Blog by Dal Stanton

I saw this leather wrapped Longchamp on the eBay auction block from a seller in the USA state of Indiana. Up to that point in time, a leather clad pipe was not part of my collection and the price was right when the final minutes ticked off the clock my bid weathered any challengers. The black leather drew my attention with the potential of cleaning the rim for a nice contrast with briar. Here’s the Longchamp that got my attention.  I brought the pipe back to Bulgaria and put it in the For “Pipe Dreamers” Only! online collection and this is where Jason saw the Longchamp. Jason sent me an email and commissioned the Longchamp and expressed satisfaction in being able to help support the work we do here in Bulgaria with the Daughters of Bulgaria. He also said that he heard about The Pipe Steward for the first time when I was interviewed by Brian Levine. Last year, I had a great time being interviewed by Brian Levine of the Pipes Magazine Radio Show! I told the story of how I began restoring pipes as The Pipe Steward and how this intersects with the efforts here in Bulgaria working with the Daughters of Bulgaria. Jason also commissioned a very nice Altinay Tear Drop Lattice Meerschaum which is next on the worktable.

I brought the pipe back to Bulgaria and put it in the For “Pipe Dreamers” Only! online collection and this is where Jason saw the Longchamp. Jason sent me an email and commissioned the Longchamp and expressed satisfaction in being able to help support the work we do here in Bulgaria with the Daughters of Bulgaria. He also said that he heard about The Pipe Steward for the first time when I was interviewed by Brian Levine. Last year, I had a great time being interviewed by Brian Levine of the Pipes Magazine Radio Show! I told the story of how I began restoring pipes as The Pipe Steward and how this intersects with the efforts here in Bulgaria working with the Daughters of Bulgaria. Jason also commissioned a very nice Altinay Tear Drop Lattice Meerschaum which is next on the worktable. After getting the Longchamp to Bulgaria, I took more pictures to get a closer look.

After getting the Longchamp to Bulgaria, I took more pictures to get a closer look.

The nomenclature is stamped into the leather on the left flank of the shank. It reads, LONGCHAMP [over] FRANCE. There is also a stamp of what looks like a horse in motion on the stem.

The nomenclature is stamped into the leather on the left flank of the shank. It reads, LONGCHAMP [over] FRANCE. There is also a stamp of what looks like a horse in motion on the stem. The practice of wrapping briar bowls with leather started in France as a creative and economically savvy way to sell sub-par bowls that were part and parcel of France’s austerity measures during WWII. Pipedia’s article uncovers this bit of pipe history in the article devoted to Longchamp:

The practice of wrapping briar bowls with leather started in France as a creative and economically savvy way to sell sub-par bowls that were part and parcel of France’s austerity measures during WWII. Pipedia’s article uncovers this bit of pipe history in the article devoted to Longchamp:

In 1948 Jean Cassegrain inherited a small shop near the French Theater on the Boulevard Poissonnière in Paris, called “Au Sultan”. Articles for smokers and fountain pens were offered there. Now, the absolute bulk of the pipes Cassegrain found in the inventory was from war-time production and due to the sharp restrictions on pipe production the French government had enforced in 1940, these pipes were of very poor quality and showed large fills. Strictly speaking, they were not marketable now that the French pipe industry produced pipes of pre-war standards again. In this situation Cassegrain had the probably most enlightened moment in his life: he took some of these pipes to a leather worker who clad bowls and shanks in leather. Only the rims of the bowls and the shanks’ faces remained blank.

In 1948 Jean Cassegrain inherited a small shop near the French Theater on the Boulevard Poissonnière in Paris, called “Au Sultan”. Articles for smokers and fountain pens were offered there. Now, the absolute bulk of the pipes Cassegrain found in the inventory was from war-time production and due to the sharp restrictions on pipe production the French government had enforced in 1940, these pipes were of very poor quality and showed large fills. Strictly speaking, they were not marketable now that the French pipe industry produced pipes of pre-war standards again. In this situation Cassegrain had the probably most enlightened moment in his life: he took some of these pipes to a leather worker who clad bowls and shanks in leather. Only the rims of the bowls and the shanks’ faces remained blank.

E voila – the pipes looked pretty good now and were eye-catching enough to become an instant success in sale. Above all among the thousands of Allied soldiers who populated Paris in those days. The thing worked well, and even unexperienced pipesters liked the covered pipes very much for they did not transmit the heat to the hand. Very soon Cassegrain had sold the old stock of pipes, and the leather-clad pipes became his only product. He began to place orders with renowned firms like Ropp or Butz-Choquin.

