Blog by Dal Stanton

A few years ago, I acquired the Jeantet Superior Chimney now on the worktable in the ‘French Lot of 50’ which demanded my attention on the French eBay auction block. It has provided several treasures that are now in the care of new stewards benefiting the Daughters of Bulgaria. Another from this Parisian Lot, is now in the offering. Skeet saw the Jeantet in the online inventory, ‘For “Pipe Dreamers” Only!’ along with a few other pipes and reached out to me with questions about the possibility of commissioning some. Part of why I love restoring pipes is not only their innate beauty and intrigue delving into their pedigrees and stories, but also when I can learn about their former stewards or potentially in this case, their future stewards. Here is a portion of Skeets initial email to me:

Greetings Dal,

I have been looking through your collection of “Help Me!” Baskets and I am overwhelmed! There are so many beautiful pipes in this group! I have received a little extra money in recent days and I am finally going to commission a pipe or two. I am (sadly) clueless on the basic expense of this and the basic value of pipe brands. I found a dozen pipes I would cherish if I had them but have cut the number down significantly. I usually tend to buy full or half bent styles, but as I looked, I was drawn to mostly “slightly bent” or even straight models. I am a newbie still even though I am 66. I don’t automatically know the relative values of each of these pipes so I may be very interested in a pipe I cannot afford. This is the primary reason for my exploratory email.

Below I have listed 5 pipes (cut down from many more!) If you could supply me with a general idea of what these might cost to commission and eventually purchase, I would be quite appreciative. I intend to commission at least one and hopefully two if I can afford it.

I appreciate your willingness to support the Daughters of Bulgaria. What a wonderful cause! Thank you for your compassion.

After communicating back and forth, Skeet’s starting point with the consideration 5 pipes was whittled down to commissioning 3. Along with the Jeantet, Skeet commissioned an interesting Kaywoodie Flame grain 09B Pear and a Butz-Choquin Regate St. Claude France 1275 shown here.

After communicating back and forth, Skeet’s starting point with the consideration 5 pipes was whittled down to commissioning 3. Along with the Jeantet, Skeet commissioned an interesting Kaywoodie Flame grain 09B Pear and a Butz-Choquin Regate St. Claude France 1275 shown here.

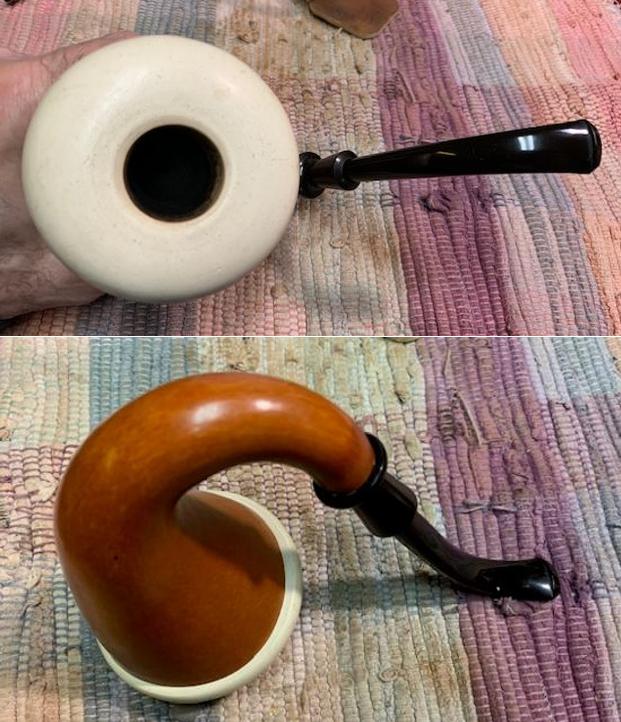

With all who commission pipes, the one condition I ask of them is patience as the pipes work through my deliberate but often slow worktable! A few months ago, before the holidays, I reached out to Skeet thanking him for his patience and letting him know that his pipes were close to the worktable. Now, the Jeantet Superior Chimney is on the table. With the 1 7/8-inch-tall bowl, which tightens and tapers toward the rim – sharp looking, I’m calling it a Chimney shape. To complete the dimensions, the length is 5 1/2 inches, the rim is 7/8 inches wide with a chamber width of 5/8 inches and depth of 1 11/16 inches. Here are a few pictures to take a closer look.

