Blog by Steve Laug

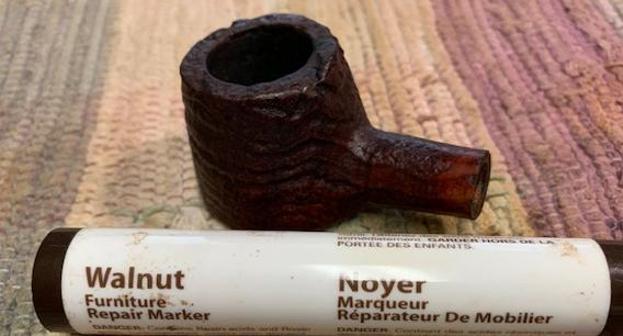

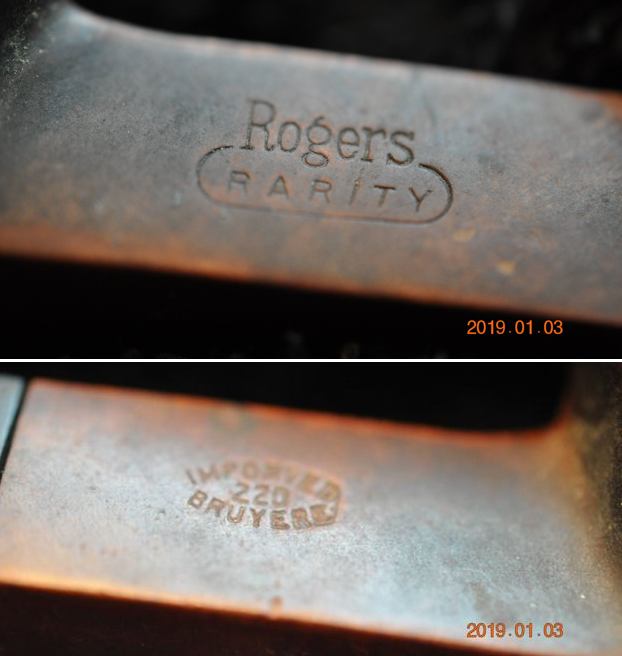

The next pipe is a really neat looking chubby Bulldog with a vulcanite saddle stem. The thick shank and stubby looking pipe was made to hold in your hand. It is quite light weight for its size and the blade on the stem is thin and looks comfortable. We picked up this pipe from an auction back 2018 in Beaumont, California, USA. He cleaned the pipe in 2019 and now I am working on it in 2021. It is stamped on the top left side of the shank and reads Rogers [over] Rarity in an oval. On the top right side it is stamped Imported [arched over] 220 [over] Bruyere. The title of the blog is a play on the term rarity as this particular pipe came to us extremely well done – tired and worn. The exterior of the bowl had a thick coat of dark heavy grime ground into the finish. It was oily and dark looking. The single ring around the cap on the bowl was filled in with grime. There was a heavy cake in the bowl and an eruption of thick lava on the rim top. It was hard to know the condition of the rim top and rim edges because of the grime and thickness of the cake and lava. The cleaning would make it very clear! The stem was dirty and lightly oxidized with light tooth marks and chatter on both sides but nothing like what I was expecting from the condition of the bowl. Jeff took photos of the pipe to give a clear picture of what we were up against with this pipe.

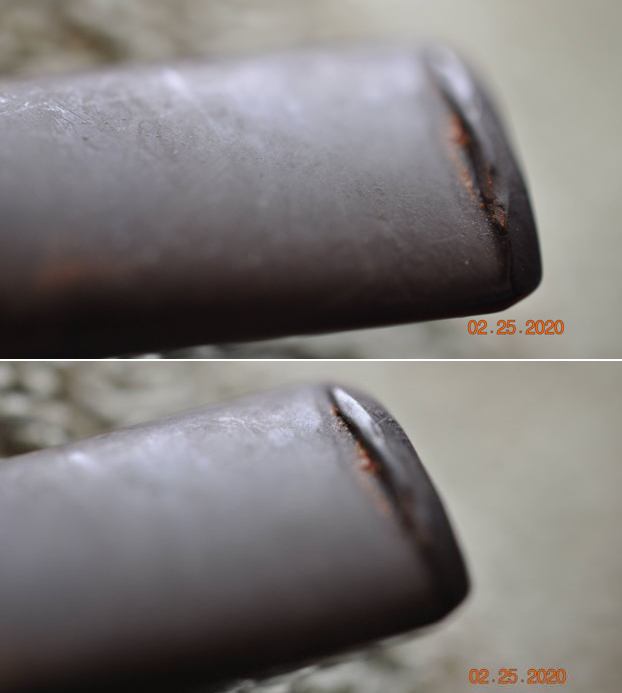

He captured the cake in the bowl and the thick eruption of lava on the rim top and edges exceptionally well in the next photos. It was very clear that the pipe had not been seriously cleaned since the first smoke. But it is also very clear that it was an exceptional smoker! The stem is oxidized, calcified and shows the took marks on the button surface and chatter on both sides ahead of the button.

