Guest Blog by Robert M. Boughton

Member, North American Society of Pipe Collectors

http://www.naspc.org

http://www.roadrunnerpipes.com

http://about.me/boughtonrobert

Photos © the Author

“Every writer is a frustrated actor who recites his lines in the hidden auditorium of his skull.”

― Rodman Edward “Rod” Serling (1924-1975), U.S. TV/film writer, narrator, anti-war and –racism activist, in “Vogue” magazine [April 1957]

INTRODUCTION

Good evening. Imagine, if you will, a rather large college town in the heart of the American Southwest, population estimated at a little more than half a million. This sprawling urban area does not appear on any globe of the Earth, nor do its lights draw the attention of a satellite passing far overhead at night in the vacuum of outer space. Nevertheless, due to the proximity of two of the country’s three top nuclear weapons developers to this liberal college and arts metropolis, it is likely the target of hundreds if not thousands of such warheads from other, potentially hostile nations or terrorists, foreign and domestic.

In today’s episode, we are about to meet a 53-year-old man named Robert Boughton, who as a matter of record resides in this sprawling burg. Mr. Boughton knows the twin peaks that are, atop the one, success and hope, and the other, defeat and futility. At the moment, he is at the very zenith of the heap of that more and more common social malaise that people glibly call the harried man. He is finding his way through one of the more interesting times of his life, in the sense of the ancient Chinese curse. Honest, hard-working and trustworthy, he has had more jobs than he could ever recall to put down on a government security clearance application, from maintenance man to assistant manager in hotels; neighborhood delivery boy to photojournalist for newspapers, and, most recently, both caregiver and pipe restorer – tobacco pipes, he always adds to prospective new customers he doesn’t know as he offers them his card.

During the past seven years, Mr. Boughton has postponed his lifelong pursuit of a literary career to dedicate almost every waking hour as caregiver to a mentally unstable roommate with a slightly shorter list of physical disorders, one of them fatal; a shrewish man a few years over the hill who carries his misfortunes the way some brag about drug abuse or petty thievery, but in his case molded into the very form and execution of his tragic worldview by the madness of living day-to-day knowing he is deteriorating from the core of marrow of his brittle bones to the disappearing sheath around every nerve fiber and the corresponding loss of sight and voluntary movement, and finally to the thin skin of his failing frame.

Mr. Boughton’s roommate has no idea how close he has come to being granted his repeated if insincere request to be put out of his misery; to a drive far out onto a back road of the desert for a very long stay. He has pushed Mr. Boughton to the limits of his self-control – to the end of his wits and the edge of his sanity. But the downward spiral is about to change, as you will soon understand. For not long ago, Mr. Boughton caught sight of a pinhole of light in the abyss; a hobby that helped him survive the slings and arrows that another writer once called outrageous fortune.

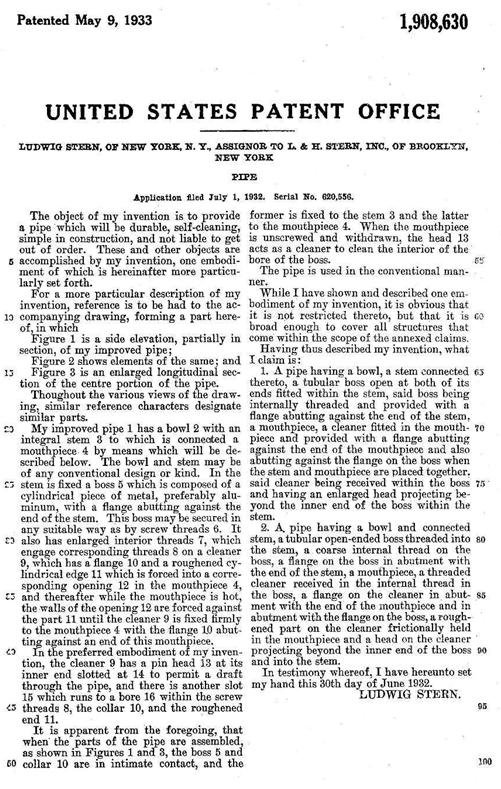

And now all of Mr. Boughton’s troubles are about to change for the better from the simple purchase of an estate lot of seven tobacco pipes in time to write off as an expense on last year’s business income taxes. All of them would have been finds for more than the $25 he paid for the lot – but at a glance, the real gem, in the eye of the restorer at any rate, first went unnoticed. See if you can spot it in the following picture from our gallery, which we call “Lot #7: Tobacco Pipes.”  If you correctly identified the L&H Stern Straight Billiard, on the right in the middle, as the object of Mr. Boughton’s growing obsession, shall we say, then you either have what is commonly referred to as the Sixth Sense or you are an astute collector of fine pipes.

