Blog by Steve Laug

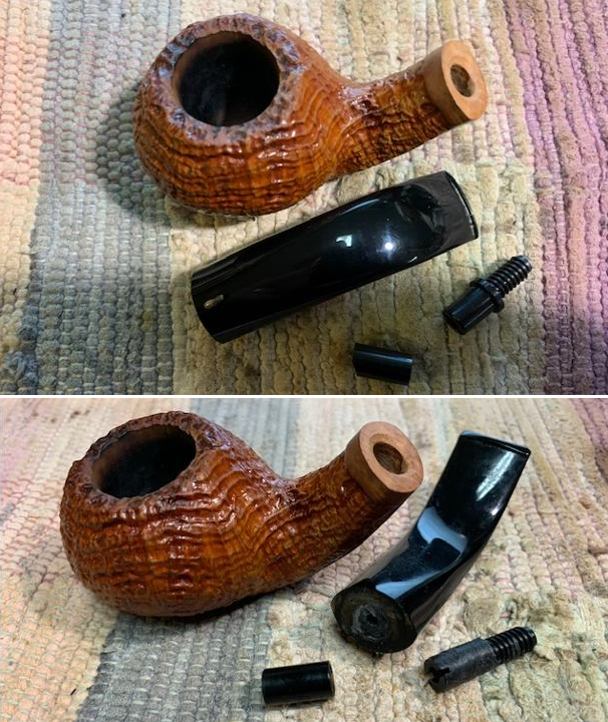

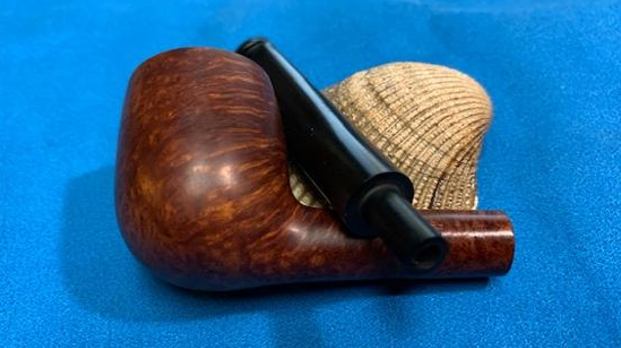

The next pipe has been here for quite a while and it is one that I have repeatedly looked at and passed over. I am guessing that it is an old timer from possibly the early 19th century. It has a red clay bowl that is unsmoked and the outside has been fired with a glaze that looks very good. It has gold paint on all eight of the angles of the octagonal bowl. The base of the bowl is a clam shell that holds the upright chimney of the bowl. There is a nickel rim cap and hinged wind cap on the bowl. There is a nickel band on the shank end with a ring for a piece of string that originally went from there to the top of the horn stem. The pipe has two embossed stamps on the left side of the bowl. The one on the bowl is an eagle with outstretched wings and the one on the base reads Partsch. Both have been embossed with gold. The shank has a corked end on the long cherry wood barked branch to keep it in the bowl end. The top of the cherry wood is capped with a polished horn ferrule and is threaded to receive a bent horn stem. There was some worm damage to the stem. The amazing thing about the pipe is that it has never been smoked.

The pipe is quite large with an overall length from the front of the scallop to the tip of the stem of 12 inches. The parts of the pipe are even longer when apart – the cherry wood shank is 9 inches long, the bowl is 2 inches long and the stem is 2 inches long. The bowl is 3 inches tall to the rim top with the wind cap adding an extra ¼ of an inch.

The pipe is quite large with an overall length from the front of the scallop to the tip of the stem of 12 inches. The parts of the pipe are even longer when apart – the cherry wood shank is 9 inches long, the bowl is 2 inches long and the stem is 2 inches long. The bowl is 3 inches tall to the rim top with the wind cap adding an extra ¼ of an inch.

