Blog by Steve Laug

Early in August I received an email from an interesting woman on Vancouver Island regarding some pipes that she had for sale. She was looking to sell the pipes from her late husband Ken and one from her Great Grandfather. Here is her email:

I have 5 John Calich pipes that date from 1979 to 1981. One is graded 11 and the other four are graded 12. I had bought them as Christmas and birthday gifts for my late husband. He was a very light smoker for a 3 year period.

I am a wood sculptor and always admired the grain and shapes of John’s best pipes. John was a friend as well. We exhibited at many exhibitions together for over 25 years.

I am wondering if you can provide any information on how I might be able to sell them.

Thanks you for any help you might be able to provide

I wrote her back and told I was very interested in the pipes that she had for sale and asked her to send me some photos of the lot. She quickly did just that and we struck a deal. I paid her through an e-transfer and the pipes were on their way to me. They arrived quite quickly and when they did I opened the box and found she had added three more pipes – a Brigham, a Dr. Plumb and a WDC Milano. There was also a wooden cigar box in the package that housed the Calich pipes. They are all lovely looking freehand style shapes – even the two apple shaped pipes had a freehand twist to them. The package also had the BBB Gourd Calabash that I have written about earlier (https://rebornpipes.com/2019/08/27/breathing-new-life-into-a-bbb-gourd-calabash-with-an-amber-stem/). I wrote to Pat and asked her if she would be willing to write short remembrance of her late husband and her Great Grandfather. She wrote that she would be happy to write about them both. In her email she included a story about John Calich that I really enjoyed. I decided it was well worth including in this first blog about these Calich pipes.

I wrote to Pat and asked her if she would be willing to write short remembrance of her late husband and her Great Grandfather. She wrote that she would be happy to write about them both. In her email she included a story about John Calich that I really enjoyed. I decided it was well worth including in this first blog about these Calich pipes.

My best John story is one you won’t likely be able to print. We were set up beside each other in the late seventies at the Ottawa Tulip Festival in army tents. It was cold and wet. John always had a jar of good tobacco that he shared with past and prospective customers. One morning a guy that looked like he was dirt poor started chatting with John. He pulled out his cheap pipe and stuffed it too full of the expensive tobacco and then asked John for a light. As he walked away John muttered under his breath to me “I’d like to give him a kick in his pants to get him puffing”

I had to laugh because in conversations I had with John we had some great laughs. He was a real character and this was truly a fitting reminder for me as I was preparing to work on the pipes.

I wrote to Pat again and told her I was thinking of restoring her husband, Ken’s pipes next. She is working on a piece for me but sent along a great story and a photo in case I “need some inspiration while you work”. I have also included that photo and the story below. It indeed was an inspiration and gave me an idea on what pipe to work on first. Here are Pat’s words:

I’d like you know that Ken was an incredibly talented and creative man with a smile and blue eyes that could light up a room. His laugh was pure magic. He could think outside the box and come up with an elegant solution to any problem.

I’d like you know that Ken was an incredibly talented and creative man with a smile and blue eyes that could light up a room. His laugh was pure magic. He could think outside the box and come up with an elegant solution to any problem.

I remember the day he had to “fess up” about burning a hole through the pocket in his new sports jacket that was bought for an upcoming gallery opening of our work…….of course the “real culprit” was that damn small John Calich pipe that he favoured above all others, because it felt so good in the palm of his hand and tucked neatly into a pocket.

Once again I had to laugh because I have also burned a hole in a pocket and more than few shirts from sparks from a lit pipe. I went through Ken’s pipes and found the pipe I think that she was referring to in the above story. I sent her a picture of the pipe and she confirmed that it was indeed the one she was talking about. Now I knew which one I was going to work on first. I brought the nice little bent apple pipe to my work table and took some photos before I started the clean up on the pipe.

Pat sent me this reflection on her husband Ken’s life. Thanks Pat for taking time to do this. I find that it gives another dimension to the pipes that I restore to know a bit about the previous pipeman. Pat and Ken were artists (Pat still is a Sculptural Weaver) and it was this that connected them to each other and to John Calich. Here are Pat’s words.

Here is the write up for Ken. We meet in University and it was love at first sight. I consider myself blessed to have shared a life together for 37 years.

Ken graduated from Ryerson University with Bachelor of Applied Arts in Design in 1975.

Ken lived his life with joy. Each day was a leap of faith in the creative process. His smile would light up the room and the hearts of the people he loved.

