Blog by Dal Stanton

I acquired this interestingly shaped pipe in an eBay Lot acquisition from France which has contained several very collectible pipes. The challenge with this French Lot has been that several names stamped on the pipes are unfamiliar to me and require more research to uncover the origins. This pipe continues that trend as its origins aren’t clear. My good friend and former colleague working in Ukraine, a pipe man and restorer himself (see: https://www.thepipery.com), saw this Robinson Paneled Tomato in the For “Pipe Dreamers” Only! collection and reached out to me about commissioning it which I was more than happy to do!

I’m categorizing this Paneled Tomato (though a case could be made that this is a Prince shape, but the shank is a bit too broad I think) pipe as a petite as its dimensions are: Length: 5 ¾ inches, Height: 1 inch, Tomato bowl width: 1 1/2 inches, Chamber width: 5/8 inches, and Chamber depth: 7/8 inches. It has a very attractive and sleek shape with the 1/4 bent stem, but what I haven’t seen before are the painted panel boarders setting off the upper dome of the Tomato along with sculpted rim notches. Here are pictures of the pipe now on my worktable:

What I thought at first was a stinger that had been cut off, might be a slotted insert of some sort. I’ll work on removing it later.

What I thought at first was a stinger that had been cut off, might be a slotted insert of some sort. I’ll work on removing it later. The left side of the shank bears the ornate, oval with ‘ROBINSON’ stamped. The right side of the shank bears what I believe is a shape number ‘8494’. I looked in my autographed copy of Herb Wilczak & Tom Colwell 3/3/97 – ‘Who Made That Pipe?’ and found only one entry for ‘Robinson’ belonging to a ‘John J. Robinson’ with the COM listed as USA. I found no reference to a ‘John J. Robinson’ in Pipedia’s listings or Pipephil.eu, my regular first stops for information. I’m dubious of the COM of USA because, and I know this is subjective, the pipe has a European feel. Its diminutive size reflects more the English and French values of the last century and the pipe has a sense of some age to it in spite of the painted panel edges and rim notches that may have been added later. Also, the shape number of ‘8494’ doesn’t lend itself to a COM of USA. I decide to do a quick survey of English/French pipe shape charts to find this shape number that corresponds to the Paneled Tomato I’m looking at. Often established pipe manufacturers will put out lines of pipes for a 3rd party company with the party’s name stamped on it but the shape will emulate the shapes that the mother manufacturer already produces. I investigate BBB and GBD specifically as the most likely possibilities but found no match that might make this Robinson 8494 a positive second or sub-brand of these well-known English/French sources. Next, I go back to Pipephil.eu and instead of searching John J. Robinson, the Wilczak & Colwell clue, I simply search more broadly, ‘Robinson’ and find an interesting listing.

