Blog by Steve Laug

Over the years I have been continually looking for better ways of cleaning out the shank of an estate pipe. I have tried and discarded many methods over that time. The one certainty about the cleaning is that it takes many pipe cleaners, cotton swabs and much alcohol. There are no short cuts to cleaning the shank and airway. Nothing takes the place of slow and repetitive cleaning. Even with using a retort, a short cut on one level, the cleaning of the pipe still takes time before and after the retort has been used. I thought it might be interesting to some of you to read about the process in detail. I have written about the cleaning process – with and without the use of a retort.

With a retort

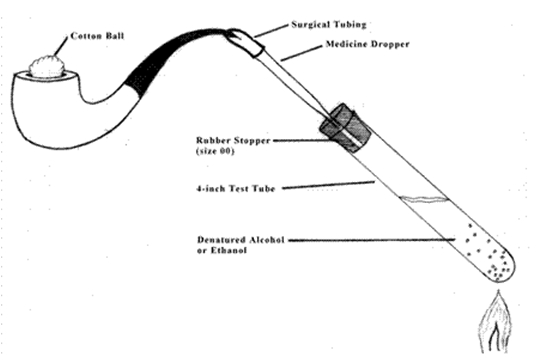

When I clean the shank with a retort I clean the inside of the stem and remove surface grime in the shank and airway. Before setting up the retort I try to remove as much of the surface grime internally as possible. I ream and clean out the bowl to remove any crumbling or breaking cake. I clean out the stem and button as well to give the pipe a relatively clean surface before I set up the retort. Some people use the retort immediately after reaming and leave out the cleaning step that I begin with. I have done it both ways but like the results of my process. The surgical tubing on the retort slides over the button on the stem and if the surface is dirty or has calcified buildup it does not seal well and the boiling alcohol will seep out around the tubing and make a mess. I clean out the inside of the stem to accelerate the cleaning in the shank. Even with pre-cleaning the pipe it often takes multiple uses of the retort to actually remove all of the tars and oils.

To prepare the pipe for the retort, I stuff a cotton boll in the bowl and do not press it down to hard into the bowl. I want it to plug the top so that the boiling alcohol does not come out the top but still allow it to circulate within the bowl and the shank. I use isopropyl alcohol in the test tube of the retort and I heat it over a tea light/small candle. The boiling point is quite low so it does not take long for alcohol to begin to boil. The stem and shank heat up as the alcohol goes through them. When it is removed from the heat the alcohol will be drawn back into the test tube and will be a dark brown. I empty out the dirty alcohol, refill the test tube and repeat the process until the alcohol come out clean. I remove the retort and run cotton swabs and pipe cleaners dipped in alcohol through the stem and the shank to absorb anything that has been left behind. When the pipe dries out it smells fresh and new.

Without a retort

The process of cleaning a shank without a retort begins the same way as the above description. I ream the bowl and clean out the bowl and shank with pipe cleaners and cotton swabs dipped in isopropyl alcohol. I use both the bristle and the fluffy pipe cleaners and also shank brushes. The process for cleaning begins with removing the surface grit and grime. This takes many pipe cleaners before they begin to come out semi clean. Then I use the drill bit that is built into the KleenReem reamer and twist it into the shank. It scrapes the sides of the airway all the way into the bowl and removes the tarry buildup. I clean the bit off with alcohol and repeat the process several times until the bit slides through the airway with no impediment. I then wrap a cut pipe cleaner around the drill bit, dip it in alcohol and run it through the shank and airway until it comes out clean. I finish the cleaning process by scrubbing out the shank and the airway with cotton swabs dipped in alcohol and then pipe cleaners folded and unfolded.

Once the pipe cleaners and the cotton swabs come out clean I smell the pipe and shank to see if it smells clean. If not then I stuff cotton bolls in to the bowl tightly. I leave about ¼ inch of clearance from the bowl rim and then fill the bowl with alcohol using an ear syringe. I have found that this keeps the alcohol within the bowl and off the finish of the pipe. I set the pipe in an old ice cube tray that I have and leave it overnight. The alcohol leaches out the oils and tars that are in the shank and bowl. I remove the cotton and wipe out the shank and bowl and repeat the process until the cotton is clean on the next morning. Once that is done the bowl and the shank are cleaned a final time with pipe cleaners and alcohol. The pipe is now ready to be used.