I love stories of innovation like the story of Jean Cassegrain and the creation of the Longchamp name which came from the name of a horse racing park near Paris. Pipedia concludes the article with this comment:

After 1970 the interest in leather-clad pipes slowly diminished. The Longchamp pipes were offered for the last time in the 1978 catalog though previously placed orders were delivered until 1980.

The splendid success inspired many other renowned producers to offer their own lines Ropp, Butz-Choquin, Gubbels, GBD… Maybe Savinelli was the very last producing them for the label of the famous designer Etienne Aigner.

The dating of the pipe on my table would be no older than 1978. The article also gave sense to the horse stamped on the stem. I found more about this in the Longchamp panel provided on Pipephil.eu. The panel shows the different versions of the very thin, ghosted horse stamping on the Longchamp matches the example on the lower right with the caption stating that this logo was on the more recent stems – so dating is for this pipe is most likely in the 70s. With this knowledge increasing my appreciation of the Longchamp story, I take a closer look at the Longchamp on my worktable. The general condition of the leather appears to be very good. I see no tears. The chamber of the Billiard shape has some cake build up but not bad. The rim is caked with lava flow, but it should clean up nicely revealing the briar beneath. The stem has oxidation and light tooth chatter, but nothing serious. I begin the refreshing of this French Leather Clad Longchamp by addressing the oxidation in the stem. I first clean the airway with pipe cleaners wetted with isopropyl 95%.

With this knowledge increasing my appreciation of the Longchamp story, I take a closer look at the Longchamp on my worktable. The general condition of the leather appears to be very good. I see no tears. The chamber of the Billiard shape has some cake build up but not bad. The rim is caked with lava flow, but it should clean up nicely revealing the briar beneath. The stem has oxidation and light tooth chatter, but nothing serious. I begin the refreshing of this French Leather Clad Longchamp by addressing the oxidation in the stem. I first clean the airway with pipe cleaners wetted with isopropyl 95%. To break up the thick oxidation, 000 steel wool is applied to the stem. I’m careful to avoid the thin Longchamp stamping. I have found that this helps give the oxidation removal a head start before putting the stem into the soak with Before & After Deoxidizer.

To break up the thick oxidation, 000 steel wool is applied to the stem. I’m careful to avoid the thin Longchamp stamping. I have found that this helps give the oxidation removal a head start before putting the stem into the soak with Before & After Deoxidizer. Next into the Before & After Deoxidizer with other stems of pipes in the queue. I leave it in the soak for about 4 hours.

Next into the Before & After Deoxidizer with other stems of pipes in the queue. I leave it in the soak for about 4 hours. When I fish the stem out of the Deoxidizer, I drain and squeegee the liquid off with my fingers. I then put another pipe cleaner wetted with alcohol through the airway to clean it of the Deoxidizer. Then using cotton pads wetted with alcohol, the raised oxidation is wiped off.

When I fish the stem out of the Deoxidizer, I drain and squeegee the liquid off with my fingers. I then put another pipe cleaner wetted with alcohol through the airway to clean it of the Deoxidizer. Then using cotton pads wetted with alcohol, the raised oxidation is wiped off. I like to use paraffin oil to help begin the process of rejuvenating the vulcanite stem. I wipe the oil on with a cotton pad and put the stem aside to absorb the oil.

I like to use paraffin oil to help begin the process of rejuvenating the vulcanite stem. I wipe the oil on with a cotton pad and put the stem aside to absorb the oil. With the stem now on the sideline, I turn to the stummel to begin cleaning out the carbon cake. After putting paper towel down for easier cleanup, I use the Pipnet Reaming Kit to do the job. I take another picture of the chamber to mark the start and I use 2 of the 4 blade heads available. After this, the Savinelli Fitsall tool further scrapes the chamber walls and I finish with sanding the chamber with 240 grade paper wrapped around a Sharpie Pen. I then wipe the chamber with a cotton pad and after inspection, determine that there are no heating problems with the chamber briar.

With the stem now on the sideline, I turn to the stummel to begin cleaning out the carbon cake. After putting paper towel down for easier cleanup, I use the Pipnet Reaming Kit to do the job. I take another picture of the chamber to mark the start and I use 2 of the 4 blade heads available. After this, the Savinelli Fitsall tool further scrapes the chamber walls and I finish with sanding the chamber with 240 grade paper wrapped around a Sharpie Pen. I then wipe the chamber with a cotton pad and after inspection, determine that there are no heating problems with the chamber briar.