He captured the cake in the bowl and the thick eruption of lava on the rim top and edges exceptionally well in the next photos. It was very clear that the pipe had not been seriously cleaned since the first smoke. But it is also very clear that it was an exceptional smoker! The stem is oxidized, calcified and shows the took marks on the button surface and chatter on both sides ahead of the button.

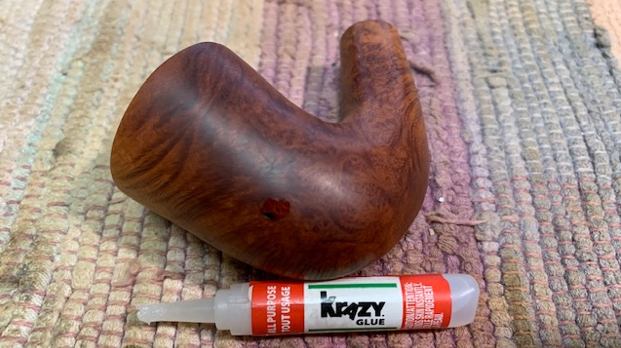

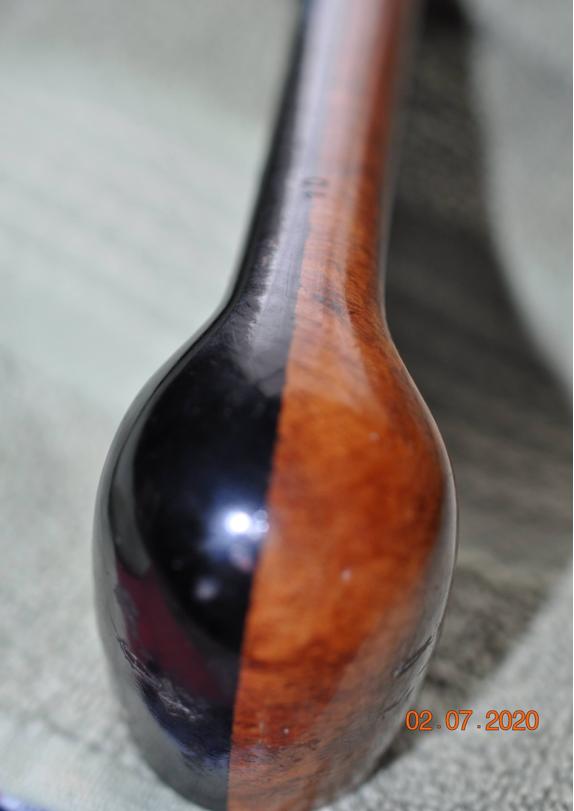

Jeff somehow captured some of the beauty of the shape and the grain in the next photos. You can certainly see what lies beneath the grime and even paint on the briar.

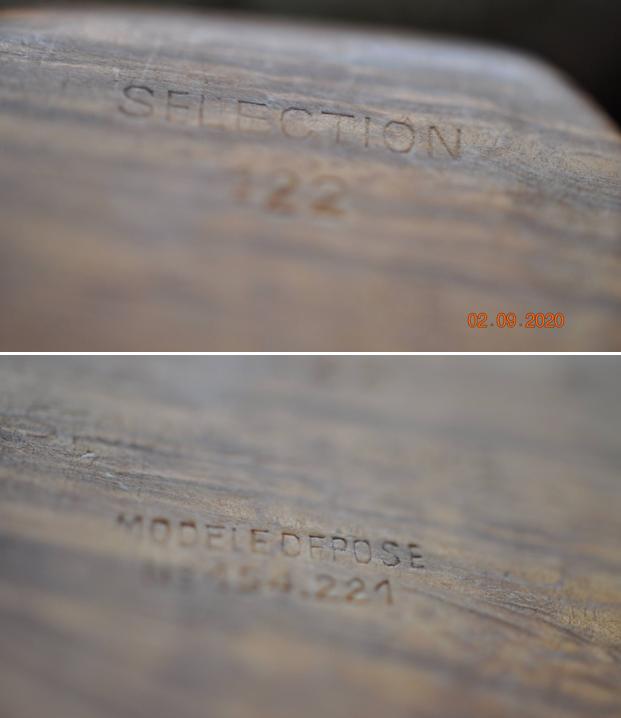

Jeff somehow captured some of the beauty of the shape and the grain in the next photos. You can certainly see what lies beneath the grime and even paint on the briar. He took photos of the stamping on the top left and right of the shank. It is clear and readable as noted above.

