Blog by Steve Laug

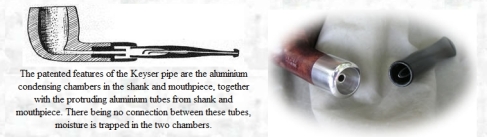

My brother sent me the links to this sale on EBay and I was hooked. It is probably the oddest pipe contraption I have seen in the many pipes that formed the pipeman’s dream of a cooler, drier smoke. There have been many over the years that vied for the oddest looking contraption but to date this one takes the prize. I have a few in my own oddity collection that would give this one a fair run for its money but I think this one is still by far the strangest. The T shaped look of the pipe is one thing but once it taken apart it is even odder. The only normal part of the pipe is the vulcanite stem. The Bakelite shank ends in a dropped down base that is part of the shank. It is as big as the briar bowl on the top. Inside the base is a metal canister contraption that has six wedge shaped holes around the edges and a single hole in the crowned centre. The crowned centre meets the hole in the bottom of the threaded briar bowl which is indented to hold the contraption in place.

Inside the base is a metal canister contraption that has six wedge shaped holes around the edges and a single hole in the crowned centre. The crowned centre meets the hole in the bottom of the threaded briar bowl which is indented to hold the contraption in place. The Bakelite shank on the pipe is the only part of the pipe that bears any identification marking. It reads Filtre T with PAT. to the left of the name and PND. to the right. Thus the stamping is Filtre T Patent Pending. The Bakelite base is quite thick with threads extending into it to hold the bowl in place. The diameter of the opening is ¾ inches and the exterior 1 inch. The length of the base and stem is 5 1/8 inches. With the bowl in place the height is 2 ½ inches tall. The hang down base is 1 ¼ inches. The bowl itself is 1 ¼ inches. The filter canister is stamped with the same stampings as the shank PAT. over FILTRET over PND. and is made of aluminum.

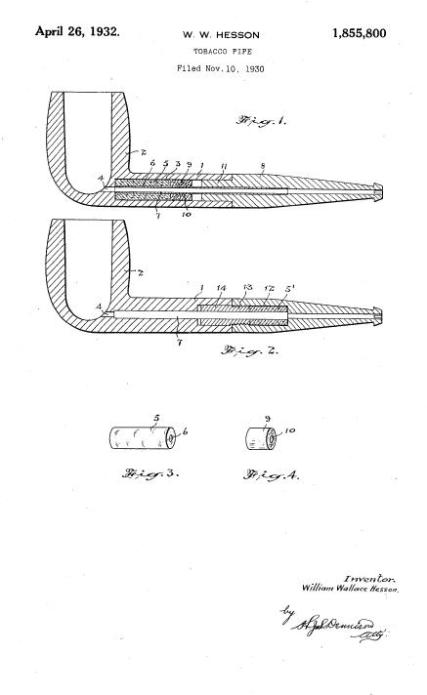

The Bakelite shank on the pipe is the only part of the pipe that bears any identification marking. It reads Filtre T with PAT. to the left of the name and PND. to the right. Thus the stamping is Filtre T Patent Pending. The Bakelite base is quite thick with threads extending into it to hold the bowl in place. The diameter of the opening is ¾ inches and the exterior 1 inch. The length of the base and stem is 5 1/8 inches. With the bowl in place the height is 2 ½ inches tall. The hang down base is 1 ¼ inches. The bowl itself is 1 ¼ inches. The filter canister is stamped with the same stampings as the shank PAT. over FILTRET over PND. and is made of aluminum. I did some hunting for a Patent on the US Patent site and found a written patent. The pipe seems to have been made by FILTRET Inc. of Seattle, Washington and the patent filed by George E. Baldwin, President on May 5, 1930. I cannot find the attached specimens mentioned in the document but this at least identifies the name and gives me a base date.

I did some hunting for a Patent on the US Patent site and found a written patent. The pipe seems to have been made by FILTRET Inc. of Seattle, Washington and the patent filed by George E. Baldwin, President on May 5, 1930. I cannot find the attached specimens mentioned in the document but this at least identifies the name and gives me a base date.

When the pipe arrived in Idaho my brother took some photos of it. The stem was slightly oxidized and it was stuck in the shank. It was underturned to the left and could not be straightened out. The rim was dirty with a tar build up and there was a cake in the bowl. The bowl itself was slightly out of round. The briar had a few small fills in it and the finish was dirty.