Next, cleaning the rim to remove the thick oil and tar crud that has collected will be a job. I do not wish to immerse the leather with Murphy’s, though I don’t think it would be a problem.

Next, cleaning the rim to remove the thick oil and tar crud that has collected will be a job. I do not wish to immerse the leather with Murphy’s, though I don’t think it would be a problem.  So, focusing to keep the cleaning only on the rim, I use Murphy’s Oil Soap undiluted and a cotton pad to begin softening the crusted rim. Using a Winchester pocketknife to scrape the rim, I carefully remove more of the crusting. Finally, I use a bristled brass wire brush to work on the rim and then take the stummel to the sink and rinse the soap from the rim.

So, focusing to keep the cleaning only on the rim, I use Murphy’s Oil Soap undiluted and a cotton pad to begin softening the crusted rim. Using a Winchester pocketknife to scrape the rim, I carefully remove more of the crusting. Finally, I use a bristled brass wire brush to work on the rim and then take the stummel to the sink and rinse the soap from the rim. There’s a huge difference on the rim after the cleaning. It appears that there originally was a bevel on the inside lip of the rim.

There’s a huge difference on the rim after the cleaning. It appears that there originally was a bevel on the inside lip of the rim. Next, to freshen the lines of the rim and to continue to clean the dark stains off the briar, I use the topping board with 240 grade paper. I only rotate the stummel a few times.

Next, to freshen the lines of the rim and to continue to clean the dark stains off the briar, I use the topping board with 240 grade paper. I only rotate the stummel a few times.  A small pit is revealed on the front-left rim after the first round of topping. This will need to be filled.

A small pit is revealed on the front-left rim after the first round of topping. This will need to be filled. I rotate the inverted stummel several more time after transitioning from 240 grade paper to 600.

I rotate the inverted stummel several more time after transitioning from 240 grade paper to 600. To clean the internal rim lip as well as to refresh the internal bevel, I tightly wrap a piece 240 paper and shape the bevel. Following this, I use 600 grade to smooth out the bevel.

To clean the internal rim lip as well as to refresh the internal bevel, I tightly wrap a piece 240 paper and shape the bevel. Following this, I use 600 grade to smooth out the bevel. Next, using cotton buds and pipe cleaners dipped in isopropyl 95% the internal cleaning commences. A small dental spoon is also used to scrape the internal mortise wall removing tars and oil build up. After the cotton buds begin to emerge lighter, I call it clean at this stage.

Next, using cotton buds and pipe cleaners dipped in isopropyl 95% the internal cleaning commences. A small dental spoon is also used to scrape the internal mortise wall removing tars and oil build up. After the cotton buds begin to emerge lighter, I call it clean at this stage. With the hour being late, I transition to utilizing a kosher salt and alcohol soak through the night to continue the internal cleaning. It is my usual practice to do this to refresh the pipe for the new steward. After creating a ‘wick’ by pulling and twisting a cotton ball, the wick is inserted into the mortise using a stiff wire to help guide it down through the mortise into the airway. The wick helps to draw out the residual tar and oil from the briar.

With the hour being late, I transition to utilizing a kosher salt and alcohol soak through the night to continue the internal cleaning. It is my usual practice to do this to refresh the pipe for the new steward. After creating a ‘wick’ by pulling and twisting a cotton ball, the wick is inserted into the mortise using a stiff wire to help guide it down through the mortise into the airway. The wick helps to draw out the residual tar and oil from the briar.  I then fill the bowl with kosher salt which, unlike iodized salt, leaves no aftertaste. After placing the stummel in the egg carton for stability, using a large eye dropper, the bowl is filled with isopropyl 95% until it surfaces over the salt. After a time, the alcohol is drawn into the pipe and after topping off the alcohol, I turn off the lights!

I then fill the bowl with kosher salt which, unlike iodized salt, leaves no aftertaste. After placing the stummel in the egg carton for stability, using a large eye dropper, the bowl is filled with isopropyl 95% until it surfaces over the salt. After a time, the alcohol is drawn into the pipe and after topping off the alcohol, I turn off the lights!

The next morning the salt and wick are soiled the brown showing the additional cleaning this process provided.