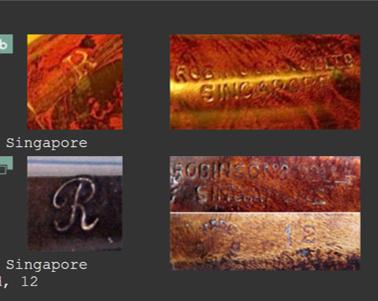

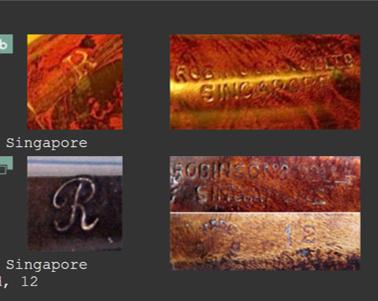

The left side of the shank bears the ornate, oval with ‘ROBINSON’ stamped. The right side of the shank bears what I believe is a shape number ‘8494’. I looked in my autographed copy of Herb Wilczak & Tom Colwell 3/3/97 – ‘Who Made That Pipe?’ and found only one entry for ‘Robinson’ belonging to a ‘John J. Robinson’ with the COM listed as USA. I found no reference to a ‘John J. Robinson’ in Pipedia’s listings or Pipephil.eu, my regular first stops for information. I’m dubious of the COM of USA because, and I know this is subjective, the pipe has a European feel. Its diminutive size reflects more the English and French values of the last century and the pipe has a sense of some age to it in spite of the painted panel edges and rim notches that may have been added later. Also, the shape number of ‘8494’ doesn’t lend itself to a COM of USA. I decide to do a quick survey of English/French pipe shape charts to find this shape number that corresponds to the Paneled Tomato I’m looking at. Often established pipe manufacturers will put out lines of pipes for a 3rd party company with the party’s name stamped on it but the shape will emulate the shapes that the mother manufacturer already produces. I investigate BBB and GBD specifically as the most likely possibilities but found no match that might make this Robinson 8494 a positive second or sub-brand of these well-known English/French sources. Next, I go back to Pipephil.eu and instead of searching John J. Robinson, the Wilczak & Colwell clue, I simply search more broadly, ‘Robinson’ and find an interesting listing. Robinson & Co. Ltd, is a retail company in Singapore and Malaysia with obvious historic English connections. Wishing to know more about this company, I found this lengthy article in Wikipedia, Robinsons & Co. that gave much information.

Robinson & Co. Ltd, is a retail company in Singapore and Malaysia with obvious historic English connections. Wishing to know more about this company, I found this lengthy article in Wikipedia, Robinsons & Co. that gave much information.

Robinsons & Co. Pte Ltd is a retail company which has department stores in Singapore and Malaysia. The company owns the Robinsons department store, John Little in Singapore and has franchise outlets of Marks and Spencer in both countries. The company has grown into one of the country’s most renowned department stores. Robinsons celebrates their 160th anniversary in 2018.

Robin sons & Co. Limited is currently part of the UAE-based Al-Futtaim Group.

sons & Co. Limited is currently part of the UAE-based Al-Futtaim Group.

The article outlines the formation of the company in 1858 by Phillip Robinson of England when the British Empire had a colonial presence in Singapore. With partnership changes the exclusive, high end department store became known as Robinson and Co., in 1859. Through the remainder of the 1800s and into the 1900s it became a landmark in the downtown Singapore store and catered mainly to expatriates and higher end customers among the local population – royalty, business, and political spheres. During WWII, the store was bombed by the Japanese and was finally closed during Japanese occupation. After WWII it reopened when the British returned to Singapore in 1946 and the business flourished. During the 1970s, the business was less profitable due to international and local conditions and finally, the publicly traded Robinson & Co. Limited was acquired by Dubai based Al Futtaim Group in 2008.

From Pipephil.eu information, I’m able to establish two facts – the Robinson Department Store in Singapore DID market pipes with ‘Robinson Co. LTS’ which, secondly, have a COM of ‘Made in England’.

The  theory takes shape in my mind, with the absence of any other corroborating information, that it is possible that the ‘Robinson’ on my table is indeed connected to the ‘Robinson & Co.’ of Singapore. The Robinson on my table lacks stampings that confirm this as with the pipes shown on Pipephil.eu. But it is conceivable, yet I cannot substantiate this, that the Robinson I have is an older version before what appears to be the newer and more developed marketing applied to the later Robinson store pipe. This is obviously a guess, which I could not substantiate even after searching for older catalogues and any other ‘Robinson’ pipes out there on the internet! So, armed with a theory which I will continue to mull over, I move on!

theory takes shape in my mind, with the absence of any other corroborating information, that it is possible that the ‘Robinson’ on my table is indeed connected to the ‘Robinson & Co.’ of Singapore. The Robinson on my table lacks stampings that confirm this as with the pipes shown on Pipephil.eu. But it is conceivable, yet I cannot substantiate this, that the Robinson I have is an older version before what appears to be the newer and more developed marketing applied to the later Robinson store pipe. This is obviously a guess, which I could not substantiate even after searching for older catalogues and any other ‘Robinson’ pipes out there on the internet! So, armed with a theory which I will continue to mull over, I move on! I begin the restoration of this possibly English made for Singapore, Robinson Quarter Bent Paneled Tomato, by addressing the moderate oxidation in the stem. After cleaning the airway with pipe cleaners dipped in isopropyl 95%, I then include the stem in a bath of Before & After Deoxidizer along with other stems of pipes that have already been restored and sent on to join new stewards. The Robinson is the last stem in this Before & After Deoxidizer batch.