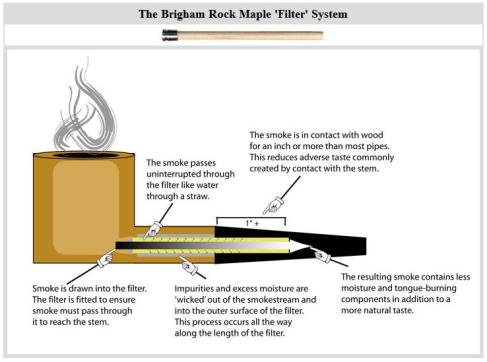

When my brother Jeff took the bowl off the base the interior of the base was very dirty with tars and oils. The metal basket was also covered with debris of tars, oils and saliva. It looked to me that the way the pipe worked was that the air was drawn through the single hole in the top of the canister and then it came out through the wedges and into the airway in the shank.

When my brother Jeff took the bowl off the base the interior of the base was very dirty with tars and oils. The metal basket was also covered with debris of tars, oils and saliva. It looked to me that the way the pipe worked was that the air was drawn through the single hole in the top of the canister and then it came out through the wedges and into the airway in the shank.

This pipe was a pleasure to work on because Jeff did the lion’s share of work on it. He reamed and cleaned the bowl. He cleaned out the stem with pipe cleaners and alcohol and the base with cotton swabs and alcohol. He flushed out the canister with alcohol and then water. He flushed it until it was clean. He scrubbed the bowl with Murphy’s Oil Soap and removed the finish and the debris from the surface of the bowl. He was able to remove much of the tar and oil on top of the bowl. The next set of four photos show the way the pipe looked when I unpacked it this afternoon. Thanks Jeff this was an easy clean up.

This pipe was a pleasure to work on because Jeff did the lion’s share of work on it. He reamed and cleaned the bowl. He cleaned out the stem with pipe cleaners and alcohol and the base with cotton swabs and alcohol. He flushed out the canister with alcohol and then water. He flushed it until it was clean. He scrubbed the bowl with Murphy’s Oil Soap and removed the finish and the debris from the surface of the bowl. He was able to remove much of the tar and oil on top of the bowl. The next set of four photos show the way the pipe looked when I unpacked it this afternoon. Thanks Jeff this was an easy clean up.

I took a close up photo of the rim top to show the damage to the inner edge of the rim. It is darkened and also has some burned areas on the top and inner edge.

I took a close up photo of the rim top to show the damage to the inner edge of the rim. It is darkened and also has some burned areas on the top and inner edge. I also took a close up photo of the stem – it was stuck tight in the shank and it was underturned to the left. I tried to heat it with hot water to try to loosen it. It would not move. After taking this photo I put it in the hot water to soak and see if it would loosen the tars and oils in the shank that were holding it tight.

I also took a close up photo of the stem – it was stuck tight in the shank and it was underturned to the left. I tried to heat it with hot water to try to loosen it. It would not move. After taking this photo I put it in the hot water to soak and see if it would loosen the tars and oils in the shank that were holding it tight. I turned my attention to the bowl and the base while the stem soaked. I cleaned out the airway in the bottom of the bowl with a cotton swab and alcohol to remove the “gunk” that was clogging the airway and reducing the air flow.

I turned my attention to the bowl and the base while the stem soaked. I cleaned out the airway in the bottom of the bowl with a cotton swab and alcohol to remove the “gunk” that was clogging the airway and reducing the air flow. I topped the bowl on a topping board with 220 grit sandpaper. I topped it until I had removed the damaged areas on the rim surface.

I topped the bowl on a topping board with 220 grit sandpaper. I topped it until I had removed the damaged areas on the rim surface. I rolled a piece of 220 grit sandpaper to sand the bowl and the inner edge to clean up the damaged inner edge and bring it back to round.

I rolled a piece of 220 grit sandpaper to sand the bowl and the inner edge to clean up the damaged inner edge and bring it back to round. I sanded the bowl and rim with a medium and a fine grit sanding block to remove the scratches in the briar. Once it was clean of scratches I stained it with a dark brown stain thinned by half with alcohol. I flamed it and repeated the process.