If you correctly identified the L&H Stern Straight Billiard, on the right in the middle, as the object of Mr. Boughton’s growing obsession, shall we say, then you either have what is commonly referred to as the Sixth Sense or you are an astute collector of fine pipes.

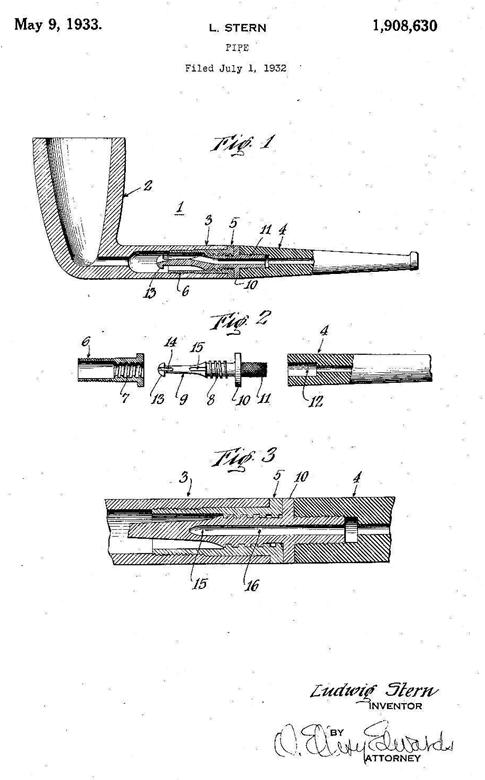

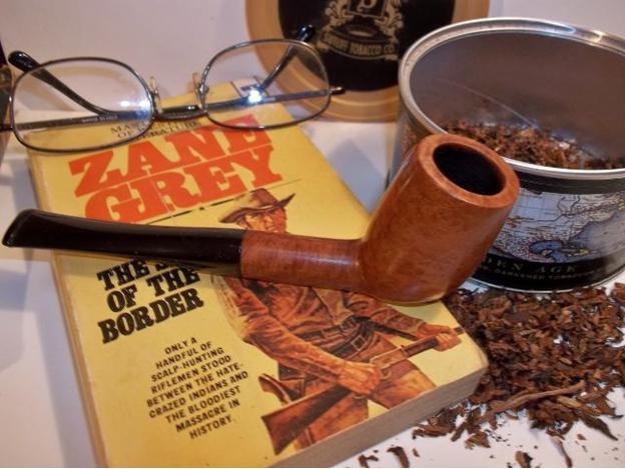

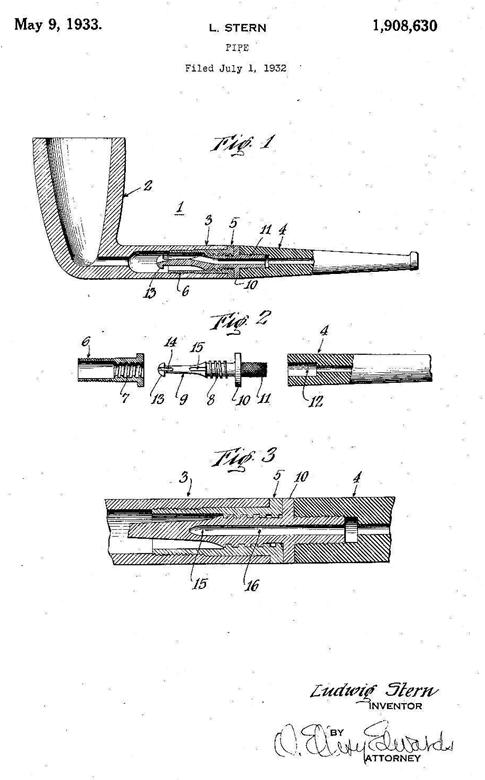

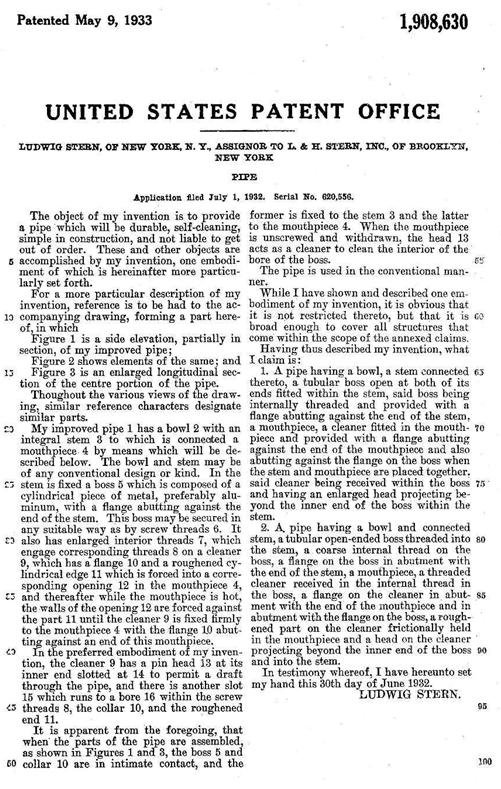

The Park Lane, an invention of the company’s primary founder, is stamped with U.S. Patent № 1908630, issued May 9, 1933. Mr. Boughton has always appreciated the elegant – in expressions of poetry, law, logic and art, to name a few – and as for Patents, he considers this one, being only two pages including the obligatory illustration of parts, to be as brief and comprehensive as they come.

L&H Stern Inc. was officially organized in 1911 by one Ludwig Stern (the L in the initials, which in the early days were fashioned L. & H. S.), with his older brother, Hugo (the H). Ludwig emigrated from Germany as a young man, after his brother, who was five years older.

L&H Stern Inc. was officially organized in 1911 by one Ludwig Stern (the L in the initials, which in the early days were fashioned L. & H. S.), with his older brother, Hugo (the H). Ludwig emigrated from Germany as a young man, after his brother, who was five years older.

(And now, if the audience will permit a brief side-bar, a point of interest: Ludwig worked for the largest supplier of tobacco products to the entire state of New York – somehow providing an estimated 90% of cigarettes, cigars, pipe tobacco and other related items to manufacturers and retailers in the area – as early as 1899, the year