Blog by Steve Laug

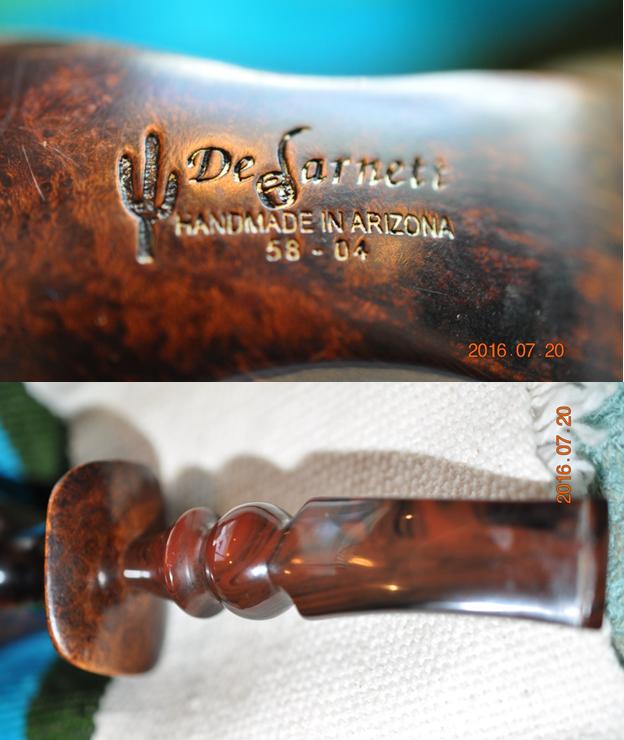

My brother sent me photos of this interestingly shaped De Jarnett pipe and wondered about it. I agreed there was something about it that grabbed me too. The grain on the darkly stained bowl, the Cumberland style Lucite stem, the curves of the pipe following the grain, the mushroom cap on the top of the bowl all were a part of the mystique of the pipe. He bid on it and the pipe was his. I received it in the mail in the last box of pipes he sent me. Last night I took it out to have a closer look at the pipe. I always have my brother take photos of the pipe before he does any work on it so he sent the following photos along with the pipe. It looks really nice but I had no idea how large the pipe was until I had it in hand. It is 6 ½ inches long, 2 ¾ inches tall, 2 ¼ inches in diameter with a chamber size of 7/8 inch. It is a handful. The stamping on the underside of the shank has a cactus which was Horace’s logo and the name De Jarnett with the J stylized into a pipe. Underneath it says Handmade in Arizona over 58-04. My guess is that the number stamping tells me that the pipe is the 58th pipe he made in 2004.

It looks really nice but I had no idea how large the pipe was until I had it in hand. It is 6 ½ inches long, 2 ¾ inches tall, 2 ¼ inches in diameter with a chamber size of 7/8 inch. It is a handful. The stamping on the underside of the shank has a cactus which was Horace’s logo and the name De Jarnett with the J stylized into a pipe. Underneath it says Handmade in Arizona over 58-04. My guess is that the number stamping tells me that the pipe is the 58th pipe he made in 2004. The photo he sent me of the rim shows the cake in the bowl and the damage to the inner edge of the rim. It looks like it is burned but once I see it and examine it I will know how bad the burn mark is. There is also a sizable dent on the bowl top and some overall darkening of the rim cap.

The photo he sent me of the rim shows the cake in the bowl and the damage to the inner edge of the rim. It looks like it is burned but once I see it and examine it I will know how bad the burn mark is. There is also a sizable dent on the bowl top and some overall darkening of the rim cap. I had heard of De Jarnett pipes in the past and talked to others about them. I have also done repairs on one of them in the past but I had never taken the time to read about the maker. I assumed he was still living which turns out to be false. I turned to my two go to sites Pipephil and Pipedia for information and found little other than the dates of the maker which showed he had died and the location of the shop which is on the pipe anyway. However, Pipedia was more fruitful. Here is the link: https://pipedia.org/wiki/DeJarnett_Pipes

I had heard of De Jarnett pipes in the past and talked to others about them. I have also done repairs on one of them in the past but I had never taken the time to read about the maker. I assumed he was still living which turns out to be false. I turned to my two go to sites Pipephil and Pipedia for information and found little other than the dates of the maker which showed he had died and the location of the shop which is on the pipe anyway. However, Pipedia was more fruitful. Here is the link: https://pipedia.org/wiki/DeJarnett_Pipes

When I read the write up on Pipedia I found that Horace DeJarnett had died on July 24, 2013. He had been battling with terminal cancer, but his wife reported that he ultimately died of a stroke. Since I had also suffered a stroke this gave me a sense of connection with the carver. I only wish that I had been able to have a chat with him before he died. I find that those conversations I have had with pipe makers have been highlights of my pipe collecting and repair/restoration hobby.

Pipedia also included a photo of Horace that was taken by Pipes& Tobacco Magazine and used by courtesy. I have included much of the Pipedia article here for ease of reference. For the details and the remainder of the article use the link above.

Horace wrote of his pipes: “All of my pipes are carved from the finest quality Algerian briar I can find. I coat each bowl with a special pre-carb treatment which speeds up the break-in process. After the third bowl, it will smoke as if it had been in your collection for years. I get a lot of positive feed-back on this feature.

Standard draft holes are 5/32″. I think that’s too small and many pipe smokers agree with me. So I drill mine to 3/16″ for a better draw. You won’t have to send my pipes out to a pipe repairman to have them opened up, as many do.