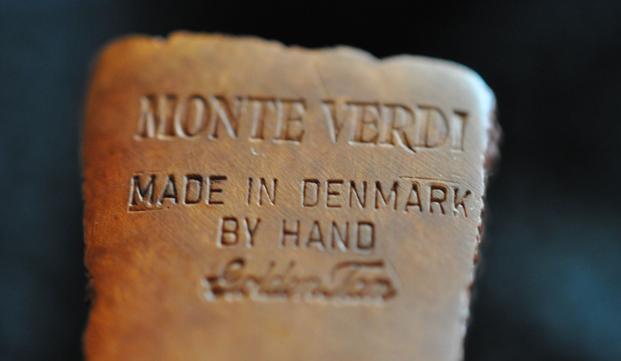

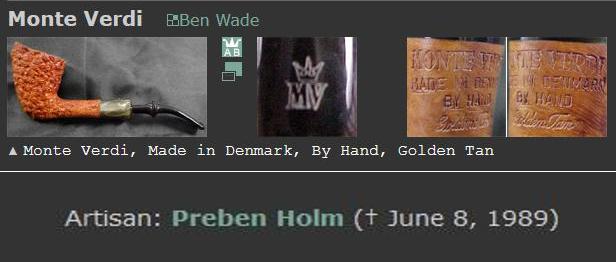

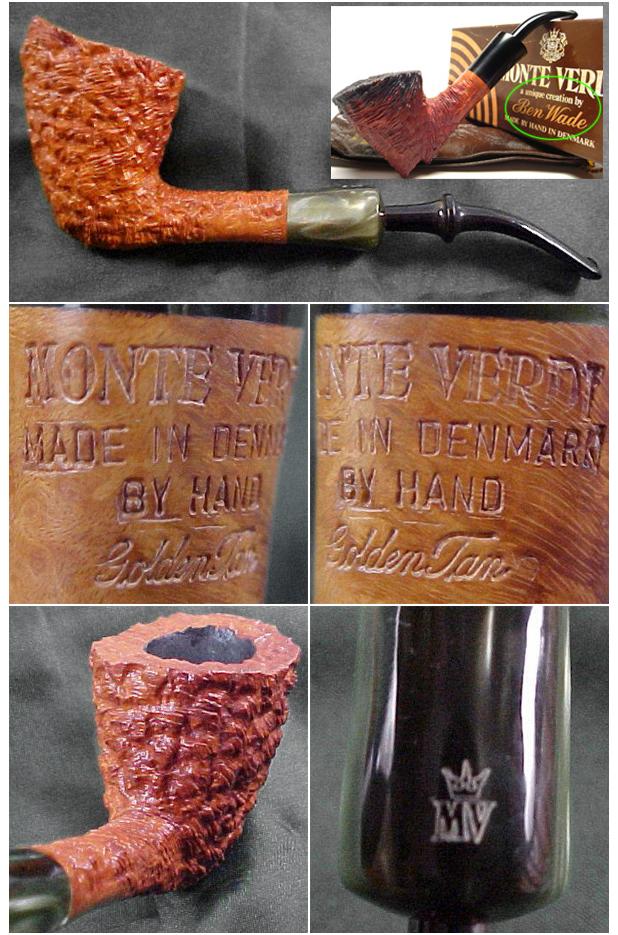

The stampings on the left side of the shank are JEANTET [over] SUPERIOR. The stem has stamped a ‘J’ with an oval encircled around it.

The stampings on the left side of the shank are JEANTET [over] SUPERIOR. The stem has stamped a ‘J’ with an oval encircled around it. One of the first pipes I restored several years ago was a Jeantet Fleuron which I found in one of my favorite antique – second-hand shops located in downtown, Sofia, Bulgaria, which I affectionately called the, ‘Hole in the Wall’. That restoration was my first dive into the labyrinth of French pipe makers and the historic center of pipe making in Saint Claude, France. I was fascinated by all the relationships and machinations of figuring out the histories of pipe names, datings, and the fluctuations caused by business deals between UK and France…. I enjoyed the research of that first French pipe on my worktable and you can take a look and read it at this link: Another nice find at the ‘Hole in the Wall’ – Jeantet Fleuron 70-7. The history of the Jeantet name in Saint Claude spans back into the 1700s. The first part of Pipedia’s Jeantet article starts by looking at the history up to WW2 – as a refresher I repeat it here:

One of the first pipes I restored several years ago was a Jeantet Fleuron which I found in one of my favorite antique – second-hand shops located in downtown, Sofia, Bulgaria, which I affectionately called the, ‘Hole in the Wall’. That restoration was my first dive into the labyrinth of French pipe makers and the historic center of pipe making in Saint Claude, France. I was fascinated by all the relationships and machinations of figuring out the histories of pipe names, datings, and the fluctuations caused by business deals between UK and France…. I enjoyed the research of that first French pipe on my worktable and you can take a look and read it at this link: Another nice find at the ‘Hole in the Wall’ – Jeantet Fleuron 70-7. The history of the Jeantet name in Saint Claude spans back into the 1700s. The first part of Pipedia’s Jeantet article starts by looking at the history up to WW2 – as a refresher I repeat it here:

The firm of the Jeantet family in Saint-Claude is first mentioned as early as 1775. By 1807 the Jeantets operated a turnery producing in particular wooden shanks for porcelain pipes and wild cherry wood pipes. The firm was named Jeantet-David in 1816, and in 1837 the enterprise was transformed into a corporation as collective name for numerous workshops scattered all over the city.

The firm of the Jeantet family in Saint-Claude is first mentioned as early as 1775. By 1807 the Jeantets operated a turnery producing in particular wooden shanks for porcelain pipes and wild cherry wood pipes. The firm was named Jeantet-David in 1816, and in 1837 the enterprise was transformed into a corporation as collective name for numerous workshops scattered all over the city.

The manufacturing of briar pipes and began in 1858. 51 persons were employed by 1890. Desirous to concentrate the workers at a single site, the corporation began to construct a factory edifying integrated buildings about 1891 at Rue de Bonneville 12 – 14. In 1898 Maurice Jeantet restructured the business. He is also presumed to enlarge Jeantet factory purchasing a workshop adjoining southerly. It belonged to the family Genoud, who were specialized in rough shaping of stummels and polishing finished pipes. (In these times it was a most common procedure to carry goods from here to there and back again often for certain steps of the production executed by dependent family based subcontractors. Manpower was cheap.)

Jeantet was transformed to a corporation with limited liability in 1938. By that time a branch workshop was operated in Montréal-la-Cluse (Ain), where mainly the less expensive pipes were finished. 107 employees – 26 of them working from their homes – were counted in Saint-Claude in 1948 and 18 in the Ain facility.

According to the Pipedia article, the Jeantet production continued to expand through the 50s with new equipment and more employees. But in 1969 production reached its zenith with the production of 30 to 35,000 dozen pipes per year with 72 workers shrinking to 1987 with 6 to 7000 dozen pipes per year with 22 workers on the payroll. The final years of the Jeantet name are described in the same Pipedia article:

Yves Grenard, formerly Jeantet’s chief designer and a great cousin of Pierre Comoy, had taken over the management of Chapuis-Comoy in 1971. Now, to preserve the brand, the Jeantet family went into negotiations with him, and resulting from that Jeantet was merged in the Cuty Fort Group (est. 1987 and headed by Chacom) in 1988 along with the pipe brands of John Lacroix and Emile Vuillard. Chacom closed the Jeantet plant, and the City of Saint-Claude purchased it in 1989. After alternative plans failed, the buildings were devoted to wrecking. The southerly workshop was wrecked before 1992.

Today Jeantet pipes were produced as a sub-brand by Chapuis-Comoy who’s mainstay is Chacom of course.

Looking at Pipephil.eu, I hoped to find more information about the Jeantet on my table in the listing. The ‘Superior’ line was not among the listings, but what was added was later information about the fate of the Jeantet name:

The company joined the Cuty-Fort Entreprises group (Chacom, Ropp, Vuillard, Jean Lacroix…) in 1992. In 2010 it dropped out and the brand isn’t part of the group any more. The label is owned by the Jeantet family (Dominique Jeantet) again. The pipe production is discontinued. Dominique Jeantet retired in 2000.