the behemoth tobacco supplier was spawned. Called the Metropolitan Tobacco Company, a corporation born of a cartel of others in the same business known to everyone who was anyone within the industry as the “Tobacco Trust,” became the object of a drawn-out restraint of trade civil complaint. The original trial and both appeals of said cause were decided, not surprisingly, in favor of the tobacco industry defendants. The small shops, banded together as plaintiffs, now collectively relegated to historical obscurity by a single last name and “et al.,” were forced to close. I submit for your consideration one question: could the wheels of justice have been greased in this case by the main product of the second of the Seven Deadly Sins? This is offered as food for thought – only available at your local diner in the Twilight Zone.) [See Link 2.)

The brothers moved the re-formed business in 1920 to Brooklyn. The new location, in a seven-story building, was – for the then-ubiquitous craft – in a convenient part of town now known by its acronym, D.U.M.B.O. (Down under the Manhattan Bridge Overpass). It remained there until closing in the mid-1960s. [See Link 3.] LHS was already so well respected in the business at the time that the company reorganization and move were news in those bygone days. [See Link 4.]

The LHS Park Lane Billiard included a brown and orange swirled Cumberland bit, handmade from Ebonite and fashioned in this case to look like wood. Mr. Boughton considered the task of restoring this pipe to be distinctly good fortune and a pleasure of restoring, in particular because of a certain aspect of the repair that was new to him. The line was made only in the 1930s. [See Link 5.]

