Blog by Steve Laug

I have two more of Mark’s uncle’s pipes left after this one. Both of them are Kaywoodies. I am really enjoying working on these and I think it is because of the known history behind these old pipes. To me one of the fun parts of this hobby is the history or backstory on the pipes. If I can find out about that it gives another dimension to the pipe repair or restoration work. I have finished four of the seven pipes that Mark sent me. The Ropp Cherrywood De Luxe (https://rebornpipes.com/2018/01/17/cleaning-and-restoring-a-ropp-cherrywood-de-luxe-805/), The Doodler (https://rebornpipes.com/2018/01/19/restoring-a-beautiful-the-doodler-bullmoose/), newer three hole stinger Kaywoodie Super Grain Billiard S-L (https://rebornpipes.com/2018/01/21/restoring-marks-uncles-third-pipe-a-kaywoodie-super-grain-s-l-billiard/) and a Savinelli Churchwarden (https://rebornpipes.com/2018/01/22/restoring-marks-uncles-savinelli-churchwarden-aged-briar-2002/) are completed and I have posted them on the blog. As I mentioned in a previous blog I often think about the pipeman who used these pipes as a daily part of his life while I am working on it. Here are some pictures of the pipes. The pipe I am working on now is the fifth pipe down in the above photo and the fifth from the left in the photo below. It is a delicate pot shaped pipe with a major piece missing from the button on the stem.

The pipe I am working on now is the fifth pipe down in the above photo and the fifth from the left in the photo below. It is a delicate pot shaped pipe with a major piece missing from the button on the stem. I am including a part of that history to give you a sense of the information that fed the desire to clean up and restore this set of old pipes. Mark wrote…

I am including a part of that history to give you a sense of the information that fed the desire to clean up and restore this set of old pipes. Mark wrote…

…My Uncle John, raised in an Appalachian Mountain family (think Hatfield and McCoy), was a large man with an affable personality – although this had limits and he could be quite formidable.

During WWII he left home and enlisted in the US Army where he was assigned to Patton’s 3rd Army as an ambulance driver. After Germany surrendered, he was transported back to the US on a converted ocean liner troop ship (I believe it was the Queen Mary). Upon reaching the US, his unit was immediately sequestered on a troop train for transport to the West Coast to be shipped to the Pacific for the invasion of Japan. About half way across the country (possibly somewhere in Texas), the train stopped and the troops informed that Japan had capitulated – WWII was over.

Before the Korean War began, my uncle re-enlisted in the US Air Force. He as assigned to a Photo Mapping unit as an Aircraft Mechanic. He worked his way up to Crew Chief and served in Photo Mapping until he medically retired in the mid 60’s due to heart problems.

Being part of an Air Force family, I did not get to spend much time with my uncle while growing up. However, I was able to stay a couple of summers with him at his West Palm Beach home while in my teens. On a desk in his Florida Room sat collection of old used pipes in a walnut pipe rack / humidor combo (very similar the Decatur Industries 6 pipe Rack and humidor combination shown in the rebornpipes store). There were a couple of packages of old dried up commercial brand tobacco in the humidor – one was cherry, I think. I never saw my uncle smoke and never discussed the pipes with him, but I was intrigued by the pipe collection. They were old, dirty, and well used – some with chewed through stems. Obviously, the pipes had been smoked by a devoted pipe enthusiast. As a young boy, I loved the smell of pipe tobacco, which you could occasionally smell in public way back then. I started smoking an occasional pipe in college. When my uncle passed away a few years later, I asked for his pipe collection and have stored it away since then. The pipes are just as I received them some thirty years ago.

While I will never know for sure, I believe my uncle purchased the pipes in various PX’s and smoked them while an Air Crew Member. The PX’s would have sold common commercially available pipe brands at a good price, nothing too expensive or exotic – consistent with the pipes in my uncle’s collection. As a Photo Mapping Air Crew Member / Chief my uncle traveled the world extensively, and was stationed at many bases – including “permanent” stations in West Palm Beach, Warner Robins, and Goose Bay Labrador, to name a few. Smoking a pipe would have been a relaxing way to spend a few monotonous hours on the flight line or in the air. After his heart problems, he must have given up pipe smoking and the pipes sat unused thereafter. If the bowls look like they were recently scraped, it would have been over fifty years ago, most likely with a Case hardware store folding knife. If dirty, it is due to sitting for many years in the back room. If well used and chewed it is due to many hours of smoking enjoyment.