I took some photos of the parts of the pipe to give a better picture of it. The first one below shows the wind cap. You can see that the diameter is quite wide. The cap has some dents and scratches that I will probably leave as is rather than risk damaging it. The second and third photos show the horn ferrule and stem. The worm damage is on the right side of the stem at the button end. The other end is threaded and there is an extra ring where the cord and tassels were attached. The next photos show the stamping on the inside of the wind cap and the side of the bowl and base. The inside of the cap reads ECHT NICKEL which translates Genuine Nickel. On the right base side it reads PARTSCH in a gold rectangle. On the side of the bowl is an gold oval with an Eagle with extended wings.

The next photos show the stamping on the inside of the wind cap and the side of the bowl and base. The inside of the cap reads ECHT NICKEL which translates Genuine Nickel. On the right base side it reads PARTSCH in a gold rectangle. On the side of the bowl is an gold oval with an Eagle with extended wings. I took the cherry wood shank off the glazed clay base and took a photo of the pipe to give a sense of the proportions and size. The cork is in such good condition that I am almost certain that it has been replaced.

I took the cherry wood shank off the glazed clay base and took a photo of the pipe to give a sense of the proportions and size. The cork is in such good condition that I am almost certain that it has been replaced. That is the pipe as it stands before I did anything to it. Remember it was unsmoked so it would not be an intrusive or intensive restoration. Rather it would be a polishing and shining up an already beautiful pipe without doing any damage to the antiquity of the pipe. But before I started on that process I wanted to learn more about the brand. What, where and who made this red fired clay pipe. It was time to do some research and dig out what I could find out about the brand.

That is the pipe as it stands before I did anything to it. Remember it was unsmoked so it would not be an intrusive or intensive restoration. Rather it would be a polishing and shining up an already beautiful pipe without doing any damage to the antiquity of the pipe. But before I started on that process I wanted to learn more about the brand. What, where and who made this red fired clay pipe. It was time to do some research and dig out what I could find out about the brand.

I turned to my usual sources to dig out any information that I could find and there was nothing on either Pipephil’s site or Pipedia. Both came up empty. I expanded the search to a general Google search for the Partsch label to see if I could find anything listed. That was a much more fruitful search. The first site that came up was picclick.co.uk and it had some information on the brand. I quote from the site below. https://picclick.co.uk/Partsch-red-tobacco-pipe-with-original-stem-Smoking-172799026344.html

Partsch red tobacco pipe with original stem. Partsch red tobacco pipe with original stem. A fine antique Partsch German long clay pipe. This beautiful long pipe has a red brown bowl with a nickel cap. The cap is stamped underneath ‘echt nickel’. The bowl is marked Partsch and has also an impressed Austrian eagle. This also appears to have its original cherry wood stem and original mouthpiece. Dimensions: 28.5cms long. Height of the bowl from cover to base 8.5cms. Cross section of the bowl 2.5cms x 2.5cms and bowl aperture is 2.1cms.Weight: 85gms Condition: Rare to get a pipe with all original parts.

The description of the pipe associates the ‘Echt Nickel’ stamp with German and identifies the pipe as a German made long clay pipe. I was not sure of that so the hunt continued.

The next mention on the Google hunt was to a pin on Pinterest. These often are unproductive so I was not overly hopeful regarding information, but I was wrong. I quote from the description on the pin below (https://www.pinterest.ca/pin/25051341664836403/).

This is a fine antique, long handle, smokers pipe that has been well used and well loved. It was made in Austria by Anton Partsch and bears the stamp “PARTSCH” as well as the “Austrian Eagle Crest” on its bowl. The bowl has a clamshell relief pattern at its base and is in a terra-cotta red glazed clay. The hinged metal wind cap has two slots and a turned down ball clasp for closure. There is a cord loop on the metal band around the shank but no cord. I believe the reddish bark coloured wood is cherry…

From that information I learned that I was dealing with a pipe made by Anton Partsch and that the stamps on the side were indeed what I thought they were. What was really helpful was the author identified the Eagle with outstretched wings as the “Austrian Eagle Crest”.

The next link provided more information. It was a pipe that was for sale/sold on Worthpoint and the description added new information to my growing understanding of the brand. (https://www.worthpoint.com/worthopedia/partsch-schemnitz-pipe-bowl-antique-1855443319) I quote below.

