Blog by Dal Stanton

When your son brings home (to Bulgaria!) a young woman for you to meet, you know it’s serious. That’s what happened this past Christmas! Our son, Josiah, who lives in St. Louis, Missouri, brought Katie, who lives in Chattanooga, Tennessee, to Sofia to meet Mom and Dad – no pressure on her! They met in college and after graduation, they stayed in touch as friends, Josiah ending up in St. Louis where he finished his master’s degree and is now a counselor. Katie stayed in Chattanooga and works on staff with youth in a church. Our daughter and husband also made the trip to Sofia from Nashville for a quintessential Bulgarian Christmas. The family was together at the Sofia Airport when Josiah (center) and Katie (flowers 😊) arrived from the US. Johanna and Niko had arrived a few days earlier – ready to celebrate Christmas!

When your son brings home (to Bulgaria!) a young woman for you to meet, you know it’s serious. That’s what happened this past Christmas! Our son, Josiah, who lives in St. Louis, Missouri, brought Katie, who lives in Chattanooga, Tennessee, to Sofia to meet Mom and Dad – no pressure on her! They met in college and after graduation, they stayed in touch as friends, Josiah ending up in St. Louis where he finished his master’s degree and is now a counselor. Katie stayed in Chattanooga and works on staff with youth in a church. Our daughter and husband also made the trip to Sofia from Nashville for a quintessential Bulgarian Christmas. The family was together at the Sofia Airport when Josiah (center) and Katie (flowers 😊) arrived from the US. Johanna and Niko had arrived a few days earlier – ready to celebrate Christmas!

As you would expect, we had limited time with our kids, and we packed it as full as we could! What Christmas celebration would be complete without including snow, riding gondolas and skiing in Bulgaria’s beautiful Pirin Mountains and spending time together as a family AND getting to know the young women who would become our future daughter-in-law in August.  The time with our kids went too quickly, but before they left, Katie’s future father-in-law was an interesting character with the moniker, The Pipe Steward, and she was interested in finding a special pipe she could commission from The Pipe Steward to give to her father as a gift for his birthday. Unlike most people who go through the virtual ‘Help me!’ baskets in the online collection I call, For “Pipe Dreamers” Only!, Katie was able to go through the physical boxes of my inventory to find the perfect pipe that called her name for her father. What added to the experience was that Katie knew that the pipe she chose would benefit the Daughters of Bulgaria! The pipe that got Katie’s attention after listening to many, many pipes, was a very hopeful Sculpted 3/4 Bent Billiard with only the marking, ‘IMPORTED Briar’ on the left shank flank which I had acquired from the Lot of 66 – a huge Lot of pipes that came from a non-profit in Georgetown, Texas, called the Caring Place. Here are some of the original pictures I took when the Lot of 66 arrived.

The time with our kids went too quickly, but before they left, Katie’s future father-in-law was an interesting character with the moniker, The Pipe Steward, and she was interested in finding a special pipe she could commission from The Pipe Steward to give to her father as a gift for his birthday. Unlike most people who go through the virtual ‘Help me!’ baskets in the online collection I call, For “Pipe Dreamers” Only!, Katie was able to go through the physical boxes of my inventory to find the perfect pipe that called her name for her father. What added to the experience was that Katie knew that the pipe she chose would benefit the Daughters of Bulgaria! The pipe that got Katie’s attention after listening to many, many pipes, was a very hopeful Sculpted 3/4 Bent Billiard with only the marking, ‘IMPORTED Briar’ on the left shank flank which I had acquired from the Lot of 66 – a huge Lot of pipes that came from a non-profit in Georgetown, Texas, called the Caring Place. Here are some of the original pictures I took when the Lot of 66 arrived.