I’m looking forward to seeing my Uncle John’s pipes in restored condition. I know they are not “collectors” items, but they bring back priceless memories of my uncle and the times we spent together sharing “war stories”…

With that reminder of the old pipeman, I turned my attention to the fifth of Mark’s uncle’s pipes – a Tally Ho pot shaped pipe. The pipe was stamped on the left side of the shank with the words Tally Ho wrapped with a swirled line almost like ribbon around the words. On the right side of the shank is stamped Made in London England and next to the shank/bowl junction is the shape number 33. The exterior of the pipe was dirty and grimy with a few small dents in the sides of the bowl. The rim top was dirty and had some light buildup on the top edge. The bevel on the inner edge was darkened and dirty. The bowl itself looked recently reamed and was clean. Overall the finish was in good condition but it was dirty and dusty. The stem was oxidized and there was a large chunk of the vulcanite missing on the top end of the stem where it had been chewed through or broken off. I knew that on this one the stem would need to be replaced. I took photos of the pipe before I started restoring it.

I took a close up photo of the rim top to show the lack of cake in the bowl and the light buildup on the rim top. It appeared that the pipe may have been reamed or cleaned at some point very recently. The inner and outer edges of the rim were in good condition. There was some darkening and tar on the inner beveled rim. I took some close up photos of the stem to show the size of the missing vulcanite chunk near the button on the top side.

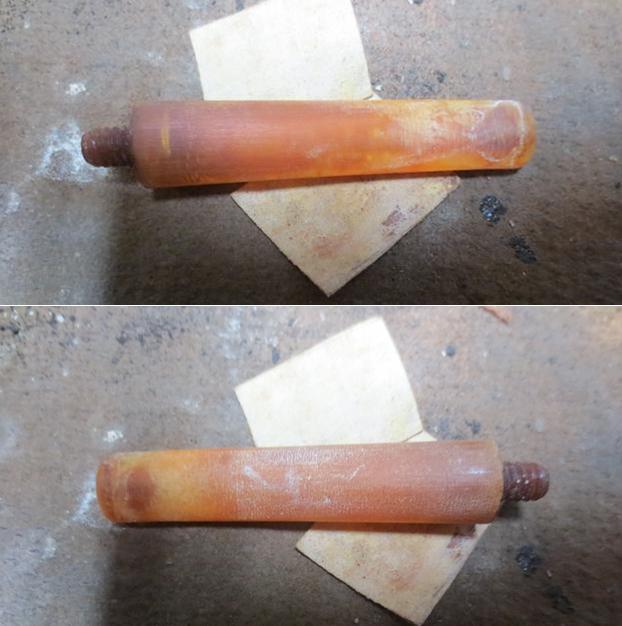

I took a close up photo of the rim top to show the lack of cake in the bowl and the light buildup on the rim top. It appeared that the pipe may have been reamed or cleaned at some point very recently. The inner and outer edges of the rim were in good condition. There was some darkening and tar on the inner beveled rim. I took some close up photos of the stem to show the size of the missing vulcanite chunk near the button on the top side. I went through my collection of stems and found an estate stem that was very close in length and diameter to the original stem. The button was different to some degree but it would work well. I would need to sand down the tenon to make it fit properly but it would not take too much work to get a decent fit on it.

I went through my collection of stems and found an estate stem that was very close in length and diameter to the original stem. The button was different to some degree but it would work well. I would need to sand down the tenon to make it fit properly but it would not take too much work to get a decent fit on it. Once the tenon was resized to fit I put the stem in place and sanded the stem diameter with 220 grit sandpaper to fit it to the shank. The new stem was going to look really good once it was polished and the fit perfected.

Once the tenon was resized to fit I put the stem in place and sanded the stem diameter with 220 grit sandpaper to fit it to the shank. The new stem was going to look really good once it was polished and the fit perfected.