The vast majority were finished in subdued solid colors of carmine, terracotta, brown, and black, the last two being the most common. and occasionally found in mottled, marbled, or dappled green and blue. These early, paneled bowls were mass-produced in the town of Banská Štiavnica, Slovakia, Selmecbánya (Hungarian), Schemnitz (German), or Chemnitz (English), once the largest and most famous mining center of the Austro-Hungarian Empire. These pipe bowls are often identified in literature as hard stone, or stoneware, because of their highly polished and transparent-glazed surface finish, but they were not of a hard stone composition; they were fired, containing a mixture of white clay for strength and red clay for sheen.

This was the most detail of the area that the bowl came from in the Austro-Hungarian Empire and that they were made of a mixture of white clay from strength and red clay for sheen. They had a glazed surface that gave them the look of stone but were not made of that. Fascinating how the picture is growing.

The next piece of the puzzle came from a discussion on Pipesmagazine.com forums. I quote some of the pertinent parts of the discussion that added to my understanding. The initial poster refers to an article on Facebook that is no longer available. You can click on the link and read the discussion in its entirety if you so choose (https://pipesmagazine.com/forums/threads/antique-schemnitz-austro-hungarian-clay-pipe-rarity-age.36245/).

…The article says they’re most common in black and brown, less so in terra-cotta and red, and “occasionally” in blue or green. I found some closed auctions on eBay and posts elsewhere showing terra-cotta, mottled brown, and black ones. They usually seem to have a scalloped metal sleeve on the bowl with a hinged wind-cap, and some have a metal band around the end of the shank, presumably to prevent cracks.

…The bowl is glazed in cream color with softly-dappled green swirl patterns, the cream becoming a sort of buttercream yellow behind the green areas. The shell bottom and shank are black, with a tiny hint of gold on the scallops. The wind-cap has eight slots around the edge and a nice curled clasp that snaps down; I’ve seen photos of very plain bands on the bowl, solid with a scalloped lower edge, and some very ornate pierced ones, and this is somewhere in the middle, plain with a fancy, pierced border. The inside of the cap has “ECHT NICKEL” (genuine nickel) stamped in big block letters…

…The maker’s mark, stamped into the shank and gold-glazed, is “PARTSCH,” which that article tells me is Anton Partsch. There is also, up on the lower part of the bowl, a gold oval stamp with a soft pattern in the center, I assume the maker’s company sigil. The shank has a plain metal band, with a loop for a cord…

…It has a bark-covered wood stem, with a cork-and-reed tip on the bottom and a turned horn ferrule (which has a tiny age crack) on top and a wooden mouthpiece (on closer examination just now, the lip is translucent under a very bright, focused light, so I think this must also be horn). The stem is kept with the bowl by a brown string or cord, tied around the mouthpiece and ending in two tassels, like many of the German wood and porcelain pipes…

I have highlighted the information that fits my pipe in bold in the quotes above. I did find from the conversation that the Terra Cotta version I have is a bit rarer to find than the black or brown versions of the pipe.

I found two scholarly articles. I have included the link to the first one below. It is a PDF on pipes made in Theresienfeld (Davey 2010 Theresienfeld pipes.pdf). I quote a portion of the paper on the PARTSCH pipes. It is very interesting and confirms the stamping.

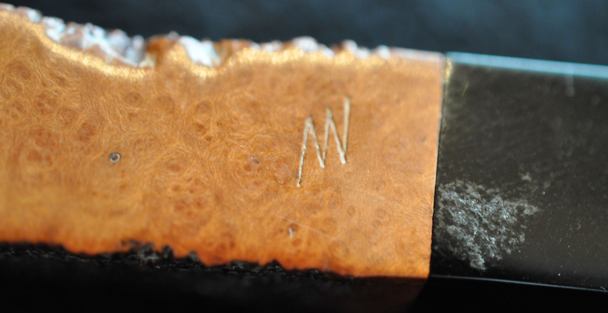

These pipes bear a PARTSCH relief stamp in a rectangular frame on the side of the socket and an oval SCHUTZMARKE relief stamp at the base of the funnel in which the legend surrounds the upper part of an eagle with spread wings.

