Blog by Dal Stanton

One of the ways I can help benefit women and girls who have been trafficked and sexually exploited – the Daughters of Bulgaria,is by fashioning Churchwardens from discarded repurposed bowls. I enjoy taking discarded bowls, no longer serving any purpose, and after restoring them, mounting them on the fore of a long, flowing Warden stem. Suddenly, the metamorphosis is realized – the neglected and discarded again becomes a treasure, sought after with great value. John, from Utah, saw another CW I created – Fashioning a Churchwarden from a Dimpled Bent Billiard Bowl when I posted it on the Old Codgers Smoking Pipe Facebook group, and he reached out to me to explore commissioning a Churchwarden for himself. This was the Dimpled Bent Billiard Churchwarden got his attention: After some months, John’s CW project finally worked its way through the queue, patience always appreciated(!) – and as I told him before, when his project was on the worktable, I would contact him with choices for a bowl. I spread out a selection of bowls next to a Warden stem and ruler. The selection included bent and straight shanks and smooth and rusticated surfaces – and different shapes. The unique thing about the Churchwarden shape is that its designation is not determined primarily by the shape of the bowl but by the length of the stem. After taking a few pictures, and sending them to John, he made his choice.

After some months, John’s CW project finally worked its way through the queue, patience always appreciated(!) – and as I told him before, when his project was on the worktable, I would contact him with choices for a bowl. I spread out a selection of bowls next to a Warden stem and ruler. The selection included bent and straight shanks and smooth and rusticated surfaces – and different shapes. The unique thing about the Churchwarden shape is that its designation is not determined primarily by the shape of the bowl but by the length of the stem. After taking a few pictures, and sending them to John, he made his choice. John’s chose a very nice-looking sculpted Apple shape pictured on the right, in the middle. Through this choice, he expressed that he preferred a straight rather than a slightly bent Warden stem. When I pulled that bowl aside and took a closer look at the shank, I discovered that on the left side was stamped the name, ‘Howal’ [over] ‘Bruyere’.

John’s chose a very nice-looking sculpted Apple shape pictured on the right, in the middle. Through this choice, he expressed that he preferred a straight rather than a slightly bent Warden stem. When I pulled that bowl aside and took a closer look at the shank, I discovered that on the left side was stamped the name, ‘Howal’ [over] ‘Bruyere’. Howal is not a well-known name in the West, but I became familiar with it after seeing several Howals here in Bulgaria – formerly under the Warsaw Pact, behind the Iron Curtain of the Former USSR. Having previously restored a Howal – a rusticated Dublin, I enjoyed the research of the Howal name which was a mystery to me. My research uncovered not only the origins of the pipe in former East Germany, but that the city where Howals were produced was a historical center for pipe manufacturing in Germany that pre-dated WW2. A fascinating story that I wrote of in this restoration: Checkered History and Heritage of an East German Howal Old Briar Rustified Dublin.

Howal is not a well-known name in the West, but I became familiar with it after seeing several Howals here in Bulgaria – formerly under the Warsaw Pact, behind the Iron Curtain of the Former USSR. Having previously restored a Howal – a rusticated Dublin, I enjoyed the research of the Howal name which was a mystery to me. My research uncovered not only the origins of the pipe in former East Germany, but that the city where Howals were produced was a historical center for pipe manufacturing in Germany that pre-dated WW2. A fascinating story that I wrote of in this restoration: Checkered History and Heritage of an East German Howal Old Briar Rustified Dublin.

Pipedia’s article that I sited in that write up was both interesting and helpful in understanding the predecessor of and origins of the Howal name:

C.S. Reich was founded by Carl Sebastian Reich in Schweina, Germany in 1887. By its 50th jubilee in 1937 C.S. Reich was the biggest pipe factory in Germany. In 1952, however, the owners of the company were imprisoned and the company itself was nationalized as Howal, an abbreviation of the German words for “wood products Liebenstein” or “Holzwaren Liebenstein”. By the 1970’s Howal, after acquiring many other smaller pipe making firms, was the sole maker of smoking pipes in East Germany. In 1990, with the fall of the Berlin Wall and reunification of the Germanys, the company was closed.

As I reread that previous research on the history of the Howal name for this write-up, I decided to restate my observations in full because I don’t restore Howals often and the history and human story draws me to retell the story as I transform this Howal bowl into a Churchwarden. From the previous restoration (my present comments in brackets):

While helpful for a broad sweep, I discovered much missing from this [Pipedia] summary and it raises more questions. From another interesting source, Edith Raddatz’s lecture on tobacco pipe production in Schweina [a link which unfortunately is no longer working!] at the Tobacco Pipe Symposium in 2003, it describes a history of pipe production in this central German village that was reminiscent of my research into France’s pipe mecca, St. Claude. A strong development of the pipe making industry can be traced in the 1800s to the apex of the C.S. Reich Co. being Germany’s largest pipe producer in 1937, but Raddatz’s lecture reveals that other producers of pipes were also based in the German village of Schweina. Pipedia’s article above describes how the owners of the C.S. Reich Co. were arrested and imprisoned followed by the nationalization of the Reich Co. and becoming ‘Howal’, an acronym for “Wood Products Liebenstein” – Bad Liebenstein was the town that bordered and absorbed the village of Schweina. The question begs to be asked – which, unfortunately introduces the human tragedy wrapped around the name ‘Howal’ – Why were the owners arrested? In an unlikely source, the website of the ‘Small Tools Museum’ adds the names of those imprisoned: shareholders Robert Hergert and Karl Reich.