At the present moment, Mr. Boughton is busy at work attempting to restore the WDC Park Lane to its original state. As noble as the endeavor may be, the only problem, with this peculiar specimen, is the invisible transformation the pipe has undergone during years of smoking by a single prior owner who had the good grace to love it. As Mr. William Shakespeare so aptly put it in “A Midsummer Night’s Dream”: “Love looks not with the eyes, but with the mind,/And therefore is wingèd Cupid painted blind.” Now, meet Mr. Boughton in his favorite activity – restoring tobacco pipes with every ounce of his love.

RESTORATION

The last shot of the Park Lane prior to restoration, above, makes the most serious problem I encountered apparent. The bit was off by about an eighth of a turn, which may seem negligible to one who has never enjoyed the ruminating quality of a fine pipe, but is in fact a microcosmic chasm along the lines of the Grand Canyon to the general viewer.

The last shot of the Park Lane prior to restoration, above, makes the most serious problem I encountered apparent. The bit was off by about an eighth of a turn, which may seem negligible to one who has never enjoyed the ruminating quality of a fine pipe, but is in fact a microcosmic chasm along the lines of the Grand Canyon to the general viewer.

The flaw was masked by the seller of these estate pipes, who, with no small amount of duplicity, placed a piece of paper around the metal tenon screw built into the opening of the shank.

The wily culpability of this particular ilk of seller is obvious from the freshness of the paper. Hence the conspicuous starting point for my restoration.

The wily culpability of this particular ilk of seller is obvious from the freshness of the paper. Hence the conspicuous starting point for my restoration.

At this point of experience restoring pipes, I consider myself a journeyman in the craft. Although familiar with various ways to tighten Vulcanite, Ebonite, Lucite and other tenon materials, I was unable to locate any useful information on the Internet – the modern day Library of Alexandria, which was dedicated to the Muses, or nine gods and goddesses of the Arts – concerning the re-alignment of metal tenons fixed either to the bit or shank.

Nevertheless, finding myself without a clue how to proceed, I sent an email to Steve Laug, who soon replied with the suggestion that I read his recent online blog on the restoration of an LHS Purex Bulldog. This amused me, as the many notices of comments on the blog in question were forwarded to me, I wondered what all the hoopla was about and had intended to check it out.

However, awaiting Steve’s reply did not hinder me from proceeding with certain steps I knew, such as the fact that the stinger extension of the tenon should come off. Thinking of that, I tried heating the entire aluminum tenon with the flame of a Bic, careful not to touch the shank opening beyond the part of the tenon Ludwig Stern referred to as the flange [see p. 1, Fig. 2, part 10 of the Patent]. Unfortunately, the tenon still would not budge. Even the stinger [illustrated as a whole as part 9, with parts 13, 14 and 15 forming its length and pushing into part 8] seemed to form a single piece. I was aware this would be odd, if not unprecedented, but after four attempts, I swear it would not come off. One lesson I did manage to learn from my dad in his countless frustrated endeavors to teach me about mechanics was that if a part of a mechanism or machine would not come free using reasonable pressure, don’t force it. But, always believing that not all of his maxims were absolute, I suspected he meant it as a guideline that was not immutable under controlled conditions I might someday, by some miracle, learn to recognize. Therefore, I found a small wash rag and a pump plier that I feared might be overkill, but it was all I owned that had not been stolen by previous apartment owners. I also possess a wicked sense of adventure at moments like these. Adjusting the rivet to match the job, I then wrapped the small towel around the base of the tenon/stinger by the flange and loosely clamped the end of the plier over the tenon. As I applied pressure, I could feel the two sides of the mouth turn and clamp firmly down on the rag-covered metal. Gripping the bit in one hand, I turned the plier with my other and immediately felt it begin to move. Slowly, it came free and undamaged.

One lesson I did manage to learn from my dad in his countless frustrated endeavors to teach me about mechanics was that if a part of a mechanism or machine would not come free using reasonable pressure, don’t force it. But, always believing that not all of his maxims were absolute, I suspected he meant it as a guideline that was not immutable under controlled conditions I might someday, by some miracle, learn to recognize. Therefore, I found a small wash rag and a pump plier that I feared might be overkill, but it was all I owned that had not been stolen by previous apartment owners. I also possess a wicked sense of adventure at moments like these. Adjusting the rivet to match the job, I then wrapped the small towel around the base of the tenon/stinger by the flange and loosely clamped the end of the plier over the tenon. As I applied pressure, I could feel the two sides of the mouth turn and clamp firmly down on the rag-covered metal. Gripping the bit in one hand, I turned the plier with my other and immediately felt it begin to move. Slowly, it came free and undamaged. In the meantime, Steve replied with the suggestion that I read his recent online blog on the restoration of an LHS Purex Bulldog. This amused me, in a good way. As the many notices of comments on the blog in question were forwarded to me, I wondered what all the hoopla was about and had intended to check it out.