I begin the restoration of this possibly English made for Singapore, Robinson Quarter Bent Paneled Tomato, by addressing the moderate oxidation in the stem. After cleaning the airway with pipe cleaners dipped in isopropyl 95%, I then include the stem in a bath of Before & After Deoxidizer along with other stems of pipes that have already been restored and sent on to join new stewards. The Robinson is the last stem in this Before & After Deoxidizer batch. Several hours later I fish out the Robinson stem and wipe it down with cotton pads wetted with isopropyl 95% to remove the raised oxidation. The texture of the vulcanite stem is rougher than usual it seems. After cleaning the stem surface, I run a few more pipe cleaners through the airway to assure that the Before & After Deoxidizer is gone. The stem looks good after the treatment.

Several hours later I fish out the Robinson stem and wipe it down with cotton pads wetted with isopropyl 95% to remove the raised oxidation. The texture of the vulcanite stem is rougher than usual it seems. After cleaning the stem surface, I run a few more pipe cleaners through the airway to assure that the Before & After Deoxidizer is gone. The stem looks good after the treatment. To start the revitalization of the vulcanite, I then apply paraffin oil – a mineral oil, to the stem and then put it aside to absorb the oil and dry.

To start the revitalization of the vulcanite, I then apply paraffin oil – a mineral oil, to the stem and then put it aside to absorb the oil and dry. Now, turning to the waiting stummel, I first address the moderate carbon cake by using the smallest blade head of the Pipnet Reaming Kit. This blade head fits the chamber perfectly. I follow by using the Savinelli Fitsall Tool to scrape the chamber wall further revealing fresher briar. Finally, I sand the chamber with 240 grit paper wrapped around a Sharpie Pen and then wipe the chamber clear of carbon dust with a cotton pad wetted with isopropyl 95%.

Now, turning to the waiting stummel, I first address the moderate carbon cake by using the smallest blade head of the Pipnet Reaming Kit. This blade head fits the chamber perfectly. I follow by using the Savinelli Fitsall Tool to scrape the chamber wall further revealing fresher briar. Finally, I sand the chamber with 240 grit paper wrapped around a Sharpie Pen and then wipe the chamber clear of carbon dust with a cotton pad wetted with isopropyl 95%.

After clearing the carbon cake, I inspect the chamber and it looks good.

After clearing the carbon cake, I inspect the chamber and it looks good. I then move directly to the internal cleaning of the mortise and airway. I start using cotton buds and pipe cleaners dipped in isopropyl 95% and…. The text describing the cleaning process is much shorter than the cleaning process. I had noticed earlier that this stummel was a bit of a stinker, so I was anxious to begin addressing this olfactory offense to my nose and adjoining rooms in our 10th floor apartment in a formerly Communist Bloc apartment building. In addition to pipe cleaners and cotton buds, I use a dental spatula to scrape the mortise walls, as well as a drill bit inserted into the airway and hand turned to excavate the tars and oils. I also use a long wire shank brush to scrub the internals. The picture shows the weapons brought to bear….

I then move directly to the internal cleaning of the mortise and airway. I start using cotton buds and pipe cleaners dipped in isopropyl 95% and…. The text describing the cleaning process is much shorter than the cleaning process. I had noticed earlier that this stummel was a bit of a stinker, so I was anxious to begin addressing this olfactory offense to my nose and adjoining rooms in our 10th floor apartment in a formerly Communist Bloc apartment building. In addition to pipe cleaners and cotton buds, I use a dental spatula to scrape the mortise walls, as well as a drill bit inserted into the airway and hand turned to excavate the tars and oils. I also use a long wire shank brush to scrub the internals. The picture shows the weapons brought to bear…. I’m still not seeing cleaner cotton buds and pipe cleaners that would reveal progress, so I decide to move on to giving the stummel a kosher salt and alcohol soak with hopes that this will loosen the grunge and clean the internals. After stretching and twisting a cotton ball to serve as a wick to help draw out the tars and oils, I insert it into the mortise and the airway with the help of a straight stiff wire. I then fill the bowl with kosher salt and place it in the egg crate to keep it steady. Using a large eye dropper, I add isopropyl 95% to fill the bowl until is surfaces over the salt. After it absorbs in a few minutes, I refill the bowl with alcohol and put it aside to soak.