Edith Raddatz’s lecture (referenced above) brings more light to the difficult geopolitical realities these people faced (Google translated from German – brackets my clarifications):

By 1945 the company, which had meanwhile [passed to] the next generation – Kurt Reich And Walter Malsch – [had] about 100 employees. Among them were many women who mainly did the painting work. At the beginning of the 1950s, an era ended in Schweina. The first [oldest] tobacco pipe factory in Schweina closed their doors. There were several reasons for this. Kurt Reich passed away in 1941, [and] Walter Malsch [in] 1954. The political situation in the newly founded GDR made the conditions for private entrepreneurship difficult. The heirs of the company “AR Sons” [Reich family] partly moved to West Germany. The operation was nationalized, and later toys were made there.

In post WWII occupied Germany, the Soviet occupied section was declared to be a sovereign state and the German Democratic Republic (GDR) was established in 1949 (See link). With a rudimentary understanding of Marxism and the economic philosophy undergirding it, it is not difficult to deduce what brought the demise of the C. S. Reich Co. and the formation of Howal. Solidification of the FDR’s hold on power paralleled the necessity to nationalize private ownership and to institute a State-centered command economy. These efforts gained momentum and forced companies/workers to work more with no additional pay. In 1952, the year that the owners of C. S. Reich Co., were arrested, this edict was advanced (See link):

state and the German Democratic Republic (GDR) was established in 1949 (See link). With a rudimentary understanding of Marxism and the economic philosophy undergirding it, it is not difficult to deduce what brought the demise of the C. S. Reich Co. and the formation of Howal. Solidification of the FDR’s hold on power paralleled the necessity to nationalize private ownership and to institute a State-centered command economy. These efforts gained momentum and forced companies/workers to work more with no additional pay. In 1952, the year that the owners of C. S. Reich Co., were arrested, this edict was advanced (See link):

In July 1952 the second party conference of the Socialist Unity Party of Germany (SED) took place in East Berlin. In SED General Secretary Walter Ulbricht‘s words, there was to be the “systematic implementation of Socialism” (planmäßiger Aufbau des Sozialismus); it was decided that the process of Sovietization should be intensified and the importance of the state expanded. The party was acting on demands made by Soviet premier Joseph Stalin.[2]

As a result, today Germany remembers the Uprising of 1953 which started in East Berlin, as factory workers revolted against the repression of the GDR, and spread to all East Germany. Many lost their lives as Moscow responded to squelch the unrest with tanks on the streets. In play also, was the mass exodus of people fleeing to West Germany, which included, per Edith Radditz’s lecture, the Reich family, who would have been heirs of the family’s legacy and company – pipe making. Also, in 1953, completing the State forced abolition of any Reich claim, the largest pipe making company of Germany was seized, nationalized, and changed from C. S. Reich Co. to Howal. As ‘Howal’, pipes continued to be produced, undoubtedly with the same hands and sweat of the people of Schweina, along with other wooden products, such as toys. In the Pipedia article I quoted above, it said:

As a result, today Germany remembers the Uprising of 1953 which started in East Berlin, as factory workers revolted against the repression of the GDR, and spread to all East Germany. Many lost their lives as Moscow responded to squelch the unrest with tanks on the streets. In play also, was the mass exodus of people fleeing to West Germany, which included, per Edith Radditz’s lecture, the Reich family, who would have been heirs of the family’s legacy and company – pipe making. Also, in 1953, completing the State forced abolition of any Reich claim, the largest pipe making company of Germany was seized, nationalized, and changed from C. S. Reich Co. to Howal. As ‘Howal’, pipes continued to be produced, undoubtedly with the same hands and sweat of the people of Schweina, along with other wooden products, such as toys. In the Pipedia article I quoted above, it said:

By the 1970’s Howal, after acquiring many other smaller pipe making firms, was the sole maker of smoking pipes in East Germany. In 1990, with the fall of the Berlin Wall and reunification of the Germanys, the company was closed.

My curiosity piqued, what does it mean when it says that Howal acquired many other smaller pipe making firms? Should we question whether these words can be understood in the normal free market enterprise way we are accustomed? Doubtful.

…So, as I had written before regarding the checkered history of the Howal name. Now, as I look again at the Howal sculpted Apple bowl on my worktable, I take a few more pictures to mark the starting point and to take a closer look.

I very much like John’s choice of a bowl to fashion a Churchwarden. The sculpting of the classic Apple shape will look very nice as a Warden – with a rustic, ‘Olde World’ look to it. The condition of the Howal bowl is generally good. The chamber has a heavy cake which will be removed to give the briar a fresh start and to check the chamber wall for heating problems. The rim has some crusting lava overflow that needs cleaning. The rusticated surface with the intricate ribs carved into the sculpting also needs scrubbing to remove grime lodged in the wood. Before working on the stem, I start the Howal Churchwarden project by using the Pipnet Reaming Kit. After taking a picture of the chamber showing the tightening chamber as the cake thickens, I use the two smallest blade heads of the 4 available and ream the chamber. The cake proves to be stubborn – hard as a brick. After the Pipnet Kit, transitioning to the Savinelli Fitsall Tool, clearing the cake continues as the tool scrapes the chamber wall. Finishing this phase, I wrap 240 paper around a Sharpie Pen and sand the walls and then wipe the excess carbon dust with a cotton pad wetted with alcohol.

I very much like John’s choice of a bowl to fashion a Churchwarden. The sculpting of the classic Apple shape will look very nice as a Warden – with a rustic, ‘Olde World’ look to it. The condition of the Howal bowl is generally good. The chamber has a heavy cake which will be removed to give the briar a fresh start and to check the chamber wall for heating problems. The rim has some crusting lava overflow that needs cleaning. The rusticated surface with the intricate ribs carved into the sculpting also needs scrubbing to remove grime lodged in the wood. Before working on the stem, I start the Howal Churchwarden project by using the Pipnet Reaming Kit. After taking a picture of the chamber showing the tightening chamber as the cake thickens, I use the two smallest blade heads of the 4 available and ream the chamber. The cake proves to be stubborn – hard as a brick. After the Pipnet Kit, transitioning to the Savinelli Fitsall Tool, clearing the cake continues as the tool scrapes the chamber wall. Finishing this phase, I wrap 240 paper around a Sharpie Pen and sand the walls and then wipe the excess carbon dust with a cotton pad wetted with alcohol.

