Blog by Steve Laug

I received a short email from a reader of the blog about a Dr. Plumb Bulldog that he had that needed a bit of work. He wanted to know if I would be willing to work on it for him. He said that there were some issues with the pipe that he wanted me to try my hand at repairing. He said that the shank had a crack, the stem had a broken stinger end lodged in the airway and the button was broken off on the underside of the stem. I wrote back and asked him to send me some photos of the pipe so I could see what he was speaking about regarding the pipe. He sent the first photo to give me an idea of the overall look of the pipe. Looking at it I have to say that it is a classic GBD shaped bent Bulldog and it had nice grain.  He sent a photo of the crack at the bowl/shank junction and noted that he had glued it but was not happy with the way it looked. The photo only shows the crack on the left side of the stem but it was also on the right side. He wanted me to clean it up and stabilize it so that it would not crack any further. That should not be too much of an issue.

He sent a photo of the crack at the bowl/shank junction and noted that he had glued it but was not happy with the way it looked. The photo only shows the crack on the left side of the stem but it was also on the right side. He wanted me to clean it up and stabilize it so that it would not crack any further. That should not be too much of an issue. He sent along a photo of the rim top showed that the outer edge of the bowl had some small nicks in it that needed to be cleaned up. The surface of the beveled rim had some lava overflow and was darkened in several places around the top and the inner edge of the bowl. It was hard to tell for certain from the photos but there was probably some wear on the top and inner edges.

He sent along a photo of the rim top showed that the outer edge of the bowl had some small nicks in it that needed to be cleaned up. The surface of the beveled rim had some lava overflow and was darkened in several places around the top and the inner edge of the bowl. It was hard to tell for certain from the photos but there was probably some wear on the top and inner edges.  The next photo he included showed the stem. Not only was it oxidized with a nice greenish brown colour but there was the “little issue” shown on the underside of the stem. There was a large chunk of vulcanite missing from the button and extended down into the surface of the stem. It appeared to be broken off and I wonder if had not happened when attempting to drill out the broken stinger. I am not sure but I have seen that kind of damage done with a drill bit on other stems in the past. The other possibility is less likely but could have happened, while inserting a thick pipe cleaner the button had cracked and come off.

The next photo he included showed the stem. Not only was it oxidized with a nice greenish brown colour but there was the “little issue” shown on the underside of the stem. There was a large chunk of vulcanite missing from the button and extended down into the surface of the stem. It appeared to be broken off and I wonder if had not happened when attempting to drill out the broken stinger. I am not sure but I have seen that kind of damage done with a drill bit on other stems in the past. The other possibility is less likely but could have happened, while inserting a thick pipe cleaner the button had cracked and come off. The final two photos pin point the second issue that he was having with the pipe. The metal stinger threaded into the tenon that comes on all Dr. Plumb pipes had been broken off with the threaded portion of it stuck in the tenon and extending part of the way up the stem. His photos included a tenon end shot and a photo of the broken stinger by itself. You can see the ragged edge of the end that would have sat flush against the end of the tenon.

