Blog by Steve Laug

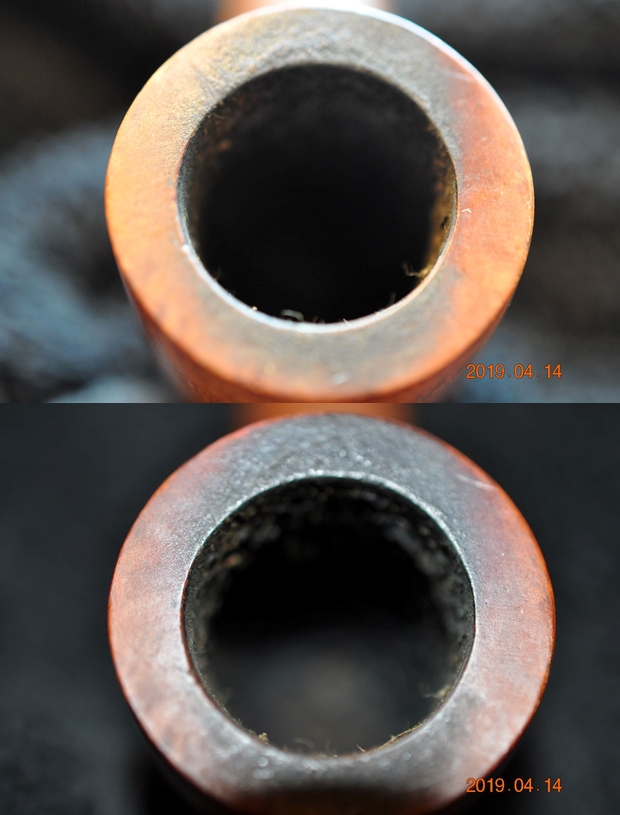

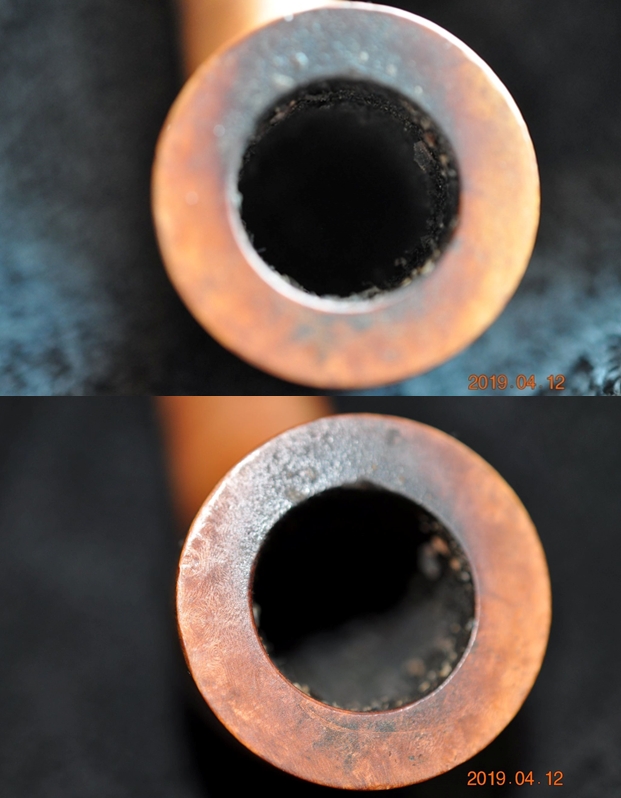

Sometimes the repetitive work on similar pipes and stems gets tiring to me and to alleviate the inevitable boredom I change things up a bit to refresh me. I have a box of stummels (bowls) here that I periodically go through and see if I have a potential stem that would fit them. Sunday afternoon I went through the box and picked out two bowls and found workable stems for them both. They were in different states of need but all had been thoroughly cleaned before I boxed them up. The pipe I chose to work on next is a nicely grained Bulldog stummel. The bowl looked very good. The grain around the sides was quite nice and a mix of flame and birdseye grain. There was one small fill on the right side of the shank but it was in good condition. The rim top was in excellent condition with a bit of darkening toward the rear of the bowl. The interior of the bowl was clean and there were not any chips, cracks or checking on the walls. The finish was dull and bit and tired but still quite redeemable. The stamping on the pipe was clear and readable. On the left side it read Bertram in script [over] Washington DC in a ribbon. The grade 60 stamp was on the same side near the bowl/shank junction. I took some photos of the bowl before I started to work on it.

I took a photo of the stamping on the left side of the shank. It reads as noted above and is clear and readable.

I took a photo of the stamping on the left side of the shank. It reads as noted above and is clear and readable. I went through some of stems and found this diamond saddle style stem that was close to the right diameter and had a tenon that would work as well. It has some file damage on the surface near the button but it would clean up well. I also took a photo of the stem and bowl together to give a sense of the look.