With a renewed appreciation for the legacy of the Jeantet pipe on my table, I look more closely at the pipe. The chamber needs cleaning to give the briar a fresh start. The carbon buildup is minor. There is some darkening on the rim from lighting, but hopefully, this should clean easily.  The stummel has attractive and expressive random grain and fire grain that wraps the bowl. Looking closely at the bowl several fills are visible which may need attention later.

The stummel has attractive and expressive random grain and fire grain that wraps the bowl. Looking closely at the bowl several fills are visible which may need attention later.  The slightly bent saddle stem shows some thick oxidation and light roughness on the bit.

The slightly bent saddle stem shows some thick oxidation and light roughness on the bit. Starting with the stem, the original Jeantet nickel stinger is lodged in the tenon. It is debated whether stingers help or hinder the smoking experience. I personally do not prefer stingers. Yet, as part of the historicity of a pipe, if it has a stinger as a part of its original production, I like to save it and allow the future steward to make his own decisions.

Starting with the stem, the original Jeantet nickel stinger is lodged in the tenon. It is debated whether stingers help or hinder the smoking experience. I personally do not prefer stingers. Yet, as part of the historicity of a pipe, if it has a stinger as a part of its original production, I like to save it and allow the future steward to make his own decisions.  To remove the stinger, a cloth is used to wrap the stinger to protect it from ‘teeth marks’ as it’s removed. With the cloth wrapped around the stinger, the needle nose pliers lightly grab the stinger while I gently rotate the stem to dislodge the stinger. This works well. I put the stinger in some alcohol to soak and to later clean with steel wool.

To remove the stinger, a cloth is used to wrap the stinger to protect it from ‘teeth marks’ as it’s removed. With the cloth wrapped around the stinger, the needle nose pliers lightly grab the stinger while I gently rotate the stem to dislodge the stinger. This works well. I put the stinger in some alcohol to soak and to later clean with steel wool. Next, the airway is cleaned with a few pipe cleaners wetted with isopropyl 99%.

Next, the airway is cleaned with a few pipe cleaners wetted with isopropyl 99%. I can see some significant deposits of oxidation in the vulcanite stem. While protecting the circled ‘J’, I go work on the oxidation before putting the stem into a soak of Before & After Deoxidizer.

I can see some significant deposits of oxidation in the vulcanite stem. While protecting the circled ‘J’, I go work on the oxidation before putting the stem into a soak of Before & After Deoxidizer. I use Soft Scrub and steel wool to try to break up the oxidation – avoiding the stem stamping.

I use Soft Scrub and steel wool to try to break up the oxidation – avoiding the stem stamping. After rinsing the stem, it is then placed in the Before & After Deoxidizer to soak through the night along with the other pipes that Skeet has commissioned.

After rinsing the stem, it is then placed in the Before & After Deoxidizer to soak through the night along with the other pipes that Skeet has commissioned. The next day, the stem is fished out of the Deoxidizer and drained. With latex surgical gloves on my hands, I squeegee the liquid off the stem.

The next day, the stem is fished out of the Deoxidizer and drained. With latex surgical gloves on my hands, I squeegee the liquid off the stem. I then use a pipe cleaner wetted with isopropyl 99% to clear the Deoxidizer from the airway. Cotton pads and alcohol are also used to wipe off the raised oxidation from the stem.

I then use a pipe cleaner wetted with isopropyl 99% to clear the Deoxidizer from the airway. Cotton pads and alcohol are also used to wipe off the raised oxidation from the stem. To help condition the vulcanite, paraffin oil, a mineral oil, is applied to the stem.

To help condition the vulcanite, paraffin oil, a mineral oil, is applied to the stem.  Looking more closely at the stem with the oil on it, and with the help of a lightened picture, residual oxidation is visible. Ugh! The greatest concentration is on the bit and on the horn of the saddle stem. I have found that the Before & After Deoxidizer does not work as well with deep oxidation. The question that has been discussed is, does this product remove oxidation or mask it? I’ll need to ask Mark Hoover about this who produces the product (www.Lpen.com)! The Deoxidizer seems to do great with stems with light oxidation, but for this stem, sanding will be needed to continue the oxidation removal.

Looking more closely at the stem with the oil on it, and with the help of a lightened picture, residual oxidation is visible. Ugh! The greatest concentration is on the bit and on the horn of the saddle stem. I have found that the Before & After Deoxidizer does not work as well with deep oxidation. The question that has been discussed is, does this product remove oxidation or mask it? I’ll need to ask Mark Hoover about this who produces the product (www.Lpen.com)! The Deoxidizer seems to do great with stems with light oxidation, but for this stem, sanding will be needed to continue the oxidation removal.  Turning now to the Chimney stummel, a fresh picture shows the chamber and the light cake build up.

Turning now to the Chimney stummel, a fresh picture shows the chamber and the light cake build up. I am only able to use the smallest diameter blade head in the Pipnet Reaming Kit to ream the chamber. The narrow chamber shaft will not accommodate more!

I am only able to use the smallest diameter blade head in the Pipnet Reaming Kit to ream the chamber. The narrow chamber shaft will not accommodate more! The Savinelli Fitsall Tool follows by scraping the chamber wall and can reach down to the floor of the chamber and navigate the tight angles. The chamber cleaning is completed with a sanding with 240 paper wrapped around a Sharpie Pen.

The Savinelli Fitsall Tool follows by scraping the chamber wall and can reach down to the floor of the chamber and navigate the tight angles. The chamber cleaning is completed with a sanding with 240 paper wrapped around a Sharpie Pen.  After wiping out the chamber with a cotton pad, an inspection reveals healthy briar – no heating or cracking problems.

After wiping out the chamber with a cotton pad, an inspection reveals healthy briar – no heating or cracking problems.  The cleaning continues with undiluted Murphy’s Oil Soap and a cotton pad. Using the cotton pad, the outer stummel is scrubbed. The darkened char on the aft of the rim is stubborn. I scrub the rim with my thumbnail and Murphy’s. The brass wired brush also is used and a careful scraping using a pocketknife. I’m extremely careful working on the rim because the rim top of the chimney bowl is very thin, and I do not want it damaged or worn down inadvertently.