I’m still not seeing cleaner cotton buds and pipe cleaners that would reveal progress, so I decide to move on to giving the stummel a kosher salt and alcohol soak with hopes that this will loosen the grunge and clean the internals. After stretching and twisting a cotton ball to serve as a wick to help draw out the tars and oils, I insert it into the mortise and the airway with the help of a straight stiff wire. I then fill the bowl with kosher salt and place it in the egg crate to keep it steady. Using a large eye dropper, I add isopropyl 95% to fill the bowl until is surfaces over the salt. After it absorbs in a few minutes, I refill the bowl with alcohol and put it aside to soak.

The next day, the salt and wick are heavily soiled and hopefully the condition of the internals is improved.

The next day, the salt and wick are heavily soiled and hopefully the condition of the internals is improved.  Using a pipe cleaner and cotton buds, I soon find out that the condition is much the same. I put on surgical gloves a long time ago during this cleanup process! I continue to dig and excavate using all the tools listed above.

Using a pipe cleaner and cotton buds, I soon find out that the condition is much the same. I put on surgical gloves a long time ago during this cleanup process! I continue to dig and excavate using all the tools listed above. With a glimmer of hope beginning to dawn with cotton buds and pipe cleaners starting to lighten, I again provide a kosher salt and alcohol soak with the hope that the tide is turning. What I discover as I became intimately familiar with the internal layout of the mortise as I inserted spatulas and dental probes to clean, was that the drilling of this stummel was in two phases. A larger drill bit was used to open the mortise. Then a smaller drill bit was used to drill the short airway and exiting into the chamber forming the draft hole. The slight up-tick in the angle of the second drilling created a small trap of sorts that collected much tar and oils over the years. It would be difficult to clean with normal pipe cleaners as they would go over to the top of the trap on their cleaning mission. To intentionally clean this small angled trap, it needs to be intentionally and regularly scraped with a probe – something stiff enough to dislodge anything collecting.

With a glimmer of hope beginning to dawn with cotton buds and pipe cleaners starting to lighten, I again provide a kosher salt and alcohol soak with the hope that the tide is turning. What I discover as I became intimately familiar with the internal layout of the mortise as I inserted spatulas and dental probes to clean, was that the drilling of this stummel was in two phases. A larger drill bit was used to open the mortise. Then a smaller drill bit was used to drill the short airway and exiting into the chamber forming the draft hole. The slight up-tick in the angle of the second drilling created a small trap of sorts that collected much tar and oils over the years. It would be difficult to clean with normal pipe cleaners as they would go over to the top of the trap on their cleaning mission. To intentionally clean this small angled trap, it needs to be intentionally and regularly scraped with a probe – something stiff enough to dislodge anything collecting.  With the kosher salt and alcohol soak cooking a second time, I pick up the stem and take another look at the slotted insert in the tenon. It doesn’t appear to be a snipped stinger, but perhaps an air restrictor insert of sorts with a slotted opening – I’m not sure if its threaded but I doubt it. I don’t have much sympathy for stingers and restrictors as they simply create more angles for the airflow – this creates condensation and more moisture…. I heat the metal insert and tenon with a Bic lighter to loosen the grip and using a pair of needle nose pliers I do not pull the insert out but accomplish snapping the top of the insert off! I hand screw a drill bit into the shaft of the metal insert remaining in the tenon and after reheating the tenon and drill bit, and a few retries, I succeed in extracting the remainder of the inserted air restrictor. It will be much easier to clean now as well.

With the kosher salt and alcohol soak cooking a second time, I pick up the stem and take another look at the slotted insert in the tenon. It doesn’t appear to be a snipped stinger, but perhaps an air restrictor insert of sorts with a slotted opening – I’m not sure if its threaded but I doubt it. I don’t have much sympathy for stingers and restrictors as they simply create more angles for the airflow – this creates condensation and more moisture…. I heat the metal insert and tenon with a Bic lighter to loosen the grip and using a pair of needle nose pliers I do not pull the insert out but accomplish snapping the top of the insert off! I hand screw a drill bit into the shaft of the metal insert remaining in the tenon and after reheating the tenon and drill bit, and a few retries, I succeed in extracting the remainder of the inserted air restrictor. It will be much easier to clean now as well.