He took photos of the stamping on the top left and right of the shank. It is clear and readable as noted above. From reading Bill Unger’s book on Custom-Bilt Pipes I remember “Rogers Rarity” was made by the same company as one of it non-sculptured or rusticated pipes. I did a Google search to see if I could confirm that online. I found a pipe labeled Rogers Rarity for sale on Worthpoint, an online sales site (https://www.worthpoint.com/worthopedia/rogers-rarity-custombilt-large-briar-1821532853). In the description they made the link to Custombilt. I quote:

From reading Bill Unger’s book on Custom-Bilt Pipes I remember “Rogers Rarity” was made by the same company as one of it non-sculptured or rusticated pipes. I did a Google search to see if I could confirm that online. I found a pipe labeled Rogers Rarity for sale on Worthpoint, an online sales site (https://www.worthpoint.com/worthopedia/rogers-rarity-custombilt-large-briar-1821532853). In the description they made the link to Custombilt. I quote:

Rogers Rarity briar pipes were made by Custombilt, and show all the beauty and originality of the brand.

I searched further and found a conversation asking about the brand on Pipesmagazine online forum. There was a great conversation about the brand.

(https://pipesmagazine.com/forums/threads/help-with-dating-a-pipe.62314/). I found a particular response by Jon Guss of the Seattle Pipe Club particularly helpful. I quote from Jon in full.

First, “Rodgers” is a misspelling; it was always spelled “Rogers”. Three generations of the Rogers family ran one of the leading importers of pipes (including Petersons for a number of years) and resellers of pipes and smokers articles; they also did a bit of manufacturing. The name of the company was Rogers Imports, Inc.

Second, for several reasons I also believe that Rogers Rarity pipes were made for Rogers Imports by CustomBilt.

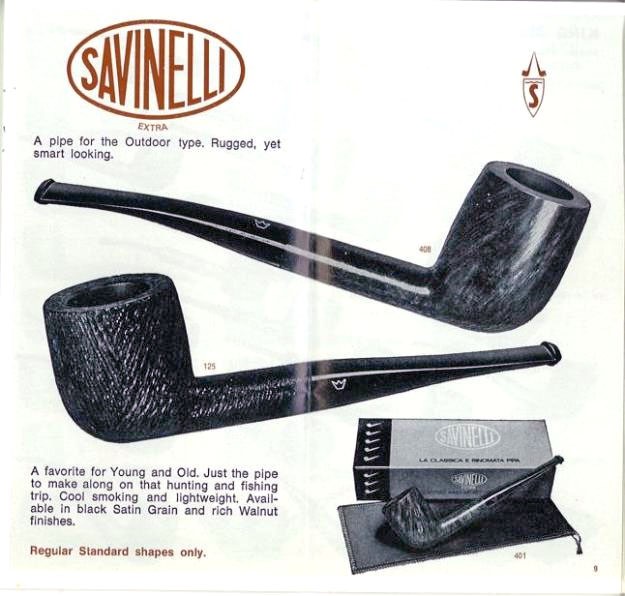

The Rogers Rarity line was introduced by the company in late 1945. The advertising copy from the spring of 1946 described Rogers Rarity pipes as “The height of pipe luxury and enjoyment”, and claimed that they were “Carved by hand of Algerian bruyere over 150 years old”. Was it true? I would guess not, but age fabrication regarding the briar from which pipes were made was a kind of industry trope for generations. While most of the Rarity pipes apparently sold for $5, the listed price range stated various models cost from $5-25. The $5 pipes were available in natural and grain finishes; there was also a $10 version called the Rogers Rarity Deluxe that was sterling banded and meerschaum lined.

I can’t be sure when the line ceased production, but believe it was by the end of 1949. Certainly Rogers Rarity pipes are no longer listed in the RTDA Almanac from 1950 on, and mentions of the pipe in advertisements to consumers become thin on the ground. More tellingly newspaper ads from 1951 show the pipe heavily discounted, suggesting that excess inventory of an obsolete line was being flushed through the channel…

Now I knew that my memory was correct. The pipe was made by CustomBilt for Rogers Imports. I also knew that it was made between 1945-1949 when the line was no longer made. It was a bit of an old timer… Now it was time to work on the pipe.

I was amazed at how clean and new the pipe looked when I took it out of the box. It is really a beautiful piece. Jeff had done a great cleanup on the pipe. He reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the bowl exterior with a tooth brush and Murphy’s Oil Soap to remove the grime on the finish of the bowl and the lava from the rim top. He rinsed it under running water. One of the benefits of this scrub is that it also tends to lift some of the scratches and nicks in the surface of the briar. He dried it off with a soft cloth. He cleaned the internals and externals of the stem with alcohol, pipe cleaners and cotton swabs. He soaked the stem in Briarville’s Pipe Stem Deoxidizer and rinsed it off with warm water and cleaned out the airway in the stem with alcohol. I took photos of the pipe as I saw it when I put it on the table.