He combined the skilled hands of a master craftsman, with the problem solving mind of an engineer, and the heart and soul of an artist. He used his talents to create unique and innovative wood sculptures. Using precious hardwoods, he incorporated the techniques of multiple lamination and three dimensional contouring to create sculptural pieces that captivate the eye and entice the hand to explore.

His career was highlighted by numerous corporate commissions, awards and public recognition in Canada and abroad.

A quote from Frank Lloyd Wright sums up Ken’s approach to design. “Form follows function – that has been misunderstood. Form and function should be joined as one in a spiritual union.”

A friendship with John Calich developed over years of exhibiting their work at exhibitions. How could a wood sculptor resist some of John’s finest creations…

Pat had included the top of a box that Ken had kept from the pipes he had purchase from John. I used the box top as a back drop for the photos of the pipe. The pipe had a very interesting shape. It is an apple with beautiful grain and a dull finish due to sitting unused in storage. The bottom of the bowl was plateau that had been sanded down to knock off the high points. It appeared that the finish was oil cured and unstained – I like that about John’s pipes as with age and use they take on colour. The bowl had a cake in it and there was slight lava overflow on the rim top. There were some small nicks in the rim top and inner edge of the bowl on the right front side. The stamping on the left side of the shank read CALICH over Hand Made. Below the stamping was the number 12 which was the grade number. The stem was lightly oxidized as was the single metal dot in the top of the saddle. There was light tooth chatter on both sides of the stem on both sides near the button. The shank and stem were dirty inside.

I took a photo of the bowl and rim top to show the cake in the bowl and the lava build up on the edges of the bowl. It was thick and hard but hopefully it had protected the rim and edges from damage. There appears to be a little damage on the right front inner and rim top of the bowl. There was some darkening on the back edge and top of the rim top. Otherwise it looks pretty good. I also took photos of the stem to show the oxidation on both sides and the light tooth chatter on both sides near the button.

I took a photo of the bowl and rim top to show the cake in the bowl and the lava build up on the edges of the bowl. It was thick and hard but hopefully it had protected the rim and edges from damage. There appears to be a little damage on the right front inner and rim top of the bowl. There was some darkening on the back edge and top of the rim top. Otherwise it looks pretty good. I also took photos of the stem to show the oxidation on both sides and the light tooth chatter on both sides near the button.  I took a photo of the left side of the shank to show the condition of the stamping. You can see the faint Calich stamp over Hand Made. Below that is the number 12.

I took a photo of the left side of the shank to show the condition of the stamping. You can see the faint Calich stamp over Hand Made. Below that is the number 12. I decided to include a bit about John Calich the pipemaker as I have loved John Calich’s pipes for over 25 years now and have collected a few of them. I have restored quite a few of them and written blogs about them that can be read if you are interested in seeing the kind of pipes that John made. They are unique and beautiful. Each one of them is a work of art to me. I am including the links to the previous blogs that have written about his pipes.

I decided to include a bit about John Calich the pipemaker as I have loved John Calich’s pipes for over 25 years now and have collected a few of them. I have restored quite a few of them and written blogs about them that can be read if you are interested in seeing the kind of pipes that John made. They are unique and beautiful. Each one of them is a work of art to me. I am including the links to the previous blogs that have written about his pipes.

https://rebornpipes.com/2015/03/03/one-of-my-john-calich-pipes-a-calich-ee-billiard/

https://rebornpipes.com/2019/01/23/i-am-the-happy-owner-of-an-unsmoked-pipe-by-the-late-john-calich/

https://rebornpipes.com/2015/03/03/one-of-my-john-calich-pipes-a-calich-ee-billiard/

https://rebornpipes.com/2014/03/21/reflecting-on-my-collection-of-john-calich-pipes/

Each of the blogs reflect on John’s pipes if you want to get a feel for them take a few minutes and read them.

When John was living I spoke with him several times via phone and had him make some new stems for some of his pipes that I picked up off eBay. He was a very kind gentleman and was always helpful when I spoke with him. He was always ready with encouragement and when I needed to know how to do something when I was first learning to repair pipes he was willing to help. He was one of the old guard of Canadian Pipe makers. I miss him. I am including a short piece from Pipedia on John to give details on his work and the grading of his pipes. The second paragraph below is highlighted in blue as it gives some information on the Grade 12 Apple that I am working on with the single silver dot now.