At this point I took a bit of time to have a look and see what I could find out about the brand. I checked on Pipedia and did not find anything. I went on to look on the Pipephil Logos and Stampings site and there I found what I needed. The brand was listed and linked to Hardcastle Pipes. It was an English made pipe as the stamping clearly showed. It was evidently a sub-brand of the Hardcastle line. http://www.pipephil.eu/logos/en/logo-t2.html

At this point I took a bit of time to have a look and see what I could find out about the brand. I checked on Pipedia and did not find anything. I went on to look on the Pipephil Logos and Stampings site and there I found what I needed. The brand was listed and linked to Hardcastle Pipes. It was an English made pipe as the stamping clearly showed. It was evidently a sub-brand of the Hardcastle line. http://www.pipephil.eu/logos/en/logo-t2.html

I took some photos of the stamping on the left, right and underside of the shank. The stamping is quite readable. The Tally Ho stamping in the above photo is identical to the stamping on the left side of the shank. The Made In London over England and the placement of the shape number 33 stamp also is a match. The placement of the Patent number on the underside of the shank is the same and the number Pat. No.227665 is also the same. I am not sure what the patent refers to but my guess would be some inner tube or stinger apparatus designed to remove moisture from the smoke as it is drawn into the mouth.

I used a small blade pen knife to scrape out the tars and oils on the inside of the mortise. Once it was removed I cleaned out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners until they came out clean.I used a folded piece of 220 grit sandpaper to work on the inner bevel of the rim. I removed the tars and oils that had built up in that place. I used 1500-2400 grit micromesh sanding pads to clean up the top of the rim and smooth out the debris that was stuck on top.

I used a small blade pen knife to scrape out the tars and oils on the inside of the mortise. Once it was removed I cleaned out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners until they came out clean.I used a folded piece of 220 grit sandpaper to work on the inner bevel of the rim. I removed the tars and oils that had built up in that place. I used 1500-2400 grit micromesh sanding pads to clean up the top of the rim and smooth out the debris that was stuck on top. I used a folded piece of 220 grit sandpaper to work on the inner bevel of the rim. I removed the tars and oils that had built up in that place. I used 1500-2400 grit micromesh sanding pads to clean up the top of the rim and smooth out the debris that was stuck on top.

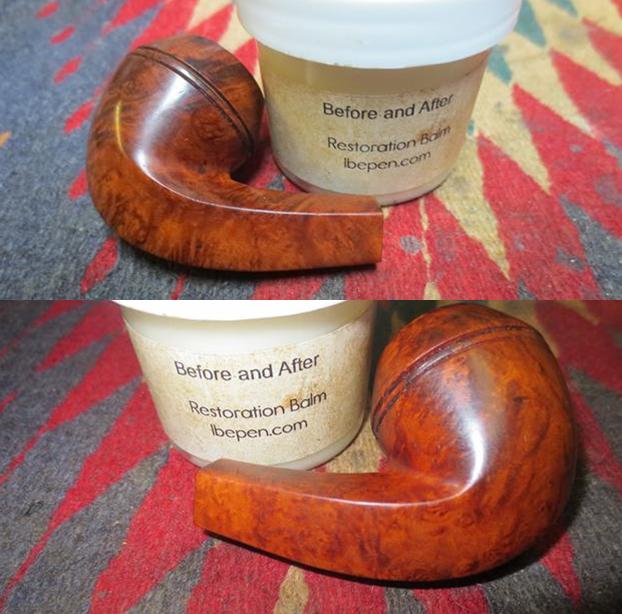

I used a folded piece of 220 grit sandpaper to work on the inner bevel of the rim. I removed the tars and oils that had built up in that place. I used 1500-2400 grit micromesh sanding pads to clean up the top of the rim and smooth out the debris that was stuck on top. I worked some Before & After Restoration Balm into the surface of the briar with my finger tips to deep clean the finish, enliven and protect the wood. I worked the balm into the rim top and inner bevel of the rim to polish the cleaned up area. I let it sit for a few minutes and then buffed it with a cotton cloth. The grain in the wood came alive and there was a rich shine to the briar. I took some photos of the bowl at this point to mark the progress in the restoration.

I worked some Before & After Restoration Balm into the surface of the briar with my finger tips to deep clean the finish, enliven and protect the wood. I worked the balm into the rim top and inner bevel of the rim to polish the cleaned up area. I let it sit for a few minutes and then buffed it with a cotton cloth. The grain in the wood came alive and there was a rich shine to the briar. I took some photos of the bowl at this point to mark the progress in the restoration.