After completing the removal of the cake and cleaning the walls, an inspection reveals no heating problems. I move on.

After completing the removal of the cake and cleaning the walls, an inspection reveals no heating problems. I move on. Next, using undiluted Murphy’s Oil Soap I begin the external cleaning. I also employ a bristled toothbrush to get into the crevasses of the sculpted vertical sweeps, which are more detailed upon closer inspection. Within each crevasse, fine lines have been carved to provide a classier sculpted appearance. I like it. From the picture above, the lava flow caking on the rim is evident. A brass brush helps with removal of the crusting without damaging the briar underneath. The sharp edge of my Winchester pocketknife also helps as I carefully scrape the rim surface.

Next, using undiluted Murphy’s Oil Soap I begin the external cleaning. I also employ a bristled toothbrush to get into the crevasses of the sculpted vertical sweeps, which are more detailed upon closer inspection. Within each crevasse, fine lines have been carved to provide a classier sculpted appearance. I like it. From the picture above, the lava flow caking on the rim is evident. A brass brush helps with removal of the crusting without damaging the briar underneath. The sharp edge of my Winchester pocketknife also helps as I carefully scrape the rim surface.

From the worktable, I take the bowl to the sink and there using different sized long shank brushes with some anti-oil dish soap, I scrub the internal mortise under warm water. After a thorough rinsing of the soap, I bring the bowl back to the worktable. The cleaning did a good job.

From the worktable, I take the bowl to the sink and there using different sized long shank brushes with some anti-oil dish soap, I scrub the internal mortise under warm water. After a thorough rinsing of the soap, I bring the bowl back to the worktable. The cleaning did a good job.  I can now see the rim more clearly with a cut on the right side and some light damage on the left.

I can now see the rim more clearly with a cut on the right side and some light damage on the left.

The cleaning also reveals the residue of old finish on the smooth briar which shows up dark and shiny in the picture. I’ll remove these patches with sanding.

The cleaning also reveals the residue of old finish on the smooth briar which shows up dark and shiny in the picture. I’ll remove these patches with sanding. Starting with the rim, I take another picture showing the damage on the top and the bottom of the picture’s orientation. The rim is sloped downwardly to form beveled rim peak. This is attractive and accentuates the Apple shape’s peaked rim.

Starting with the rim, I take another picture showing the damage on the top and the bottom of the picture’s orientation. The rim is sloped downwardly to form beveled rim peak. This is attractive and accentuates the Apple shape’s peaked rim.  Going with this flow, I use 240 grade paper and sand the rim to freshen the lines and to remove the damage. I show a few pictures to show the freshening progression.

Going with this flow, I use 240 grade paper and sand the rim to freshen the lines and to remove the damage. I show a few pictures to show the freshening progression.

I follow the 240 paper by dry sanding with 600 grade paper on the rim. I’m liking the emergence of a smooth grain contrast underneath. A few blemishes remain on the rim at this point but I like the more rustic look – some imperfections on the rim accents the overall look.

I follow the 240 paper by dry sanding with 600 grade paper on the rim. I’m liking the emergence of a smooth grain contrast underneath. A few blemishes remain on the rim at this point but I like the more rustic look – some imperfections on the rim accents the overall look. Next, to address the patches of old, dark shiny finish on the bowl’s surface, I dry sand using a 1500 micromesh pad to remove the old finish patches from the smooth briar surfaces of the sculpted motif. I intentionally leave the rough rusticated briar in the sculpting untouched to preserve the original, darkened patina. I’m aiming for an attractive contrast between the smooth briar, which will naturally lighten through the restoration process, revealing briar grain, with the rough, darkened sculpted briar.

Next, to address the patches of old, dark shiny finish on the bowl’s surface, I dry sand using a 1500 micromesh pad to remove the old finish patches from the smooth briar surfaces of the sculpted motif. I intentionally leave the rough rusticated briar in the sculpting untouched to preserve the original, darkened patina. I’m aiming for an attractive contrast between the smooth briar, which will naturally lighten through the restoration process, revealing briar grain, with the rough, darkened sculpted briar.

Not forgetting where I am in the cleaning process, I return to working on the internals with cotton buds and pipe cleaners dipped in isopropyl 95% – the strongest rubbing/cleaning alcohol available to me here in Bulgaria. For a smaller Apple bowl, the internals were rife with old oils and tars. I also did much excavation of tars and oils using the small dental spoon as well as drill bits. With the bits, I hand turn a bit that is the same size as the drilling diameter which scrapes the wall. The gunk seemed to have no end, yet finally, the cotton buds started to lighten, and I call the cleaning provisionally finished. Later, I’ll continue the cleaning and refreshing of the internals by using a kosher salt and alcohol soak.

Not forgetting where I am in the cleaning process, I return to working on the internals with cotton buds and pipe cleaners dipped in isopropyl 95% – the strongest rubbing/cleaning alcohol available to me here in Bulgaria. For a smaller Apple bowl, the internals were rife with old oils and tars. I also did much excavation of tars and oils using the small dental spoon as well as drill bits. With the bits, I hand turn a bit that is the same size as the drilling diameter which scrapes the wall. The gunk seemed to have no end, yet finally, the cotton buds started to lighten, and I call the cleaning provisionally finished. Later, I’ll continue the cleaning and refreshing of the internals by using a kosher salt and alcohol soak.

Now to the stem fabrication. I cease the stummel work at this point because there will be additional sanding as I size and sand the stem with the shank. I take a few pictures to mark the starting point. John prefers a straight stem for his Churchwarden which is not a problem. The precast Warden stem has a very slight bend as it arrived on my table. This will remain as it helps with maintaining the up/down orientation of the mounted stem.

