Blog by Dal Stanton

The Pipstar Standard 06 026 Dublin Sitter now on my worktable, is simply a cool looking pipe. I was attracted to it because of the Dublin Sitter shape eBay description and the grain had great potential. I like the lines and the very gentle bend of the stem flowing out of a rounded sitter heel. The pipe really doesn’t sit well as a sitter, but the flat rounded bottom is more for artistic consideration (as a French pipe) than utilitarian. I saw it on the eBay auction block from a seller in Akron, Ohio. My bid held true and the Pipstar Standard Dublin made its way to Bulgaria where I posted it in the ‘For “Pipe Dreamers” Only! online virtual ‘Help Me!’ baskets where pipe men and women commission pipes to be restored. These hopeful restorations benefit the Daughters of Bulgaria, the work in Bulgaria helping women and girls who have been trafficked and sexually exploited. This is where Nathan saw the Pipstar along with 3 other pipes he commissioned to benefit the Daughters. Here are pictures of the Pipstar Dublin Sitter that got his attention.

The nomenclature is found stamped on the underside of the shank. The stamping reads ‘PiPstar’ bracketed, followed by ‘STANDARD’. Underneath this is stamped ’26 026’ which I assume is a shape number that I’m sure, will remain a mystery. The stem bears an interesting stamp of a ‘P’ and a miniature star to its right.

The nomenclature is found stamped on the underside of the shank. The stamping reads ‘PiPstar’ bracketed, followed by ‘STANDARD’. Underneath this is stamped ’26 026’ which I assume is a shape number that I’m sure, will remain a mystery. The stem bears an interesting stamp of a ‘P’ and a miniature star to its right. There isn’t much information about the Pipstar name. Pipedia shows it to be a brand of C.J. Verguet Frères – a French factory in St. Claude that began in the 19th century. It also cites that,

There isn’t much information about the Pipstar name. Pipedia shows it to be a brand of C.J. Verguet Frères – a French factory in St. Claude that began in the 19th century. It also cites that,

In 1906, its merger with Sina & Cie., gave rise to a large company within the Oppenheimer Pipe group and run by Lucien Verguet. In 1917, the factory produced 4.8 million pipes and bowls.

More information was offered on pipephil.eu with a Pipstar panel stating that the company closed it’s doors in St. Claude in 1970. This let’s me know that the dating of the Pipstar on the table is at least that old.  Now looking at the St. Claude, France, made Pipstar Dublin Sitter on the worktable, it appears to have originally had an Oxblood or red finish. Looking at the stummel there are a few blotches of what appears to be dye hanging on from former days. What’s interesting to me is that the brown leftover is attractive. I’ll be interested to see how the stummel cleans up.

Now looking at the St. Claude, France, made Pipstar Dublin Sitter on the worktable, it appears to have originally had an Oxblood or red finish. Looking at the stummel there are a few blotches of what appears to be dye hanging on from former days. What’s interesting to me is that the brown leftover is attractive. I’ll be interested to see how the stummel cleans up.

There are also nicks and scratches on the stummel from normal wear and usage.

There are also nicks and scratches on the stummel from normal wear and usage.

The chamber has thick cake buildup which will need to be cleaned out to allow fresh briar to emerge. This also allows inspection of the chamber walls to detect heating problems.

The chamber has thick cake buildup which will need to be cleaned out to allow fresh briar to emerge. This also allows inspection of the chamber walls to detect heating problems. The stem has thick oxidation which needs addressing. The picture from the eBay seller shows this very well.

The stem has thick oxidation which needs addressing. The picture from the eBay seller shows this very well.  There is a bite compression on the lower bit, but overall, not in bad shape.

There is a bite compression on the lower bit, but overall, not in bad shape. Beginning the process of restoring and recommissioning this French Pipstar Standard, I clean the airway with pipe cleaners dipped in isopropyl 95%.

Beginning the process of restoring and recommissioning this French Pipstar Standard, I clean the airway with pipe cleaners dipped in isopropyl 95%. Next, to begin addressing the deep, heavy oxidation on the entire stem, a ‘Soft-Scrub-like’ product called CIF, available here in Bulgaria, is used along with 000 steel wool. I use the steel wool and CIF to break up the oxidation with the hope that it enables the Before & After Deoxidizer soak to follow to be more productive.