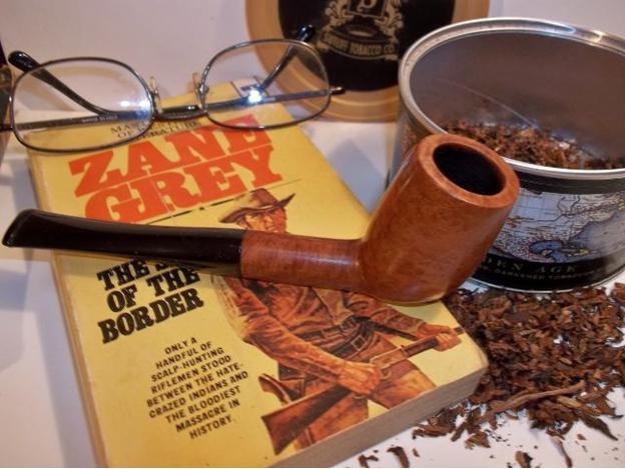

I went through some of stems and found this diamond saddle style stem that was close to the right diameter and had a tenon that would work as well. It has some file damage on the surface near the button but it would clean up well. I also took a photo of the stem and bowl together to give a sense of the look. The pipe is a Bertram from the Bertram Pipe Shop in Washington DC. I have posted a lot of different blogs on the brand so the information available is quite accessible. I am including pic of a post card that a reader of the blog sent me. It is a great memento that I love to spend time looking at.

The pipe is a Bertram from the Bertram Pipe Shop in Washington DC. I have posted a lot of different blogs on the brand so the information available is quite accessible. I am including pic of a post card that a reader of the blog sent me. It is a great memento that I love to spend time looking at.  I started my work on the pipe by fitting the new stem to the shank. I trimmed down the tenon diameter slightly with a file so that the fit in the shank was snug. The stem diameter needed more work so I worked it with a file to match it to the shank. I sanded it with 220 grit sandpaper to smooth it out.

I started my work on the pipe by fitting the new stem to the shank. I trimmed down the tenon diameter slightly with a file so that the fit in the shank was snug. The stem diameter needed more work so I worked it with a file to match it to the shank. I sanded it with 220 grit sandpaper to smooth it out.

I removed the stem and polished the briar (bowl and sanded shank end) with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping it down with a damp cloth after each pad. It really began to shine.

I removed the stem and polished the briar (bowl and sanded shank end) with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiping it down with a damp cloth after each pad. It really began to shine.

I restained the shank end where I had sanded it to make the transition to the new stem smooth with an Oak stain pen. The colour was a perfect match. Once the bowl was buffed the newly stained section will blend in even better.

I restained the shank end where I had sanded it to make the transition to the new stem smooth with an Oak stain pen. The colour was a perfect match. Once the bowl was buffed the newly stained section will blend in even better.

I worked some Before & After Restoration Balm into the surface of the smooth briar with my finger tips. The product is amazing and works to clean, enliven and protect the briar. I let it sit on the briar for 10 or more minutes and then buff it off with a soft cloth. It really makes the grain sing.

I worked some Before & After Restoration Balm into the surface of the smooth briar with my finger tips. The product is amazing and works to clean, enliven and protect the briar. I let it sit on the briar for 10 or more minutes and then buff it off with a soft cloth. It really makes the grain sing.

I set the bowl aside and turned my attention to the stem. I flattened out the file marks as much as possible with a flat file. I knew I would not remove them this way but I wanted make them flatter. I filled in the deeper cut marks with clear CA glue and once it was hard smoothed out the repairs with 220 grit sandpaper and started polishing the stem with 400 grit wet dry sandpaper.

I set the bowl aside and turned my attention to the stem. I flattened out the file marks as much as possible with a flat file. I knew I would not remove them this way but I wanted make them flatter. I filled in the deeper cut marks with clear CA glue and once it was hard smoothed out the repairs with 220 grit sandpaper and started polishing the stem with 400 grit wet dry sandpaper.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a cloth and Obsidian Oil. I finished the polishing with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil.

I polished the stem with micromesh sanding pads – dry sanding with 1500-12000 grit pads. I wiped the stem down after each pad with a cloth and Obsidian Oil. I finished the polishing with Before & After Pipe Stem Polish – both Fine and Extra Fine. I gave it a final coat of Obsidian Oil.

I used my heat gun to bend the vulcanite stem to match the angles of the bowl and give it a proper Bent Bulldog look.

I used my heat gun to bend the vulcanite stem to match the angles of the bowl and give it a proper Bent Bulldog look.