Looking now at the stem, the bit area on the upper and lower has some bite compressions, but not significant. The lower button lip has also been chewed a little. I’m thinking that sanding and a little filing should rectify the situation.

Looking now at the stem, the bit area on the upper and lower has some bite compressions, but not significant. The lower button lip has also been chewed a little. I’m thinking that sanding and a little filing should rectify the situation. I use a flat needle file to freshen the button and 240 grit paper to sand out the compressions. This works well.

I use a flat needle file to freshen the button and 240 grit paper to sand out the compressions. This works well. I also sand the entire stem with 240 grit paper to remove the rough, goose skin surface of the vulcanite. I employ a disc I fashioned to guard again shouldering the shank face of the stem.

I also sand the entire stem with 240 grit paper to remove the rough, goose skin surface of the vulcanite. I employ a disc I fashioned to guard again shouldering the shank face of the stem. I then wet sand the entire stem using 600 grade paper followed by 0000 steel wool.

I then wet sand the entire stem using 600 grade paper followed by 0000 steel wool. Without pause I move to the micromesh regimen using pads 1500 to 12000. First, I wet sand using pads 1500 to 2400 followed by dry sanding with pads 3200 to 4000 and 6000 to 12000. Between each set of three I apply Obsidian Oil to the stem to revitalize the vulcanite – and it is coming to life! The rough surface smoothed and polished up well.

Without pause I move to the micromesh regimen using pads 1500 to 12000. First, I wet sand using pads 1500 to 2400 followed by dry sanding with pads 3200 to 4000 and 6000 to 12000. Between each set of three I apply Obsidian Oil to the stem to revitalize the vulcanite – and it is coming to life! The rough surface smoothed and polished up well.

The next morning (again), with something akin to Handel’s Hallelujah Chorus in the backdrop of my mind joyfully reverberating and echoing, I see that the second kosher/alcohol soak has furthered the cleanup effort significantly. After dumping the soiled salt and cleaning the stummel of salt crystals, I run a few more buds and pipe cleaners through the internals and the cleaning is now complete! The bowl is also freshened from the stink odor that dominated its presence before. This cleaning was a bear – and it’s not finished!

The next morning (again), with something akin to Handel’s Hallelujah Chorus in the backdrop of my mind joyfully reverberating and echoing, I see that the second kosher/alcohol soak has furthered the cleanup effort significantly. After dumping the soiled salt and cleaning the stummel of salt crystals, I run a few more buds and pipe cleaners through the internals and the cleaning is now complete! The bowl is also freshened from the stink odor that dominated its presence before. This cleaning was a bear – and it’s not finished! Turning now to the external briar surface, I wonder what the cleaning will do to the paint job this stummel has received. If it’s acrylic paint, the cleaning should remove it. If not, well, it’s something else, probably oil based. I have a very difficult time conceiving of any scenario where paint was part of the original motif of this Paneled Tomato – I believe the rim notches were a later addition as well, but perhaps not! I’ll clean and see what happens.

Turning now to the external briar surface, I wonder what the cleaning will do to the paint job this stummel has received. If it’s acrylic paint, the cleaning should remove it. If not, well, it’s something else, probably oil based. I have a very difficult time conceiving of any scenario where paint was part of the original motif of this Paneled Tomato – I believe the rim notches were a later addition as well, but perhaps not! I’ll clean and see what happens.

I use undiluted Murphy’s Oil Soap with cotton pads to clean the stummel. There’s lava overflow covering the rim which I also deal with using a brass bristle brush.

I use undiluted Murphy’s Oil Soap with cotton pads to clean the stummel. There’s lava overflow covering the rim which I also deal with using a brass bristle brush. The cleaning removes the grime and I discover the panel boarder painted strips firmly intact, hmm. On the left flank of the stummel is the loan fill that I detect after seeing more of the stummel. After the cleaning, the old fill material is soft, and I remove it easily with a dental probe to be replaced later with CA and briar dust putty.