Now to the stem fabrication. I cease the stummel work at this point because there will be additional sanding as I size and sand the stem with the shank. I take a few pictures to mark the starting point. John prefers a straight stem for his Churchwarden which is not a problem. The precast Warden stem has a very slight bend as it arrived on my table. This will remain as it helps with maintaining the up/down orientation of the mounted stem.  The picture below shows the rough tenon oversizing which will be shaped to form a good junction with the Howal shank and tenon seating in the mortise.

The picture below shows the rough tenon oversizing which will be shaped to form a good junction with the Howal shank and tenon seating in the mortise.  No shank/stem fitting is the same which means that sanding and finetuning the junction is always required. The picture below illustrates this – the mortise drilling is slightly higher in the mortise which means that the upper thickness of the shank/mortise briar will be thinner and the lower will be slightly thicker. Shaping the stem fit must factor this offset.

No shank/stem fitting is the same which means that sanding and finetuning the junction is always required. The picture below illustrates this – the mortise drilling is slightly higher in the mortise which means that the upper thickness of the shank/mortise briar will be thinner and the lower will be slightly thicker. Shaping the stem fit must factor this offset. The first step in fashioning the CW stem is to size the tenon. I use the PIMO Tenon Turning Tool that I purchased from Vermont Freehand. I keep the instructions tacked on the wall in front of me for a reminder and safe keeping! A very useful tool to have for fashioning tenons.

The first step in fashioning the CW stem is to size the tenon. I use the PIMO Tenon Turning Tool that I purchased from Vermont Freehand. I keep the instructions tacked on the wall in front of me for a reminder and safe keeping! A very useful tool to have for fashioning tenons. First, using an electronic caliper to measure the diameter of the mortise marks the target sizing of the tenon of the precast stem. The mortise measurement is 7.95mm in diameter. Using Charles Lemon’s (of Dad’s Pipes) methodology, I add about 50mm to this exact measurement to give me my ‘fat’ target. The ‘fat’ target is what I will aim for when bringing the tenon down to size using the PIMO Tenon Turning Tool. The ‘fat’ target (7.95mm minus 50mm) is about 8.45mm. From this ‘fat’ point, I will sand the tenon by hand which gradually and patiently custom sizes the tenon to the mortise.

First, using an electronic caliper to measure the diameter of the mortise marks the target sizing of the tenon of the precast stem. The mortise measurement is 7.95mm in diameter. Using Charles Lemon’s (of Dad’s Pipes) methodology, I add about 50mm to this exact measurement to give me my ‘fat’ target. The ‘fat’ target is what I will aim for when bringing the tenon down to size using the PIMO Tenon Turning Tool. The ‘fat’ target (7.95mm minus 50mm) is about 8.45mm. From this ‘fat’ point, I will sand the tenon by hand which gradually and patiently custom sizes the tenon to the mortise. The first thing needed is to pre-drill the tenon airway with the drill bit provided by the PIMO tool. This enlarges the airway slightly enabling the insertion of the PIMO tool guide pin. I mount the drill bit to the hand drill and drill out the airway.

The first thing needed is to pre-drill the tenon airway with the drill bit provided by the PIMO tool. This enlarges the airway slightly enabling the insertion of the PIMO tool guide pin. I mount the drill bit to the hand drill and drill out the airway. Next, the PIMO Tenon Turning Tool is mounted on the hand drill and I cut a small test sizing to give me the distance between the test cut and the ‘Fat’ target. After cutting the test, I measure with the caliper and record 9.23mm and subtract the ‘Fat’ target, 8.45mm, leaving about .78mm to remove using the PIMO tool.

Next, the PIMO Tenon Turning Tool is mounted on the hand drill and I cut a small test sizing to give me the distance between the test cut and the ‘Fat’ target. After cutting the test, I measure with the caliper and record 9.23mm and subtract the ‘Fat’ target, 8.45mm, leaving about .78mm to remove using the PIMO tool.

Using the Allen wrench provided with the PIMO tool, I close the gap of the cutting arm and cut again. I only cut a small portion out of the end of the tenon and then measure – this additional test cut guards from taking off too much. The measurement of this test cut after closing the gap of the carbide cutter arm is 8.45mm. On the button! I finish the cut to the stem facing and begin sanding the tenon down.

Using the Allen wrench provided with the PIMO tool, I close the gap of the cutting arm and cut again. I only cut a small portion out of the end of the tenon and then measure – this additional test cut guards from taking off too much. The measurement of this test cut after closing the gap of the carbide cutter arm is 8.45mm. On the button! I finish the cut to the stem facing and begin sanding the tenon down.

Using 240 grade paper, I uniformly sand the tenon so that the fit is snug, but not too snug. As I sand the tenon, I often test the progress by inserting the tenon into the mortise. I NEVER force the tenon to make it fit – a cracking sound of a shank is not a happy thing!

Using 240 grade paper, I uniformly sand the tenon so that the fit is snug, but not too snug. As I sand the tenon, I often test the progress by inserting the tenon into the mortise. I NEVER force the tenon to make it fit – a cracking sound of a shank is not a happy thing! I come to a point where the end of the tenon was butting up against the closing ridge from the mortise drilling. I could detect the bump in the mortise. Using the sanding paper and a flat needle file, I focus on tapering the end of the tenon so that it can navigate the narrowing mortise. I don’t want to cut off the end of the tenon as a longer tenon provides a bit more strength for the longer stem’s reach.

I come to a point where the end of the tenon was butting up against the closing ridge from the mortise drilling. I could detect the bump in the mortise. Using the sanding paper and a flat needle file, I focus on tapering the end of the tenon so that it can navigate the narrowing mortise. I don’t want to cut off the end of the tenon as a longer tenon provides a bit more strength for the longer stem’s reach. Finally, a good snug fit it accomplished and the stem is seated well.