The cleaning continues with undiluted Murphy’s Oil Soap and a cotton pad. Using the cotton pad, the outer stummel is scrubbed. The darkened char on the aft of the rim is stubborn. I scrub the rim with my thumbnail and Murphy’s. The brass wired brush also is used and a careful scraping using a pocketknife. I’m extremely careful working on the rim because the rim top of the chimney bowl is very thin, and I do not want it damaged or worn down inadvertently.  To continue the cleaning the stummel is transferred to the sink where using anti-oil liquid dishwashing soap and warm water, the mortise is scrubbed using shank brushes. After scrubbing, the stummel is thoroughly rinsed and transferred back to the worktable.

To continue the cleaning the stummel is transferred to the sink where using anti-oil liquid dishwashing soap and warm water, the mortise is scrubbed using shank brushes. After scrubbing, the stummel is thoroughly rinsed and transferred back to the worktable.  The rim cleaned up more but burn damage is there. The aft quadrant shows where most of the lighting activity has transpired – over the rim. The front shows some burns as well, but more localized. I’m an old school match user – over the bacca and draw down not over! This rim damage will be addressed later.

The rim cleaned up more but burn damage is there. The aft quadrant shows where most of the lighting activity has transpired – over the rim. The front shows some burns as well, but more localized. I’m an old school match user – over the bacca and draw down not over! This rim damage will be addressed later. During the external surface cleaning process, weakened patches, probably made of water-based fill material, filling the pitting in the briar are revealed. I had noted these fills earlier. The beauty of highly active briar grain often has the downside of small imperfections in the briar that have to be filled with patch material. I count 5 patches in need of repair.

During the external surface cleaning process, weakened patches, probably made of water-based fill material, filling the pitting in the briar are revealed. I had noted these fills earlier. The beauty of highly active briar grain often has the downside of small imperfections in the briar that have to be filled with patch material. I count 5 patches in need of repair.

While the old patch material is still damp, I use a dental probe to dig the remnant filler material.

While the old patch material is still damp, I use a dental probe to dig the remnant filler material.

Before continuing with patching, the cleaning of the internals of the stummel need completion. I prefer working on clean pipes! It only takes a few cotton buds and pipe cleaners dipped in isopropyl 99% to finish the cleaning. I will further the cleaning later with a kosher salt and alcohol soak.

Before continuing with patching, the cleaning of the internals of the stummel need completion. I prefer working on clean pipes! It only takes a few cotton buds and pipe cleaners dipped in isopropyl 99% to finish the cleaning. I will further the cleaning later with a kosher salt and alcohol soak. With the pipe now clean, I will address the 5 pits that emerged through the cleaning process now emptied of old fill material.

With the pipe now clean, I will address the 5 pits that emerged through the cleaning process now emptied of old fill material.

To repair the briar, I refill the pits using a mixture of briar dust and CA glue. The mixture creates a ‘briar putty’ that is then applied to the pits. I first clean the surface with alcohol AND discover another pit or possibly a chip in the shank, just to the right of the nomenclature. Well, now there’s 6 patches to be made. I clean the area with a dental probe and alcohol. The appearance seems that it’s a chip and not a pit that lost its fill material.

To repair the briar, I refill the pits using a mixture of briar dust and CA glue. The mixture creates a ‘briar putty’ that is then applied to the pits. I first clean the surface with alcohol AND discover another pit or possibly a chip in the shank, just to the right of the nomenclature. Well, now there’s 6 patches to be made. I clean the area with a dental probe and alcohol. The appearance seems that it’s a chip and not a pit that lost its fill material.

To make the briar putty, I use a plastic disk as the mixing palette. To help with clean up and to keep the CA glue pristine, a piece of clear packing tape covers the disk. To mix on a paper or an index card may change the viscosity of the CA glue during mixing and cause it to solidify too soon. A small pile of briar dust is placed on the palette, and then, beside this, a small puddle of extra thick CA glue is placed. The picture shows the set up before the mixing commences.

To make the briar putty, I use a plastic disk as the mixing palette. To help with clean up and to keep the CA glue pristine, a piece of clear packing tape covers the disk. To mix on a paper or an index card may change the viscosity of the CA glue during mixing and cause it to solidify too soon. A small pile of briar dust is placed on the palette, and then, beside this, a small puddle of extra thick CA glue is placed. The picture shows the set up before the mixing commences. Using the toothpick, briar dust is gradually pulled into the CA and mixed in with the toothpick. Additional briar dust is pulled into the thickening mixture until it reaches the viscosity of molasses.

Using the toothpick, briar dust is gradually pulled into the CA and mixed in with the toothpick. Additional briar dust is pulled into the thickening mixture until it reaches the viscosity of molasses. When the putty is thick enough and no longer runny, the toothpick is used to trowel the putty to spot place onto each pit. I use an accelerator to hold the patches in place and to quicken the curing process. The pictures below show the patches in place. While applying the putty, I saw another small pit – and then there were 7.

When the putty is thick enough and no longer runny, the toothpick is used to trowel the putty to spot place onto each pit. I use an accelerator to hold the patches in place and to quicken the curing process. The pictures below show the patches in place. While applying the putty, I saw another small pit – and then there were 7.

The hour is late and with the patches on the stummel firm, I will do one last project before turning out the lights. A kosher salt and alcohol soak will continue the internal cleaning and refresh the pipe for the new steward. Starting with a cotton ball, it is pulled and twisted until it forms a ‘wick’ to help draw out the tars and oils from the internal briar.

The hour is late and with the patches on the stummel firm, I will do one last project before turning out the lights. A kosher salt and alcohol soak will continue the internal cleaning and refresh the pipe for the new steward. Starting with a cotton ball, it is pulled and twisted until it forms a ‘wick’ to help draw out the tars and oils from the internal briar.  The end of the cotton ball wick is guided with the help of a stiff wire down the mortise into the airway as far as the draft hole. The bowl is then filled with kosher salt and the stummel is placed in an egg crate to keep it stable and to maintain the proper angle – the top of the salt and end of the shank are parallel. Kosher salt is used because it leaves no aftertaste.

The end of the cotton ball wick is guided with the help of a stiff wire down the mortise into the airway as far as the draft hole. The bowl is then filled with kosher salt and the stummel is placed in an egg crate to keep it stable and to maintain the proper angle – the top of the salt and end of the shank are parallel. Kosher salt is used because it leaves no aftertaste.  With a large eye dropper, isopropyl 99% is introduced slowly into the bowl until the alcohol surfaces over the salt. After about 10 minutes, the alcohol is absorbed into the salt and cotton wick to some degree. The bowl is then topped off with additional alcohol until it surfaces once more above the salt. I set the crate stummel aside resting in the egg crate and turn out the lights.

