to address this issue. I need to sharpen the button edges and shall do so with a flat needle file.

The moment I saw and held the stem in my hands, I was not sure if the stem was vulcanite or made of some plastic derivative. It was very light weight and considerably harder than vulcanite. It was lightly oxidized and had minor tooth chatter on either surface in the bite zone. The button edges on either surface are slightly deformed with tooth indentations. I shall not risk heating the bite zone with the flame of a lighter to raise the tooth chatter but would rather try and sand it out. In case required, I shall further use charcoal and superglue mix to address this issue. I need to sharpen the button edges and shall do so with a flat needle file.  The Process

The Process

I embarked on the journey of restoring this pipe by addressing the stem first since it would take considerable time to repair and polish. Abha had done a fantastic job of cleaning the stem both internally and externally and this facilitated me to straight away sand the stem surface with a 220 grit sand paper to even out the raised tooth indentation and remove the oxidation from the surface. I follow it up by cleaning the surface with a cotton swab and alcohol. I wipe the stem with a cotton swab and Murphy’s oil soap to deep clean the surface. The tooth chatter has been addressed to a very great extent. The minor tooth marks that remain will further reduce after I had sanded the stem surface with 320 to 1000 grit sand papers followed by the micromesh pads. The button edges are a lot straighter and crispier than before. I further sand the stem surface with 320 followed by 400, 600 and 800 grit sandpapers. I finished the sandpaper cycle by wet sanding the entire stem surface with a piece of 1000 grit sandpaper. I wiped the stem with a moist cloth to remove the sanding dust and applied a small quantity of EVO to hydrate the stem.

I further sand the stem surface with 320 followed by 400, 600 and 800 grit sandpapers. I finished the sandpaper cycle by wet sanding the entire stem surface with a piece of 1000 grit sandpaper. I wiped the stem with a moist cloth to remove the sanding dust and applied a small quantity of EVO to hydrate the stem. I completed the polishing cycle of the stem by wet sanding the surface with 1500 to 12000 girt pads. The stem looks great with the tooth chatter nicely matched with the rest of the surface. I also polished the aluminum stinger and the spacer ring with micromesh pads. I gave a final rub with “Before and After Extra Fine” stem polish compound to remove fine scratches from the stem surface. I rub a little quantity of Extra Virgin Olive oil in to the stem surface and set it aside to be absorbed by the vulcanite. The stem polished up nicely and I am happy with the appearance of the stem at this point in restoration.

I completed the polishing cycle of the stem by wet sanding the surface with 1500 to 12000 girt pads. The stem looks great with the tooth chatter nicely matched with the rest of the surface. I also polished the aluminum stinger and the spacer ring with micromesh pads. I gave a final rub with “Before and After Extra Fine” stem polish compound to remove fine scratches from the stem surface. I rub a little quantity of Extra Virgin Olive oil in to the stem surface and set it aside to be absorbed by the vulcanite. The stem polished up nicely and I am happy with the appearance of the stem at this point in restoration.  With the stem refurbishing nearly completed, save for final polish using Blue Diamond and wax, I move to clean the exterior of the stummel. I used a hard bristled tooth brush, Scotch Brit pad and Murphy’s Oil soap to scrub the stummel and rim top. I shall be candid in confessing that I was extra aggressive using the Scotch Brit pad as I was keen to completely remove the peeling lacquer coating over the stummel surface. After the scrub with oil soap, I washed the stummel under running warm water with anti oil dish washing detergent till the stummel surface was clean and dried it using paper towels and soft cotton cloth. I once again cleaned the shank internals with the detergent and hard bristled shank brush and set the stummel aside to dry out naturally. The two fills have gone soft and would need to be refreshed. The stummel has cleaned up nicely with the old lacquer coat completely removed from the surface. The ghost smells are completely eliminated and the pipe now smells fresh, odorless and clean. The shank air way is nice and open. I shall refresh the fills over the stummel surface with a mix of briar dust and superglue.

