Blog by Steve Laug

The next pipe on the work table was purchased from an antique mall on 09/09/17 in Salt Lake City, Utah, USA and has been sitting here for five years waiting for me to work on it. It is a nice smooth Bent Dublin with a variegated brown/gold/tan acrylic stem. It is stamped Prince of Wales over Hand Made on the left side of the shank and Italy on the underside near the stem shank junction. The finish was quite dirty and the rim top had a thick overflow of lava on the inner edge on the top. The bowl was thickly caked and there were some nicks on the outer edge. The stem was an acrylic saddle shape that was quite nice. It was dirty and had some tooth marks and chatter on both sides near the button. There was no logo stamped on the stem. Jeff took some photos of the pipe to show the general condition of the pipe before he started his clean up.

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. You can see the cake in the bowl and the thickness of the lava coat on the top and inner edge. He captured the tooth damage on both sides of the stem in the photos.

He took some photos of the rim top and bowl from various angles to give me a clear picture of the condition of the rim top and bowl. You can see the cake in the bowl and the thickness of the lava coat on the top and inner edge. He captured the tooth damage on both sides of the stem in the photos.

Jeff took some photos of the sides and heel of the bowl to show the condition of the finish on the pipe. Under the oils and grime it was a nice looking bowl. I think it will be a beauty once it is restored.

Jeff took some photos of the sides and heel of the bowl to show the condition of the finish on the pipe. Under the oils and grime it was a nice looking bowl. I think it will be a beauty once it is restored.

He took a photo of the stamping on the side of the shank. It is stamped on the left side of the shank and reads as noted above. It is clear and readable. He did not capture the Italy stamp on the underside of the shank but it is faint and readable.

He took a photo of the stamping on the side of the shank. It is stamped on the left side of the shank and reads as noted above. It is clear and readable. He did not capture the Italy stamp on the underside of the shank but it is faint and readable. Before I started my part of the restoration I wanted to have a clear picture of the background and what the stamping looked like on the Prince of Wales pipe. I turned to Pipephil as he often has photos that give me the information that I am looking for (http://www.pipephil.eu/logos/en/logo-p5.html). Sure enough he had a photo showing the stamping on the shank. I did a screen capture of the picture on the site and include it below.

Before I started my part of the restoration I wanted to have a clear picture of the background and what the stamping looked like on the Prince of Wales pipe. I turned to Pipephil as he often has photos that give me the information that I am looking for (http://www.pipephil.eu/logos/en/logo-p5.html). Sure enough he had a photo showing the stamping on the shank. I did a screen capture of the picture on the site and include it below. What is interesting in these photos is that it is the same logo but several of them say made in Leeds. They seem to be English made or at least maybe made for a pipe shop. The logo is a Scottish Flag in the photos but the one I am working on does not have a stamp on the stem. The shank is stamped Italy which makes me think that someone had the pipe made by an Italian company for their shop.

What is interesting in these photos is that it is the same logo but several of them say made in Leeds. They seem to be English made or at least maybe made for a pipe shop. The logo is a Scottish Flag in the photos but the one I am working on does not have a stamp on the stem. The shank is stamped Italy which makes me think that someone had the pipe made by an Italian company for their shop.

I turned to Pipedia and looked up the brand there (https://pipedia.org/wiki/Prince_Of_Wales). Here is what I found there. I quote in full.

“It is quite a three pipe problem …”

- The name “Prince of Wales” was used at times by GBD for a sub-brand.

- Pipephil shows English made Prince of Wales which bear the Scottish flag (X-shaped cross representing the cross of the Christian martyr Saint Andrew, the patron saint of Scotland) as logo.

- Also listed by Pipephil is a brand named P.O.W. attributed to a Scottish firm G.M. Frame. Now, if P.O.W. doesn’t stand for “prisoner of war”, this might be an indication that there are two different Prince of Wales productions.

- Danish made semi-freehands stamped “PRINCE OF WALES” + “DANISH LINE” + “HANDMADE IN DENMARK”. The stems, as usual for the bulk of such pipes, often as stitch in stems. Decorated with a white ring and a stylized Danish flag. (Were once mentioned as order production for GBD. – Unconfirmed!)

- Prince of Wales Made in Italy. Quotation: “In the spirit of the Bing’s Favorite Pipe, Savinelli expands its line of pipes favored by famous pipesmokers. Prince of Wales Favorite series features a new mosaic designed mouthpiece which gives it a unique look like no other series. This pipe can be used with or without Savinelli balsa inserts (20pk included).”

Now I knew I was dealing with a bit of a mystery pipe. It has an Italy stamp on the shank and the name Prince of Wales which sounds British. Very interesting piece. The fifth option above makes me wonder if it is not a Savinelli product. But no definitive information!

Jeff once again did an amazing job cleaning the pipe. He reamed it with a PipNet pipe reamer and got rid of the cake. He cleaned up the reaming with a Savinelli Fitsall Pipe Knife. He took the cake out completely so that we could see the walls of the bowl and assess for damage. He cleaned the internals of the shank and stem with cotton swabs, pipe cleaners and alcohol. He scrubbed the exterior with undiluted Murphy’s Oil Soap and a tooth brush. He rinsed the pipe under warm water. He dried it off with a cloth and then let it air dry. The rim top cleaned up pretty good. I took pictures of the pipe before I started my work on it.