In the meantime, Steve replied with the suggestion that I read his recent online blog on the restoration of an LHS Purex Bulldog. This amused me, in a good way. As the many notices of comments on the blog in question were forwarded to me, I wondered what all the hoopla was about and had intended to check it out.

Reading through to the first mention of the difficulty encountered by Steve, my heartbeat quickened. Confident I was on the verge of making the discovery that would enlighten me, I continued, on the edge of my seat on the couch in my living room, as though I were reading a real page-turner of a book or watching an Alfred Hitchcock thriller or perhaps “The Twilight Zone.” Indeed, in my mind I envisioned the Canadian master at work in his studio, so vivid were the words and photographs flashing across his computer screen.

Nearing the expected moment of revelation, I was consumed with anticipation – only to come to a single photograph of Steve’s LHS shank that dashed my hopes in a nanosecond, as is the popular if peculiarly à propos phrase these days; for the illustration revealed the exact reverse of my predicament, one that could not be repaired in the same fashion.

Delayed but not daunted, I set out to do that which I knew I should have attempted in the first place: taking the Park Lane to my own friend and mentor, Chuck Richards, I humbly sought his advice.

Before doing that, I continued where I had left off, cleaning the tenon and stinger inside and out, including the corroded threads that screwed into the bit, using a small square piece of cotton cloth soaked with Everclear and bristly cleaners that passed through the airways. To be done with it, I also ran a pipe cleaner with alcohol through the air hole of the bit, and when it came out filthy, recalled Steve’s words in his blog that this sort of pipe often needs considerable cleaning of the shank and bit. Quite a few cleaners later, I had the mess under control for the time. Known to my dad for having “a mind like a steel trap” and to my friends as being on the stubborn – or, as I prefer to think, confident side – I was by whatever label loathe to surrender to any challenge.

When I arrived at the pipe shop and we exchanged pleasantries, I presented my distressed pipe. Chuck, pipe of the day in mouth, put on his eyeglasses and examined the LHS closely. Within a blurring handful of seconds, my older, more experienced mentor made his diagnosis, telling me with his typical certitude to heat the tenon before tightening it into the bit. A man who prefers to let people learn as much as they can on their own, Chuck then offered the rare treat of extra advice: “It will be counter-intuitive.”

When I arrived at the pipe shop and we exchanged pleasantries, I presented my distressed pipe. Chuck, pipe of the day in mouth, put on his eyeglasses and examined the LHS closely. Within a blurring handful of seconds, my older, more experienced mentor made his diagnosis, telling me with his typical certitude to heat the tenon before tightening it into the bit. A man who prefers to let people learn as much as they can on their own, Chuck then offered the rare treat of extra advice: “It will be counter-intuitive.”

Intrigued, I took a seat in the pipe shop and, starting a fresh bowl full of tobacco in a new pipe, mulled over the problem in my mind. In a flash, I thought of a comparison, and unfortunately blurted it to the complete perplexity of all of the cigar smokers present.

“Like turning into the skid on ice!”

Chuck, caught unawares by the outburst and not at first grasping the metaphor, at last smiled and said, “Yes, something like that.”

At home later, the first chance I had, I sat down with my movable feast of standard implements of construction, including quite a few that were improvised, to make my first attempt at the genuine repair of a loose bit. Following Chuck’s advice, and keeping the counter-intuitive dog treat in mind, I was set to apply heat to the tenon stinger when the idea struck me to try removing the stinger again. Of course, then it came out with a simple turn of my fingers, apparently loosened by the work I did earlier and the passage of time.

Following Chuck’s advice, and keeping the counter-intuitive dog treat in mind, I was set to apply heat to the tenon stinger when the idea struck me to try removing the stinger again. Of course, then it came out with a simple turn of my fingers, apparently loosened by the work I did earlier and the passage of time.