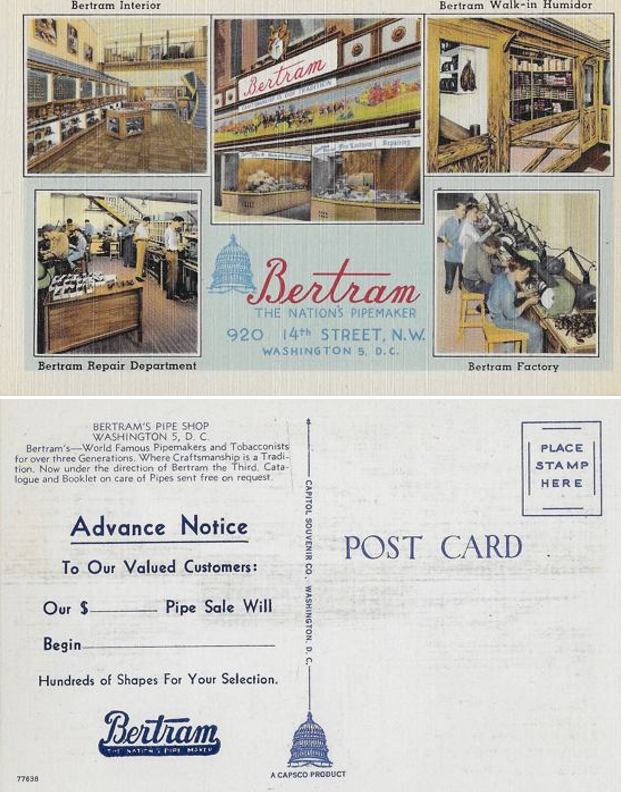

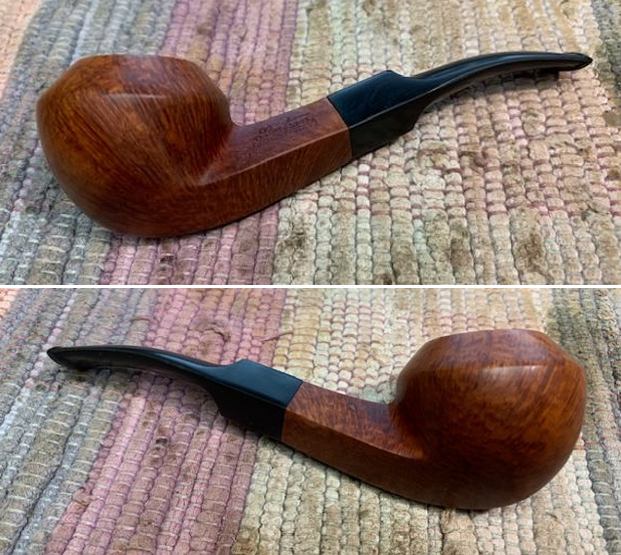

I put the pipe together – the bowl with its new stem. This restored and restemmed Bertram Washington DC Grade 60 Bent Bulldog is a real beauty and I think the chosen stem works well with it. The grain on the bowl came alive with the buffing. I used Blue Diamond on the buffing wheel on both the bowl and stem. I gave both multiple coats of carnauba wax on the wheel then buffed it with a clean buffing pad to raise the shine. I hand buffed it with a microfibre cloth to deepen the shine. The Bertram Bent Bulldog feels great in the hand. It is lightweight and the contrast in the browns of the briar and the polished vulcanite stem with the popping grain on the mixed brown stained bowl is quite amazing. The dimensions of the pipe are Length:5 ½ inches, Height: 1 ¾ inches, Outer diameter of the bowl: 1 ¾ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.31 ounces/37 grams. It really is a beauty. I will be putting it on the rebornpipes store in the American Pipe Makers section shortly if you are interested in adding it to your collection. Thanks for walking through the restemming and the restoration with me. Cheers.

I put the pipe together – the bowl with its new stem. This restored and restemmed Bertram Washington DC Grade 60 Bent Bulldog is a real beauty and I think the chosen stem works well with it. The grain on the bowl came alive with the buffing. I used Blue Diamond on the buffing wheel on both the bowl and stem. I gave both multiple coats of carnauba wax on the wheel then buffed it with a clean buffing pad to raise the shine. I hand buffed it with a microfibre cloth to deepen the shine. The Bertram Bent Bulldog feels great in the hand. It is lightweight and the contrast in the browns of the briar and the polished vulcanite stem with the popping grain on the mixed brown stained bowl is quite amazing. The dimensions of the pipe are Length:5 ½ inches, Height: 1 ¾ inches, Outer diameter of the bowl: 1 ¾ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.31 ounces/37 grams. It really is a beauty. I will be putting it on the rebornpipes store in the American Pipe Makers section shortly if you are interested in adding it to your collection. Thanks for walking through the restemming and the restoration with me. Cheers.