The next morning the salt and wick are soiled the brown showing the additional cleaning this process provided.  After cleaning the stummel of the expended kosher salt using a paper towel and blowing forcefully through the mortise, I follow with a few additional pipe cleaners and cotton buds to clean the remaining remnants of tar and oils. All is good and I move on.

After cleaning the stummel of the expended kosher salt using a paper towel and blowing forcefully through the mortise, I follow with a few additional pipe cleaners and cotton buds to clean the remaining remnants of tar and oils. All is good and I move on. Next, addressing the hole on the rim, I first dig out and clean the pitted area using a sharp dental probe.

Next, addressing the hole on the rim, I first dig out and clean the pitted area using a sharp dental probe.

After wiping the area with alcohol to assure that it is clean, I then spot-drop the hole with regular clear CA glue.

After wiping the area with alcohol to assure that it is clean, I then spot-drop the hole with regular clear CA glue. After the CA glue cures, a flat needle file is used to file the patch down. Following the filing, 240 and 600 sanding papers smooth the area further.

After the CA glue cures, a flat needle file is used to file the patch down. Following the filing, 240 and 600 sanding papers smooth the area further. Transitioning then to applying the full regiment of micromesh pads, I wet sand with pads 1500 to 2400 and follow with dry sanding with pads 3200 to 4000 and 6000 to 12000. The micromesh process brings out the grain nicely. I love the briar/leather contrast created by the rim.

Transitioning then to applying the full regiment of micromesh pads, I wet sand with pads 1500 to 2400 and follow with dry sanding with pads 3200 to 4000 and 6000 to 12000. The micromesh process brings out the grain nicely. I love the briar/leather contrast created by the rim.

Applying Before & After Restoration continues to bring out the more subtle hues of the rim’s briar grain. Applying first the Balm with my fingers and working it into the briar, I then set it aside for a few minutes for the Balm to be absorbed. After about 20 minutes I wipe off the excess Balm and buff the rim with a microfiber cloth.

Applying Before & After Restoration continues to bring out the more subtle hues of the rim’s briar grain. Applying first the Balm with my fingers and working it into the briar, I then set it aside for a few minutes for the Balm to be absorbed. After about 20 minutes I wipe off the excess Balm and buff the rim with a microfiber cloth. To treat the black leather, I use ‘Weiman Leather Wipes’ to clean and condition the leather. This product works very well. The leather is very attractive with a clean, healthy sheen.

To treat the black leather, I use ‘Weiman Leather Wipes’ to clean and condition the leather. This product works very well. The leather is very attractive with a clean, healthy sheen.

I put the stummel aside and transition to the stem, which is not in too bad of shape. There are some tooth chatter and compressions on the upper bit which I first address with the heating method. Using a Bic lighter, the bit is painted with the flame heating and expanding the vulcanite. As the vulcanite is heated it expands to reclaim its original shaping – or closer. The pictures show a before and after comparison. The compressions are still visible but much reduced.

I put the stummel aside and transition to the stem, which is not in too bad of shape. There are some tooth chatter and compressions on the upper bit which I first address with the heating method. Using a Bic lighter, the bit is painted with the flame heating and expanding the vulcanite. As the vulcanite is heated it expands to reclaim its original shaping – or closer. The pictures show a before and after comparison. The compressions are still visible but much reduced. I follow by sanding the upper and lower bit using 240 grade paper to erase the residual chatter and what remains of the compressions.

I follow by sanding the upper and lower bit using 240 grade paper to erase the residual chatter and what remains of the compressions. I then take the stem to the kitchen sink and wet sand the entire stem using 600 grade paper – careful not to sand the very thin running horse stamping on the stem. Following the 600 grade paper, 000 grade steel wool is applied to smooth further.

I then take the stem to the kitchen sink and wet sand the entire stem using 600 grade paper – careful not to sand the very thin running horse stamping on the stem. Following the 600 grade paper, 000 grade steel wool is applied to smooth further. Next, I transition directly to applying micromesh pads to the stem by wet sanding with pads 1500 to 2400 then dry sanding with pads 3200 to 4000 and 6000 to 12000. Between each set of 3 pads, Obsidian Oil is applied to rejuvenate the vulcanite as well as helping to prevent oxidation.

Next, I transition directly to applying micromesh pads to the stem by wet sanding with pads 1500 to 2400 then dry sanding with pads 3200 to 4000 and 6000 to 12000. Between each set of 3 pads, Obsidian Oil is applied to rejuvenate the vulcanite as well as helping to prevent oxidation.