And so I flicked my Bic and held it under the small tenon with even more care not to burn the precious Cumberland bit. (A Cumberland, by the way, is made from a special sort of Ebonite that can be colored with limits, which in turn is a particular variation of Vulcanite. This subject, I understand from research, is a matter of some hot debate.) With the tenon blackened, I quickly tossed a small rag over it and grabbed my pump pliers, clamping them firmly and remembering not to turn the small metal insert opposite from the direction the bit was off but toward it – as one would, if one hoped to avoid losing control of a vehicle and crashing or rolling, turn into the skid on black ice. Thus one particularly memorable experience on a bridge late one night in Colorado Springs, when my training and reflexes saved me, proved useful in this new endeavor. Each of several increasingly difficult rounds of this process brought the bit closer until it was aligned snugly.

Reaming the chamber and sanding it with 150-grit paper before 200 and then 320 was an easy task, as was using super fine 0000 steel wool to remove the rim char and excess dark stain that was popular when the pipe was made somewhere around three-quarters of a century ago. The rim and bowl then only needed a progression of micromesh from 1500-4000.

At this late stage of the restore, I retorted the pipe, again, unfortunately, with the tenon in place. I at least left the stinger aside for that process, which required about five Pyrex tubes of Everclear boiled through the pipe’s innards to clear out decades of crud and juices soaked into the briar from considerable use by someone who loved this pipe.

I stained the briar with Lincoln Brown boot stain, as opposed to Medium Brown which appears lighter, and flamed it before removing the thin layer of char with gentle rubbing using 3600 micromesh.

At last I am at the end of this rather strange, I admit, blog. I buffed the stem with white and red Tripoli and White Diamond, using a soft cotton cloth and a clean wheel between each. Then I used white Tripoli, White Diamond and carnauba on the wood, with the same steps between each.

At last I am at the end of this rather strange, I admit, blog. I buffed the stem with white and red Tripoli and White Diamond, using a soft cotton cloth and a clean wheel between each. Then I used white Tripoli, White Diamond and carnauba on the wood, with the same steps between each.

CONCLUSION

CONCLUSION

Mr. Boughton had intended to offer this fine LHS pipe for sale at his online store. But following an odd impulse he could neither resist nor explain, he found himself loading a bowl of one of his best tobacco blends and, before he knew it, striking a match and placing the flame to the firm top layer.

The magical qualities of the pipe immediately became apparent. Where he had been tense to the point of explosive results, he was consumed with a sense that all was right in the world. Continuing to puff the mysterious pipe that had somehow found its way to him, he pondered the possible reasons behind the overwhelming sense of attraction to the diminutive pipe. Nothing he could imagine provided a satisfactory explanation, and Mr. Boughton also found he no longer cared.

Mr. Shakespeare also wrote, on the same subject and in the same play: “And yet, to say the truth, reason and love keep little company together nowadays.” Truer words may never have been written.

For at that very moment, although Mr. Boughton thought he was sitting on his sofa in his suddenly less dreary little apartment in the heart of the American Southwest, he was, in fact, still on the outskirts of the Twilight Zone.

SOURCES

1. “The Twilight Zone,” Introduction, Season 2, with thanks. http://www.imdb.com/title/tt0052520/quotes

2. Locker et al. v. American Tobacco Co. et al, NY Sup. Ct. (1907), pp. 115-124. https://books.google.com/books?id=34g7AAAAIAAJ&pg=PA117&lpg=PA117&dq=metropolitan+tobacco+company+brooklyn&source=bl&ots=hQ6aVa_tY8&sig=1uaY2AesgKT4mCKepaOyan9gB9I&hl=en&sa=X&ei=MIiQVZGuHYizoQSxsouAAg&ved=0CCgQ6AEwAg#v=onepage&q=metropolitan%20tobacco%20company%20brooklyn&f=false