Next, to begin addressing the deep, heavy oxidation on the entire stem, a ‘Soft-Scrub-like’ product called CIF, available here in Bulgaria, is used along with 000 steel wool. I use the steel wool and CIF to break up the oxidation with the hope that it enables the Before & After Deoxidizer soak to follow to be more productive.

After a few hours, I fish out the Pipstar stem and clear the liquid from the airway with pipe cleaners wetted with isopropyl 95%. Cotton pads wetted with alcohol are also used to wipe away oxidation that has been raised.

After a few hours, I fish out the Pipstar stem and clear the liquid from the airway with pipe cleaners wetted with isopropyl 95%. Cotton pads wetted with alcohol are also used to wipe away oxidation that has been raised. To help begin the conditioning process, paraffin oil, a mineral oil, is applied to the vulcanite stem. The stem is then put to the side to absorb the oil.

To help begin the conditioning process, paraffin oil, a mineral oil, is applied to the vulcanite stem. The stem is then put to the side to absorb the oil. After putting the stem to the side, I start the work on the stummel by cleaning the chamber of the cake build-up. I take a starting picture and using the Pipnet Reaming Kit, I go to work starting with the smallest blade head. I discover quickly that the conical Dublin chamber angles too sharply for a ‘regular’ reaming blade to traverse. Instead of pressing down on the blade head, which will cause a ‘reaming ridge’ I simply press toward the walls of the chamber to remove cake buildup. I use two blade heads in this manner and then switch to the Savinelli Fitsall tool to reach the narrower areas of the chamber. I also utilize an older, vintage Kleen Reem Pipe Tool which can close and expand the cutting blades orientation. It works well in the Dublin chamber!

After putting the stem to the side, I start the work on the stummel by cleaning the chamber of the cake build-up. I take a starting picture and using the Pipnet Reaming Kit, I go to work starting with the smallest blade head. I discover quickly that the conical Dublin chamber angles too sharply for a ‘regular’ reaming blade to traverse. Instead of pressing down on the blade head, which will cause a ‘reaming ridge’ I simply press toward the walls of the chamber to remove cake buildup. I use two blade heads in this manner and then switch to the Savinelli Fitsall tool to reach the narrower areas of the chamber. I also utilize an older, vintage Kleen Reem Pipe Tool which can close and expand the cutting blades orientation. It works well in the Dublin chamber!

After cleaning the cake buildup, I wipe the chamber with a cotton pad wetted with isopropyl 95% to clear the carbon dust and examine the chamber. The chamber is healthy regarding heating and burning issues, but I detect what I was mindful of earlier – what I call a ‘reaming ridge’. Overzealous reaming when the chamber narrows to a tighter angle than the reaming blade can pass results in the blades cutting into the chamber wall above the floor of the chamber.

After cleaning the cake buildup, I wipe the chamber with a cotton pad wetted with isopropyl 95% to clear the carbon dust and examine the chamber. The chamber is healthy regarding heating and burning issues, but I detect what I was mindful of earlier – what I call a ‘reaming ridge’. Overzealous reaming when the chamber narrows to a tighter angle than the reaming blade can pass results in the blades cutting into the chamber wall above the floor of the chamber.  Moving on to the cleaning of the external surface, undiluted Murphy’s Oil Soap is used with a cotton pad to scrub the smooth briar surface. I’m interested to see how the Oxblood spots fair in the cleaning. A brass bristled brush is also employed to clean the rim as well as my Winchester pocketknife to scrape some hard gunk carefully off the rim.

Moving on to the cleaning of the external surface, undiluted Murphy’s Oil Soap is used with a cotton pad to scrub the smooth briar surface. I’m interested to see how the Oxblood spots fair in the cleaning. A brass bristled brush is also employed to clean the rim as well as my Winchester pocketknife to scrape some hard gunk carefully off the rim.

Next, the stummel is transferred to the kitchen sink where the cleaning commences on the internals. Using shank brushes and anti-oil liquid dishwashing soap with warm water, I work on the internals of the pipe, scrubbing the mortise. After a thorough rinsing, the pipe is back on the worktable.

Next, the stummel is transferred to the kitchen sink where the cleaning commences on the internals. Using shank brushes and anti-oil liquid dishwashing soap with warm water, I work on the internals of the pipe, scrubbing the mortise. After a thorough rinsing, the pipe is back on the worktable. After the cleaning, the Oxblood stained spots are as firm as ever hanging on while the rest of the briar surface is cleaning nicely. I’ll need to address these spots.

