Blog by Steve Laug

The next pipe I am working on came from a friend, Lee who lives in the US. It is a Peterson’s Straight Bulldog. It is stamped on the left side of the shank and reads Peterson’s [over] Jade. On the right side it is stamped Made in the [over] Republic [over] of Ireland followed by the shape number 150. He sent me an email detailing what he saw in the pipe and gave his assessment as well as several pictures of the pipe. He wrote:

The Peterson Bulldog is hardly in horrible shape, but would like you to go at this thing to bring to ‘showcase’ quality if possible. Of course, you’ll have to see the pipe first before expectations are set. He had picked it up on eBay. Would like you to take this to the best it could be – will leave it to you to assess, but will mention that the ‘jewel’ fastening between bowl and stem fascinates me as something for differentiate the pipe from the rest of my collection. Whatever you can do…

Here are the photos he included.

The pipe arrived and I went over it to see what I thought of it before I started my work on it. Here is what I sent to Lee.

The pipe arrived and I went over it to see what I thought of it before I started my work on it. Here is what I sent to Lee.

Peterson’s Republic Era Jade Bulldog.

- Bowl exterior is dirty with a few dings and dents in the ring and on the sharp diamond edges of the shank… particularly on the sides.

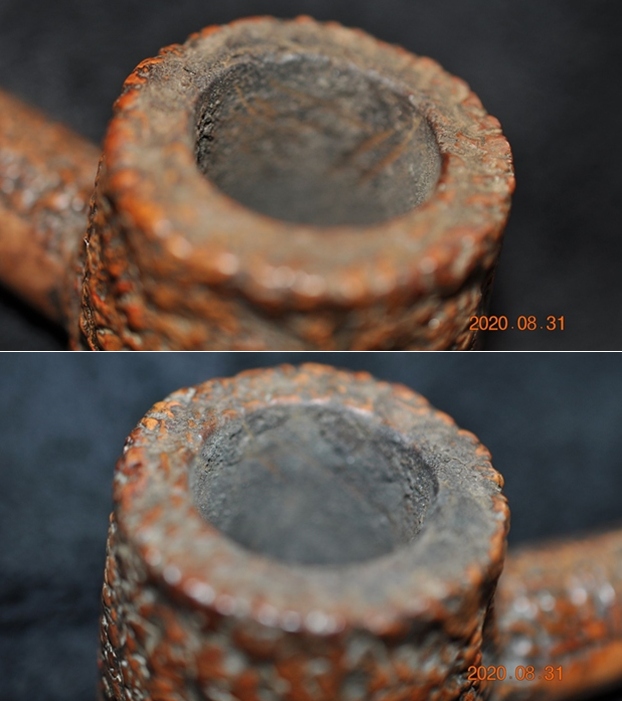

- Rim top is a bit of a mess. There are a lot of nicks and dings in the briar, some darkening and lava on the inner beveled edge of the bowl. The inner edge looks ok under the lava as far as I can see. Outer edge has some nicks and dings. Worn spots.

- Bowl internals show a heavy cake that greatly reduces the bowl capacity. Needs to be reamed and cleaned. Strong Latakia smell.

- Stem is scratched and lightly oxidized. There are deep tooth marks on both sides and a lot of tooth chatter marking the stem surface ahead of the button.

Overall in moderately good condition

I took photos of the pipe before I started my cleanup work. They tell the story of what I have noted above in short form. They also give a glimpse of the promise that Lee saw in this pipe.

I took photos of the rim top and stem to show the condition of the bowl and stem. The interior the bowl had a heavy cake that overflowed like lava onto the rim top. There are dings and dents in the rim top and some darkening on the inner edge. The stem is oxidized, calcified and has deep tooth marks and chatter on the top and underside near the button. The stylized P stamp on the top left side of the saddle is faded but present.

I took photos of the rim top and stem to show the condition of the bowl and stem. The interior the bowl had a heavy cake that overflowed like lava onto the rim top. There are dings and dents in the rim top and some darkening on the inner edge. The stem is oxidized, calcified and has deep tooth marks and chatter on the top and underside near the button. The stylized P stamp on the top left side of the saddle is faded but present.  I took photos of the sides of the shank to show the stamping. The stamping is readable in the photos below and is as noted above. The decorative band on the shank end is twin brass plates separated by a pearlized acrylic.

I took photos of the sides of the shank to show the stamping. The stamping is readable in the photos below and is as noted above. The decorative band on the shank end is twin brass plates separated by a pearlized acrylic.  I took the stem off the shank and took a photo. It is a nice looking pipe and the shank end decorative piece looks very good.

I took the stem off the shank and took a photo. It is a nice looking pipe and the shank end decorative piece looks very good. I am including the information from Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson). I have included a bit of the pertinent history here.

I am including the information from Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson). I have included a bit of the pertinent history here.

1950 – 1989 The Republic Era – From 1950 to the present time, the stamp for this era is “Made in the Republic of Ireland” in a block format generally in three lines but two lines have been used with or without Republic being abbreviated.

During the 1950’s and 60’s the Kapp & Peterson Company was still in the ownership of the Kapp family. However 1964 saw the retiral of the company Managing Director Frederick Henry(Harry) Kapp.

I knew that I was dealing with a Republic Era pipe made between 1950-1989. It was a nice looking straight Bulldog with a unique shank end decoration. The finish was stained with a medium brown stain. Now it was time to work on the pipe.