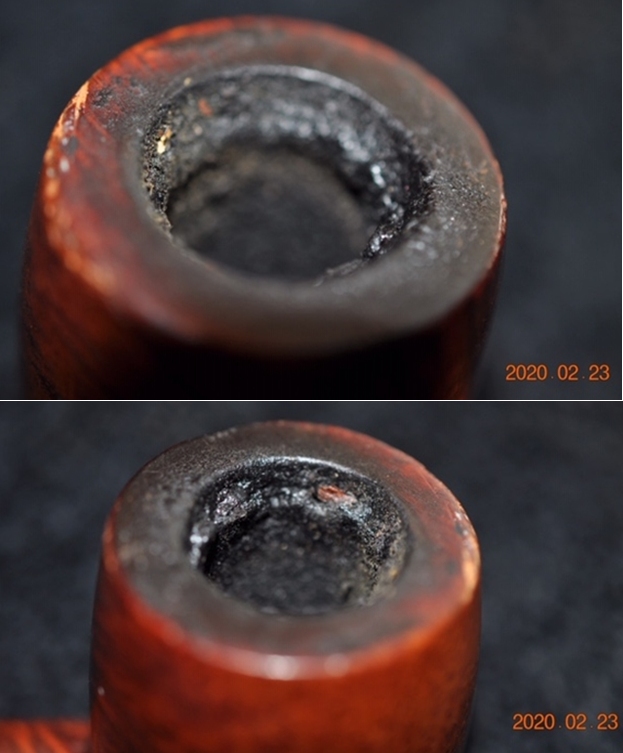

Christmas is now, long gone, our world has changed by the covid-19 pandemic, the kids are in the US navigating life, and Katie’s pipe for her father is now on my worktable. I take a closer look at the Sculpted Bent Billiard with some pictures. There is genuinely nice briar grain lurking beneath the darkened, tired finish – many bird’s eye formations draw my attention. The upper bowl surface is darkened in comparison to the other briar landscape indicating potential overheating problems which may be revealed when the chamber is cleared of the cake.

Christmas is now, long gone, our world has changed by the covid-19 pandemic, the kids are in the US navigating life, and Katie’s pipe for her father is now on my worktable. I take a closer look at the Sculpted Bent Billiard with some pictures. There is genuinely nice briar grain lurking beneath the darkened, tired finish – many bird’s eye formations draw my attention. The upper bowl surface is darkened in comparison to the other briar landscape indicating potential overheating problems which may be revealed when the chamber is cleared of the cake. The rim is in rough shape with thick lava flow and nicks and skinned edges – it’s been a well-used pipe!

The rim is in rough shape with thick lava flow and nicks and skinned edges – it’s been a well-used pipe! The picture doesn’t show the thick carbon cake buildup that I can see with the eye. The chamber closes and narrows as you move toward the chamber floor.

The picture doesn’t show the thick carbon cake buildup that I can see with the eye. The chamber closes and narrows as you move toward the chamber floor. The mortise is too loose so that the tenon has no grab. This needs to be addressed and tightened.

The mortise is too loose so that the tenon has no grab. This needs to be addressed and tightened. The stem has deep oxidation and calcium buildup on the bit area. The button needs refreshing.

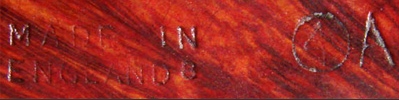

The stem has deep oxidation and calcium buildup on the bit area. The button needs refreshing. The nomenclature is thin with only ‘Imported Briar’ on the shank. The spelling of briar probably indicates this to be a US manufactured pipe. To begin the restoration of Katie’s pipe, the stem’s airway is cleaned with a pipe cleaner wetted in isopropyl 95%.

The nomenclature is thin with only ‘Imported Briar’ on the shank. The spelling of briar probably indicates this to be a US manufactured pipe. To begin the restoration of Katie’s pipe, the stem’s airway is cleaned with a pipe cleaner wetted in isopropyl 95%. With the oxidation being so deep and with the calcium buildup, I get a head start on removing the oxidation using 000 grade steel wool along with a ‘Soft Scrub-like’ product I can get here in Bulgaria. This helps with the cleaning before putting the stem into the soak.