The cleaning removes the grime and I discover the panel boarder painted strips firmly intact, hmm. On the left flank of the stummel is the loan fill that I detect after seeing more of the stummel. After the cleaning, the old fill material is soft, and I remove it easily with a dental probe to be replaced later with CA and briar dust putty. The stummel cleans up well and has lightened considerably revealing some nice grain patterns on the diminutive bowl, but it also shows the nicks, wear and tear of normal usage. After the cleaning and scrubbing, the rim is still showing some burn areas.

The stummel cleans up well and has lightened considerably revealing some nice grain patterns on the diminutive bowl, but it also shows the nicks, wear and tear of normal usage. After the cleaning and scrubbing, the rim is still showing some burn areas. Not much consideration was needed to bring out the chopping board that serves as my topping board. I use 240 grade paper to refresh the paneled rim. I would like the six sides and corners to be sharper and more distinct. The shank extends beyond or above the rim plane, so I hang the shank over the edge and begin the topping like that. I also utilize a small sanding block that is very useful for fine-tuning a topping project by allowing me to focus on an area. The pictures show the progression using 240 grade paper.

Not much consideration was needed to bring out the chopping board that serves as my topping board. I use 240 grade paper to refresh the paneled rim. I would like the six sides and corners to be sharper and more distinct. The shank extends beyond or above the rim plane, so I hang the shank over the edge and begin the topping like that. I also utilize a small sanding block that is very useful for fine-tuning a topping project by allowing me to focus on an area. The pictures show the progression using 240 grade paper.

When satisfied with the progress, I change the board to 600 grade paper to smooth the rim from the 240 grit scratches.

When satisfied with the progress, I change the board to 600 grade paper to smooth the rim from the 240 grit scratches. Next, before working on the stummel proper, I repair the small pit on the left side of the stummel by refilling it with a putty created from mixing briar dust and CA glue. It doesn’t take much to fill. I use an accelerator after mixing and applying the putty with a tooth pick. This quickens the curing process so that I can quickly file and sand it and continue the project.

Next, before working on the stummel proper, I repair the small pit on the left side of the stummel by refilling it with a putty created from mixing briar dust and CA glue. It doesn’t take much to fill. I use an accelerator after mixing and applying the putty with a tooth pick. This quickens the curing process so that I can quickly file and sand it and continue the project.

Thankfully, Bulgaria is beginning to experience some intermittent spring-like weather. I take advantage of the mild weather and move out to the Man Cave, my 10th floor balcony, where I file and sand the patch mound and enjoy Red’s Cherry blend in my Gasparini MGM Rock 1912. A wonderful time filing and sanding!

Thankfully, Bulgaria is beginning to experience some intermittent spring-like weather. I take advantage of the mild weather and move out to the Man Cave, my 10th floor balcony, where I file and sand the patch mound and enjoy Red’s Cherry blend in my Gasparini MGM Rock 1912. A wonderful time filing and sanding!

To erase as much of the inner rim scorching damage that darkens the briar, I introduce a bevel. I first tightly roll a piece of coarser 120 grit paper to do the initial clearing. I then follow with 240 grit paper also tightly rolled.

To erase as much of the inner rim scorching damage that darkens the briar, I introduce a bevel. I first tightly roll a piece of coarser 120 grit paper to do the initial clearing. I then follow with 240 grit paper also tightly rolled.

After applying the bevel, I return to the topping board and turn a few rotations to refresh the rim.

After applying the bevel, I return to the topping board and turn a few rotations to refresh the rim. Oh my! At this point in the restoration, I discover that I’m not restoring a mangled pipe that was painted and rim notched for fun! After re-topping the rim, I see that what I thought was paint framing the panels is not paint at all. It’s metal – a metal inlay of some sort. An inlay?! That takes time and skill! I examine the rim where the top of the ‘paint’ met the rim and I see that it has depth. I take a few more close ups to show the dimensions from differing angles.

Oh my! At this point in the restoration, I discover that I’m not restoring a mangled pipe that was painted and rim notched for fun! After re-topping the rim, I see that what I thought was paint framing the panels is not paint at all. It’s metal – a metal inlay of some sort. An inlay?! That takes time and skill! I examine the rim where the top of the ‘paint’ met the rim and I see that it has depth. I take a few more close ups to show the dimensions from differing angles.