The next information came from a Master’s Thesis for Oregon State University. I included the link and the identifying information below. I quote tow paragraphs that help give information on the Partsch pipe I am working on.

An Abstract Of The Thesis Of – Oregon State University

AN ABSTRACT OF THE THESIS OF Diane Zentgraf for the degree of Master of Science in Applied Anthropology presented on December 14, 2018.

Title: Mid-Nineteenth Century Clay Smoking Pipes from Fort Hoskins (35BE15) and Fort

Yamhill (35PO75), Oregon.

…Reed stem clay pipe manufacturing began in the Austro-Hungarian Empire during

the last quarter of the 17th century (Gačić 2011: 31), utilizing local clays in Northern and

Western Hungary (Gačić 2011:31, citing Ridovics 2009:64). During the 19th century, the

pipe making was concentrated in Wiener Neustadt, Theresienfeld and Pernitz, in the

southern section of Austria, with strong connections to production centers in Hungary.

Twenty pipe making workshops have been identified by Bielich and Curny (2009: 342-

348), including pipe makers S. Boscovitz, Anton Partsch, Jacob Reinitz, S. Seiler, Károly

Zachar, Anton Ress, Michael Honig, M. Amstätter and Joseph Schmidt.

The Hapsburg dynasty required pipes be marked with a maker’s mark in the early 19th century (Bielich and Curney 2009:358). In the literature these are termed Austro-Hungarian pipes and are characterized by a consistent form that was repeated with very little change (Gacic 2011:54). The most common pipe form is termed a Schemnitz pipe and is described as made of good quality clay in molds and having a narrow “tall cylindrical head (with either round or polygonal cross-section) profiled like a shell at the bottom” (Gacic 2011:54). These pipes were popular and often copied (Figure 21) 49 (Morgenroth 2001:56), and are described as having muted colors, reddish to black in color, marbled black-grey color, often mixed with white clay.

I am pretty certain I have found the last piece of information I needed. It seems that there were many pipe making workshops in the early 19th century concentrated in three areas in southern Austria – Wiener Neustadt, Theresienfeld and Pernitz. It is in those areas that Anton Partsch is said to have been a pipe maker. It is also clear that during the Hapsburg Dynasty all pipes had to be marked with the maker’s mark in the early 19th century. That further locks the date down for the pipe I am working on.