Finally, a good snug fit it accomplished and the stem is seated well.  The next step in the project is to fashion the shank around the new stem. The pictures following show the overbite of the shank which needs sanding.

The next step in the project is to fashion the shank around the new stem. The pictures following show the overbite of the shank which needs sanding. To protect the Howal nomenclature and provide a sanding barrier, I wrap masking tape around the shank. Using 240 sanding paper, I begin the process of sanding to bring the shank and stem into alignment.

To protect the Howal nomenclature and provide a sanding barrier, I wrap masking tape around the shank. Using 240 sanding paper, I begin the process of sanding to bring the shank and stem into alignment.  After making good progress, I discover a dimple at the seam of the precast stem just at the tenon facing. I’ve seen this before. To take the dimple out by sanding also will remove the corresponding briar on the shank side. This I don’t wish to do more than is necessary. I could also use the PIMO Tool to shave off more of the facing to remove the dimple. Yet this would shorten the overall length of the Warden stem – not a good solution either.

After making good progress, I discover a dimple at the seam of the precast stem just at the tenon facing. I’ve seen this before. To take the dimple out by sanding also will remove the corresponding briar on the shank side. This I don’t wish to do more than is necessary. I could also use the PIMO Tool to shave off more of the facing to remove the dimple. Yet this would shorten the overall length of the Warden stem – not a good solution either.  To remedy the dimple, after cleaning the area with a cotton pad wetted with alcohol, I spot drop regular CA glue on the dimple and immediately give it a spray of an accelerator so that the glue patch stays in place. I don’t want CA glue running down the tenon facing!

To remedy the dimple, after cleaning the area with a cotton pad wetted with alcohol, I spot drop regular CA glue on the dimple and immediately give it a spray of an accelerator so that the glue patch stays in place. I don’t want CA glue running down the tenon facing! Shortly after, I rejoin the stem and Howal stummel and continue sanding the patch area. The patch did the trick. The pictures show the results and the shank and stem are now in alignment. I move on.

Shortly after, I rejoin the stem and Howal stummel and continue sanding the patch area. The patch did the trick. The pictures show the results and the shank and stem are now in alignment. I move on.

Even though a precast Warden stem is new, it doesn’t arrive on the scene ready for action. Precast stems will usually not have smooth surfaces but tend to be ‘wavy’ – a leftover from the casting process. Therefore, sanding the entire stem is necessary. To do the initial rough sanding of the stem I use a coarse 120 paper to do the heavy lifting. As I sand the stem, the first picture below reveals what I’m describing as sanding reveals the rippled surface.

Even though a precast Warden stem is new, it doesn’t arrive on the scene ready for action. Precast stems will usually not have smooth surfaces but tend to be ‘wavy’ – a leftover from the casting process. Therefore, sanding the entire stem is necessary. To do the initial rough sanding of the stem I use a coarse 120 paper to do the heavy lifting. As I sand the stem, the first picture below reveals what I’m describing as sanding reveals the rippled surface.  After much sanding and bothersome rubber dust(!), the stem is shaping up well. I’m liking what I’m seeing.

After much sanding and bothersome rubber dust(!), the stem is shaping up well. I’m liking what I’m seeing. With the rough sanding of the stem-proper done, I shape the button using the 120 grade paper and a flat needle file. The first two pictures show the starting point and sanding – upper then lower.

With the rough sanding of the stem-proper done, I shape the button using the 120 grade paper and a flat needle file. The first two pictures show the starting point and sanding – upper then lower.

My day is ending, and the final project is to continue the internal cleaning and refreshing of the stummel. To do this I use kosher salt and isopropyl 95% to give the internals a soak which helps draw out the tars and oils embedded in the internal briar. I first stretch and twist a cotton ball to serve as a ‘wick’ that helps draw the oils out of the mortise walls.

My day is ending, and the final project is to continue the internal cleaning and refreshing of the stummel. To do this I use kosher salt and isopropyl 95% to give the internals a soak which helps draw out the tars and oils embedded in the internal briar. I first stretch and twist a cotton ball to serve as a ‘wick’ that helps draw the oils out of the mortise walls.  Using a stiff wire, I guide the wick down the mortise and airway. I then fill the bowl with kosher salt – kosher doesn’t leave an aftertaste as iodized salt.

Using a stiff wire, I guide the wick down the mortise and airway. I then fill the bowl with kosher salt – kosher doesn’t leave an aftertaste as iodized salt.  After placing the stummel in an egg carton that keeps it stable, with a large eyedropper I fill the bowl with isopropyl 95% until the alcohol surfaces over the salt. After a few minutes, the alcohol is absorbed, and I refill the bowl with alcohol. I put the stummel aside to soak through the night.

After placing the stummel in an egg carton that keeps it stable, with a large eyedropper I fill the bowl with isopropyl 95% until the alcohol surfaces over the salt. After a few minutes, the alcohol is absorbed, and I refill the bowl with alcohol. I put the stummel aside to soak through the night.

The next morning, the salt and wick are soiled indicating the activity of the soak through the night. I toss the expended salt in the waste, wipe the chamber with paper towel and blow through the mortise to dislodge any salt crystals left behind. To make sure all is clean, I again employ a pipe cleaner and cotton buds dipped in isopropyl 95% to finish the cleaning. Not long after, the buds are emerging clean. I move on.

The next morning, the salt and wick are soiled indicating the activity of the soak through the night. I toss the expended salt in the waste, wipe the chamber with paper towel and blow through the mortise to dislodge any salt crystals left behind. To make sure all is clean, I again employ a pipe cleaner and cotton buds dipped in isopropyl 95% to finish the cleaning. Not long after, the buds are emerging clean. I move on.

I return now to a reunited stem and stummel, using 240 sanding paper I now start the fine tuning of the stem after the coarse 120 paper.