Not sure what I’m looking at, I show my discovery to my wife, and she asks me if I have a magnet? I didn’t, but she took a magnet off the freezer holding up a photograph and she says to test the magnetic pull of the metal. It has no magnetic pull at all. Her conclusion is, “It’s probably silver.” After a quick search on Google for, ‘Silver inlay in wood’, I found these pictures on Pinterest.

Not sure what I’m looking at, I show my discovery to my wife, and she asks me if I have a magnet? I didn’t, but she took a magnet off the freezer holding up a photograph and she says to test the magnetic pull of the metal. It has no magnetic pull at all. Her conclusion is, “It’s probably silver.” After a quick search on Google for, ‘Silver inlay in wood’, I found these pictures on Pinterest.

I am suddenly more firmly convinced of my theory about the origin of this ‘Robinson’ – from a high-end store in Singapore. Who would pay for such a pipe as this? Who would be drawn to a pipe with silver inlay? Now that I know what it is, the pipe itself is transformed from a discarded pipe that someone painted and notched trying to be cleaver to a pipe that was the recipient of a fine jeweler’s careful process of silver inlay in wood – and not just wood but situated perfectly and uniformly framing the panels of this pipe. Looking at some videos and pictures I see online, the process was probably done using a silver wire that was tapped into place as the first picture above. The next urgent question coming to mind was not how to remove it but how to protect it!? The inlay has stayed intact this long, I don’t want to change the status quo! I decide to use sanding sponges to work on the scratches and nicks that are prevalent on the stummel. The sponges shouldn’t be too invasive if inadvertently moving over the silver. Before starting with the sponges, I see that the left side of the stummel, just under the panel, has significant pitting. I apply a small amount of CA glue here to fill the pits and apply an accelerator to quicken the curing time.

I am suddenly more firmly convinced of my theory about the origin of this ‘Robinson’ – from a high-end store in Singapore. Who would pay for such a pipe as this? Who would be drawn to a pipe with silver inlay? Now that I know what it is, the pipe itself is transformed from a discarded pipe that someone painted and notched trying to be cleaver to a pipe that was the recipient of a fine jeweler’s careful process of silver inlay in wood – and not just wood but situated perfectly and uniformly framing the panels of this pipe. Looking at some videos and pictures I see online, the process was probably done using a silver wire that was tapped into place as the first picture above. The next urgent question coming to mind was not how to remove it but how to protect it!? The inlay has stayed intact this long, I don’t want to change the status quo! I decide to use sanding sponges to work on the scratches and nicks that are prevalent on the stummel. The sponges shouldn’t be too invasive if inadvertently moving over the silver. Before starting with the sponges, I see that the left side of the stummel, just under the panel, has significant pitting. I apply a small amount of CA glue here to fill the pits and apply an accelerator to quicken the curing time. I use 240 grit paper, then 600, to sand out the patches until flush with the briar surface and smooth.

I use 240 grit paper, then 600, to sand out the patches until flush with the briar surface and smooth. I then use sanding sponges, starting with coarse, medium, then light, to work out the blemishes throughout the stummel. I avoid as much as possible direct movement over the silver inlay but work around it on each panel.

I then use sanding sponges, starting with coarse, medium, then light, to work out the blemishes throughout the stummel. I avoid as much as possible direct movement over the silver inlay but work around it on each panel. I then utilize the full regimen of micromesh pads, 1500 to 12000. I first wet sand using pads 1500 to 2400, then dry sand with 3200 to 4000 and 6000 to 12000. As with the sanding sponges, I do not intentionally focus the pads over the silver inlay but work around it.

I then utilize the full regimen of micromesh pads, 1500 to 12000. I first wet sand using pads 1500 to 2400, then dry sand with 3200 to 4000 and 6000 to 12000. As with the sanding sponges, I do not intentionally focus the pads over the silver inlay but work around it.

With the assumption now that the twin rim notches on the forward panels are part of the original motif, I freshen two of them using a carpenter’s blade.

