Chuck posted this on Smokers Forums and I thought it merited posting here as well. I asked him for permission to post and use his photos. I copied the exchange from his side in writing about his cleaning process. I include it here as it is helpful to see another refurbisher at work.

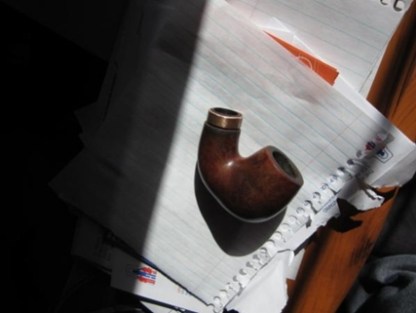

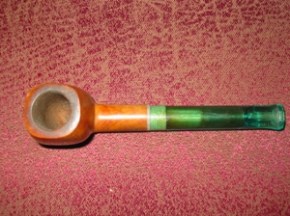

It is one thing to restore pipes for yourself, and then later on start giving them to friends. It is quite another to restore as an adjunct to working as a Tobacconist, in a Brick and Mortar Shop. I am slipping into that position, as my pipes have been well received in our Estate Pipe (sorry Ben) display case. I find myself challenged, and we will see, together, the outcome. Here is a trio of pipes that were they to show up in a group from eBay, would go directly to my “Someday Box”. They are caked heavily and there is damage beginning to the structure of the bowls. The briar is tar soaked to the point that grain is no longer visible, and the bits cannot go further into the shanks, nor be withdrawn in one pipe.

Stay tuned over this weekend, as I see what can be made of these three.

Mike….I have practiced on a number of pipes that were badly caked, actually a few were my Dad’s handed down, and I even purchased a few off eBay in that condition. I use my “Someday Pipes” to increase my skill level. I have acquired seven specialized tools that I use to vanquish this demon cake. And I examine closely for any existing damage, pointing it out to the customer and explaining a worst case ending to the attempted restoration.

And I sure hope in these three cases they end up resembling a pipe….

After carefully removing the bits from the shanks, I went to work on the cake. As Mike pointed out, one has to be very careful, as a pipe caked to this extent is almost assuredly suffering from some damage to the briar.

Special note – New Mexico Environmental has informed me that they plan to insist that I get the certification required for coal strip mining, if I plan to continue to bring back pipes in this condition…..

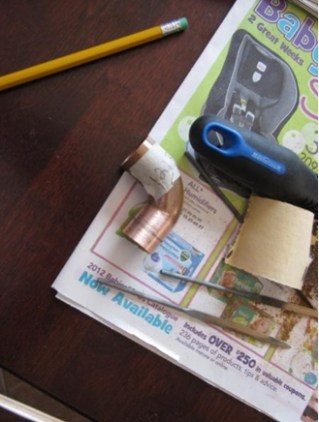

Stage one of the “Cleanup”….Bits soaked overnight in my magic solution and then steel wooled while still wet. Total bristle clean-out of the airway and the tenon area. Two solution scrubs of the briar and clean-out of the mortise…..now on to sanding and briar repair.

I would have had these done Sunday evening, but with the temperature hovering around 100 degrees, we had a wide spread power outage on our side of the Mountain…..six hours later, we could check the update for fires, cool off and relax. The pipes had to wait….until now.

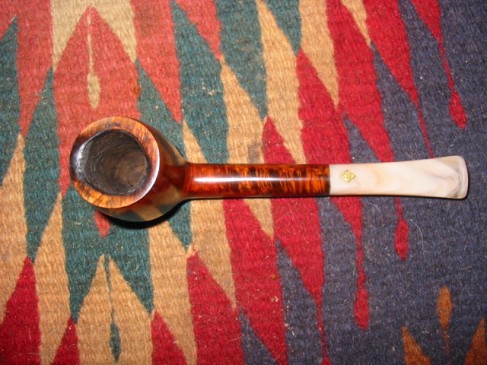

I did not restore the surface bite marks on the bits, as they were going back to the same owner. Leaving them as intact as they came to me, with no heavy sanding, allows him to retain much of the original thickness. Buffing them out and then resurfacing the finish has them looking good.

The customer had a funny response when he picked up his pipes today. He quietly picked them up, one at a time, and examined them for several minutes. He then looked up at me with a big smile on his face and said “Alright! What did you do with MY pipes?” Quiet for another minute, and then “They haven’t looked like this in 20 years.”

And then he paid his bill and added a tip to cover my lunch.