I return now to a reunited stem and stummel, using 240 sanding paper I now start the fine tuning of the stem after the coarse 120 paper.  To show the completed condition of the stem after the 240 grade paper sanding, two close-ups show the improved texture of the sanded surface.

To show the completed condition of the stem after the 240 grade paper sanding, two close-ups show the improved texture of the sanded surface. Next, for more fine tuning of the stem’s surface, I wet sand with 600 grade paper and follow by applying a buff with 000 grade steel wool. I love to see the emergence of the buffed-up vulcanite stem! I keep the stem and stummel united throughout the sanding process to assure that the stem’s tenon facing remains sharp and in alignment with the shank – shouldering the stem is not an option!

Next, for more fine tuning of the stem’s surface, I wet sand with 600 grade paper and follow by applying a buff with 000 grade steel wool. I love to see the emergence of the buffed-up vulcanite stem! I keep the stem and stummel united throughout the sanding process to assure that the stem’s tenon facing remains sharp and in alignment with the shank – shouldering the stem is not an option! Turning back to the Howal bowl, I remove the masking tape and take some pictures marking the stage of progress. I like the rustic look this bowl already has. My approach will be to run the bowl through the full regimen of micromesh pads to bring out the shine and briar of the smooth briar surfaces – going over for the most part, the sculpted surfaces. At that point I’ll determine if I need to darken the shank end that was lightened because of the stem sanding. I also will freshen the darker sculpted sections with a stain stick. I’ll keep the stem and stummel joined through this process which will aid me later when I continue with the micromesh process on the stem. I take pictures of the bowl to mark the starting point.

Turning back to the Howal bowl, I remove the masking tape and take some pictures marking the stage of progress. I like the rustic look this bowl already has. My approach will be to run the bowl through the full regimen of micromesh pads to bring out the shine and briar of the smooth briar surfaces – going over for the most part, the sculpted surfaces. At that point I’ll determine if I need to darken the shank end that was lightened because of the stem sanding. I also will freshen the darker sculpted sections with a stain stick. I’ll keep the stem and stummel joined through this process which will aid me later when I continue with the micromesh process on the stem. I take pictures of the bowl to mark the starting point.

Beginning with micromesh pads 1500 to 2400, I wet sand followed by dry sanding with pads 3200 to 4000 and 6000 to 12000. The pictures show the progression.

Beginning with micromesh pads 1500 to 2400, I wet sand followed by dry sanding with pads 3200 to 4000 and 6000 to 12000. The pictures show the progression.

The grain came out of the smooth briar nicely. Now, to freshen the sculpted sections. With the fine lined carvings in each sculpted section, briar dust has collected from all the sanding. I first brush the carvings with a bristled brush. This removes a good deal. Following this, with an alcohol wetted cotton bud, I wipe out each carved section.

The grain came out of the smooth briar nicely. Now, to freshen the sculpted sections. With the fine lined carvings in each sculpted section, briar dust has collected from all the sanding. I first brush the carvings with a bristled brush. This removes a good deal. Following this, with an alcohol wetted cotton bud, I wipe out each carved section.

Next, using a very dark brown dye stick which turns out to be a mahogany, which looked the best after blending with the original surface, I trace the carvings darkening the sculpted briar. After finishing, I give another quick sanding over the smooth briar surface with the last of the micromesh sanding pads, 12000. I do this to clean off any inadvertent overrun of the dye stick onto the smooth briar and to sharpen the lines.

Next, using a very dark brown dye stick which turns out to be a mahogany, which looked the best after blending with the original surface, I trace the carvings darkening the sculpted briar. After finishing, I give another quick sanding over the smooth briar surface with the last of the micromesh sanding pads, 12000. I do this to clean off any inadvertent overrun of the dye stick onto the smooth briar and to sharpen the lines.

Using Before & After Restoration Balm, I place some on my fingers and work the Balm into the briar surface. I’m careful to work it into the crevasses of the sculpting. B&E Restoration Balm is an excellent product from Mark Hoover at www.ibepen.com that raises the natural hues in subtle ways that enhances the presentation of the pipe. After thoroughly working the Balm into the briar surface, I set the bowl aside for 20 minutes to allow the Balm to do its thing. The second picture shows this state. After 20 minutes, I wipe the excess Balm with a cotton cloth and then buff the stummel with a microfiber cloth to thoroughly remove the excess Balm and to raise the shine.

Using Before & After Restoration Balm, I place some on my fingers and work the Balm into the briar surface. I’m careful to work it into the crevasses of the sculpting. B&E Restoration Balm is an excellent product from Mark Hoover at www.ibepen.com that raises the natural hues in subtle ways that enhances the presentation of the pipe. After thoroughly working the Balm into the briar surface, I set the bowl aside for 20 minutes to allow the Balm to do its thing. The second picture shows this state. After 20 minutes, I wipe the excess Balm with a cotton cloth and then buff the stummel with a microfiber cloth to thoroughly remove the excess Balm and to raise the shine. The next step is to apply Blue Diamond compound to the entire pipe. After reuniting stem and stummel, I mount a cotton cloth buffing wheel to the Dremel, set the speed at about 40% full power and apply a light application of the compound focusing primarily, but not exclusively, on the smooth briar sections. I keep it light because I do not want the compound to cake up in the rusticated ridges of the sculpting. I apply the compound to the smooth and rusticated surfaces and to the stem.

The next step is to apply Blue Diamond compound to the entire pipe. After reuniting stem and stummel, I mount a cotton cloth buffing wheel to the Dremel, set the speed at about 40% full power and apply a light application of the compound focusing primarily, but not exclusively, on the smooth briar sections. I keep it light because I do not want the compound to cake up in the rusticated ridges of the sculpting. I apply the compound to the smooth and rusticated surfaces and to the stem. Following the compound, I use a felt cloth to wipe the pipe to clean it of compound dust. I don’t want compound mixing with the waxing phase.