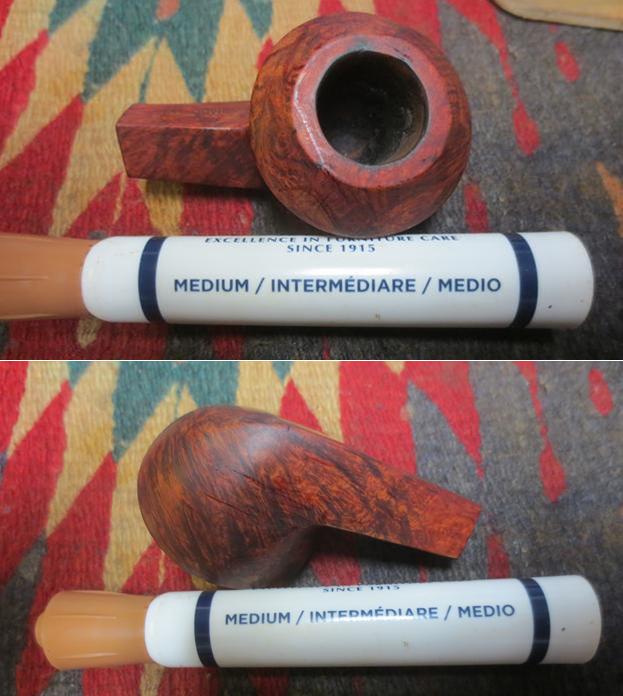

The final two photos pin point the second issue that he was having with the pipe. The metal stinger threaded into the tenon that comes on all Dr. Plumb pipes had been broken off with the threaded portion of it stuck in the tenon and extending part of the way up the stem. His photos included a tenon end shot and a photo of the broken stinger by itself. You can see the ragged edge of the end that would have sat flush against the end of the tenon. Once I saw the photos, I wrote back and told him to send the pipe up to Canada and I would see what I could do with the issues on the pipe. He packed it up and sent it off to me. It did not take too long for it to arrive here in Vancouver. I unpacked it from the mailing envelope it came in and had a look at it. It was even a better looking little Bulldog in person. There were a few small fills on the shank. The largest of the fills was on the right side of the shank right at the junction of the stem and bowl. The crack went through and around the fill. The pipe was stamped faintly on the left side of the shank with the script Dr. Plumb over Perfect Pipe and on the right side it was faintly stamped Made in England and the shape number 134. The stamping was only readable under a bright light. The shank was dirty and the airway in the bowl was tarry and dirty from the buildup around the stinger apparatus. The airway in the stem was dirty and partially blocked by the broken stinger. I took photos of the pipe when I received it so I would have a base to show the progress once I had finished. The third photo shows the damaged stem and I have circled the missing chunk of vulcanite in red.

Once I saw the photos, I wrote back and told him to send the pipe up to Canada and I would see what I could do with the issues on the pipe. He packed it up and sent it off to me. It did not take too long for it to arrive here in Vancouver. I unpacked it from the mailing envelope it came in and had a look at it. It was even a better looking little Bulldog in person. There were a few small fills on the shank. The largest of the fills was on the right side of the shank right at the junction of the stem and bowl. The crack went through and around the fill. The pipe was stamped faintly on the left side of the shank with the script Dr. Plumb over Perfect Pipe and on the right side it was faintly stamped Made in England and the shape number 134. The stamping was only readable under a bright light. The shank was dirty and the airway in the bowl was tarry and dirty from the buildup around the stinger apparatus. The airway in the stem was dirty and partially blocked by the broken stinger. I took photos of the pipe when I received it so I would have a base to show the progress once I had finished. The third photo shows the damaged stem and I have circled the missing chunk of vulcanite in red.

I took a close up photo of the rim top to show the darkening to the rim and the debris that was built up on the top. There was some damage to the inner edge of the rim that would need to be smoothed out.

I took a close up photo of the rim top to show the darkening to the rim and the debris that was built up on the top. There was some damage to the inner edge of the rim that would need to be smoothed out. I took some photos of the stem to show the oxidation and the damaged area on the underside at the button.

I took some photos of the stem to show the oxidation and the damaged area on the underside at the button. I made a wedge out of cardboard and cellophane tape and pushed it into the slot in the button to provide a base for the repair. I mixed charcoal powder with black super glue and built up the missing chunk. I removed the wedge and slid a greased pipe cleaner into the slot and built up the area on the end of the button. I filled in the deep tooth marks on the top side of the stem with the mixture.

I made a wedge out of cardboard and cellophane tape and pushed it into the slot in the button to provide a base for the repair. I mixed charcoal powder with black super glue and built up the missing chunk. I removed the wedge and slid a greased pipe cleaner into the slot and built up the area on the end of the button. I filled in the deep tooth marks on the top side of the stem with the mixture.

I filed the repair on the underside of the stem with a rasp and a file to begin to shape the button edge and blend the repair into the surface of the stem. I shaped the button with the files as well to begin to shape it in a classic football shape to match the top half of the stem. The photos show the progress of the shaping. Once I had the levels on the surface correct I wiped the stem down and could see the tiny air bubbles in the repair. I filled them in with clear super glue and let them cure.

I filed the repair on the underside of the stem with a rasp and a file to begin to shape the button edge and blend the repair into the surface of the stem. I shaped the button with the files as well to begin to shape it in a classic football shape to match the top half of the stem. The photos show the progress of the shaping. Once I had the levels on the surface correct I wiped the stem down and could see the tiny air bubbles in the repair. I filled them in with clear super glue and let them cure.

Once the repairs had cured I used needle files to reshape the button and slot in the end of the stem. There were a few more air bubbles that showed up as I reshaped the button. Once they dried I sanded repaired spots. I used the files to cut the sharp edge of the button. When the spots dried I sanded the surface of the stem with 220 grit sandpaper to smooth out the repaired areas and blend them into the rest of the stem.

Once the repairs had cured I used needle files to reshape the button and slot in the end of the stem. There were a few more air bubbles that showed up as I reshaped the button. Once they dried I sanded repaired spots. I used the files to cut the sharp edge of the button. When the spots dried I sanded the surface of the stem with 220 grit sandpaper to smooth out the repaired areas and blend them into the rest of the stem.

I set the stem aside for awhile and worked on the bowl. I wiped down the area around the crack in the shank and drilled small microdrill bit holes in the end of each of them. I fount that on the right side there was a third trail of crack so I drilled it as well. I filled in the drill holes with clear super glue. I layered in the glue to a bubble and let it dry.