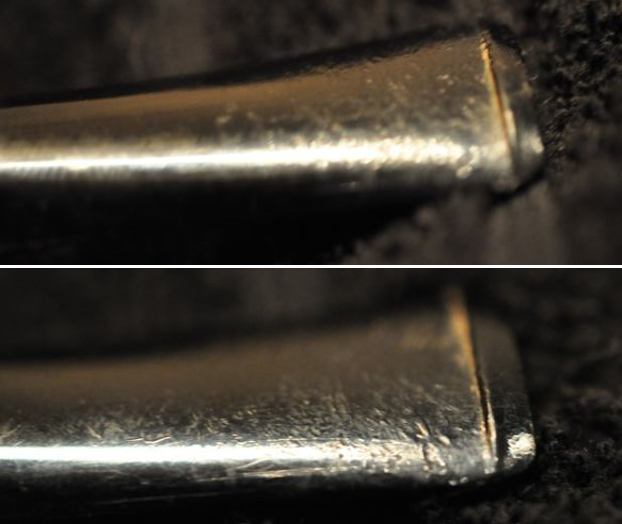

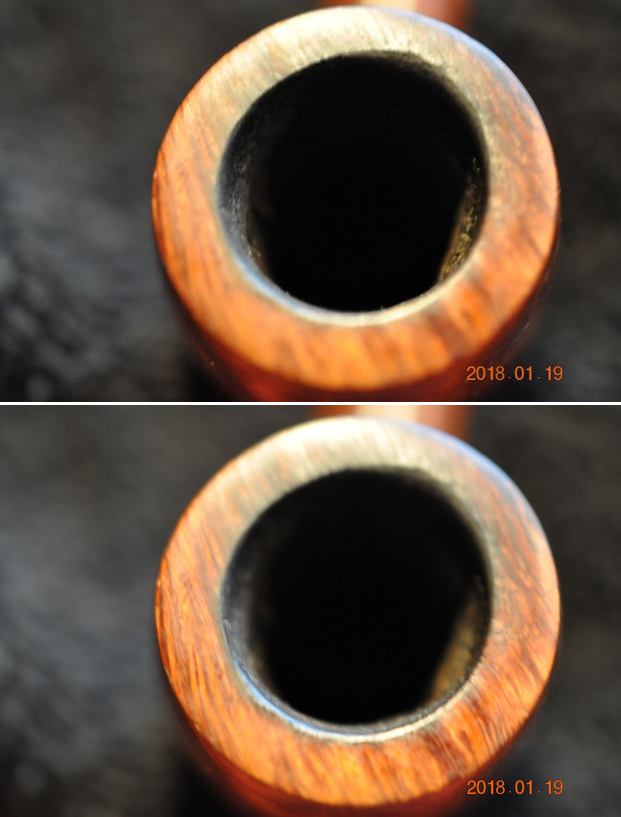

Now that I had gathered a bit of an education on the maker and pipe it was time to do some polishing on the pipe. I polished the horn ferrule with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiped it down with Obsidian Oil. The horn took on a lot of life and depth from the polishing It is a nice looking piece.

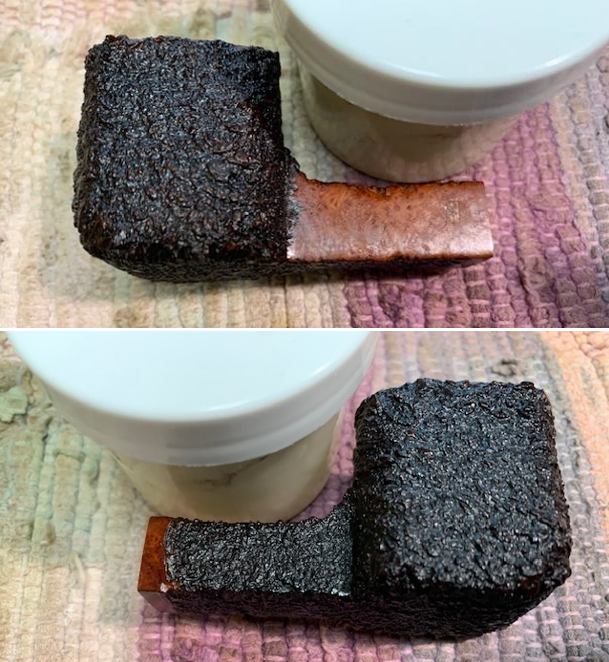

I rubbed the bark of the cherry wood shank piece with Before & After Restoration Balm. I worked it into the bark, cork and horn with my finger tips. It works to clean, preserve and protect wood. I let it sit for 15 minutes then buffed it off with a soft cotton cloth.

I rubbed the bark of the cherry wood shank piece with Before & After Restoration Balm. I worked it into the bark, cork and horn with my finger tips. It works to clean, preserve and protect wood. I let it sit for 15 minutes then buffed it off with a soft cotton cloth.  The bent horn stem had some worm damage on the right side near the button. I filled it in with some clear CA glue and built up the damaged area. I reshaped the button as well as it had some nicks in it. I sanded the repaired area with 220 grit sandpaper to smooth it out and then started polishing the horn with 400 grit wet dry sandpaper. It looked better.

The bent horn stem had some worm damage on the right side near the button. I filled it in with some clear CA glue and built up the damaged area. I reshaped the button as well as it had some nicks in it. I sanded the repaired area with 220 grit sandpaper to smooth it out and then started polishing the horn with 400 grit wet dry sandpaper. It looked better.