With the stem refurbishing nearly completed, save for final polish using Blue Diamond and wax, I move to clean the exterior of the stummel. I used a hard bristled tooth brush, Scotch Brit pad and Murphy’s Oil soap to scrub the stummel and rim top. I shall be candid in confessing that I was extra aggressive using the Scotch Brit pad as I was keen to completely remove the peeling lacquer coating over the stummel surface. After the scrub with oil soap, I washed the stummel under running warm water with anti oil dish washing detergent till the stummel surface was clean and dried it using paper towels and soft cotton cloth. I once again cleaned the shank internals with the detergent and hard bristled shank brush and set the stummel aside to dry out naturally. The two fills have gone soft and would need to be refreshed. The stummel has cleaned up nicely with the old lacquer coat completely removed from the surface. The ghost smells are completely eliminated and the pipe now smells fresh, odorless and clean. The shank air way is nice and open. I shall refresh the fills over the stummel surface with a mix of briar dust and superglue.

Next I addressed the issues of the two fills in the stummel surface. With a sharp dental tool, I gouged out the fill on the right side of the stummel and one on the left side of the shank. Using the layering method, I filled these gouges with a mix of briar dust and CA superglue till the mound of the mix was slightly above the rest of the stummel surface. This helps in a better blending of the fill with the rest of the stummel surface while sanding and reduces the scratches caused by the use of a needle file since you have a correct perspective of the sanding that is required. I set the stummel aside for the fills to cure.

Next I addressed the issues of the two fills in the stummel surface. With a sharp dental tool, I gouged out the fill on the right side of the stummel and one on the left side of the shank. Using the layering method, I filled these gouges with a mix of briar dust and CA superglue till the mound of the mix was slightly above the rest of the stummel surface. This helps in a better blending of the fill with the rest of the stummel surface while sanding and reduces the scratches caused by the use of a needle file since you have a correct perspective of the sanding that is required. I set the stummel aside for the fills to cure.

Using a flat needle file, I sand the fill till I had achieved a rough match with the surrounding stummel surface. I sand the entire stummel with a piece of 220 grit sand paper to further blend in the fills with the stummel surface.

Using a flat needle file, I sand the fill till I had achieved a rough match with the surrounding stummel surface. I sand the entire stummel with a piece of 220 grit sand paper to further blend in the fills with the stummel surface.

I topped the rim top surface on a piece of 220 grit sand paper, checking frequently for the progress being made as I hate to loose briar estate any more than absolutely necessary. The issue of uneven rim top surface has now been completely addressed. At this stage, the slight darkening to the outer edge too has been completely addressed while the charring to the inner edge, though eliminated to a great extent, is still discernible. I shall create a bevel to the inner edge to blend and mask the damaged edge with the rest of the inner edge.

I topped the rim top surface on a piece of 220 grit sand paper, checking frequently for the progress being made as I hate to loose briar estate any more than absolutely necessary. The issue of uneven rim top surface has now been completely addressed. At this stage, the slight darkening to the outer edge too has been completely addressed while the charring to the inner edge, though eliminated to a great extent, is still discernible. I shall create a bevel to the inner edge to blend and mask the damaged edge with the rest of the inner edge.  The inner rim edge appeared to be slightly uneven at the front and at the back end of the rim top due to charring and I decided to mask it by creating a bevel. With a folded piece of a 220 grit sand paper pinched between my thumb and forefinger, I create a nice and even bevel on the inner edge. I was careful so as not to alter the profile of the stummel by excessive topping or creation of the bevel. I am pretty pleased with the appearance of the rim top and edges at this stage. The following pictures show the progress being made and improvements to the inner and outer rim edges.

The inner rim edge appeared to be slightly uneven at the front and at the back end of the rim top due to charring and I decided to mask it by creating a bevel. With a folded piece of a 220 grit sand paper pinched between my thumb and forefinger, I create a nice and even bevel on the inner edge. I was careful so as not to alter the profile of the stummel by excessive topping or creation of the bevel. I am pretty pleased with the appearance of the rim top and edges at this stage. The following pictures show the progress being made and improvements to the inner and outer rim edges.