With a large eye dropper, isopropyl 99% is introduced slowly into the bowl until the alcohol surfaces over the salt. After about 10 minutes, the alcohol is absorbed into the salt and cotton wick to some degree. The bowl is then topped off with additional alcohol until it surfaces once more above the salt. I set the crate stummel aside resting in the egg crate and turn out the lights.  The next morning, the kosher salt and alcohol soak have been at work. The salt and the wick are soiled indicating a continued drawing out of the oils and tars from the internal briar.

The next morning, the kosher salt and alcohol soak have been at work. The salt and the wick are soiled indicating a continued drawing out of the oils and tars from the internal briar.  To make sure all is cleaned and refreshed, a cotton bud and pipe cleaner wetted with isopropyl 99% confirm all is good.

To make sure all is cleaned and refreshed, a cotton bud and pipe cleaner wetted with isopropyl 99% confirm all is good. With the stummel clean, next is the process of filing down all the briar putty patches. The basic approach for all the patches is to use a flat needle file with the goal to file exclusively on the patch mound and not to wander off the patch area onto the surrounding briar. The mounds are filed down close to the briar surface. These next few pictures give the idea.

With the stummel clean, next is the process of filing down all the briar putty patches. The basic approach for all the patches is to use a flat needle file with the goal to file exclusively on the patch mound and not to wander off the patch area onto the surrounding briar. The mounds are filed down close to the briar surface. These next few pictures give the idea.

After all the mounds are filed down, 240 grade sandpaper is used to sand the patches further. The goal is to remove all the excess dried putty surrounding the patch itself. You can tell when excess glue is remaining as you sand – the glue is a powdery white whereas briar is not. A few more pictures showing sanding on different patches.

After all the mounds are filed down, 240 grade sandpaper is used to sand the patches further. The goal is to remove all the excess dried putty surrounding the patch itself. You can tell when excess glue is remaining as you sand – the glue is a powdery white whereas briar is not. A few more pictures showing sanding on different patches.

With the patches filed and sanded down, I switch my focus to the rim. I like the design of the rim as it culminates. It is very compact as it crowns the coned taper of the bowl. The rim itself is a narrow 1/8 inch wide. The front and back of the rim have sustained charring and burn damage from lighting. The entire circumference of the inner rim is darkened.

With the patches filed and sanded down, I switch my focus to the rim. I like the design of the rim as it culminates. It is very compact as it crowns the coned taper of the bowl. The rim itself is a narrow 1/8 inch wide. The front and back of the rim have sustained charring and burn damage from lighting. The entire circumference of the inner rim is darkened.  To clean and refresh the rim, I top the stummel – oh, but precious little! To begin, 240 paper is used on the top of a chopping board which serves as my topping board. After inverting the stummel on the paper, I give it a few rotations and check. The last thing I want to do is take off too much with such a tightly fashioned rim. A few rotations are enough it seems to me.

To clean and refresh the rim, I top the stummel – oh, but precious little! To begin, 240 paper is used on the top of a chopping board which serves as my topping board. After inverting the stummel on the paper, I give it a few rotations and check. The last thing I want to do is take off too much with such a tightly fashioned rim. A few rotations are enough it seems to me.

Switching on the topping board now to 600 grade paper, several more rotations are given on the less abrasive paper. In the picture below after topping on the 600 paper, the rim looks better. There remains a burn mark on the front side that reaches into the rim. The back side damage to the rim, which appeared to be worse, has pretty much been erased except for the inner lip radius which still is darkened.

Switching on the topping board now to 600 grade paper, several more rotations are given on the less abrasive paper. In the picture below after topping on the 600 paper, the rim looks better. There remains a burn mark on the front side that reaches into the rim. The back side damage to the rim, which appeared to be worse, has pretty much been erased except for the inner lip radius which still is darkened. Using a tightly rolled piece of 240 paper followed by 600 paper, the inside rim lip is gently sanded to remove the black char stain. I call the sanding ‘gentle’ because I don’t want to create a bevel on a rim this narrow. I only desire to clean and freshen it. The rim looks great – nice grain has emerged. The only quandary I have is that there is still a small bit of char darkening remaining (upper arrow), but I don’t want to take more off the rim. Another question is right next to the dark spot – when I run my finger over it, it is not smooth (lower arrow). This appears to be an imperfection in the briar and topping the stummel to remove it will probably require a good bit more briar to be removed. Briar is the most important real estate on a pipe, and one does not give it up unless necessary.

Using a tightly rolled piece of 240 paper followed by 600 paper, the inside rim lip is gently sanded to remove the black char stain. I call the sanding ‘gentle’ because I don’t want to create a bevel on a rim this narrow. I only desire to clean and freshen it. The rim looks great – nice grain has emerged. The only quandary I have is that there is still a small bit of char darkening remaining (upper arrow), but I don’t want to take more off the rim. Another question is right next to the dark spot – when I run my finger over it, it is not smooth (lower arrow). This appears to be an imperfection in the briar and topping the stummel to remove it will probably require a good bit more briar to be removed. Briar is the most important real estate on a pipe, and one does not give it up unless necessary.  To avoid topping more and sacrificing more briar off the rim, I spot drop CA glue to fill the small crevasse on the rim.

To avoid topping more and sacrificing more briar off the rim, I spot drop CA glue to fill the small crevasse on the rim.  After the CA is cured, a pointed half moon needle file works well to file down the excess CA on the inner curve of the chamber.

After the CA is cured, a pointed half moon needle file works well to file down the excess CA on the inner curve of the chamber. Flipping the file over to the flat edge, it works well to remove the excess CA patch on the flat rim surface. I’m careful to keep the file on top of the patch mound so not to impact the surrounding briar.

Flipping the file over to the flat edge, it works well to remove the excess CA patch on the flat rim surface. I’m careful to keep the file on top of the patch mound so not to impact the surrounding briar. The rim patch is completed with 240 sanding paper followed by 600. The rim is now smooth to the touch and the patch blends well with the surrounding briar.

The rim patch is completed with 240 sanding paper followed by 600. The rim is now smooth to the touch and the patch blends well with the surrounding briar. Next, with the several patches required on the stummel surface, to blend these patches and to clean the surface, sanding sponges are used.