John Calich was one of Canada’s finest carvers. He died in July 2008. John was a full time pipe maker for the last 40 years. Calich pipes were mostly traditional shapes. His signature style is rustication and smooth on the same pipe along with his unique skill to stain a pipe in contrasting colors. He used only top quality Grecian and Calabrian briar. The mouthpieces are hand finished Vulcanite “A”. Each pipe was entirely made by hand. John Calich was featured in the summer 2005 issue of Pipes & Tobacco.

His pipes are graded 3E – 7E. Retail prices range from$ 145.00 to $ 500.00 Each pipe is stamped “CALICH” 3-8E, his earlier pipes were graded from 3-14, and a single, tiny silver dot is applied to the top of the stem (https://pipedia.org/wiki/Calich).

I summarize the dating information from those blogs now: From my research and conversations I learned that John’s his later pipes were graded 3E – 8E. The retail prices for them ranged from $145.00 to $500.00. Each pipe was stamped “CALICH” and given an E grade. His earlier pipes were graded from 3-14 and had a single, tiny silver dot applied to the top of the stem. More information can be found at the Pipedia article above. All of this information told me as expected that the pipe I had was an earlier one.

Armed with Pat’s story of the pipe and Ken’s coat and information about John’s grading system it was time to work on the pipe. I reamed the bowl with a PipNet Pipe reamer using the third cutting head. I took the cake back to bare briar so that I could check out the inside walls. I used a Savinelli Fitsall Pipe Knife to scrape back the remaining cake. I finished my cleanup of the walls by sanding it with 220 grit sandpaper wrapped around a piece of dowel.

There was some darkening and damage on the inner edge of the rim that needed to be addressed. I sanded it with a folded piece of 220 grit sandpaper to remove and minimize the damage to the edge. I continued by starting to polish it with 400 grit wet dry sandpaper. I wiped the rim edge down with a damp cloth to remove the sanding dust on the briar. The finished rim top looked much better than when I started. I was able to minimize the damage on the front inner edge of the rim. It is still damaged but it looks considerably better. I took a photo of the sanded rim top and also the inside of the bowl. The rim looks very good but there is also a large flaw/split in the right side of the bowl.

There was some darkening and damage on the inner edge of the rim that needed to be addressed. I sanded it with a folded piece of 220 grit sandpaper to remove and minimize the damage to the edge. I continued by starting to polish it with 400 grit wet dry sandpaper. I wiped the rim edge down with a damp cloth to remove the sanding dust on the briar. The finished rim top looked much better than when I started. I was able to minimize the damage on the front inner edge of the rim. It is still damaged but it looks considerably better. I took a photo of the sanded rim top and also the inside of the bowl. The rim looks very good but there is also a large flaw/split in the right side of the bowl.  I decided to repair that flaw with some JB Weld (steel weld that dries hard and impervious and is heat resistant). I mixed the two parts on an old envelope with a tooth pick and press it into the flaw on the wall of the bowl. I used a dental spatula to spread out the mix across the surface around the flaw. Once it had cured I would need to sanded it smooth and minimize the footprint on the wall of the bowl.

I decided to repair that flaw with some JB Weld (steel weld that dries hard and impervious and is heat resistant). I mixed the two parts on an old envelope with a tooth pick and press it into the flaw on the wall of the bowl. I used a dental spatula to spread out the mix across the surface around the flaw. Once it had cured I would need to sanded it smooth and minimize the footprint on the wall of the bowl.  I scrubbed the briar with Before & After Briar Cleaner and rinsed it off with warm running water. I dried the bowl off with a soft microfiber cloth and gave it a light buffing. The photos show the cleaned briar and the grain is really beginning to pop. John really followed the grain on the shaping of this pipe.

I scrubbed the briar with Before & After Briar Cleaner and rinsed it off with warm running water. I dried the bowl off with a soft microfiber cloth and gave it a light buffing. The photos show the cleaned briar and the grain is really beginning to pop. John really followed the grain on the shaping of this pipe.

I polished the bowl with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped the bowl down after each sanding pad with a damp cloth.

I polished the bowl with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped the bowl down after each sanding pad with a damp cloth.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

I rubbed the bowl down with Before & After Restoration Balm. I worked it into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed with a cotton cloth to raise the shine. Mark Hoover’s Balm is a product that I have come to appreciate and one I use on every pipe I have been working on.

With the externals cleaned I worked on the internals. I scraped the inside of the mortise with a dental spatula to remove the hardened tars and oils that lined the walls of the shank. Once I had that done I cleaned out the airway to the bowl, the mortise and the airway in the stem with pipe cleaners, cotton swabs and alcohol. When I finished the pipe smelled very clean.