On the home stretch – after mounting a cotton cloth buffing wheel to the Dremel, with the speed set at about 40% full power, Blue Diamond compound, a fine abrasive, is applied to the stem and briar rim. Following this, after another buffing wheel has been mounted at the same speed, carnauba wax is applied to the stem and briar rim. The restoration is completed with a rigorous hand-buffing to raise the shine of both the stem and briar rim, but also the black leather wrap.

On the home stretch – after mounting a cotton cloth buffing wheel to the Dremel, with the speed set at about 40% full power, Blue Diamond compound, a fine abrasive, is applied to the stem and briar rim. Following this, after another buffing wheel has been mounted at the same speed, carnauba wax is applied to the stem and briar rim. The restoration is completed with a rigorous hand-buffing to raise the shine of both the stem and briar rim, but also the black leather wrap. This Leather Clad French Longchamp is a nice pipe. The leather gives that comfortable laid-back feel and the contrasting briar rim and white seams of stitching provide a great aesthetic presentation. The classic Billiard workhorse shape has a great feel and balance in the hand – ready for a new steward! Jason has the first opportunity to claim this French Longchamp from The Pipe Steward Store benefiting the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!

This Leather Clad French Longchamp is a nice pipe. The leather gives that comfortable laid-back feel and the contrasting briar rim and white seams of stitching provide a great aesthetic presentation. The classic Billiard workhorse shape has a great feel and balance in the hand – ready for a new steward! Jason has the first opportunity to claim this French Longchamp from The Pipe Steward Store benefiting the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!

I took the small jars out of the box and took several pictures of them. They had an ivory colored label with black images and lettering on them. There were six different snuffs in the box. These included Menthus, Menthus Plus, Aperitif, French Carotte, Carnation and Oriental. These different varieties were described in the booklet that came with the snuffs. I have included photos of the booklet below.

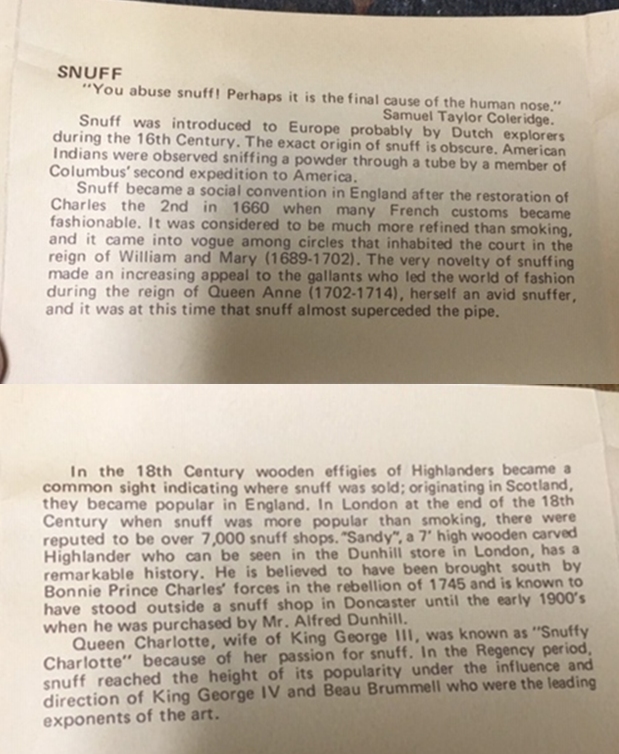

I took the small jars out of the box and took several pictures of them. They had an ivory colored label with black images and lettering on them. There were six different snuffs in the box. These included Menthus, Menthus Plus, Aperitif, French Carotte, Carnation and Oriental. These different varieties were described in the booklet that came with the snuffs. I have included photos of the booklet below. The pamphlet had a cover with two figures on each side of an oval sign that read Alfred Dunhill Special Snuff and was written by Richard Dunhill. The backside read Dunhill with a crest that read By Appointment to Her Majesty the Queen (over) Suppliers of Smoking Requisites (over) Alfred Dunhill London.