For over 40 years I worked in the grocery industry. In 1984 I founded my own food brokerage business. It prospered and grew into a multi-state corporation. In 1999 I sold my portion of the business and retired.

Due to health concerns and public scrutiny, I quit smoking cigarettes in 1993 and took up the pipe.

(I believed then – and still do – that health risks are greatly reduced by not inhaling and just puffing.) Serious pipe-smoking is conducive to day-dreaming, and thus the idea of making my own pipes became a quest.

I was fortunate to study under Andrew Kovacs, a well-known carver in Northern Arizona (trade name “Jandrew”) for about a year, off and on. I learned a lot of the basics from Andy, but some of my best counsel came via long telephone conversations with Mark Tinsky.

Over the years I have made and sold approximately 1,000 pipes, most of them here in the United States, but I do have customers in Indonesia, Germany, Japan, England, Israel, Canada, and Thailand.

What began as a hobby has become my passion. I lost my leg in 2001 due to a blood clot, so fortunately for me, I have an occupation that is “handicap friendly”.

That glimpse of Horace from his own words gives a clear picture of what he brought to the making of each pipe that he sent out. I have no idea where the pipe that arrived in Vancouver has been before coming here nor do I know where it will go afterward. But I know that it will certainly outlive me. The quality of briar and craftsmanship give it a great chance at longevity.

My brother Jeff did his normal thorough cleanup of the exterior and the interior of the pipe. When it arrived it had been reamed, cleaned and sent to me for the final touches. It is really nice to have him doing the grunt work on these pipes. This was no exception. I took a few photos of the cleaned up pipe when I brought it to my work table.  The next photo shows the darkening and burn mark on the rim. A close up of that area is shown in the photos that follow.

The next photo shows the darkening and burn mark on the rim. A close up of that area is shown in the photos that follow. The burn mark and darkening at the front of the bowl was more extensive than I had originally guessed from the photos sent. The front inner edge is burned and beveled inward with the darkening extending quite a way into the rim top. The back edge also shows some burning that will need to be address. The second photo gives another view of the stamping.

The burn mark and darkening at the front of the bowl was more extensive than I had originally guessed from the photos sent. The front inner edge is burned and beveled inward with the darkening extending quite a way into the rim top. The back edge also shows some burning that will need to be address. The second photo gives another view of the stamping. The stem had some tooth chatter on the top and the underside and the edge of the button was worn and flattened.

The stem had some tooth chatter on the top and the underside and the edge of the button was worn and flattened.  To remove the burn damage on the inner edge of the rim I used a folded piece of 220 grit sandpaper to bevel the rim edge inward to accommodate the damage on the bowl front. I carried that bevel around the entire rim edge to clean up the damage at the rear as well. The next two photos show the newly beveled rim. The angle on the second photo makes the bevel appear to be thicker at the front of the bowl than the back. However, in hand the bevel is the same size around the bowl.

To remove the burn damage on the inner edge of the rim I used a folded piece of 220 grit sandpaper to bevel the rim edge inward to accommodate the damage on the bowl front. I carried that bevel around the entire rim edge to clean up the damage at the rear as well. The next two photos show the newly beveled rim. The angle on the second photo makes the bevel appear to be thicker at the front of the bowl than the back. However, in hand the bevel is the same size around the bowl. I wet sanded the rim with 1500-2400 grit micromesh sanding pads and dry sanded it with 3200-12000 grit pads to polish the scratches and the new bevel. I used a dark brown stain pen to touch up the inner edge of the rim to match the colour of the bowl. All that remains of the burn mark is a small dark spot on the front top of the bowl and some darkening in the inner edge. It is far better than when I began.

I wet sanded the rim with 1500-2400 grit micromesh sanding pads and dry sanded it with 3200-12000 grit pads to polish the scratches and the new bevel. I used a dark brown stain pen to touch up the inner edge of the rim to match the colour of the bowl. All that remains of the burn mark is a small dark spot on the front top of the bowl and some darkening in the inner edge. It is far better than when I began.  I sanded out the tooth chatter and reshaped the button with 220 grit sandpaper. I wet sanded the stem with 1500-2400 grit micromesh sanding pads, wiped it down with a damp cloth and dry sanded it with 3200-12000 grit pads. I wiped it down with a damp cloth a final time.

I sanded out the tooth chatter and reshaped the button with 220 grit sandpaper. I wet sanded the stem with 1500-2400 grit micromesh sanding pads, wiped it down with a damp cloth and dry sanded it with 3200-12000 grit pads. I wiped it down with a damp cloth a final time.

I buffed the pipe and stem with Blue Diamond on the buffing wheel. I gave the bowl and stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise and shine and hand buffed it with a microfibre cloth. The finished pipe is shown in the photos below. It is a big pipe so it will eventually be listed on the store for sale. If you are interested in it before that time just send me an email at slaug@uniserve.com or send me a message or a comment here or on Facebook. Thanks for looking.

I buffed the pipe and stem with Blue Diamond on the buffing wheel. I gave the bowl and stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise and shine and hand buffed it with a microfibre cloth. The finished pipe is shown in the photos below. It is a big pipe so it will eventually be listed on the store for sale. If you are interested in it before that time just send me an email at slaug@uniserve.com or send me a message or a comment here or on Facebook. Thanks for looking.