After the cleaning, the Oxblood stained spots are as firm as ever hanging on while the rest of the briar surface is cleaning nicely. I’ll need to address these spots.

I continue with the internal cleaning regimen using cotton buds and pipe cleaners wetted with isopropyl 95%. I also utilize a small dental spoon to scrape the internal walls and excavate old tars and oils. This helps a great deal. After some time, the buds and pipe cleaners begin to emerge lighter. I stop cleaning now to continue at the end of the workday with a kosher salt and alcohol soak to continue to clean and freshen the internal briar.

I continue with the internal cleaning regimen using cotton buds and pipe cleaners wetted with isopropyl 95%. I also utilize a small dental spoon to scrape the internal walls and excavate old tars and oils. This helps a great deal. After some time, the buds and pipe cleaners begin to emerge lighter. I stop cleaning now to continue at the end of the workday with a kosher salt and alcohol soak to continue to clean and freshen the internal briar. I take another look at the Oxblood stains on the stummel. I first try rubbing alcohol on the spots, but this does not phase them.

I take another look at the Oxblood stains on the stummel. I first try rubbing alcohol on the spots, but this does not phase them.  Next, using a cotton pad, acetone is applied to the stains and some color was raised on the cotton pad. In the end, I decide to put the stummel in a soak with acetone to break down the old dye.

Next, using a cotton pad, acetone is applied to the stains and some color was raised on the cotton pad. In the end, I decide to put the stummel in a soak with acetone to break down the old dye.

With the stummel soaking, I return to the stem. The lower bit has a small bite compression which I address using the heating method. I use a Bic lighter to paint the lower bit and as the vulcanite heats, the compression expands to regain its original condition, or closer to it. This compression responds well as the comparison of the pictures shows. Sanding should easily dispatch the compression.

With the stummel soaking, I return to the stem. The lower bit has a small bite compression which I address using the heating method. I use a Bic lighter to paint the lower bit and as the vulcanite heats, the compression expands to regain its original condition, or closer to it. This compression responds well as the comparison of the pictures shows. Sanding should easily dispatch the compression. Next, using a flat needle file, the button lips on the upper and lower sides are refreshed. With 240 grade paper, the bit is sanded and the remaining compressions are dispatched.

Next, using a flat needle file, the button lips on the upper and lower sides are refreshed. With 240 grade paper, the bit is sanded and the remaining compressions are dispatched. Using 240 grade paper, sanding is expanded over the entire stem to address latent oxidation. Not shown is the plastic disk I use to sand against to prevent shouldering the stem facing.

Using 240 grade paper, sanding is expanded over the entire stem to address latent oxidation. Not shown is the plastic disk I use to sand against to prevent shouldering the stem facing. Next, 600 grade paper is used to wet sand the stem followed by applying 000 grade steel wool. Throughout the sanding I’m mindful of the Pipstar stem stamping.

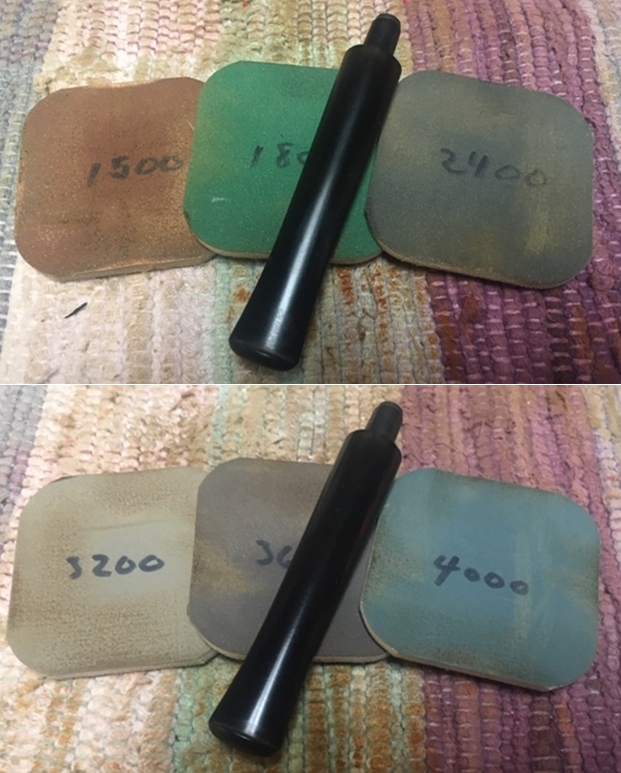

Next, 600 grade paper is used to wet sand the stem followed by applying 000 grade steel wool. Throughout the sanding I’m mindful of the Pipstar stem stamping. Moving now to apply the full regimen of micromesh pads, using pads 1500 to 2400, I wet sand followed by dry sanding with pads 3200 to 4000 and 6000 to 12000. Between each set of 3 pads Obsidian Oil is applied to further condition and to prevent the development of oxidation. The stem pops!