I polished the horn with micromesh sanding pads – 1500-12000 grit pads. I wiped it down after each pad with some Obsidian Oil. I gave it a final polish with Before & After Stem Polish – both Fine and Extra Fine. I gave it another rub down with Obsidian Oil. The horn really began to shine as I finished the polishing.

I polished the horn with micromesh sanding pads – 1500-12000 grit pads. I wiped it down after each pad with some Obsidian Oil. I gave it a final polish with Before & After Stem Polish – both Fine and Extra Fine. I gave it another rub down with Obsidian Oil. The horn really began to shine as I finished the polishing.

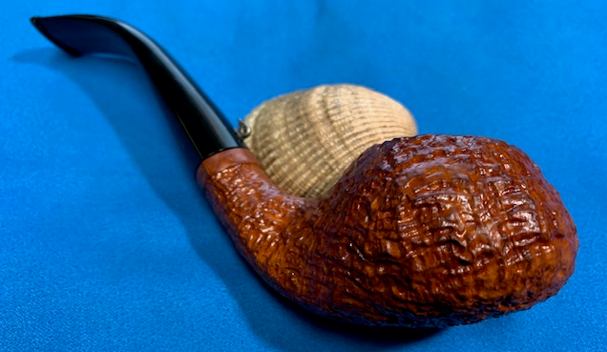

With the stem repaired and polished I was finished with my work on the pipe. I wiped down the nickel plated rim and wind cap as well as the nickel plated shank end cap with a jewelers cloth to remove the moderate oxidation and to protect it. I did not want to remove the dents in the wind cap as it could actually ruin the value of the pipe. I gave it a coat of Conservator’s Wax and a hand buff with a fluffy cloth to raise the shine. This Anton Partsch Red Glazed Pottery Bowled Long Pipe came out looking quite amazing. The horn ferrule and stem polished nicely as did the cherry wood shank. It all came together well. To think that the pipe is at least 200 years old and never been smoked is quite unbelievable. The dimensions of the pipe are, Length: 12 inches, Height: 3 inches, Outside diameter of the bowl: 1 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is; 92 grams/3.25 ounces. I really enjoyed working on this beauty and felt a sense of touching the past in a tangible way. The pipe will stay in my own collection to be enjoyed and savored. I don’t think I will ever fire up a bowl as it has not been smoked since it was made and there is something unique about that. But then again, the right day may come and I will fire it up. We shall see. Thanks for walking through the restoration with me. As Paresh always says, “Stay Safe”.

With the stem repaired and polished I was finished with my work on the pipe. I wiped down the nickel plated rim and wind cap as well as the nickel plated shank end cap with a jewelers cloth to remove the moderate oxidation and to protect it. I did not want to remove the dents in the wind cap as it could actually ruin the value of the pipe. I gave it a coat of Conservator’s Wax and a hand buff with a fluffy cloth to raise the shine. This Anton Partsch Red Glazed Pottery Bowled Long Pipe came out looking quite amazing. The horn ferrule and stem polished nicely as did the cherry wood shank. It all came together well. To think that the pipe is at least 200 years old and never been smoked is quite unbelievable. The dimensions of the pipe are, Length: 12 inches, Height: 3 inches, Outside diameter of the bowl: 1 inch, Chamber diameter: ¾ of an inch. The weight of the pipe is; 92 grams/3.25 ounces. I really enjoyed working on this beauty and felt a sense of touching the past in a tangible way. The pipe will stay in my own collection to be enjoyed and savored. I don’t think I will ever fire up a bowl as it has not been smoked since it was made and there is something unique about that. But then again, the right day may come and I will fire it up. We shall see. Thanks for walking through the restoration with me. As Paresh always says, “Stay Safe”.

The nomenclature on the left flank of the shank is stamped in what appears to be an old English font slightly arched upwardly, ‘Yorkshire’ [over] STANDARD [over in a reversed downward arch] ALGERIAN BRIAR. I could find no other markings on the…

The nomenclature on the left flank of the shank is stamped in what appears to be an old English font slightly arched upwardly, ‘Yorkshire’ [over] STANDARD [over in a reversed downward arch] ALGERIAN BRIAR. I could find no other markings on the…