With the oxidation being so deep and with the calcium buildup, I get a head start on removing the oxidation using 000 grade steel wool along with a ‘Soft Scrub-like’ product I can get here in Bulgaria. This helps with the cleaning before putting the stem into the soak. The next step is to give the stem a soak in Before & After Deoxidizer that does an adequate job of removing oxidation that isn’t too deep. The stem joins other stems and pipes in the queue. I let it soak for several hours.

The next step is to give the stem a soak in Before & After Deoxidizer that does an adequate job of removing oxidation that isn’t too deep. The stem joins other stems and pipes in the queue. I let it soak for several hours. After removing the stem from the Deoxidizer, I let the liquid drain and I squeegee the stem with my fingers. I then use cotton pads wetted with isopropyl 95% to wipe the stem removing raised oxidation. I clear the fluid from the airway with a few pipe cleaners also wetted with isopropyl 95%.

After removing the stem from the Deoxidizer, I let the liquid drain and I squeegee the stem with my fingers. I then use cotton pads wetted with isopropyl 95% to wipe the stem removing raised oxidation. I clear the fluid from the airway with a few pipe cleaners also wetted with isopropyl 95%. To help condition the vulcanite stem, paraffin oil is applied with a cotton pad. Paraffin Oil is a mineral oil. I then put the stem aside to give time for the oil to be absorbed.

To help condition the vulcanite stem, paraffin oil is applied with a cotton pad. Paraffin Oil is a mineral oil. I then put the stem aside to give time for the oil to be absorbed. Next, turning to the bowl, I use the Pipnet Reaming Kit to start clearing the hard, thick carbon cake from the chamber. I use 3 of the 4 blade heads available in the kit to ream the bowl. I follow the reaming tool by scraping the chamber wall with the Savinelli Fitsall Tool. I finish by sanding the chamber with 240 paper wrapped around a Sharpie Pen.

Next, turning to the bowl, I use the Pipnet Reaming Kit to start clearing the hard, thick carbon cake from the chamber. I use 3 of the 4 blade heads available in the kit to ream the bowl. I follow the reaming tool by scraping the chamber wall with the Savinelli Fitsall Tool. I finish by sanding the chamber with 240 paper wrapped around a Sharpie Pen.  After wiping the chamber with a cotton pad wetted with alcohol, I discover what appears to be some heating damage on the upper backside of the chamber – behind the sculpting. There is a hole with a crevasse cutting to the left from the deep pit. This will need attention after the cleaning of the stummel is completed.

After wiping the chamber with a cotton pad wetted with alcohol, I discover what appears to be some heating damage on the upper backside of the chamber – behind the sculpting. There is a hole with a crevasse cutting to the left from the deep pit. This will need attention after the cleaning of the stummel is completed. Next, I continue with the cleaning of the external surface using undiluted Murphy’s Oil Soap on a cotton pad. I also utilize a brass bristled brush to work on the lava covered rim. Brass does not damage the briar and adds some cleaning power.

Next, I continue with the cleaning of the external surface using undiluted Murphy’s Oil Soap on a cotton pad. I also utilize a brass bristled brush to work on the lava covered rim. Brass does not damage the briar and adds some cleaning power.

I transport the pipe to the kitchen sink and continue the cleaning using shank brushes and anti-oil dish soap. With the brushes the mortise is scrubbed. After a thorough rinsing, the bowl is back on the worktable.

I transport the pipe to the kitchen sink and continue the cleaning using shank brushes and anti-oil dish soap. With the brushes the mortise is scrubbed. After a thorough rinsing, the bowl is back on the worktable. The rim cleaned up revealing the internal edge burn damage from lighting practices on the right side of the bowl. This will be addressed later.

The rim cleaned up revealing the internal edge burn damage from lighting practices on the right side of the bowl. This will be addressed later. The bigger surprise comes after inspection of the sculpted area. The center of the sculpting is a filler. The question is, was the sculpting used to hide an imperfection in the briar itself or to blend a repair possibly caused by a burn-through? I don’t believe it’s a burn through, but the fill corresponds to the hole in the chamber.