I took photos of the rim top and stem to show the condition. The rim top looked pretty good but the inner edge of the bowl showed some damage and was out of round. There was also some burn damage to the outer edge of the bowl on the front. The stem was vulcanite and there were light tooth marks on the button and some light marks and chatter on both sides ahead of the button.

I took photos of the rim top and stem to show the condition. The rim top looked pretty good but the inner edge of the bowl showed some damage and was out of round. There was also some burn damage to the outer edge of the bowl on the front. The stem was vulcanite and there were light tooth marks on the button and some light marks and chatter on both sides ahead of the button.  The stamping on the top left and right sides of the diamond shaped shank are clear and readable. It reads as noted above.

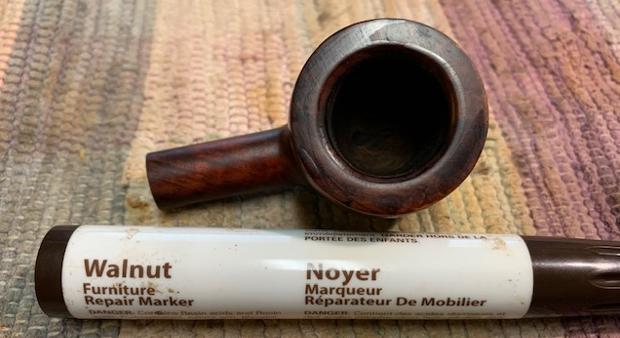

The stamping on the top left and right sides of the diamond shaped shank are clear and readable. It reads as noted above. I started my work on this pipe by dealing with the damage to the inner edge of the bowl. I used a folded piece of 220 grit sandpaper to smooth out the inner edge and give it form once again. The cleaned up rim edge looked very good. I sanded the darkening/burn damage on the front outer edge of the bowl with 220 grit sandpaper as well. I finished the cleanup of the rim top by gently topping it on a topping board to smooth out the damage and minimize it on the edges. The result was actually quite good.

I started my work on this pipe by dealing with the damage to the inner edge of the bowl. I used a folded piece of 220 grit sandpaper to smooth out the inner edge and give it form once again. The cleaned up rim edge looked very good. I sanded the darkening/burn damage on the front outer edge of the bowl with 220 grit sandpaper as well. I finished the cleanup of the rim top by gently topping it on a topping board to smooth out the damage and minimize it on the edges. The result was actually quite good.

I polished the briar with 1200-1500 micromesh sanding pads and wiping it down with damp cloth after each sanding pad. As I worked through the cycle of pads the shine developed with each change of pad. The pipe looks very good.

I polished the briar with 1200-1500 micromesh sanding pads and wiping it down with damp cloth after each sanding pad. As I worked through the cycle of pads the shine developed with each change of pad. The pipe looks very good.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for 10 minutes, then buffed with a cotton cloth to raise the shine. The Balm did its magic and the grain stood out on the briar.

I rubbed the bowl and shank down with Before & After Restoration Balm. I worked it into the surface of the bowl sides and shank with my fingertips to clean, enliven and protect the briar. I let the balm sit for 10 minutes, then buffed with a cotton cloth to raise the shine. The Balm did its magic and the grain stood out on the briar.

I polished it with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad.

I polished it with micromesh sanding pads – 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad.

This Chubby 1945-49 Rogers Rarity 220 Straight Bulldog with a vulcanite saddle stem is a well grained pipe with a flowing shape that looks great . The rich browns of the darkened natural finish makes the grain come alive with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Rogers Rarity Bulldog really is a beauty and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 2 inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.52oz./43grams. This old timer will soon be on the American Pipe Makers section of the rebornpipes store if you would like to add it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!

This Chubby 1945-49 Rogers Rarity 220 Straight Bulldog with a vulcanite saddle stem is a well grained pipe with a flowing shape that looks great . The rich browns of the darkened natural finish makes the grain come alive with the polishing and waxing. I put the stem back on the bowl and carefully buffed the pipe with Blue Diamond on the buffing wheel using a light touch on the briar. I gave the bowl and the stem multiple coats of carnauba wax on the buffing wheel and followed that by buffing the entire pipe with a clean buffing pad. I hand buffed the pipe with a microfiber cloth to deepen the shine. The finished Rogers Rarity Bulldog really is a beauty and fits nicely in the hand and looks very good. Give the finished pipe a look in the photos below. The dimensions of the pipe are Length: 5 inches, Height: 2 inches, Outside diameter of the bowl: 1 1/8 inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 1.52oz./43grams. This old timer will soon be on the American Pipe Makers section of the rebornpipes store if you would like to add it to your collection. Thanks for reading this blog and my reflections on the pipe while I worked on it. There are many more to come!