With the externals cleaned I worked on the internals. I scraped the inside of the mortise with a dental spatula to remove the hardened tars and oils that lined the walls of the shank. Once I had that done I cleaned out the airway to the bowl, the mortise and the airway in the stem with pipe cleaners, cotton swabs and alcohol. When I finished the pipe smelled very clean.

I called it a night and set the repaired bowl aside to cure. I turned the lights out and went upstairs. In the morning I sanded the repaired bowl wall with 220 grit sandpaper to remove the excess repair. I wanted to leave only the repair in the crevice in the wall and not on the rest of the wall.

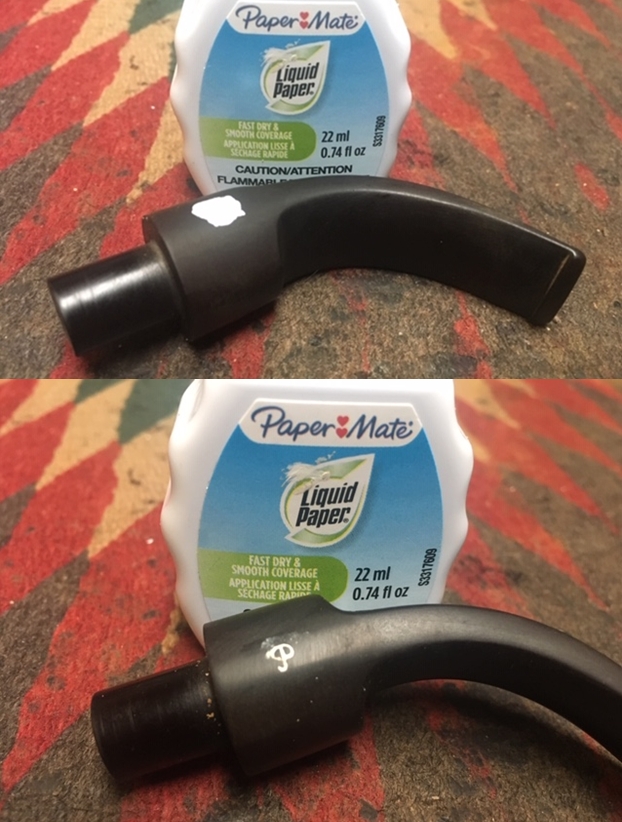

I called it a night and set the repaired bowl aside to cure. I turned the lights out and went upstairs. In the morning I sanded the repaired bowl wall with 220 grit sandpaper to remove the excess repair. I wanted to leave only the repair in the crevice in the wall and not on the rest of the wall. I set the bowl aside and turned my attention to the stem. I sanded the stem with 220 grit sandpaper to break up the oxidation. I started the polishing with 400 grit wet dry sandpaper to remove the scratching. It is starting to look good.

I set the bowl aside and turned my attention to the stem. I sanded the stem with 220 grit sandpaper to break up the oxidation. I started the polishing with 400 grit wet dry sandpaper to remove the scratching. It is starting to look good.  I have one more tin of Denicare Mouthpiece Polish left from a few that I have picked up over the years. It is a coarse red pasted that serves to help remove oxidation. I polished the stem with that to further smooth out the surface of the vulcanite (and to be honest – to use it up).