The bigger surprise comes after inspection of the sculpted area. The center of the sculpting is a filler. The question is, was the sculpting used to hide an imperfection in the briar itself or to blend a repair possibly caused by a burn-through? I don’t believe it’s a burn through, but the fill corresponds to the hole in the chamber. Using a dental probe, it doesn’t take much to clean the hole and to complete the tunnel passageway to the chamber. Daylight is now visible looking from the inside. Ugh. There appears to be a lateral crack that the sculpting has incorporated. This pipe falls into the ‘Dreamer’ category but is not beyond hope! The briar surface is nice, and this challenge I hope does not create too much of an obstacle.

Using a dental probe, it doesn’t take much to clean the hole and to complete the tunnel passageway to the chamber. Daylight is now visible looking from the inside. Ugh. There appears to be a lateral crack that the sculpting has incorporated. This pipe falls into the ‘Dreamer’ category but is not beyond hope! The briar surface is nice, and this challenge I hope does not create too much of an obstacle.

Continuing with the cleaning regimen, I return to cleaning the internals using cotton buds and pipe cleaners wetted with isopropyl 95%. I discover that a couple pipe cleaners and one cotton bud are all that is needed. The internals are clean.

Continuing with the cleaning regimen, I return to cleaning the internals using cotton buds and pipe cleaners wetted with isopropyl 95%. I discover that a couple pipe cleaners and one cotton bud are all that is needed. The internals are clean. My approach to repairing the hole in the stummel is to first start with applying briar dust putty to the external briar side. I don’t push the putty through into the chamber but leave a gap that will be filled with JB Weld on the internal fire side. Using burrs with the Dremel, I’ll ‘re-sculpt’ the external surface to blend the patch. Working on a plastic disk as a mixing palette, scotch tape helps with an easy cleanup.

My approach to repairing the hole in the stummel is to first start with applying briar dust putty to the external briar side. I don’t push the putty through into the chamber but leave a gap that will be filled with JB Weld on the internal fire side. Using burrs with the Dremel, I’ll ‘re-sculpt’ the external surface to blend the patch. Working on a plastic disk as a mixing palette, scotch tape helps with an easy cleanup.  After cleaning the area with alcohol, I begin by mixing briar dust with BSI Extra Thick Maxi-Cure CA glue using a toothpick. I draw briar dust into the puddle of glue until the thickness is that of molasses. I then use the toothpick to trowel the putty to the hole. I press the putty into the hole partially to fill it. I use an accelerator to quicken the curing and to hold the patch in place.

After cleaning the area with alcohol, I begin by mixing briar dust with BSI Extra Thick Maxi-Cure CA glue using a toothpick. I draw briar dust into the puddle of glue until the thickness is that of molasses. I then use the toothpick to trowel the putty to the hole. I press the putty into the hole partially to fill it. I use an accelerator to quicken the curing and to hold the patch in place.

After the briar dust putty is fully cured, the next step is to apply JB Weld to the internal fracture and crevasse. JB Weld is heat resistant and works well has a chamber repair. I mix equal parts of the ‘Steel Resin’ and the ‘Hardener’ and then mix with a toothpick. The mixed epoxy begins to harden in about 4 minutes giving plenty of time to apply the Weld to the hole and to the crevasse running from it. After applied, I set the stummel aside for some hours for the patch to cure.

After the briar dust putty is fully cured, the next step is to apply JB Weld to the internal fracture and crevasse. JB Weld is heat resistant and works well has a chamber repair. I mix equal parts of the ‘Steel Resin’ and the ‘Hardener’ and then mix with a toothpick. The mixed epoxy begins to harden in about 4 minutes giving plenty of time to apply the Weld to the hole and to the crevasse running from it. After applied, I set the stummel aside for some hours for the patch to cure.