Moving now to apply the full regimen of micromesh pads, using pads 1500 to 2400, I wet sand followed by dry sanding with pads 3200 to 4000 and 6000 to 12000. Between each set of 3 pads Obsidian Oil is applied to further condition and to prevent the development of oxidation. The stem pops!

The stummel has been soaking in an acetone bath for a few hours. After fishing the stummel out of the acetone, steel wool helps in removing the Oxblood stain spots that lingered. It continued to need quite a bit of sanding from the steel wool but in the end, the stummel is now clean, natural briar. Due to this soak, there is no need to further soak the stummel with alcohol and kosher salt.

The stummel has been soaking in an acetone bath for a few hours. After fishing the stummel out of the acetone, steel wool helps in removing the Oxblood stain spots that lingered. It continued to need quite a bit of sanding from the steel wool but in the end, the stummel is now clean, natural briar. Due to this soak, there is no need to further soak the stummel with alcohol and kosher salt.

To clean the stummel of the minor nicks and dents that comes through normal wear, and to freshen the surface, sanding sponges are used starting with the coarser sponge and graduating to the finer sponges. In total, 4 sponges are applied in sanding the briar surface. The pictures show the results after 4 sponges. The grain has started to make a nice appearance!

To clean the stummel of the minor nicks and dents that comes through normal wear, and to freshen the surface, sanding sponges are used starting with the coarser sponge and graduating to the finer sponges. In total, 4 sponges are applied in sanding the briar surface. The pictures show the results after 4 sponges. The grain has started to make a nice appearance!

Continuing with the external briar sanding and polishing, the full regimen of micromesh pads is applied. Beginning by wet sanding with pads 1500 to 2400, then dry sanding follows with pads 3200 to 4000 and 6000 to 12000.

Continuing with the external briar sanding and polishing, the full regimen of micromesh pads is applied. Beginning by wet sanding with pads 1500 to 2400, then dry sanding follows with pads 3200 to 4000 and 6000 to 12000.

I reunite the St. Claude made Pipstar Standard Dublin stem and stummel to get a fresh look at the progress. It’s looking great! I’m at the point in the process where a decision is needed regarding whether to apply a dye to the briar surface or to leave the natural briar hue that is emerging through the process. The purpose of applying a dye, probably Light Brown, would be to bring more distinction to the dark grains and the lighter wood. Yet, the natural grain is rocking by itself. I decided to ask the expert – my wife. Without hesitation she said that this pipe needed no dye to help it. Decision made!

I reunite the St. Claude made Pipstar Standard Dublin stem and stummel to get a fresh look at the progress. It’s looking great! I’m at the point in the process where a decision is needed regarding whether to apply a dye to the briar surface or to leave the natural briar hue that is emerging through the process. The purpose of applying a dye, probably Light Brown, would be to bring more distinction to the dark grains and the lighter wood. Yet, the natural grain is rocking by itself. I decided to ask the expert – my wife. Without hesitation she said that this pipe needed no dye to help it. Decision made! Staying with the natural briar hue, next Mark Hoover’s (www.ibepen.com) Before & After Restoration Balm is applied. This is an excellent product Mark has produced that teases out and deepens the natural hues of the briar. Applying it now, I place a small amount on my fingers and word it into the briar. At the start, it has a cream-like texture but thickens as it’s worked into the briar surface. After applied, I set the stummel aside for 15 or so minutes while the Balm does its thing – the picture below is during this period. I then use a microfiber cloth dedicated to wiping off the excess Balm (and I use the cloth to refresh other pipes with a quick buffing) and then buff the surface. The results are as good as hoped!