I set the stem aside for awhile and worked on the bowl. I wiped down the area around the crack in the shank and drilled small microdrill bit holes in the end of each of them. I fount that on the right side there was a third trail of crack so I drilled it as well. I filled in the drill holes with clear super glue. I layered in the glue to a bubble and let it dry.

Once the glue had dried I sanded the length of each crack in the shank and the repaired holes as well until they were smooth. I sanded the beveled rim top to smooth out the damage and clean up the surface. I worked over the inner edge with sandpaper to smooth out the damaged areas.

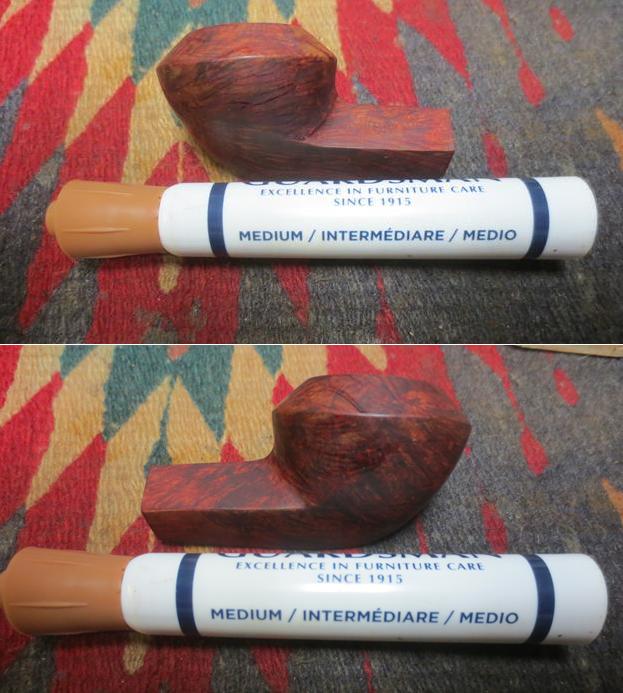

Once the glue had dried I sanded the length of each crack in the shank and the repaired holes as well until they were smooth. I sanded the beveled rim top to smooth out the damage and clean up the surface. I worked over the inner edge with sandpaper to smooth out the damaged areas. I used a dark brown stain pen to touch up the repaired and sanded areas on the shank and on the beveled rim top.

I used a dark brown stain pen to touch up the repaired and sanded areas on the shank and on the beveled rim top.

I cleaned out the inside of the shank and mortise with cotton swabs, pipe cleaners and alcohol until the shank was clean and all of the oils and tars were removed.

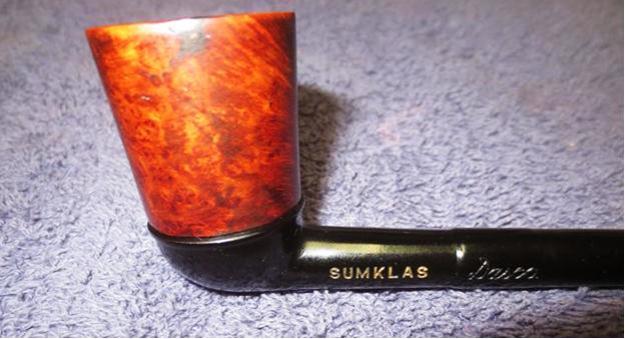

I cleaned out the inside of the shank and mortise with cotton swabs, pipe cleaners and alcohol until the shank was clean and all of the oils and tars were removed. I stained the bowl and shank with a dark brown aniline stain. I flamed the stain to set it in the briar and repeated the process until the coverage around the bowl was even.

I stained the bowl and shank with a dark brown aniline stain. I flamed the stain to set it in the briar and repeated the process until the coverage around the bowl was even.  I wiped down the briar with alcohol on cotton pads to make it more transparent. After wiping it down the grain shone through the stain coat. I think that once it is polished it would be a beautiful finish for this Dr. Plumb.

I wiped down the briar with alcohol on cotton pads to make it more transparent. After wiping it down the grain shone through the stain coat. I think that once it is polished it would be a beautiful finish for this Dr. Plumb.