Next, with the several patches required on the stummel surface, to blend these patches and to clean the surface, sanding sponges are used.  I use a coarser grade sponge to start. Following this, a medium then a fine grade sponge to complete this phase.

I use a coarser grade sponge to start. Following this, a medium then a fine grade sponge to complete this phase.

Transitioning next to dry sanding with micromesh pads, pads 1500 to 2400 are followed by 3200 to 4000 and then 6000 to 12000. The grain emerges very nicely through the micromesh sanding process.

Transitioning next to dry sanding with micromesh pads, pads 1500 to 2400 are followed by 3200 to 4000 and then 6000 to 12000. The grain emerges very nicely through the micromesh sanding process.

Before putting the stummel aside to focus on the stem, Before & After Restoration Balm (www.Lpen.com) is applied to the stummel. The Balm does a great job bringing out the subtle hues of the natural briar. After placing some of the Balm on my fingers, the Balm is rubbed into the briar surface with a creamy consistency and it gradually thickens. Once the surface is thoroughly covered, the stummel is set aside for about 20 minutes for the Balm to do its work.

Before putting the stummel aside to focus on the stem, Before & After Restoration Balm (www.Lpen.com) is applied to the stummel. The Balm does a great job bringing out the subtle hues of the natural briar. After placing some of the Balm on my fingers, the Balm is rubbed into the briar surface with a creamy consistency and it gradually thickens. Once the surface is thoroughly covered, the stummel is set aside for about 20 minutes for the Balm to do its work. After 20 minutes, the excess Balm is wiped off with a microfiber cloth and then buffed. It’s looking great!

After 20 minutes, the excess Balm is wiped off with a microfiber cloth and then buffed. It’s looking great! Turning now to the stem, the picture I took earlier after the Deoxidizer soak is a reminder of the deep oxidation the remained.

Turning now to the stem, the picture I took earlier after the Deoxidizer soak is a reminder of the deep oxidation the remained.  Interestingly, as I look at the stem now, I am not able to see the oxidation as I was earlier…. Hmmm. Even so, I elect to sand the stem so that the oxidation doesn’t show itself later during the fine polishing phase.

Interestingly, as I look at the stem now, I am not able to see the oxidation as I was earlier…. Hmmm. Even so, I elect to sand the stem so that the oxidation doesn’t show itself later during the fine polishing phase.  Using 240 sanding paper, the entire stem is sanded careful to guard against accidentally sanding over the Jeantet Circle ‘J’ stem stamping.

Using 240 sanding paper, the entire stem is sanded careful to guard against accidentally sanding over the Jeantet Circle ‘J’ stem stamping.  Following the 240 grade coarser sanding, I wet sand using 600 grade paper and then finish after applying 0000 grade steel wool.

Following the 240 grade coarser sanding, I wet sand using 600 grade paper and then finish after applying 0000 grade steel wool. Continuing with the stem using micromesh pads, the stem is wet sanded with pads 1500 to 2400. Following the wet sanding, I dry sand with pads 3200 to 4000 and 6000 to 12000. Between each set of 3 pads, Obsidian Oil is applied to further condition the stem and to guard it from future oxidation.

Continuing with the stem using micromesh pads, the stem is wet sanded with pads 1500 to 2400. Following the wet sanding, I dry sand with pads 3200 to 4000 and 6000 to 12000. Between each set of 3 pads, Obsidian Oil is applied to further condition the stem and to guard it from future oxidation.

After completing the sanding of the saddle stem, I reunite the stem and stummel to get an overall look at the progress. What I discover is that the fit of the tenon and mortise has tightened through the cleaning process – this happens. I do not risk forcing the stem and stummel together which could result in hearing that dreaded snap of a cracked shank.

After completing the sanding of the saddle stem, I reunite the stem and stummel to get an overall look at the progress. What I discover is that the fit of the tenon and mortise has tightened through the cleaning process – this happens. I do not risk forcing the stem and stummel together which could result in hearing that dreaded snap of a cracked shank.  The remedy is to pinch 240 sanding paper around the tenon and rotate the stem to create the abrasion which gradually reduces the diameter of the tenon to fit the mortise.

The remedy is to pinch 240 sanding paper around the tenon and rotate the stem to create the abrasion which gradually reduces the diameter of the tenon to fit the mortise.  After several rotation sessions and fittings to test the size, the tenon gradually fits – snugly but not too tight. The Jeantet Superior Chimney is coming along very nicely.

After several rotation sessions and fittings to test the size, the tenon gradually fits – snugly but not too tight. The Jeantet Superior Chimney is coming along very nicely. The next step is to refresh the Circle ‘J’ stem stamping with white acrylic paint. It appears that there’s enough ‘tread’ left in the stamping to give the paint traction to be held in the imprint.

The next step is to refresh the Circle ‘J’ stem stamping with white acrylic paint. It appears that there’s enough ‘tread’ left in the stamping to give the paint traction to be held in the imprint. The first step is to place a small drop of white acrylic paint over the stamping. The toothpick then is used to spread the paint over the lettering.

The first step is to place a small drop of white acrylic paint over the stamping. The toothpick then is used to spread the paint over the lettering. I then daub the wet paint with a cotton pad to absorb the excess and to spread the paint evenly over the lettering. This also dries the paint quickly.

I then daub the wet paint with a cotton pad to absorb the excess and to spread the paint evenly over the lettering. This also dries the paint quickly. I use both the flat edge of a toothpick and its point to clean the excess paint away and to sharpen the stamping. I use the side of the toothpick to scrape over the entire stamping removing most of the paint on the stem surface – leaving the paint in the troughs of the stamping. The point of the toothpick allows me to finish the edges of the stamping more closely. I repeat applying paint a couple times with daubing and then the toothpick finishing process until the Jeantet stamping looked good.

I use both the flat edge of a toothpick and its point to clean the excess paint away and to sharpen the stamping. I use the side of the toothpick to scrape over the entire stamping removing most of the paint on the stem surface – leaving the paint in the troughs of the stamping. The point of the toothpick allows me to finish the edges of the stamping more closely. I repeat applying paint a couple times with daubing and then the toothpick finishing process until the Jeantet stamping looked good. Now on the home stretch. After remembering to replace the original nickel stinger after it was cleaned and polished with steel wool, and rejoining the stem and stummel, a cotton cloth buffing wheel is mounted onto the rotary tool to apply Blue Diamond compound to the stem and stummel. The speed is set at about 40% full power as I methodically apply the fine abrasive to the surface of the briar and vulcanite.