I sanded the bowl and rim with a medium and a fine grit sanding block to remove the scratches in the briar. Once it was clean of scratches I stained it with a dark brown stain thinned by half with alcohol. I flamed it and repeated the process. I wiped the bowl down with cotton pads and alcohol to make the stain more transparent and to make the grain show through.

I wiped the bowl down with cotton pads and alcohol to make the stain more transparent and to make the grain show through. I took the stem and base out of the hot water and wiggled it until the stem turned. I removed the stem so that I could clean the inside of the shank and base.

I took the stem and base out of the hot water and wiggled it until the stem turned. I removed the stem so that I could clean the inside of the shank and base. I used a dental spatula inside the tube of the shank to scrape away some of the thick build up on the walls of the shank. I then scrubbed it down with alcohol, cotton swabs and pipe cleaners until they finally came out clean. I also scrubbed down the inside of the base with them to remove the grime in the base.

I used a dental spatula inside the tube of the shank to scrape away some of the thick build up on the walls of the shank. I then scrubbed it down with alcohol, cotton swabs and pipe cleaners until they finally came out clean. I also scrubbed down the inside of the base with them to remove the grime in the base. I used the micromesh sanding pads to polish the Bakelite base and the shank. I sanded it with 1500-12000 grit pads and then wiped it down with some Obsidian Oil.

I used the micromesh sanding pads to polish the Bakelite base and the shank. I sanded it with 1500-12000 grit pads and then wiped it down with some Obsidian Oil. I scrubbed out the canister one more time and found that it was very clean. I dropped it in place in the base.

I scrubbed out the canister one more time and found that it was very clean. I dropped it in place in the base. With the canister in place I screwed the bowl onto the base and took some photos.

With the canister in place I screwed the bowl onto the base and took some photos.

It was ready to buff with Blue Diamond so I took it to the wheel and buffed the bowl and the base. I gave bowl several coats of carnauba wax and then buffed it with a clean buffing pad to raise the shine. Once I finish the stem I will give it several more coats of wax.

It was ready to buff with Blue Diamond so I took it to the wheel and buffed the bowl and the base. I gave bowl several coats of carnauba wax and then buffed it with a clean buffing pad to raise the shine. Once I finish the stem I will give it several more coats of wax.

I cleaned out the airway in the stem with alcohol, cotton swabs and pipe cleaners. After heating it with the hot water to loosen the stem a lot of grime came loose in the shank and ran down the stem.

I cleaned out the airway in the stem with alcohol, cotton swabs and pipe cleaners. After heating it with the hot water to loosen the stem a lot of grime came loose in the shank and ran down the stem. The stem had some tooth chatter along with the oxidation that I brought out with the hot water bath. I sanded it with 220 grit sandpaper to remove both the chatter and the oxidation. I wiped it down with Obsidian Oil.

The stem had some tooth chatter along with the oxidation that I brought out with the hot water bath. I sanded it with 220 grit sandpaper to remove both the chatter and the oxidation. I wiped it down with Obsidian Oil. I wet sanded the stem with 1500-2400 grit micromesh sanding pads and rubbed it down with Obsidian Oil. I dry sanded it with 3200-4000 and gave it another coat of oil. I finished sanding it with 6000-12000 grit pads and gave it another coat of oil. I buffed it on the buffer with Blue Diamond polish and gave it a final coat of Obsidian Oil and set it aside to dry.

I wet sanded the stem with 1500-2400 grit micromesh sanding pads and rubbed it down with Obsidian Oil. I dry sanded it with 3200-4000 and gave it another coat of oil. I finished sanding it with 6000-12000 grit pads and gave it another coat of oil. I buffed it on the buffer with Blue Diamond polish and gave it a final coat of Obsidian Oil and set it aside to dry.

I put the pipe back together and gave it a final buff with Blue Diamond and then gave it multiple coats of carnauba wax. I buffed it with a clean buffing pad and then by hand with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. It is a true oddity but the more I worked on it the more I am intrigued with it. I wonder how the contraption works in real-time. Well, I may have to give it a try one day soon. Thanks for looking.

I put the pipe back together and gave it a final buff with Blue Diamond and then gave it multiple coats of carnauba wax. I buffed it with a clean buffing pad and then by hand with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. It is a true oddity but the more I worked on it the more I am intrigued with it. I wonder how the contraption works in real-time. Well, I may have to give it a try one day soon. Thanks for looking.