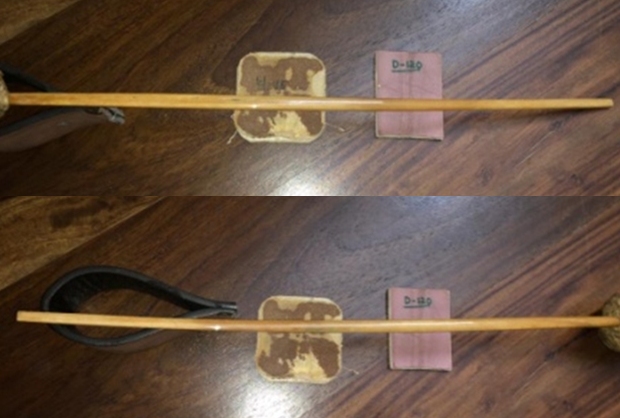

Switching my focus now to the stem, to expand the tooth compressions on the upper and lower bit, I first use the heating method. Using a Bic lighter, I paint the bit with the flame thereby warming and expanding the rubber compound, vulcanite. I take before and after pictures to show the comparison on the upper and lower.

Switching my focus now to the stem, to expand the tooth compressions on the upper and lower bit, I first use the heating method. Using a Bic lighter, I paint the bit with the flame thereby warming and expanding the rubber compound, vulcanite. I take before and after pictures to show the comparison on the upper and lower.

The heating method may have helped some, but not enough to avoid using Black CA glue to spot drop patches on the upper and lower bit. After applying the CA glue, I put the stem aside for the patches to cure.

The heating method may have helped some, but not enough to avoid using Black CA glue to spot drop patches on the upper and lower bit. After applying the CA glue, I put the stem aside for the patches to cure. With the stem on the side curing, I turn again to the stummel. The JB Weld patch has fully cured. To remove the excess epoxy and to smooth the chamber wall, I mount a sanding drum to the Dremel. It does a quick and good job.

With the stem on the side curing, I turn again to the stummel. The JB Weld patch has fully cured. To remove the excess epoxy and to smooth the chamber wall, I mount a sanding drum to the Dremel. It does a quick and good job.

I then sand and smooth the chamber patch using 240 grade paper wrapped around a Sharpie Pen. The patch looks good conforming exactly to the hole and crevasse it filled.

I then sand and smooth the chamber patch using 240 grade paper wrapped around a Sharpie Pen. The patch looks good conforming exactly to the hole and crevasse it filled.

The rim has sustained a good bit of damage on the right inner edge. My first thought was to top the stummel at this point to remove the damage. After a second thought, this would remove a good bit of briar real estate from the rim. Instead, I decide to rebuild the inner edge using briar dust putty then after the patch cures to top and sand the rim.

The rim has sustained a good bit of damage on the right inner edge. My first thought was to top the stummel at this point to remove the damage. After a second thought, this would remove a good bit of briar real estate from the rim. Instead, I decide to rebuild the inner edge using briar dust putty then after the patch cures to top and sand the rim.  I first remove all the residual carbon from the surface from the lighting damage that caused the problems. I brush the area with the brass wired brush as well as sand it with 240 paper getting down to fresh briar.

I first remove all the residual carbon from the surface from the lighting damage that caused the problems. I brush the area with the brass wired brush as well as sand it with 240 paper getting down to fresh briar. This picture shows the damage to the rim well and the area needing to be rebuilt.

This picture shows the damage to the rim well and the area needing to be rebuilt. I mix briar dust with Extra Thick CA glue by gradually pulling briar dust into the puddle until it reaches the thickness of molasses. Then the briar putty is applied with the toothpick to the inside of the lip to build up toward the rim and in toward the chamber. I use an accelerator to quicken the curing process.

I mix briar dust with Extra Thick CA glue by gradually pulling briar dust into the puddle until it reaches the thickness of molasses. Then the briar putty is applied with the toothpick to the inside of the lip to build up toward the rim and in toward the chamber. I use an accelerator to quicken the curing process.

Allowing the rim patch to thoroughly cure, I turn back to the stem filing and sanding the black CA glue patches on the upper and lower bit. I use the file to refresh and redefine the button. The sanding is expanded to the entire stem to remove vestiges of oxidation.