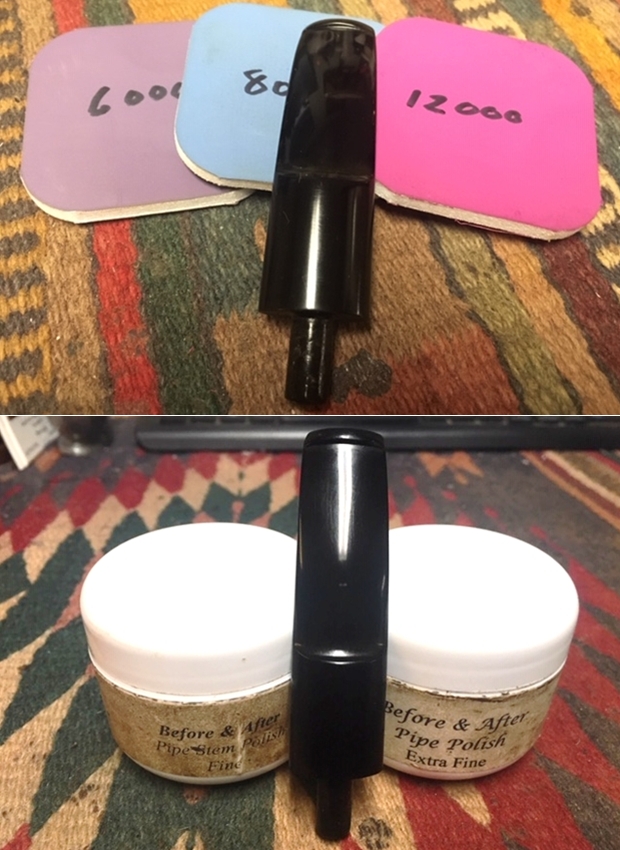

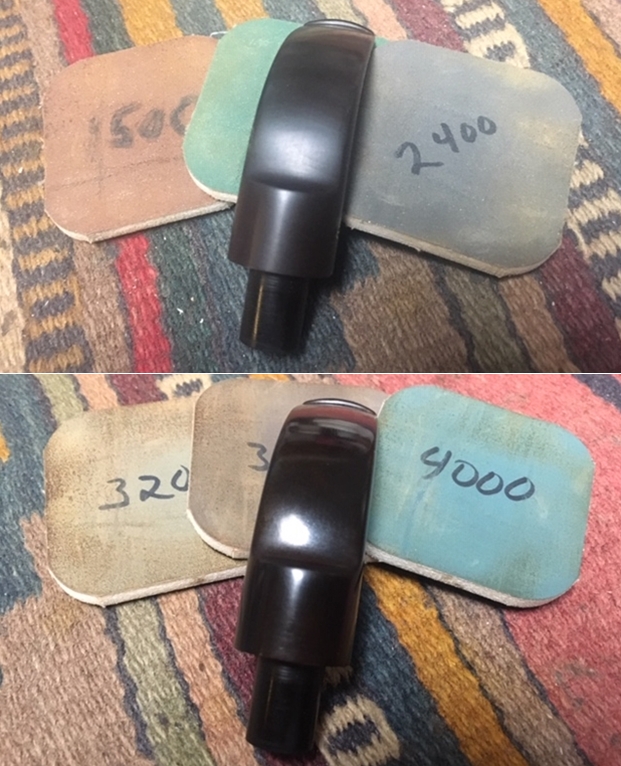

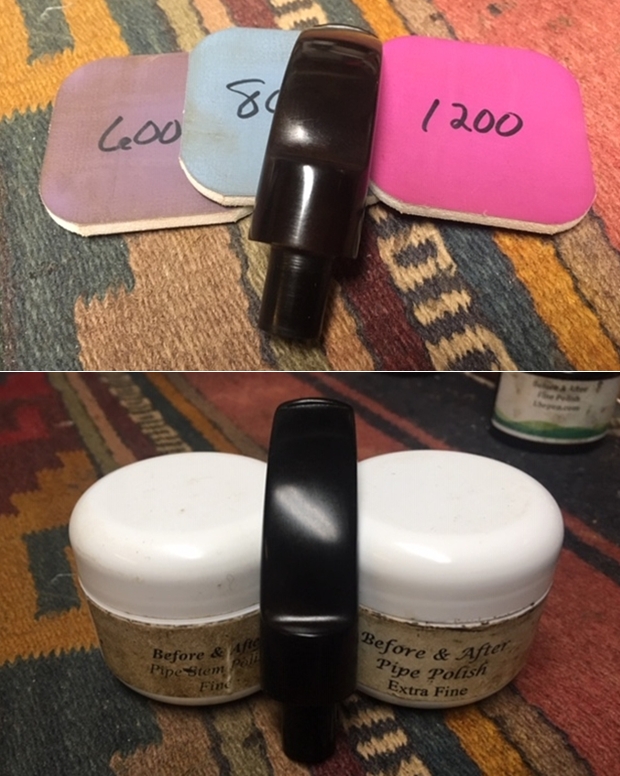

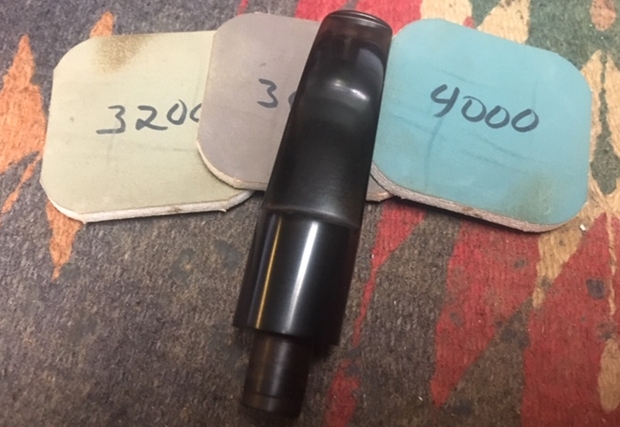

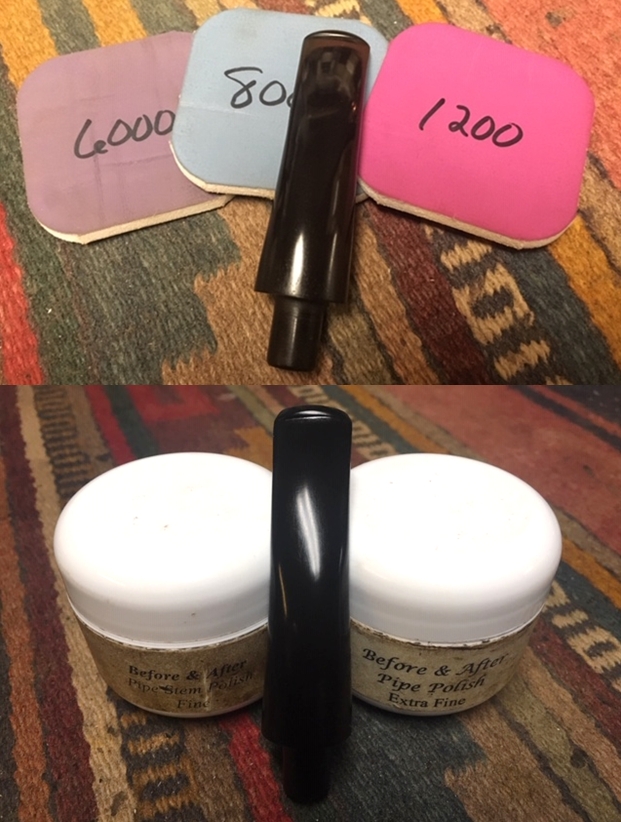

I have one more tin of Denicare Mouthpiece Polish left from a few that I have picked up over the years. It is a coarse red pasted that serves to help remove oxidation. I polished the stem with that to further smooth out the surface of the vulcanite (and to be honest – to use it up).  I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of oil and set it aside to dry.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped the stem down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. Once I had finished the polishing I gave it final coat of oil and set it aside to dry.

This is the first Calich from Ken’s Estate that I am working on. It is a beautifully grained apple shaped Hand Made. It has the kind of beauty I have come to expect from John’s pipes with the carved groove on the right side of the bowl and the plateau on the underside of the bowl. I am excited to be on the homestretch with this beauty from Ken’s pipes. This is the part I look forward to when it all comes back together, polished and waxed. I put the bowl and stem back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. There is straight and flame grain around the sides of the bowl is quite stunning. There is birdseye on the top and underside of the shank and on the rim top. The polished smooth finish look really good with the black vulcanite. This Calich Hand Made was fun to bring back to life because of the story that Pat shared with us. The connection between Ken and Pat and John Calich adds colour. The natural finish really makes