I wet sand the entire stummel with 1500 to 12000 grit micromesh pads, wiping frequently with a moist cloth to check the progress.I also polished the shank end aluminum spacer ring with the micromesh pads to a nice shine. I really like the looks of the stummel at this point in restoration. The grains and the clean lines of this piece of briar is really appreciable. The few scratches and dings that were noticed over the stummel surface too have been addressed by this stage due to the sanding and micromesh pad polishing. The fills are quite evident and whether to mask it using a dark brown stain or let it be, is a decision that I shall take subsequently.

I wet sand the entire stummel with 1500 to 12000 grit micromesh pads, wiping frequently with a moist cloth to check the progress.I also polished the shank end aluminum spacer ring with the micromesh pads to a nice shine. I really like the looks of the stummel at this point in restoration. The grains and the clean lines of this piece of briar is really appreciable. The few scratches and dings that were noticed over the stummel surface too have been addressed by this stage due to the sanding and micromesh pad polishing. The fills are quite evident and whether to mask it using a dark brown stain or let it be, is a decision that I shall take subsequently.

Next, I rub a small quantity of “Before and After Restoration Balm” in to the stummel surface with my finger tips and let it rest for a few minutes. I worked the restoration balm deep in to the briar wood. The balm almost immediately works its magic and the briar now has a nice vibrant appearance. The stummel looks very handsome with the contrasting dark and light brown hues. The fills have blended in quite nicely with the surrounding dark brown hues taken on by the stummel surface after the application of the balm.

Next, I rub a small quantity of “Before and After Restoration Balm” in to the stummel surface with my finger tips and let it rest for a few minutes. I worked the restoration balm deep in to the briar wood. The balm almost immediately works its magic and the briar now has a nice vibrant appearance. The stummel looks very handsome with the contrasting dark and light brown hues. The fills have blended in quite nicely with the surrounding dark brown hues taken on by the stummel surface after the application of the balm.

To complete the restoration, I mount a cotton cloth buffing wheel on to my hand held rotary tool and applied a coat of Blue Diamond to the stummel and the stem to polish out the minor scratches.

To complete the restoration, I mount a cotton cloth buffing wheel on to my hand held rotary tool and applied a coat of Blue Diamond to the stummel and the stem to polish out the minor scratches.

With a cotton buffing wheel that I use for carnauba wax, I apply a coat of carnauba wax and continue to work on it till the complete coat of wax had been polished out. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The completed pipe looks fresh, vibrant and ready for its next innings with a piper interested in adding it to his/ her collection. This piece of briar feels fantastic in hands with its ultra lightweight, classic shape and a size that is just right for a quick smoke in between breaks. Thank you to all esteemed readers for joining me and walking with me through this restoration. Cheers!!

With a cotton buffing wheel that I use for carnauba wax, I apply a coat of carnauba wax and continue to work on it till the complete coat of wax had been polished out. I finished the restoration by giving the entire pipe a rigorous hand buffing using a microfiber cloth to raise the shine further. The completed pipe looks fresh, vibrant and ready for its next innings with a piper interested in adding it to his/ her collection. This piece of briar feels fantastic in hands with its ultra lightweight, classic shape and a size that is just right for a quick smoke in between breaks. Thank you to all esteemed readers for joining me and walking with me through this restoration. Cheers!!

P.S. I had consulted with my wife, Abha, whether or not to stain this pipe with a dark brown stain to mask the fills since she has a better understanding and appreciation of colors than me (isn’t that true for all the men?). She suggested that the natural color of the briar looks smashing while any staining will hide the grain patterns and that the fills actually blend in nicely when seen in person. It’s actually a fact that pictures highlights flaws more than they actually appear in person.

P.S. I had consulted with my wife, Abha, whether or not to stain this pipe with a dark brown stain to mask the fills since she has a better understanding and appreciation of colors than me (isn’t that true for all the men?). She suggested that the natural color of the briar looks smashing while any staining will hide the grain patterns and that the fills actually blend in nicely when seen in person. It’s actually a fact that pictures highlights flaws more than they actually appear in person.

Praying for the safety and well being of all readers and their loved ones…