Allowing the rim patch to thoroughly cure, I turn back to the stem filing and sanding the black CA glue patches on the upper and lower bit. I use the file to refresh and redefine the button. The sanding is expanded to the entire stem to remove vestiges of oxidation. Following the 240 sanding paper, the stem is wet sanded with 600 grade paper followed by applying 000 grade steel wool. The stem is shaping up nicely.

Following the 240 sanding paper, the stem is wet sanded with 600 grade paper followed by applying 000 grade steel wool. The stem is shaping up nicely. The rim briar dust putty rebuild is fully cured and using the sanding drum mounted onto the Dremel, I begin removing the excess patch material on the internal chamber wall. The goal is to restore a rounded chamber.

The rim briar dust putty rebuild is fully cured and using the sanding drum mounted onto the Dremel, I begin removing the excess patch material on the internal chamber wall. The goal is to restore a rounded chamber.

Next, the excess patch material is removed from the rim top.

Next, the excess patch material is removed from the rim top. I also smooth out the external hole path in the sculpted area.

I also smooth out the external hole path in the sculpted area.  With the excess patch material removed from the rim, I then take the stummel to the topping board. I removed the excess first so that the topping will be more balanced and not get pushed off or out of balance because of the different level of surface. I start first with 240 sanding paper on the chopping board.

With the excess patch material removed from the rim, I then take the stummel to the topping board. I removed the excess first so that the topping will be more balanced and not get pushed off or out of balance because of the different level of surface. I start first with 240 sanding paper on the chopping board.  After some rotations on the board, the ‘roundness’ or lack of, of the chamber becomes more distinct.

After some rotations on the board, the ‘roundness’ or lack of, of the chamber becomes more distinct.  I return to the sanding drum on the Dremel to continue to round the chamber wall and rim edge. This goes slowly to make sure not to take too much off! I also use 240 sanding paper rolled to clean the outer and inner edges of the rim. It’s looking good.

I return to the sanding drum on the Dremel to continue to round the chamber wall and rim edge. This goes slowly to make sure not to take too much off! I also use 240 sanding paper rolled to clean the outer and inner edges of the rim. It’s looking good. After changing the topping board to 600 grade paper, the stummel is rotated several more times. I like what I see. The rim rebuild patch looks good and the rim’s balance has been restored without great loss of briar off the top of the bowl.

After changing the topping board to 600 grade paper, the stummel is rotated several more times. I like what I see. The rim rebuild patch looks good and the rim’s balance has been restored without great loss of briar off the top of the bowl. Before continuing with sanding the stummel, I attach a burr to the stummel to shape the sculpting. I try to match some swings and swirls but dipping in and out with the burr is pretty random. At the end, I think it looks good.

Before continuing with sanding the stummel, I attach a burr to the stummel to shape the sculpting. I try to match some swings and swirls but dipping in and out with the burr is pretty random. At the end, I think it looks good.

I plan to apply a light brown dye to the stummel. To clean the surface and to help to lighten the dark spots caused by heating, especially near the rim, I apply sanding sponges.

I plan to apply a light brown dye to the stummel. To clean the surface and to help to lighten the dark spots caused by heating, especially near the rim, I apply sanding sponges.

I usually use 3 sanding sponges – coarse, medium and light to finish. I add a coarser sponge to this regimen with a total of 4 sanding cycles.

I usually use 3 sanding sponges – coarse, medium and light to finish. I add a coarser sponge to this regimen with a total of 4 sanding cycles.

The grain has started to emerge. I continue by using the full regimen of micromesh pads. Starting with pads 1500 to 2400 I wet sand. Following this, dry sanding with pads 3200 to 4000 and 6000 to 12000 bring out the latent grain in the briar. I’m liking the appearance of several bird’s eye swirls. The grain is lively and expressive.

The grain has started to emerge. I continue by using the full regimen of micromesh pads. Starting with pads 1500 to 2400 I wet sand. Following this, dry sanding with pads 3200 to 4000 and 6000 to 12000 bring out the latent grain in the briar. I’m liking the appearance of several bird’s eye swirls. The grain is lively and expressive.