the pipe look attractive. It is another comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 inch, Chamber diameter: 7/8 of an inch. Thanks for reading this blog and my reflections on the pipe while I worked on it. This is an interesting estate to bring back to life.

This is the first Calich from Ken’s Estate that I am working on. It is a beautifully grained apple shaped Hand Made. It has the kind of beauty I have come to expect from John’s pipes with the carved groove on the right side of the bowl and the plateau on the underside of the bowl. I am excited to be on the homestretch with this beauty from Ken’s pipes. This is the part I look forward to when it all comes back together, polished and waxed. I put the bowl and stem back together. I polished the bowl and stem with Blue Diamond to polish out the scratches in the briar and the vulcanite. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. There is straight and flame grain around the sides of the bowl is quite stunning. There is birdseye on the top and underside of the shank and on the rim top. The polished smooth finish look really good with the black vulcanite. This Calich Hand Made was fun to bring back to life because of the story that Pat shared with us. The connection between Ken and Pat and John Calich adds colour. The natural finish really makes the pipe look attractive. It is another comfortable pipe to hold in the hand. The finished pipe is shown in the photos below. The dimensions of the pipe are Length: 5 ½ inches, Height: 1 ½ inches, Outside diameter of the bowl: 1 inch, Chamber diameter: 7/8 of an inch. Thanks for reading this blog and my reflections on the pipe while I worked on it. This is an interesting estate to bring back to life.