Following the compound, I use a felt cloth to wipe the pipe to clean it of compound dust. I don’t want compound mixing with the waxing phase. After switching to another cotton cloth buffing wheel, maintaining the same speed, carnauba wax is applied to the entire pipe. As with the compound, I go easy on the rusticated ridges not wanting wax to cake. After applying wax to the entire pipe, I use a microfiber cloth to give the Howal Churchwarden a rigorous hand buffing to remove excess wax and to raise the shine.

After switching to another cotton cloth buffing wheel, maintaining the same speed, carnauba wax is applied to the entire pipe. As with the compound, I go easy on the rusticated ridges not wanting wax to cake. After applying wax to the entire pipe, I use a microfiber cloth to give the Howal Churchwarden a rigorous hand buffing to remove excess wax and to raise the shine. The Howal Sculpted Apple bowl looks great mounted on the bow of the Churchwarden stem! I’m pleased how the smooth briar surfaces cleaned up and how the grain provides a striking contrast with the sculpted design. The added rusticated ribs in the carvings adds a nice detail. The overall presentation of the Howal Sculpted Churchwarden gives a very old, rustic feel. I’m glad John was patient waiting for this Churchwarden to come to life. He will have the first opportunity to add this pipe to his own collection from The Pipe Steward Store. This Churchwarden project benefits the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!

The Howal Sculpted Apple bowl looks great mounted on the bow of the Churchwarden stem! I’m pleased how the smooth briar surfaces cleaned up and how the grain provides a striking contrast with the sculpted design. The added rusticated ribs in the carvings adds a nice detail. The overall presentation of the Howal Sculpted Churchwarden gives a very old, rustic feel. I’m glad John was patient waiting for this Churchwarden to come to life. He will have the first opportunity to add this pipe to his own collection from The Pipe Steward Store. This Churchwarden project benefits the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!

I took some photos of the rim top and bowl to show the condition of the pipes when they arrived. The bowls were very clean. Both rims had some darkening and the inner edge of both had some damage to them. The photos of the stems show the condition of both of them. They both are in excellent condition.

I took some photos of the rim top and bowl to show the condition of the pipes when they arrived. The bowls were very clean. Both rims had some darkening and the inner edge of both had some damage to them. The photos of the stems show the condition of both of them. They both are in excellent condition.

I took photos of the stamping on both pipes. The first is the Belgique with straight shank and the second is the Calabash with the bent shank. You can see the clear stamping on both pipes. The left side shows the arched Peterson’s Dublin with a forked P and the right side shows Made in the Republic of Ireland.

I took photos of the stamping on both pipes. The first is the Belgique with straight shank and the second is the Calabash with the bent shank. You can see the clear stamping on both pipes. The left side shows the arched Peterson’s Dublin with a forked P and the right side shows Made in the Republic of Ireland.

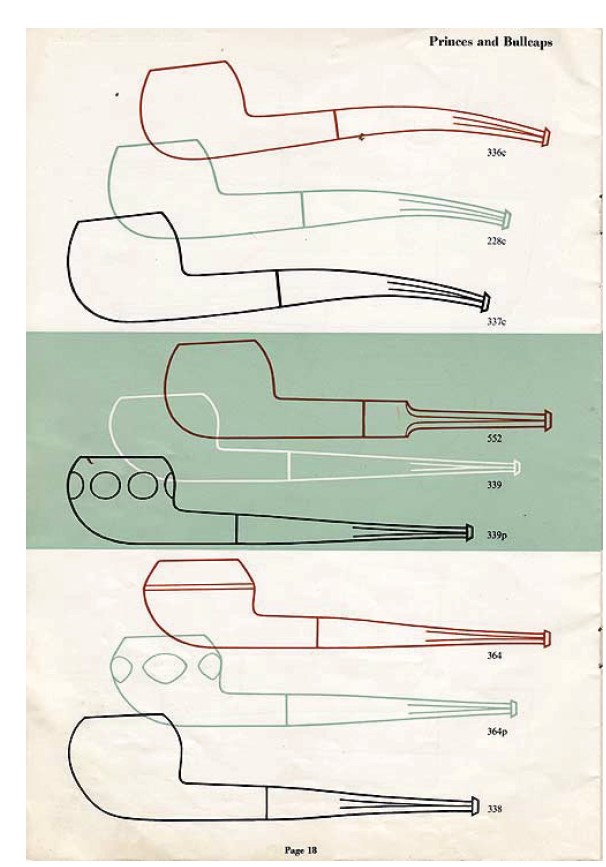

I have a 2010 Peterson Catalogue on rebornpipes that shows the various shapes that Peterson made. There is a page there on Specialty Pipes that shows the pipes that I am working on. The pipes pictured are different from the two that I am working on in that both of these are military mount stem. It states that the Belgique and Calabash are two petite and lightweight Peterson crafted with all the care and know how of century old pipe makers, from finest quality briar in red polish and rustic finishes with Fishtail mouthpieces only. However they are described in the catalogue the two shapes that are extremely lightweight. These two are not red polish but actually a rich matte brown finish. The fishtail mouthpieces are classic military mounts that can easily be removed to fit in the pocket. They represent the best micro-pocket pipe within the Peterson portfolio. I have included the noted page below (https://rebornpipes.com/2015/05/15/).

I have a 2010 Peterson Catalogue on rebornpipes that shows the various shapes that Peterson made. There is a page there on Specialty Pipes that shows the pipes that I am working on. The pipes pictured are different from the two that I am working on in that both of these are military mount stem. It states that the Belgique and Calabash are two petite and lightweight Peterson crafted with all the care and know how of century old pipe makers, from finest quality briar in red polish and rustic finishes with Fishtail mouthpieces only. However they are described in the catalogue the two shapes that are extremely lightweight. These two are not red polish but actually a rich matte brown finish. The fishtail mouthpieces are classic military mounts that can easily be removed to fit in the pocket. They represent the best micro-pocket pipe within the Peterson portfolio. I have included the noted page below (https://rebornpipes.com/2015/05/15/). I did a bit more digging on the Peterson Pipe Notes blog. There I found that Mark had included a photo of the various Speciality pipes. Peterson’s first put these four small pipes on the market in 1945 – Tankard & Barrel, Calabash & Belgique seen in the photo below. Here is the link to Mark’s Blog (https://www.petersonpipenotes.org/tag/peterson-valentia-pipe/).