I adjusted the fit of the stem to the shank with a bit more sanding. I put the stem in the shank and sanded with the stem in place to make the transition smooth to touch.

I adjusted the fit of the stem to the shank with a bit more sanding. I put the stem in the shank and sanded with the stem in place to make the transition smooth to touch.

Once the transition was smooth I worked it over the stem with micromesh sanding pads. I polished out the sanding scratches and marks in the vulcanite – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads and wiped it down with Obsidian Oil after each one. When I finished with the 12000 grit pad I gave it a final coat of oil and let it dry.

Once the transition was smooth I worked it over the stem with micromesh sanding pads. I polished out the sanding scratches and marks in the vulcanite – wet sanding it with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads and wiped it down with Obsidian Oil after each one. When I finished with the 12000 grit pad I gave it a final coat of oil and let it dry.

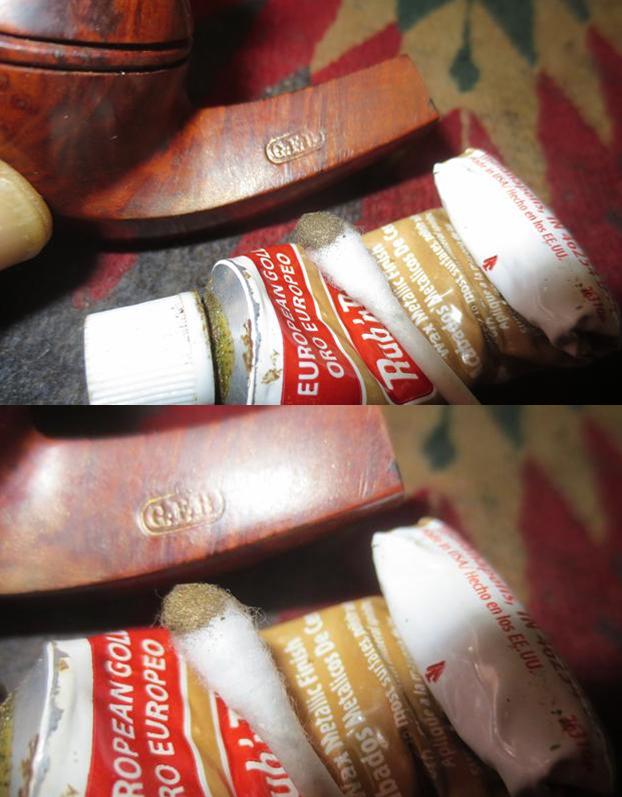

I used micromesh sanding pads (1500-12000 grit) to polish the sanding end of the shank to remove the scratches left behind by the sandpaper. I stained it with a dark brown stain pen to blend it into the colour of the rest of the bowl and shank. Once it dried I rubbed it down with some Conservator’s Wax and buffed it with a soft cloth to polish it. I took the following photos to show the bowl at this time.

I used micromesh sanding pads (1500-12000 grit) to polish the sanding end of the shank to remove the scratches left behind by the sandpaper. I stained it with a dark brown stain pen to blend it into the colour of the rest of the bowl and shank. Once it dried I rubbed it down with some Conservator’s Wax and buffed it with a soft cloth to polish it. I took the following photos to show the bowl at this time.

I put the stem back on the bowl and took the pipe to the buffing wheel to work it over. I buffed the bowl and stem with Blue Diamond to polish them. I gave the bowl and stem multiple coats of carnauba wax. I buffed the entire pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The finished pipe is shown in the photos below. The briar really shines and the dark stain looks beautiful. The vulcanite stem came out quite nice with a deep shine. The pipe and new stem look very good. Just two more of the uncle’s pipes to finish up and then these will be heading back to the US. Thanks for looking.

I put the stem back on the bowl and took the pipe to the buffing wheel to work it over. I buffed the bowl and stem with Blue Diamond to polish them. I gave the bowl and stem multiple coats of carnauba wax. I buffed the entire pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The finished pipe is shown in the photos below. The briar really shines and the dark stain looks beautiful. The vulcanite stem came out quite nice with a deep shine. The pipe and new stem look very good. Just two more of the uncle’s pipes to finish up and then these will be heading back to the US. Thanks for looking.