3. L&H Stern background, including D.U.M.B.O.

Featured Fade – L & H Stern – Smoking Pipes & Holders – DUMBO – Fred King

4. Magazine story on L&H Stern 1920 move.

https://books.google.com/books?id=rpc7AQAAMAAJ&pg=RA1-PA22&lpg=RA1-PA22&dq=l%26h+stern+inc&source=bl&ots=cDWCX4gIom&sig=eLu9PUkd8JzfNPCZDb7df71R4Ic&hl=en&sa=X&ei=M5-MVbi1FM7IogThw5ToDg&ved=0CCsQ6AEwAg#v=onepage&q=l%26h%20stern%20inc&f=false

5. LHS Park Lane dating confirmation.

http://www.smokingpipes.com/pipes/estate/united-states/moreinfo.cfm? Product_ID=100458

I gave it a moment’s thought as I vaguely heard them chortling, and the truth hit me like the bright Christmas ornament Victor had made of my beautiful new pipe: it was plastic!

I gave it a moment’s thought as I vaguely heard them chortling, and the truth hit me like the bright Christmas ornament Victor had made of my beautiful new pipe: it was plastic!

Doesn’t it look like the dragon broke its hind quarters with the bit fully closed at an exact half-turn off? I set the dratted thing away with my broken pipes, all of the others of which had one thing in common, even the cheapest Medicos – they were real pipes, not plastic and Made in Japan, if the fatally flawed tobacco pipe was not in fact made in one of the Koreas.

Doesn’t it look like the dragon broke its hind quarters with the bit fully closed at an exact half-turn off? I set the dratted thing away with my broken pipes, all of the others of which had one thing in common, even the cheapest Medicos – they were real pipes, not plastic and Made in Japan, if the fatally flawed tobacco pipe was not in fact made in one of the Koreas. By the way, not only is the direction to turn the tenon counterintuitive, as Chuck warned me obliquely, but the entire concept of heating metal (which thereby expands it) takes some pondering to get a handle on. But if nothing else, my mind does thrive on theories that seem to defy logic. Consider this: the turning of the tenon, in the direction it is off-set, is made possible by the very expansion of the metal stretching that which surrounds it. The trick is not heating it to the point of cracking the outer substance.

By the way, not only is the direction to turn the tenon counterintuitive, as Chuck warned me obliquely, but the entire concept of heating metal (which thereby expands it) takes some pondering to get a handle on. But if nothing else, my mind does thrive on theories that seem to defy logic. Consider this: the turning of the tenon, in the direction it is off-set, is made possible by the very expansion of the metal stretching that which surrounds it. The trick is not heating it to the point of cracking the outer substance. While I was at it, I used the super fine steel wool #0000 on the bit and turned it from a creamy color to bright white. I finished the bit with 4000 micromesh.

While I was at it, I used the super fine steel wool #0000 on the bit and turned it from a creamy color to bright white. I finished the bit with 4000 micromesh. I happened to have a dark red votive candle that was perfect for my plan.

I happened to have a dark red votive candle that was perfect for my plan. Peeling away the paper label from the bottom of it, I removed the wick and its aluminum base and inserted it in the direct center of the chamber.

Peeling away the paper label from the bottom of it, I removed the wick and its aluminum base and inserted it in the direct center of the chamber. By now I’m sure it’s clear where I’m headed with this. If not, there is something wrong with the reader’s sense of foreshadowing. At any rate, I bent the top of the wick to a side and melted the rim of the candle into the chamber until it was almost full. I set it aside to harden again and clipped the excess wick.

By now I’m sure it’s clear where I’m headed with this. If not, there is something wrong with the reader’s sense of foreshadowing. At any rate, I bent the top of the wick to a side and melted the rim of the candle into the chamber until it was almost full. I set it aside to harden again and clipped the excess wick. The waxed that dripped onto the pipe’s rim came off easily, and since no buffing on a wheel was necessary or even possible, I was finished.

The waxed that dripped onto the pipe’s rim came off easily, and since no buffing on a wheel was necessary or even possible, I was finished.

CONCLUSION

CONCLUSION I guess all I have left to say at this point is: Happy Birthday, Mom! I hope you enjoy your new, very special Japanese plastic tobacco pipe candle for many years. And remember, you can burn it as often as you like, and I’ll always refill it for you.

I guess all I have left to say at this point is: Happy Birthday, Mom! I hope you enjoy your new, very special Japanese plastic tobacco pipe candle for many years. And remember, you can burn it as often as you like, and I’ll always refill it for you.