I took a close up photo of the rim top to show how clean it was. There was some darkening on the inner edge on the right front of the bowl. Overall the pipe looked impressive at this point in comparison to where it had started.

I took a close up photo of the rim top to show how clean it was. There was some darkening on the inner edge on the right front of the bowl. Overall the pipe looked impressive at this point in comparison to where it had started.  I took photos of the stamping on the left and underside of the shank. It is clear and readable though faint in some spots.

I took photos of the stamping on the left and underside of the shank. It is clear and readable though faint in some spots.  I took a photo of the bowl and stem taken apart.

I took a photo of the bowl and stem taken apart.  I started my work on the pipe by addressing the remaining darkening on the inner edge of the bowl and nicks on the outer edge. I used a folded piece of 220 grit sandpaper and when finished the pipe looked better.

I started my work on the pipe by addressing the remaining darkening on the inner edge of the bowl and nicks on the outer edge. I used a folded piece of 220 grit sandpaper and when finished the pipe looked better.  I polished the briar with micromesh sanding pads (carefully avoiding the stamping). I used 1500-12000 grit pads and wiped the bowl down after each pad with a damp cloth. The bowl really took on a shine.

I polished the briar with micromesh sanding pads (carefully avoiding the stamping). I used 1500-12000 grit pads and wiped the bowl down after each pad with a damp cloth. The bowl really took on a shine.

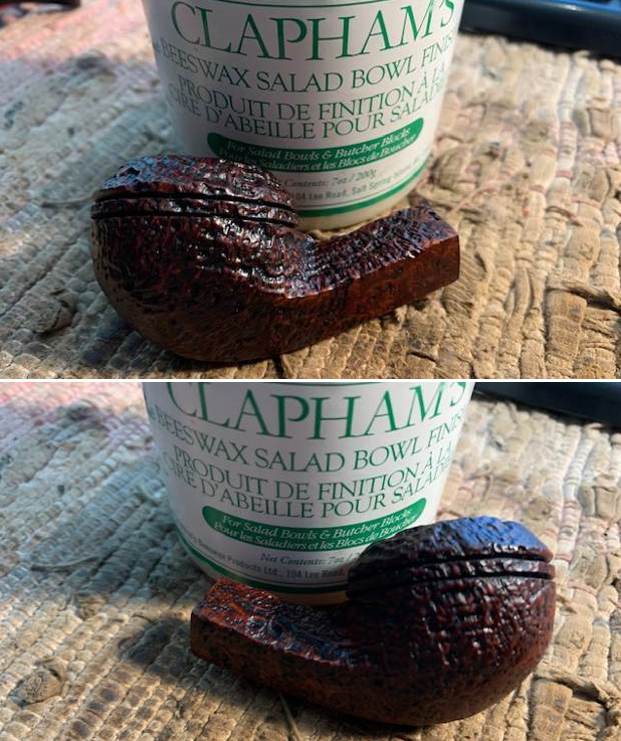

I worked some Before & After Restoration Balm into the briar with my finger tips. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I work on.

I worked some Before & After Restoration Balm into the briar with my finger tips. The product is a great addition to the restoration work. It enlivens, enriches and protects the briar while giving it a deep glow. It is a product I use on every pipe I work on.

I set the bowl aside and turned my attention to the stem. I filled in the rough bite marks with clear CA glue and set the stem aside to cure. Once it cured I flattened it with a small file and sharpened the edge of the button at the same time.

I set the bowl aside and turned my attention to the stem. I filled in the rough bite marks with clear CA glue and set the stem aside to cure. Once it cured I flattened it with a small file and sharpened the edge of the button at the same time.

I sanded out the tooth chatter and marks in the acrylic with a folded piece of 220 grit sandpaper and polished out the scratches with 440 grit wet dry sandpaper.

I sanded out the tooth chatter and marks in the acrylic with a folded piece of 220 grit sandpaper and polished out the scratches with 440 grit wet dry sandpaper.  I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I buffed the stem with a soft cloth to raise the shine.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine. I buffed the stem with a soft cloth to raise the shine.

As always I am excited to finish a pipe that I am working on. I put the Italian Made Prince of Wales Bent Dublin back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad and hand buffed it to raise the shine. It is fun to see what the polished bowl looks like with the grain popping around the bowl and shank. Added to that the polished variegated brown/gold/tan acrylic saddle stem was a beautiful touch. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 59 grams/2.08 ounces. It is a beautiful pipe and one that will be on the rebornpipes store in the Italian Pipe Makers section. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog. I want to keep reminding us of the fact that we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next pipeman or woman.

As always I am excited to finish a pipe that I am working on. I put the Italian Made Prince of Wales Bent Dublin back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad and hand buffed it to raise the shine. It is fun to see what the polished bowl looks like with the grain popping around the bowl and shank. Added to that the polished variegated brown/gold/tan acrylic saddle stem was a beautiful touch. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 5 ½ inches, Height: 2 inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: ¾ of an inch. The weight of the pipe is 59 grams/2.08 ounces. It is a beautiful pipe and one that will be on the rebornpipes store in the Italian Pipe Makers section. If you are interested in adding it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog. I want to keep reminding us of the fact that we are not pipe owners; we are pipemen and women who hold our pipes in trust until they pass on into the trust of the next pipeman or woman.