Blog by Steve Laug

For many years now I have been making the trek from Vancouver, British Columbia into the US to Bellingham, Washington to visit a pipe shop in old Bellingham, a place called Fairhaven. The shop is called the Fairhaven Smoke Shop and is located at 1200 Harris Avenue Suite 100 Bellingham, Washington. When I first started visiting shop 15-18 years ago it was operated be an older gent who seemed like he could have cared less if he had customers, but he had a huge assortment of estate pipes and some great older tobaccos. I got to know him over the years and enjoyed his company. About 8 years ago a young fellow – mid 20’s bought the shop and took over. I had visions of it becoming yet another head shop! But you got to give him credit. He kept it as a pipe and tobacco shop (mind you he added the typical glass pipes and hookahs). He upgraded the shop layout and look, added new pipes and tobaccos and continued in the tradition of a pipe shop. He set up a web presence at http://fairhavensmokes.com/ I really expected the place to shrivel up and disappear in the anti-smoking environment of Washington State. But instead it seems to have done well.

On Saturday I made the trip to Bellingham once again. I really was hoping to get a side trip over to Fairhaven but we did not have time to visit the shop on this trip. My wife and I brought along two of our daughters for the day. Whenever we are in Bellingham my wife and I always visit a little coffee and donut shop on Holly St. called Rocket Donuts so we wanted to show it to the girls. As we made our way to the shop my youngest daughter pointed up the street to a sign that said The Senate Tobacconist and Smoke Shop. I have walked down that street for over 20 years and I had never seen that shop. You know how sometimes you wonder if you missed seeing something because you were focused on other things? That is what crossed my mind when she pointed out the shop. My wife and the girls went in for coffee and donuts but needless to say, I had to go check out the shop.

In a world in which more and more head shops with glass pipes, bongs and the like are replacing the old bona fide tobacconist shops I had really low expectations about this shop. I walked up the street toward it and paused to read the sandwich board on the street. As yet I had not looked in the window. I have to say the sign had elements of both hopefulness and resignation in its words – hopeful: tobacco at the top of the list, and cigars – resignation: herbs and glassware. Before getting to the shop I had already made up my mind as to what I could expect when I entered. Glassware! Herbs! Sheesh, it was almost like experiencing again what I had experienced when the Tinderbox Tobacco Shops became glorified gift shops that also sold tobacco and cigars. So was this going to be a head shop that also sold a few cigars and some tobacco? I tell you what, I almost turned and went back to the coffee and donuts. I really did not want yet another disappointment.

But my curiosity got the better of me and I shrugged my shoulders and went over to the window and looked in. I fully expected a typical smoke shop/paraphernalia shop but what I saw was not that. I could not believe my eyes. The glassware was not that visible and what I saw through the window was a pipeman’s feast – lots of display cases with pipes and tins and jars of bulk tobacco front and center. Then in the back, away from the window were bookcase style humidors with many cigar choices. Off to the side in the corner was the collection of glassware. To be honest I never went over to that corner to have a look. It is truly amazing in this day and age to see a shop like this in my neck of the woods. This was a fully-fledged tobacconist!

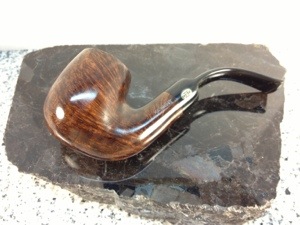

I opened the door and went in. I laugh now, but I must have looked like a kid in a candy shop. I eyed the open topped display case of tins and pouches of tobacco for sale on my left. I looked at the brands of tobacco that were carried and available and was pleased to see many of my favourite blends. I proceeded down the display counters on the left and looked at pipes – Vauen, Peterson, Ascorti, Big Ben, Stanwell, Butz-Choquin and others beautifully laid out for the buyer to see. There were both briars and meerschaums of every shape and size and price range. The display cases were well lit and the pipes were well displayed. It was a briar feast for the eyes. I only wish I had had more time to look things over more carefully. I walked past the cash register and the Three Brass Monkeys on display in front of it, past the tobacco scales on the counter to have a look at the bulk tobacco selections. There was an unbelievable array of blends – Aromatics, Virginias, English and some straight blending tobaccos – Latakia and Perique. There were even some cigarette cut tobacco. I went through the well labeled Virginia, Virginia Perique and English blends and took each lid off to have a good sniff of the blend in the jars. I skipped over the aromatics – chocolate, raspberry, cherry, vanilla, mocha, caramel and other mixtures with edible names as it has been a long time since I smoked them. I could easily have spent more time going through the many blends that were carried by the shop. As I was only in Bellingham for one day I could only purchase a 100 gram pouch and hope to not get dinged with duty at the border. But I would be back!

I wandered through the cigar humidor sections – I loved the cherry wood cabinets that each housed cedar lined walls and shelves and a humidor unit so that each glass doored cabinet was a sealed unit. The only thing missing that I could see were the Cubans that we have in Canada. There were all kinds of cigars and all kinds of sizes. I am pretty cigar ignorant but the selection seemed to cover a wide range of country of origin, price, blend and style.

I went back to the bulk tobaccos and picked the blend I had chosen, a Dark English – Virginias, Stoved Virginias, Latakia, Orientals and Perique and carried the jar to the scale to have the proprietor weigh it out and bag it up for me. To my surprise the gent behind the counter was the same fellow who had purchased the old Fairhaven Shop, now eight years older. He recognized me and remembered our first meeting many years earlier when he had given me two tins of Erinmore Flake on a visit I made to the shop. I asked him how that shop was doing and he said it was doing well. I asked him when he had opened the Senate and why. He responded that he had always wanted a shop in this area and had opened the doors four months earlier. Business was doing well and he loved the new location. We had a great visit and I asked him about several tobaccos that he did not have. He said he would order them in. I paid for my tobacco and a couple of bundles of pipe cleaners before I headed out the door. I am looking forward to another longer visit soon.

If you find yourself in the Bellingham area, I would heartily recommend that you stop by the shop and have a visit. The shop is called the Senate and is located at 215 West Holly Street, Suite H-20. The phone number is 360-756-7552. It has a great selection of pipes and cigars as well as house blends and tinned tobacco to purchase. The proprietor Mike Waters is a great guy – personable, knowledgeable and genuinely interested in serving the pipe and cigar smoking public. Stop by and say hi. In this anti-smoking state of Washington in the anti-smoking climate of our world it was great to see a new tobacco shop open its doors. It was encouraging to see this young fellow doing well enough in his first shop to open this second one. The store will have a web presence soon as the shop website, http://www.senatecigar.com is under development. Check it often as Mike says that the full site will be open soon. Who knows we may run into each other at the shop. Until then enjoy your pipe!

Steve Laug

06/17/13