Blog by Steve Laug

I wrote about the estate lot that I was tasked to clean up and sell on a previous blog at https://rebornpipes.com/2016/10/25/this-favourite-gbd-marquis-752-was-a-mess-not-any-more/. About a month ago a friend of mine, Richard who has a tobacco shop here in Vancouver gave me a call and asked me to stop by for a visit. I went on a Sunday afternoon and we visited for a while. At the end of the visit he took me to another counter in his shop and brought out some display cases of pipes – four of them and a small bag. He told the story to me. An elderly gentleman who was a customer of his had died and his wife had stopped by and gave him the fellow’s pipes. She wanted nothing for them she just wanted him to get them cleaned up and sold to folks who would appreciate them. Richard is a reader of the blog and he thought that I would have fun cleaning these up and selling them. As we went through the display cases and bag I was pretty pumped about the collection. There were some really nice GBD pipes, Comoy’s, Stanwells, Peterson’s as well as some brands I was not familiar with.

The second pipe I chose to work on was a Peterson’s Dublin oval shank billiard shaped pipe.The old gentleman seemed to favour Peterson’s as there were quite a few in the estate lot. It was very dirty. It was stamped on the topside of the shank with K&P over DUBLIN. There is also a silver band on the shank that bears three hallmarks over Sterling Silver. On the right side of the shank is the shape number 203. On the underside of the shank it is stamped with a COM (Country of Manufacture) circle that reads Made in England with the “in” stamped in the centre of the circle. The stamping is clear and sharp. The finish is in decent shape with a medium brown stain over mixed grain. There is an uneven cake in the bowl that spilled thickly over the beveled rim. It is hard to tell if there is rim damage as it is so dirty. There were sandpits on the left side of the bowl and on the back side above the shank. There is no P stamping on the P-lip stem but it appears to be an original not a replacement. There is calcification from a softee bit on the stem and button. There are light tooth marks and chatter on the top and bottom side of the stem ahead of the P-lip. The button itself was in good shape.

Here are some photos of the pipe when I started cleaning it. The pipe has good lines and some interesting grain underneath the grime.

I took some close up photos of the bowl, stamping, band and stem to give a good picture of what I needed to work on. The first photo shows the cake in the bowl and the overflow of hard carbon buildup on the rim. The photo of the silver band shows the Sterling Silver stamp and three hallmark symbols. It is hard to read them but with a magnifying lens they read K&P. I was hoping to be able to date the pipe by the hallmarks but no such luck. The photos of the stamping show that they are faint but still readable. The stem photos show the tooth chatter and wear on the button itself.

I took some close up photos of the bowl, stamping, band and stem to give a good picture of what I needed to work on. The first photo shows the cake in the bowl and the overflow of hard carbon buildup on the rim. The photo of the silver band shows the Sterling Silver stamp and three hallmark symbols. It is hard to read them but with a magnifying lens they read K&P. I was hoping to be able to date the pipe by the hallmarks but no such luck. The photos of the stamping show that they are faint but still readable. The stem photos show the tooth chatter and wear on the button itself.

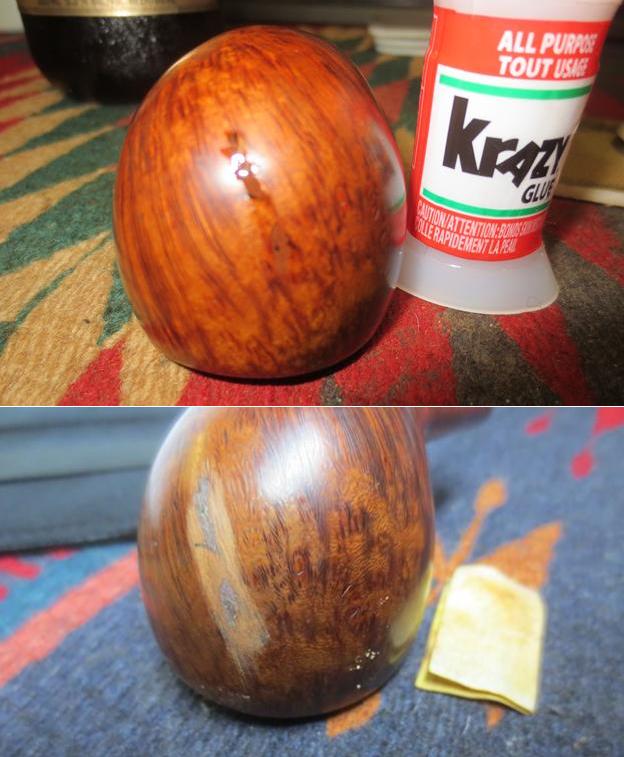

When I removed the stem I could see some divots in the end of the shank. There were cutouts that as far as I could see served no purpose. Someone had tried to repair them but left a bit of a mess so the stem did not fit snugly. I cleaned out the divots and smoothed them out with needle files until they matched the inside of the mortise. I filled in the end with some super glue and briar dust to even out the shank end.