Now on the home stretch. After remembering to replace the original nickel stinger after it was cleaned and polished with steel wool, and rejoining the stem and stummel, a cotton cloth buffing wheel is mounted onto the rotary tool to apply Blue Diamond compound to the stem and stummel. The speed is set at about 40% full power as I methodically apply the fine abrasive to the surface of the briar and vulcanite.  After applying the compound, the pipe is wiped/buffed with a felt cloth to remove left over compound dust particles. I don’t want the abrasive particles to mix with the wax that comes next. Another wheel, dedicated to applying carnauba wax is mounted and with the speed remaining the same, wax is applied to the pipe. When this is completed, the pipe enjoys a rigorous hand buffing with a microfiber cloth to remove any excess wax from the surface and to raise the shine.

After applying the compound, the pipe is wiped/buffed with a felt cloth to remove left over compound dust particles. I don’t want the abrasive particles to mix with the wax that comes next. Another wheel, dedicated to applying carnauba wax is mounted and with the speed remaining the same, wax is applied to the pipe. When this is completed, the pipe enjoys a rigorous hand buffing with a microfiber cloth to remove any excess wax from the surface and to raise the shine.  Skeet commissioned this Jeantet Superior Chimney because he saw its potential. The Chimney shape gives a sharp, clean-cut look. This joined with the slightly bent saddle stem gives the pipe a comfortable symmetry. The briar required several repairs to fill pits, but the results were worth the effort! There is no such thing as a perfect piece of briar! The briar block appears to have been cut near the edge of the bole which manifests the beautiful, active briar seen in this stummel. The fire grain seems to hug and wrap around the bowl tightening into a spider web knot on the back side of the bowl. Without question, a striking landscape for a new steward to enjoy! Skeet will have the first opportunity to claim this Jeantet Superior Chimney from The Pipe Steward Store benefitting the Daughters of Bulgaria – helping women and girls who have been trafficked and sexually exploited. Thanks for joining me!

Skeet commissioned this Jeantet Superior Chimney because he saw its potential. The Chimney shape gives a sharp, clean-cut look. This joined with the slightly bent saddle stem gives the pipe a comfortable symmetry. The briar required several repairs to fill pits, but the results were worth the effort! There is no such thing as a perfect piece of briar! The briar block appears to have been cut near the edge of the bole which manifests the beautiful, active briar seen in this stummel. The fire grain seems to hug and wrap around the bowl tightening into a spider web knot on the back side of the bowl. Without question, a striking landscape for a new steward to enjoy! Skeet will have the first opportunity to claim this Jeantet Superior Chimney from The Pipe Steward Store benefitting the Daughters of Bulgaria – helping women and girls who have been trafficked and sexually exploited. Thanks for joining me!

History:

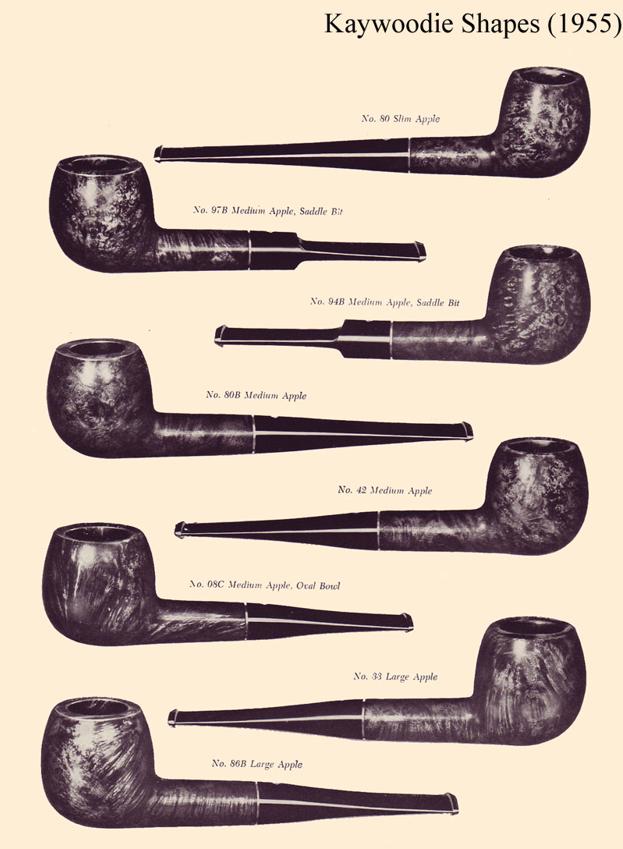

History: Picture from: https://pipedia.org/wiki/Collector%27s_Guide_to_Kaywoodie_Pipes courtesy ChrisKeene.com

Picture from: https://pipedia.org/wiki/Collector%27s_Guide_to_Kaywoodie_Pipes courtesy ChrisKeene.com

The outside was extremely dirty. So, I cleaned the pipe 4 or 5 times with Murphy’s Oil Soap. I really soaked the rim well to try to soften the lava. It took a ton of scrubbing and a little work with a knife, but I was able to get most of it off and remove a lot of the burn marks on the shank. Unfortunately, this revealed a great deal of damage to the rim. There were also multiple fills, and I even had to remove a protruding grain of sand from the briar.

The outside was extremely dirty. So, I cleaned the pipe 4 or 5 times with Murphy’s Oil Soap. I really soaked the rim well to try to soften the lava. It took a ton of scrubbing and a little work with a knife, but I was able to get most of it off and remove a lot of the burn marks on the shank. Unfortunately, this revealed a great deal of damage to the rim. There were also multiple fills, and I even had to remove a protruding grain of sand from the briar.

To repair the damage to the rim, I carefully sanded back the damaged areas on a topping board, careful not to change the shape of the rim.

To repair the damage to the rim, I carefully sanded back the damaged areas on a topping board, careful not to change the shape of the rim.

I put a dab of Vaseline on the logo to protect it, then soaked the stem in an oxyclean bath. This would help loosen up all the gunk inside and make it easier to clean the oxidation off the outside. I also filled the bowl with cotton balls, stuck pipe cleaners in the shank, and then used a syringe to fill the bowl with alcohol to help remove any ghosting in the pipe, as well as loosen up any remaining cake inside the bowl to make it easier to clean.