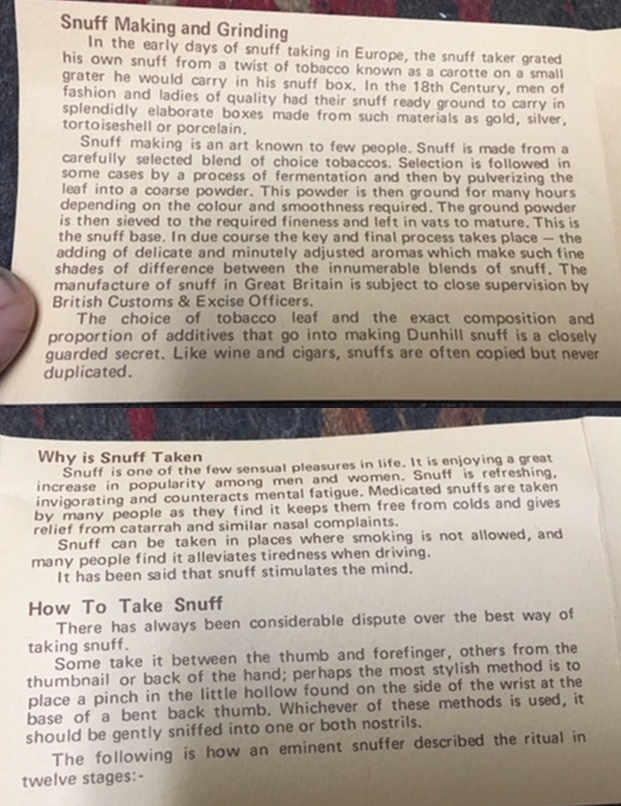

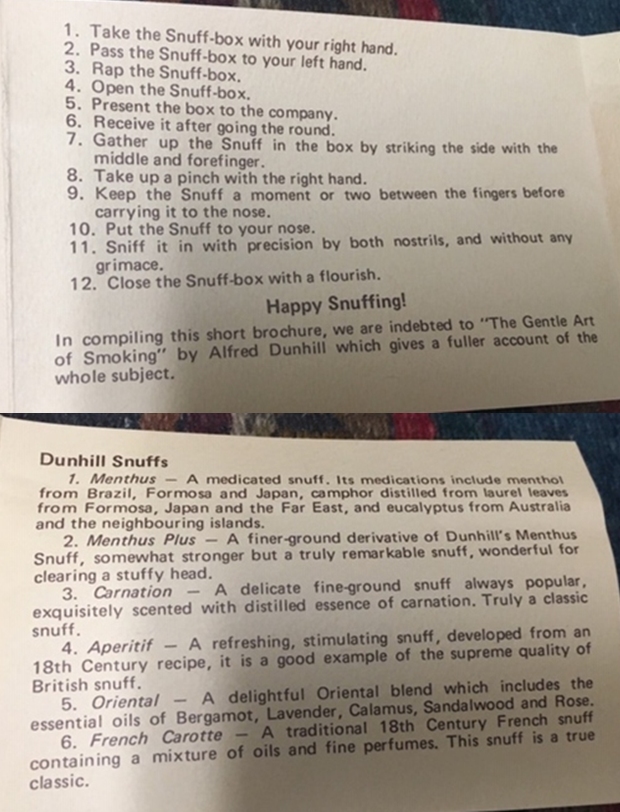

The pamphlet had a cover with two figures on each side of an oval sign that read Alfred Dunhill Special Snuff and was written by Richard Dunhill. The backside read Dunhill with a crest that read By Appointment to Her Majesty the Queen (over) Suppliers of Smoking Requisites (over) Alfred Dunhill London.  Inside was an interesting article written by Richard Dunhill himself. On one side it gave a series of paragraphs including Snuff Making and Grinding, Why is Snuff Taken, How to Take Snuff, Happy Snuffing. The other side had a Description of the Snuffs included in the sampler and a brief History of Snuff. I have included the pages below for your reading pleasure. Richard Dunhill had a way with words as both his book and this pamphlet show.

Inside was an interesting article written by Richard Dunhill himself. On one side it gave a series of paragraphs including Snuff Making and Grinding, Why is Snuff Taken, How to Take Snuff, Happy Snuffing. The other side had a Description of the Snuffs included in the sampler and a brief History of Snuff. I have included the pages below for your reading pleasure. Richard Dunhill had a way with words as both his book and this pamphlet show.

Each of the bottles of snuff was described clearly in the pamphlet. Those descriptions are interesting so I have included them here.

Each of the bottles of snuff was described clearly in the pamphlet. Those descriptions are interesting so I have included them here.