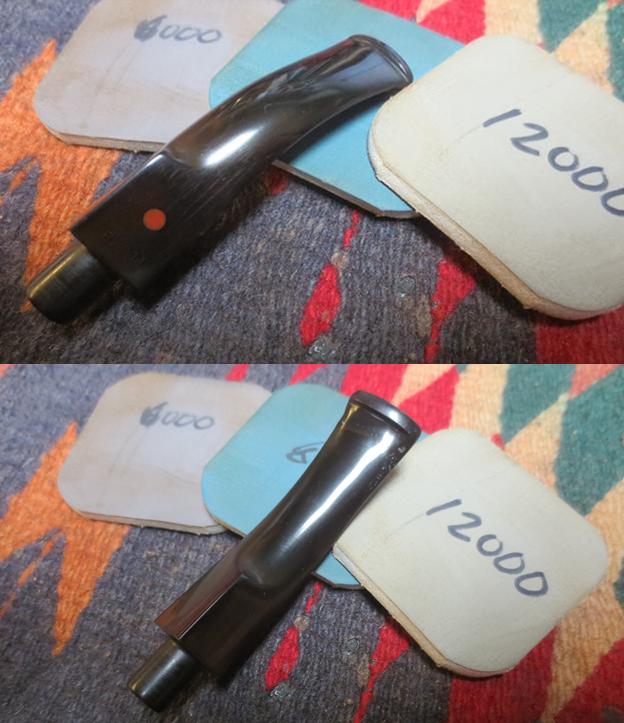

Polishing the stem was a harder prospect and took more work than the bowl. The sanding and polishing process repeatedly revealed new air bubbles in the newly built up underside of the stem and button. I sanded and added drops of clear super glue to take care of each air bubble. It was tedious but it paid off. I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and wiping down the stem after each pad with Obsidian Oil. I checked for new air bubbles and then went on to dry sand it with 3200-4000 grit pads. I gave it a coat of oil after each one and then finished polishing it with 6000-12000 grit pads. I repeated the oil after each pad and after the 12000 grit pad I set the stem aside to dry.

Polishing the stem was a harder prospect and took more work than the bowl. The sanding and polishing process repeatedly revealed new air bubbles in the newly built up underside of the stem and button. I sanded and added drops of clear super glue to take care of each air bubble. It was tedious but it paid off. I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and wiping down the stem after each pad with Obsidian Oil. I checked for new air bubbles and then went on to dry sand it with 3200-4000 grit pads. I gave it a coat of oil after each one and then finished polishing it with 6000-12000 grit pads. I repeated the oil after each pad and after the 12000 grit pad I set the stem aside to dry.

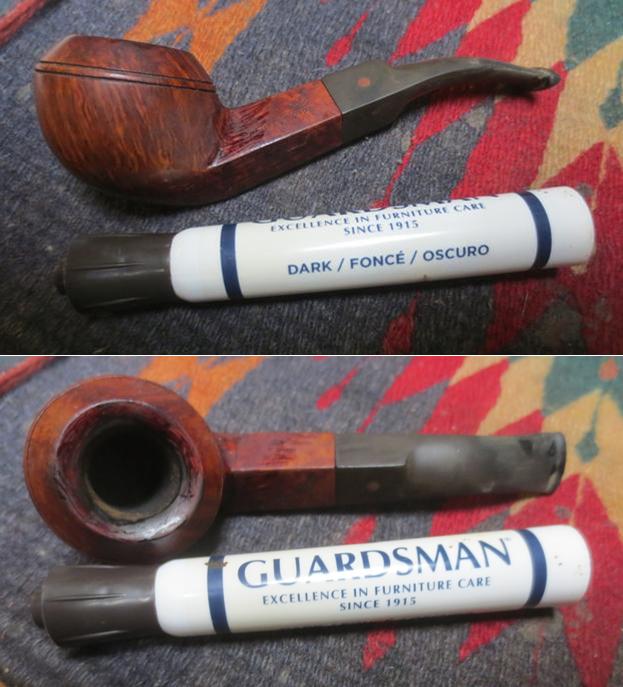

I put the stem back on the bowl and buffed the pipe with Blue Diamond. I kept a light touch in buffing the underside of the stem and button as I did not want to do any harm to the repair. I buffed the repairs on the shank normally and the rest of the pipe the same way. I gave the bowl and stem multiple coats of carnauba wax and buffed it with a clean buffing pad to raise the shine in the briar and vulcanite. I hand buffed it with a microfiber cloth to deepen the shine. The pipe is almost ready to go back to the pipe man who sent it to me. It will go out later this week after I do a last minute check up on the entire pipe. I want it to go back to him in good condition. Thanks for walking with me through this repair and restoration project.

I put the stem back on the bowl and buffed the pipe with Blue Diamond. I kept a light touch in buffing the underside of the stem and button as I did not want to do any harm to the repair. I buffed the repairs on the shank normally and the rest of the pipe the same way. I gave the bowl and stem multiple coats of carnauba wax and buffed it with a clean buffing pad to raise the shine in the briar and vulcanite. I hand buffed it with a microfiber cloth to deepen the shine. The pipe is almost ready to go back to the pipe man who sent it to me. It will go out later this week after I do a last minute check up on the entire pipe. I want it to go back to him in good condition. Thanks for walking with me through this repair and restoration project.