I put a dab of Vaseline on the logo to protect it, then soaked the stem in an oxyclean bath. This would help loosen up all the gunk inside and make it easier to clean the oxidation off the outside. I also filled the bowl with cotton balls, stuck pipe cleaners in the shank, and then used a syringe to fill the bowl with alcohol to help remove any ghosting in the pipe, as well as loosen up any remaining cake inside the bowl to make it easier to clean.

After I got the stem out of the oxy bath, it revealed a lot of oxidation that would need to be cleaned up. The internals of the stem were also gooped up, but I was able to now force a pipe cleaner through it. I cleaned much of the surface oxidation with a Magic Eraser, then moved on to the internals.

After I got the stem out of the oxy bath, it revealed a lot of oxidation that would need to be cleaned up. The internals of the stem were also gooped up, but I was able to now force a pipe cleaner through it. I cleaned much of the surface oxidation with a Magic Eraser, then moved on to the internals. I sanded the stem with 600, 800, 1000, then moved into micro mesh pads from 1200 – 12000. Once finished, I oiled the stem with Obsidian Stem Oil and let it soak in. I turned my attention back to the bowl and did my best to clean out the inside of the shank and bowl with Q Tips and Pipe Cleaners soaked in alcohol. Then I set it aside for day 1.

I sanded the stem with 600, 800, 1000, then moved into micro mesh pads from 1200 – 12000. Once finished, I oiled the stem with Obsidian Stem Oil and let it soak in. I turned my attention back to the bowl and did my best to clean out the inside of the shank and bowl with Q Tips and Pipe Cleaners soaked in alcohol. Then I set it aside for day 1.

After letting the pipe dry over night, I was able to see more clearly the inside and outside of the pipe. No surprise with how burned the outside of the pipe was that there were also heat fissures inside the bowl. I inspected them carefully and gauged their depth with dental picks. They, luckily, were not too deep.

After letting the pipe dry over night, I was able to see more clearly the inside and outside of the pipe. No surprise with how burned the outside of the pipe was that there were also heat fissures inside the bowl. I inspected them carefully and gauged their depth with dental picks. They, luckily, were not too deep.

I was also now able to see some of the fills, scratches, and sand pits better on the outside of the bowl. I used a wet rag and a hot iron to try to raise them a bit. Then I carefully cleaned them out with my dental picks. At this point, I got a little ahead of myself as I focused on cleaning out the pits. I moved on to filling the pits and scratches with CA glue before fully stripping the finish.

I was also now able to see some of the fills, scratches, and sand pits better on the outside of the bowl. I used a wet rag and a hot iron to try to raise them a bit. Then I carefully cleaned them out with my dental picks. At this point, I got a little ahead of myself as I focused on cleaning out the pits. I moved on to filling the pits and scratches with CA glue before fully stripping the finish.

After the glue cured, I sanded down the glue spots. Then I wiped the entire stummel down with high-proof alcohol followed by acetone to really remove the finish.

After the glue cured, I sanded down the glue spots. Then I wiped the entire stummel down with high-proof alcohol followed by acetone to really remove the finish.

Since I did my steps slightly out of order, the CA glue had softened in a couple of the fills. So, I picked it out and refilled it. I let the glue cure and then sanded the entire stummel. I had to be very careful over the stamping to preserve it.

Since I did my steps slightly out of order, the CA glue had softened in a couple of the fills. So, I picked it out and refilled it. I let the glue cure and then sanded the entire stummel. I had to be very careful over the stamping to preserve it.

With the finish removed and the stummel sanded, I placed a wine cork in the bowl and coated it with dye.

With the finish removed and the stummel sanded, I placed a wine cork in the bowl and coated it with dye. It’s hard to tell in the pictures, but the dye came out a little too dark, more similar to a Flame Grain. To keep it authentic with a Super Grain, I needed to lighten it back up a bit. I lightly sanded it with my sequence of micromesh pads which also brought the shine back.

It’s hard to tell in the pictures, but the dye came out a little too dark, more similar to a Flame Grain. To keep it authentic with a Super Grain, I needed to lighten it back up a bit. I lightly sanded it with my sequence of micromesh pads which also brought the shine back.

After the stummel was sanded, the color was nearly perfect. I then buffed it using Tripoli, followed by White Diamond, and finally Carnauba.

After the stummel was sanded, the color was nearly perfect. I then buffed it using Tripoli, followed by White Diamond, and finally Carnauba.

Now that the outside was finished, I moved on to the inside. After really inspecting the fissures, some of them were deeper than I would like. If it was my pipe, I would have done a bowl coating and just kept an eye on them to address later, but since this pipe was for someone else, I wanted to address it now. This way they won’t have to deal with it down the road. I mixed up some JB Weld, which dries inert and can handle the heat. I carefully stuck it only into the fissures, using as little as possible so as not to coat the briar, since JB Weld won’t breathe like briar.

Now that the outside was finished, I moved on to the inside. After really inspecting the fissures, some of them were deeper than I would like. If it was my pipe, I would have done a bowl coating and just kept an eye on them to address later, but since this pipe was for someone else, I wanted to address it now. This way they won’t have to deal with it down the road. I mixed up some JB Weld, which dries inert and can handle the heat. I carefully stuck it only into the fissures, using as little as possible so as not to coat the briar, since JB Weld won’t breathe like briar. After it cured, I sanded down the JB Weld to make the bowl smooth and flush, as well as to remove any that was not inside the fissures.

After it cured, I sanded down the JB Weld to make the bowl smooth and flush, as well as to remove any that was not inside the fissures. Then I coated the bowl with activated charcoal in a great method I learned from Dad’s Pipes. (https://dadspipes.com/2015/08/12/a-simple-effective-bowl-coating/)

Then I coated the bowl with activated charcoal in a great method I learned from Dad’s Pipes. (https://dadspipes.com/2015/08/12/a-simple-effective-bowl-coating/) After cleaning the charcoal off the rim, I noticed it had dulled a little bit. So, I threw the buffing wheel back on and gave it another coat of Carnauba. The pipe was now complete! I hope it will bring its new owner joy for many years!

After cleaning the charcoal off the rim, I noticed it had dulled a little bit. So, I threw the buffing wheel back on and gave it another coat of Carnauba. The pipe was now complete! I hope it will bring its new owner joy for many years!