I did a bit more digging on the Peterson Pipe Notes blog. There I found that Mark had included a photo of the various Speciality pipes. Peterson’s first put these four small pipes on the market in 1945 – Tankard & Barrel, Calabash & Belgique seen in the photo below. Here is the link to Mark’s Blog (https://www.petersonpipenotes.org/tag/peterson-valentia-pipe/). I did a bit more digging and found some descriptions of the two shapes that I am working on. The various descriptions of the Belgique come from a variety of sites and the final one is quoted on the Brothers of Briar site.

I did a bit more digging and found some descriptions of the two shapes that I am working on. The various descriptions of the Belgique come from a variety of sites and the final one is quoted on the Brothers of Briar site. I polished exterior of the bowl and the vulcanite shank extensions with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad to wipe of the dust and polish it.

I polished exterior of the bowl and the vulcanite shank extensions with micromesh sanding pads – wet sanding with 1500-12000 grit pads. I wiped it down with Obsidian Oil after each sanding pad to wipe of the dust and polish it.

I rubbed the bowls down with Before & After Restoration Balm. I worked it into the briar and into the vulcanite shank extension to preserve, protect and enliven it. I let it sit on the surface of the bowls for about 10 minutes and then buffed the pipe with a cotton cloth. The photos tell the story. These pipes had some stunning grain on the bowls.

I rubbed the bowls down with Before & After Restoration Balm. I worked it into the briar and into the vulcanite shank extension to preserve, protect and enliven it. I let it sit on the surface of the bowls for about 10 minutes and then buffed the pipe with a cotton cloth. The photos tell the story. These pipes had some stunning grain on the bowls.

I polished the vulcanite shank extensions with Denicare Mouthpiece Polish from a tin of it I have in the drawer here. It is a gritty red paste that I rub on with my finger tips and work into the surface of the stem and button and buff off with a cotton pad. It gives me a bit of a head start on the polishing work plus I have a tin to use up!

I polished the vulcanite shank extensions with Denicare Mouthpiece Polish from a tin of it I have in the drawer here. It is a gritty red paste that I rub on with my finger tips and work into the surface of the stem and button and buff off with a cotton pad. It gives me a bit of a head start on the polishing work plus I have a tin to use up!

I touched up the “P” stamp on the shank extensions with PaperMate liquid paper. I filled in the stamping with the liquid applying it with a dauber and a tooth pick. Once it dried I rubbed it off with a cotton cloth. The second photo shows the stem before the polishing on the buffing wheel.

I touched up the “P” stamp on the shank extensions with PaperMate liquid paper. I filled in the stamping with the liquid applying it with a dauber and a tooth pick. Once it dried I rubbed it off with a cotton cloth. The second photo shows the stem before the polishing on the buffing wheel. I polished the stem with Denicare Mouthpiece Polish from a tin of it I have in the drawer here. It is a gritty red paste that I rub on with my finger tips and work into the surface of the stem and button and buff off with a cotton pad. It gives me a bit of a head start on the polishing work plus I have a tin to use up!

I polished the stem with Denicare Mouthpiece Polish from a tin of it I have in the drawer here. It is a gritty red paste that I rub on with my finger tips and work into the surface of the stem and button and buff off with a cotton pad. It gives me a bit of a head start on the polishing work plus I have a tin to use up! I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a final coat of Obsidian Oil.

I polished the stem with micromesh sanding pads – wet sanding with 1500-12000 grit sanding pads. I wiped it down after each sanding pad with Obsidian Oil. I polished it with Before & After Pipe Stem Polish – both Fine and Extra Fine and buffed it off with a final coat of Obsidian Oil.

This pair of Peterson’s Speciality Pipes is a great addition. The Belgique and the Calabash shapes are classic in every way. They are petite, lightweight and comfortable in the hand. They will be a short smoke. The briar is beautifully grained and the black vulcanite military/stick Fishtail stems go well with the briar and the vulcanite shank extension. I polished stems and the bowls with Blue Diamond polish on the buffing wheel. I gave the bowls multiple coats of stems multiple coats of carnauba wax. I buffed the pipes with a clean buffing pad to raise the shine. I hand buffed them with a microfiber cloth to deepen the shine. The pipes polished up pretty nicely. The rich stained briar on both bowls took on life with the buffing. The rich brown colour of the briar bowls work well with the polished vulcanite stems. The finished pipes have a rich look that is quite catching. Have a look at it with the photos below. The shape, finish and flow of the pipe and stem are very well done.

This pair of Peterson’s Speciality Pipes is a great addition. The Belgique and the Calabash shapes are classic in every way. They are petite, lightweight and comfortable in the hand. They will be a short smoke. The briar is beautifully grained and the black vulcanite military/stick Fishtail stems go well with the briar and the vulcanite shank extension. I polished stems and the bowls with Blue Diamond polish on the buffing wheel. I gave the bowls multiple coats of stems multiple coats of carnauba wax. I buffed the pipes with a clean buffing pad to raise the shine. I hand buffed them with a microfiber cloth to deepen the shine. The pipes polished up pretty nicely. The rich stained briar on both bowls took on life with the buffing. The rich brown colour of the briar bowls work well with the polished vulcanite stems. The finished pipes have a rich look that is quite catching. Have a look at it with the photos below. The shape, finish and flow of the pipe and stem are very well done.