Staying with the natural briar hue, next Mark Hoover’s (www.ibepen.com) Before & After Restoration Balm is applied. This is an excellent product Mark has produced that teases out and deepens the natural hues of the briar. Applying it now, I place a small amount on my fingers and word it into the briar. At the start, it has a cream-like texture but thickens as it’s worked into the briar surface. After applied, I set the stummel aside for 15 or so minutes while the Balm does its thing – the picture below is during this period. I then use a microfiber cloth dedicated to wiping off the excess Balm (and I use the cloth to refresh other pipes with a quick buffing) and then buff the surface. The results are as good as hoped! While the Restoration Balm was working on the stummel, the Pipstar stem also receives the treatment of Before & After Fine and Extra Fine Polishes. Starting with the Fine Polish, I apply the black oily liquid to the stem and work it in well. After some minutes, the excess polish is wiped off. Following this, the same process with the Extra Fine Polish is done. After some minutes, the excess is wiped off and the stem is buffed up with a microfiber cloth. These polishes continue the removal of oxidation and conditions the stem according to Mark’s billing.

While the Restoration Balm was working on the stummel, the Pipstar stem also receives the treatment of Before & After Fine and Extra Fine Polishes. Starting with the Fine Polish, I apply the black oily liquid to the stem and work it in well. After some minutes, the excess polish is wiped off. Following this, the same process with the Extra Fine Polish is done. After some minutes, the excess is wiped off and the stem is buffed up with a microfiber cloth. These polishes continue the removal of oxidation and conditions the stem according to Mark’s billing. Before moving on to apply compound and wax, the Pipstar stem stamping needs refreshing. To do this, white acrylic paint is used. I place a small amount of paint onto the stamping and then I dob it dry using a cotton pad. Following this, the flat side of the toothpick is used to scrape the excess gently from the stem surface. The stamping is left refreshed with new paint. The star looks good!

Before moving on to apply compound and wax, the Pipstar stem stamping needs refreshing. To do this, white acrylic paint is used. I place a small amount of paint onto the stamping and then I dob it dry using a cotton pad. Following this, the flat side of the toothpick is used to scrape the excess gently from the stem surface. The stamping is left refreshed with new paint. The star looks good!

On the home stretch – after rejoining stem and stummel and mounting a cotton cloth buffing wheel on the Dremel set and 40% full power, Blue Diamond compound is applied to the pipe. After completing this, the pipe is wiped/buffed with a felt cloth to clean it of compound dust in preparation for application of the wax.

On the home stretch – after rejoining stem and stummel and mounting a cotton cloth buffing wheel on the Dremel set and 40% full power, Blue Diamond compound is applied to the pipe. After completing this, the pipe is wiped/buffed with a felt cloth to clean it of compound dust in preparation for application of the wax. Next, another cotton cloth buffing wheel is mounted on the Dremel at the same speed. A few coats of carnauba are then applied to stem and stummel. After application of the wax, a microfiber cloth is used to give the pipe a rigorous hand buffing to raise the shine and to disperse any wax that was not distributed.

Next, another cotton cloth buffing wheel is mounted on the Dremel at the same speed. A few coats of carnauba are then applied to stem and stummel. After application of the wax, a microfiber cloth is used to give the pipe a rigorous hand buffing to raise the shine and to disperse any wax that was not distributed. Wow! I’m pleased with the results! The French Pipstar Standard’s grain is beautiful as it climbs the Dublin bowl and swirls here and there with bird’s eye and flame formations. The original presentation of this pipe was with an Oxblood or reddish stain, but I believe the natural grain is much more appealing when the grain is as expressive as on this gently bent Dublin semi-Sitter. The rounded rim and the rounded heel complement each other and the gentle slight bend of the oval stem create an extremely attractive ensemble. This is the third of the 4 pipes that Nathan commissioned from the For “Pipe Dreamers” Only! online collection. He will have the first opportunity to acquire the French Pipstar Standard in The Pipe Steward Store benefitting the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!

Wow! I’m pleased with the results! The French Pipstar Standard’s grain is beautiful as it climbs the Dublin bowl and swirls here and there with bird’s eye and flame formations. The original presentation of this pipe was with an Oxblood or reddish stain, but I believe the natural grain is much more appealing when the grain is as expressive as on this gently bent Dublin semi-Sitter. The rounded rim and the rounded heel complement each other and the gentle slight bend of the oval stem create an extremely attractive ensemble. This is the third of the 4 pipes that Nathan commissioned from the For “Pipe Dreamers” Only! online collection. He will have the first opportunity to acquire the French Pipstar Standard in The Pipe Steward Store benefitting the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!