The stummel still shows darkened areas from charring and heating. This is especially on the rim and near the top of the bowl. I decided early on with the repairs and the briar blemishes, that I would apply Fiebing’s Light Brown Leather Dye to the briar surface. I assemble the dying module on my work desk.

The stummel still shows darkened areas from charring and heating. This is especially on the rim and near the top of the bowl. I decided early on with the repairs and the briar blemishes, that I would apply Fiebing’s Light Brown Leather Dye to the briar surface. I assemble the dying module on my work desk. I begin by heating the stummel with a hot air gun. The gun heats and expands the briar helping it to be more receptive to the dye. I then paint the stummel with the aniline dye using a folded pipe cleaner and with each section, I ‘flame it’ by lighting it with the lit candle with the result that the alcohol in the dye combusts leaving behind the dye pigment.

I begin by heating the stummel with a hot air gun. The gun heats and expands the briar helping it to be more receptive to the dye. I then paint the stummel with the aniline dye using a folded pipe cleaner and with each section, I ‘flame it’ by lighting it with the lit candle with the result that the alcohol in the dye combusts leaving behind the dye pigment. I thoroughly apply the dye and fire it making sure the entire stummel has been covered. The stummel is then set aside for several hours to ‘rest’. This allows the new dye to be absorbed into the briar grain.

I thoroughly apply the dye and fire it making sure the entire stummel has been covered. The stummel is then set aside for several hours to ‘rest’. This allows the new dye to be absorbed into the briar grain. With the stummel resting, I turn again to the stem. I apply the full regiment of micromesh pads by wet sanding with pads 1500 to 2400 and dry sanding with pads 3200 to 4000 and 6000 to 12000. Between each set of 3 pads, Obsidian Oil is applied to help condition the stem and to protect from oxidation.

With the stummel resting, I turn again to the stem. I apply the full regiment of micromesh pads by wet sanding with pads 1500 to 2400 and dry sanding with pads 3200 to 4000 and 6000 to 12000. Between each set of 3 pads, Obsidian Oil is applied to help condition the stem and to protect from oxidation.

The newly dyed stummel has been resting for several hours and it’s time to ‘unwrap’ the fire crusted shell. I use a felt buffing wheel mounted on the Dremel at the lowest speed. Using the felt wheel Tripoli compound is applied to the stummel surface.

The newly dyed stummel has been resting for several hours and it’s time to ‘unwrap’ the fire crusted shell. I use a felt buffing wheel mounted on the Dremel at the lowest speed. Using the felt wheel Tripoli compound is applied to the stummel surface. Next, I wipe the stummel with a cotton pad wetted with alcohol not so much to lighten but to remove excess dye ‘clumped up’ that was missed through the buffing process.

Next, I wipe the stummel with a cotton pad wetted with alcohol not so much to lighten but to remove excess dye ‘clumped up’ that was missed through the buffing process. Next, I reunite stem and stummel and apply (stem attachment not shown!) and apply Blue Diamond compound. With a cotton buffing wheel attached to the Dremel, the speed is set at approximately 40% full power and the compound is applied to pipe. After applying the compound, a felt cloth is used to wipe/buff the pipe to remove any compound dust in preparation for adding wax.

Next, I reunite stem and stummel and apply (stem attachment not shown!) and apply Blue Diamond compound. With a cotton buffing wheel attached to the Dremel, the speed is set at approximately 40% full power and the compound is applied to pipe. After applying the compound, a felt cloth is used to wipe/buff the pipe to remove any compound dust in preparation for adding wax. I had observed earlier that the stem was loose. There is too much play with the mortise fitting. To remedy this, I use the smooth end of a drill bit, one-step larger than the airway diameter.

