By Al Jones

The Savinelli 320 shape has been on my “Holy Grail” list for a few years, but I wanted the pipe to be in the Guibileo d’Oro grade and have a vulcanite stem. After a while, it seemed hopeless to actually find one. In fact, I had dropped it from my eBay search list last year. Only because of the eagle eye of my friend, Dave J, was I able to acquire one. Dave gave me the heads up on this pipe when it was listed. I put in a last second bid and lost by one dollar. I figured it was not to be. A few weeks later, the seller messaged me that the winning bidder had never made payment and it was mine for my final bid, how fortunate!

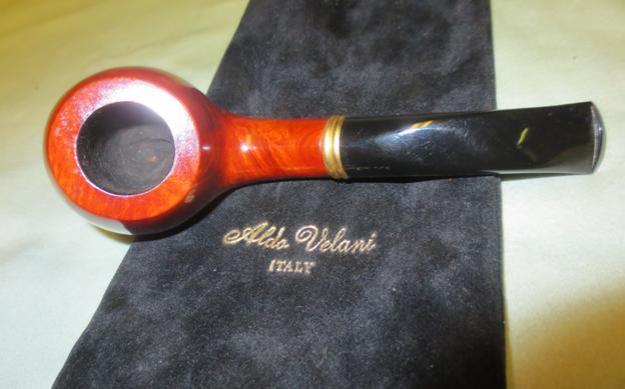

After making the purchase, it only occurred to me that this one has the additional “Fiamatta Straight Grain” stamp. I knew that only one in a thousand Savinelli’s make the Guibileo d’Oro grade but I had no idea on how many of those had the “Fiamatta” stamp. This pipe has a Vulcanite stem, with no filter, which means it was made before 1982 when the factory switched to acrylic/filter stems.

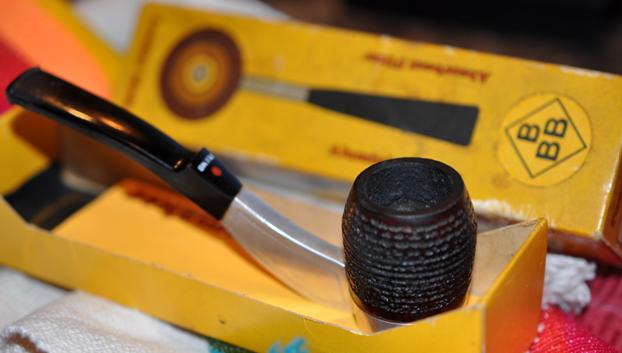

The pipe was in very good shape, with a mild cake, some oxidation on the stem and a few minor bite marks. The stem fitment was excellent.

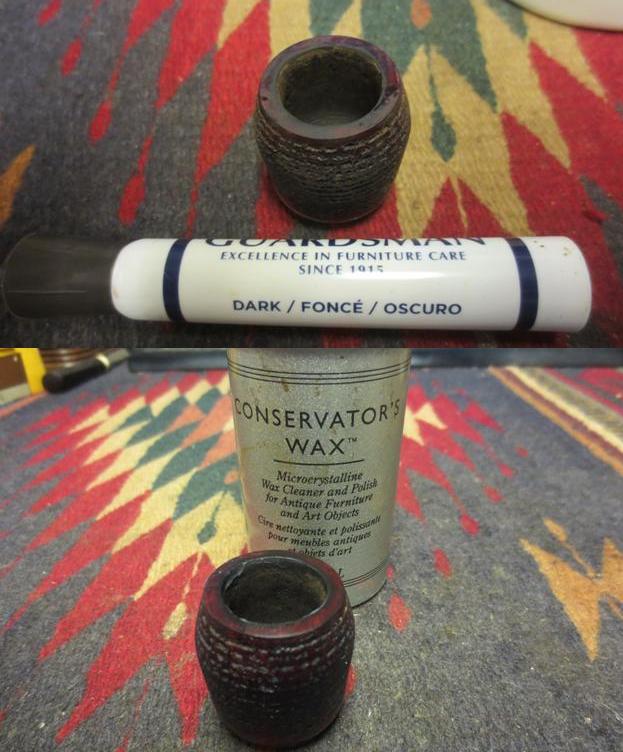

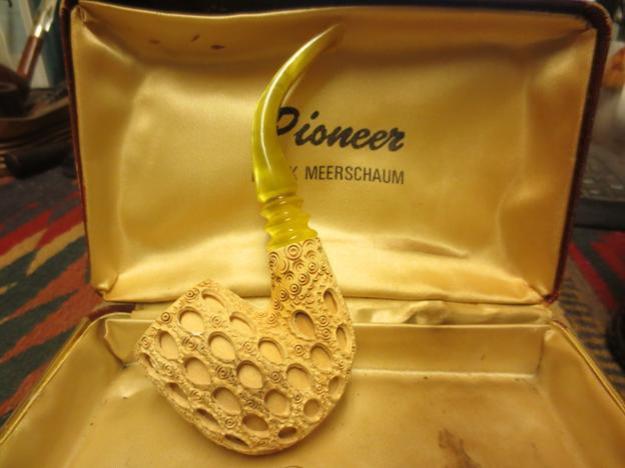

I used a wet cloth to remove the thin layer of buildup on the polished rim. It was undamaged underneath. I removed the cake with my Castleford reamer set. The bowl is quite wide, conical and in excellent condition. The briar was then soaked with alcohol and sea salt. Here’s a shot as it was soaking, after the rim was cleaned, polished with White Diamond and some Carnuba wax.

?

I put some grease on the gold stem dots and soaked it in a mild Oxy-Clean solution. While it was soaking, I removed the salt from the bowl and cleaned it with a bristle brush and alcohol. I was able to raise the teeth marks with some heat from a lighter flame. The stem was then mounted to the bowl and I used 800, 1000 and 2000 grades of sandpaper to remove the oxidation and polish the stem. 8,000 grade micromesh was then used. The stem was buffed with White Diamond and Meguiars plastic polish.

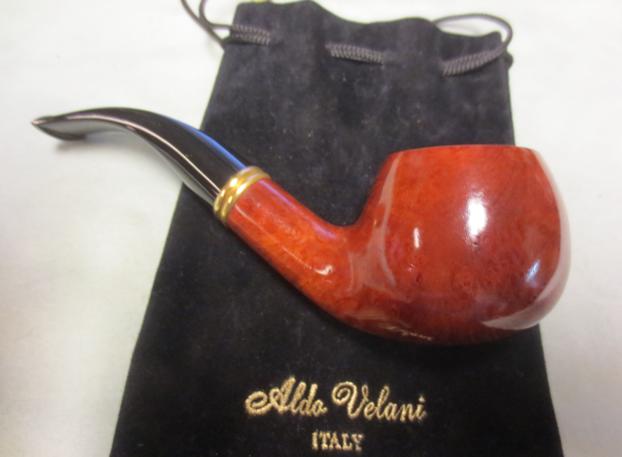

The KS designation is for an oversized pipe and this one is a hefty 70 grams, which is slightly larger than a GBD 9438. Here is the finished pipe.

If anyone has information on the “Fiamatta” stamp, please comment.

?