When I removed the stem I could see some divots in the end of the shank. There were cutouts that as far as I could see served no purpose. Someone had tried to repair them but left a bit of a mess so the stem did not fit snugly. I cleaned out the divots and smoothed them out with needle files until they matched the inside of the mortise. I filled in the end with some super glue and briar dust to even out the shank end. The lava buildup on the rim top was rock hard. I scrubbed at it but it would not come off. The outer edges of the rim were also damaged from knocking out the pipe on hard surfaces. I lightly topped the bowl to remove the hard tars and clean up the outer edges.

The lava buildup on the rim top was rock hard. I scrubbed at it but it would not come off. The outer edges of the rim were also damaged from knocking out the pipe on hard surfaces. I lightly topped the bowl to remove the hard tars and clean up the outer edges. I reamed the bowl with the Savinelli Pipe Knife and took the cake back to bare briar.

I reamed the bowl with the Savinelli Pipe Knife and took the cake back to bare briar. There were some drops of a clear hard substance on the back of the bowl and on the right side that I could not take off without damaging the bowl. I scrubbed them down with some alcohol on a cotton pad and was able to soften them enough to remove them.

There were some drops of a clear hard substance on the back of the bowl and on the right side that I could not take off without damaging the bowl. I scrubbed them down with some alcohol on a cotton pad and was able to soften them enough to remove them.

I restained the rim to match the bowl using a combination of a medium and a dark stain pen. I also touched up the light areas around the silver band on the shank end.

I restained the rim to match the bowl using a combination of a medium and a dark stain pen. I also touched up the light areas around the silver band on the shank end. I polished the silver with some tarnish remover applied with cotton pads. I finished polishing it with a jeweler’s cloth. Once I had finished I could see the hallmarks more clearly and they read K&P – each letter in its own cartouche.

I polished the silver with some tarnish remover applied with cotton pads. I finished polishing it with a jeweler’s cloth. Once I had finished I could see the hallmarks more clearly and they read K&P – each letter in its own cartouche.

I gave the bowl a quick coat of Conservators Wax and hand buffed it to see where I stood. I chose to leave the sandpits on the left side and back of the bowl as they add character.

I gave the bowl a quick coat of Conservators Wax and hand buffed it to see where I stood. I chose to leave the sandpits on the left side and back of the bowl as they add character.

I sanded the tooth chatter, reshaped the button and removed the calcification and oxidation on the stem with 220 grit sandpaper.

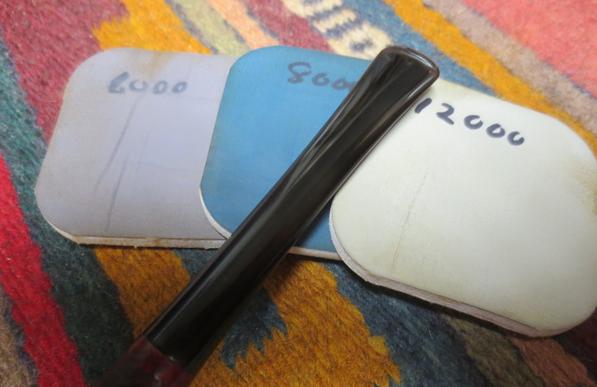

I sanded the tooth chatter, reshaped the button and removed the calcification and oxidation on the stem with 220 grit sandpaper. I wet sanded the stem with 1500-2400 grit micromesh sanding pads and dry sanded it with 3200-12000 grit pads. I rubbed it down with a coat of Obsidian Oil after each set of three pads. I gave it a final coat of oil and set it aside to dry.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and dry sanded it with 3200-12000 grit pads. I rubbed it down with a coat of Obsidian Oil after each set of three pads. I gave it a final coat of oil and set it aside to dry.

With all the parts finished individually I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. The Blue Diamond is a plastic polish and gives the finish a glass like polish. I really like the way it works. I gave the bowl and stem multiple coats of carnauba wax and buffed it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to finish the polishing process. The finished pipe is shown in the photos below. This second pipe from the older gentleman’s estate is a beauty. The fit and finish give it a look of elegance. This pipe is also available for sale. If you are interested in the pipe let me know via email at slaug@uniserve.com or through a message on Facebook. Thanks for walking through the process of restoration with me.

With all the parts finished individually I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. The Blue Diamond is a plastic polish and gives the finish a glass like polish. I really like the way it works. I gave the bowl and stem multiple coats of carnauba wax and buffed it with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to finish the polishing process. The finished pipe is shown in the photos below. This second pipe from the older gentleman’s estate is a beauty. The fit and finish give it a look of elegance. This pipe is also available for sale. If you are interested in the pipe let me know via email at slaug@uniserve.com or through a message on Facebook. Thanks for walking through the process of restoration with me.