I had observed earlier that the stem was loose. There is too much play with the mortise fitting. To remedy this, I use the smooth end of a drill bit, one-step larger than the airway diameter.  I then heat the mortise carefully with a Bic lighter to warm the vulcanite making it more supple. As the mortise heats, I gently insert the larger drill bit into the airway expanding the diameter of the tenon as I go.

I then heat the mortise carefully with a Bic lighter to warm the vulcanite making it more supple. As the mortise heats, I gently insert the larger drill bit into the airway expanding the diameter of the tenon as I go.  The procedure works well. The mortise-tenon fit is snugger as it should be.

The procedure works well. The mortise-tenon fit is snugger as it should be. Next, just to help guard against dye leeching when the pipe is first put into service, I reheat the stummel and wipe it well with a cotton cloth. This emulates the heating when the pipe is first put into service. Sometimes, newly dyed stummels will leech the dye when they are first used coloring the new steward’s fingers – in this case, Katie’s father! I don’t want this to happen!

Next, just to help guard against dye leeching when the pipe is first put into service, I reheat the stummel and wipe it well with a cotton cloth. This emulates the heating when the pipe is first put into service. Sometimes, newly dyed stummels will leech the dye when they are first used coloring the new steward’s fingers – in this case, Katie’s father! I don’t want this to happen! With the repair having been done to the upper chamber with the filling of the hole with JB Weld, a protective coating of natural Bulgarian yogurt and activated charcoal will help initiate a layer for a carbon cake to develop. The normal healthy cake width for a chamber is the width of a US dime. Not much, but this helps to guard the briar in the fire chamber.

With the repair having been done to the upper chamber with the filling of the hole with JB Weld, a protective coating of natural Bulgarian yogurt and activated charcoal will help initiate a layer for a carbon cake to develop. The normal healthy cake width for a chamber is the width of a US dime. Not much, but this helps to guard the briar in the fire chamber.  I add the charcoal to a small amount of natural yogurt. Sour cream can also be used.

I add the charcoal to a small amount of natural yogurt. Sour cream can also be used. I add charcoal until the mud mixture will not drip off the pipe nail but remains firm.

I add charcoal until the mud mixture will not drip off the pipe nail but remains firm. After putting a pipe cleaner in the airway to guard the draft hole from being obstructed, I then trowel the mud into the chamber and cover the chamber wall thoroughly. The hour is late, so I put the stummel aside for the mud to dry through the night.

After putting a pipe cleaner in the airway to guard the draft hole from being obstructed, I then trowel the mud into the chamber and cover the chamber wall thoroughly. The hour is late, so I put the stummel aside for the mud to dry through the night.

The next day, after rejoining stem and stummel, carnauba wax is applied to the entire pipe. Another cotton cloth buffing wheel is mounted on the Dremel for this purpose and the speed is maintained at 40% full power. After the application of a few coats of wax, the pipe is given a rigorous hand buffing with a microfiber cloth to remove any excess wax and to raise the shine.

The next day, after rejoining stem and stummel, carnauba wax is applied to the entire pipe. Another cotton cloth buffing wheel is mounted on the Dremel for this purpose and the speed is maintained at 40% full power. After the application of a few coats of wax, the pipe is given a rigorous hand buffing with a microfiber cloth to remove any excess wax and to raise the shine. Wow! This Sculpted 3/4 Bent Billiard had some issues to work through. The hole repair and the rim were the largest challenges and I’m pleased with how these repairs turned out. The briar grain is fun and expressive and really made an appearance through the dying and buffing process. I’m pleased and I trust that my future daughter-in-law, Katie, will be pleased as well as she gives this pipe to her father as a gift for his birthday. What makes this gift even more valuable is that this pipe benefits the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!

Wow! This Sculpted 3/4 Bent Billiard had some issues to work through. The hole repair and the rim were the largest challenges and I’m pleased with how these repairs turned out. The briar grain is fun and expressive and really made an appearance through the dying and buffing process. I’m pleased and I trust that my future daughter-in-law, Katie, will be pleased as well as she gives this pipe to her father as a gift for his birthday. What makes this gift even more valuable is that this pipe benefits the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!