I decided to start my restoration work on this one by starting my cleanup of the bowl. I reamed the thick cake back with a PipNet pipe reamer using the smallest cutting head on this petite pipe. The cake was thick and crumbly and came out easily. I followed that by cleaning up the remnants of cake with a Savinelli Fitsall Pipe Knife and finish with a piece of dowel wrapped in 220 grit sandpaper.

I decided to deal with the damaged rim top next. I lightly topped the bowl to remove the significant dents and damage to the top and outer edge. It did not take too much work to remove it. I used a folded piece of 220 grit sandpaper to smooth out the bevel on the inner edge of the bowl and remove the burn damage there. It came out looking much better. Once it is polished it will look very good and match the finish on the bowl quite well.

I decided to deal with the damaged rim top next. I lightly topped the bowl to remove the significant dents and damage to the top and outer edge. It did not take too much work to remove it. I used a folded piece of 220 grit sandpaper to smooth out the bevel on the inner edge of the bowl and remove the burn damage there. It came out looking much better. Once it is polished it will look very good and match the finish on the bowl quite well. I wiped off the exterior of the bowl with a damp cloth to remove the sanding dust and grime. Once it was clean it was time to deal with the interior. I scrubbed out the shank and the airway in the stem with pipe cleaners, cotton swabs and alcohol to remove the tars and oils. There was also some brown stain that came out of the inside of the shank and the end of the stem.

I wiped off the exterior of the bowl with a damp cloth to remove the sanding dust and grime. Once it was clean it was time to deal with the interior. I scrubbed out the shank and the airway in the stem with pipe cleaners, cotton swabs and alcohol to remove the tars and oils. There was also some brown stain that came out of the inside of the shank and the end of the stem.  I polished the rim top and bowl with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the briar down after each pad with a damp cloth. The photos tell the story of the progress of the rim and bowl.

I polished the rim top and bowl with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the briar down after each pad with a damp cloth. The photos tell the story of the progress of the rim and bowl.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for about 15-20 minutes and then buffed it with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process. With that done the bowl was finished other than a final buffing.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips and a horsehair shoe brush to clean, enliven and protect the briar. I let the balm sit for about 15-20 minutes and then buffed it with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process. With that done the bowl was finished other than a final buffing.

I set it aside and turned my attention to the stem. I “painted” the surface of the stem to lift the tooth marks and dents I was able to lift many of them but several remained on the top and underside near the button. I filled them in with black superglue and set them aside to cure. Once they had cured I smoothed them out with a file to start to blend them into the surface of the stem.

I set it aside and turned my attention to the stem. I “painted” the surface of the stem to lift the tooth marks and dents I was able to lift many of them but several remained on the top and underside near the button. I filled them in with black superglue and set them aside to cure. Once they had cured I smoothed them out with a file to start to blend them into the surface of the stem.

I sanded the repaired areas with 220 grit sandpaper to smooth out the repairs. I started the polishing with 400 grit wet dry sandpaper.

I sanded the repaired areas with 220 grit sandpaper to smooth out the repairs. I started the polishing with 400 grit wet dry sandpaper.  I scrubbed the surface of the stem to remove the remaining oxidation with Soft Scrub all Purpose cleanser. I rubbed it on and off with a cotton pad and was able to remove a lot of oxidation.

I scrubbed the surface of the stem to remove the remaining oxidation with Soft Scrub all Purpose cleanser. I rubbed it on and off with a cotton pad and was able to remove a lot of oxidation.  I touched up the P stamp on the left side of the saddle with Rub’n Buff Antique Gold. I applied it to the stamping with a tooth pick. I buffed it off with a paper towel and was pleased by the gold left behind in the stamp.

I touched up the P stamp on the left side of the saddle with Rub’n Buff Antique Gold. I applied it to the stamping with a tooth pick. I buffed it off with a paper towel and was pleased by the gold left behind in the stamp.  I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine.

I am excited to finish this Republic Era Peterson’s Jade 150 Bulldog. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed it with a clean buffing pad to raise the shine and followed that with a quick hand buff with a microfibre cloth to deepen the shine. It is fun to see what the polished bowl looks like with the polished shank decoration on the end and the black vulcanite stem is a great contrast of colour. This Peterson’s Jade Bulldog is a great looking pipe and it feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. It is a beautiful pipe. Thanks for walking through the restoration with me as I worked over this pipe. I am looking forward to seeing what my friend Lee thinks of the pipe after the restoration. One more of his to restore then I will mail them back to them. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next pipeman or woman.

I am excited to finish this Republic Era Peterson’s Jade 150 Bulldog. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed it with a clean buffing pad to raise the shine and followed that with a quick hand buff with a microfibre cloth to deepen the shine. It is fun to see what the polished bowl looks like with the polished shank decoration on the end and the black vulcanite stem is a great contrast of colour. This Peterson’s Jade Bulldog is a great looking pipe and it feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside diameter of the bowl: 1 ¼ inches, Chamber diameter: ¾ of an inch. It is a beautiful pipe. Thanks for walking through the restoration with me as I worked over this pipe. I am looking forward to seeing what my friend Lee thinks of the pipe after the restoration. One more of his to restore then I will mail them back to them. Thanks to each of you who are reading this blog. Remember we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next pipeman or woman.