With the assumption now that the twin rim notches on the forward panels are part of the original motif, I freshen two of them using a carpenter’s blade. During the initial cleaning of the stummel, the shank cap had popped off and I put it aside for safe keeping. Now that I’ve discovered the silver inlay, I’m wondering if this cap is more than the nickel plating that I originally suspected. To clean, I take it to the sink and wash it with warm water and mild soap, using my fingernail as well as a brass brush to help in the cleaning. After cleaned I rinse it and dry it thoroughly.

During the initial cleaning of the stummel, the shank cap had popped off and I put it aside for safe keeping. Now that I’ve discovered the silver inlay, I’m wondering if this cap is more than the nickel plating that I originally suspected. To clean, I take it to the sink and wash it with warm water and mild soap, using my fingernail as well as a brass brush to help in the cleaning. After cleaned I rinse it and dry it thoroughly. I then apply Tarn-X to the ring with a cotton pad and wipe thoroughly then take it to the sink and again rinse and dry.

I then apply Tarn-X to the ring with a cotton pad and wipe thoroughly then take it to the sink and again rinse and dry. This time with a magnifying glass, I check the band and my original assumption seems to be correct that it is nickel. I find no stamping on the metal to indicate that it is silver. Next, I apply the magnet to the ring, and it is not magnetic at all. After a quick search in Google to check the magnetic composition of nickel, I discover that it is indeed magnetic. The band, shank cap before me is not. It is becoming clearer now that I am not working on a maligned basket pipe. If this band is indeed silver, it is rawer and unmarked. Again, my theory of an English, Singapore, connection is encouraged.

This time with a magnifying glass, I check the band and my original assumption seems to be correct that it is nickel. I find no stamping on the metal to indicate that it is silver. Next, I apply the magnet to the ring, and it is not magnetic at all. After a quick search in Google to check the magnetic composition of nickel, I discover that it is indeed magnetic. The band, shank cap before me is not. It is becoming clearer now that I am not working on a maligned basket pipe. If this band is indeed silver, it is rawer and unmarked. Again, my theory of an English, Singapore, connection is encouraged.  Before reattaching the cap to the shank, I mount a cotton cloth buffing wheel to the Dremel dedicated to applying White Diamond compound on silver. I have wheels dedicated for several different compounds and metals. I carefully hold the band and buff it with White Diamond compound and then buff it with a microfiber cloth.

Before reattaching the cap to the shank, I mount a cotton cloth buffing wheel to the Dremel dedicated to applying White Diamond compound on silver. I have wheels dedicated for several different compounds and metals. I carefully hold the band and buff it with White Diamond compound and then buff it with a microfiber cloth. To bring out the depth of the grain that has emerged, I apply Before & After Restoration Balm to my fingers then work it into the surface of the briar. The Balm begins with a thinner oil consistency then thickens as I work it into the surface. At the end it’s like a wax. I allow it to sit for several minutes then I wipe it off with a clean cloth and buff it up until the stummel is clear of excess Balm. The Balm does a great job bringing out the nuanced tones of the briar.

To bring out the depth of the grain that has emerged, I apply Before & After Restoration Balm to my fingers then work it into the surface of the briar. The Balm begins with a thinner oil consistency then thickens as I work it into the surface. At the end it’s like a wax. I allow it to sit for several minutes then I wipe it off with a clean cloth and buff it up until the stummel is clear of excess Balm. The Balm does a great job bringing out the nuanced tones of the briar.

After applying the Restoration Balm and without remounting the silver shank cap, I reunite the stem and stummel setting the speed at 40% full power and apply Blue Diamond compound to the entire pipe. I don’t remount the silver shank cap so that I can apply the compound without worry of impacting the band. As well, during the buffing, I stay clear of the silver inlay to avoid the chemical reaction that can stain the wood with black.

After applying the Restoration Balm and without remounting the silver shank cap, I reunite the stem and stummel setting the speed at 40% full power and apply Blue Diamond compound to the entire pipe. I don’t remount the silver shank cap so that I can apply the compound without worry of impacting the band. As well, during the buffing, I stay clear of the silver inlay to avoid the chemical reaction that can stain the wood with black.  After the application of Blue Diamond compound is finished, I apply two small dots of CA glue to the inner side of the silver shank cap and remount it on the end of the shank. It looks great!

After the application of Blue Diamond compound is finished, I apply two small dots of CA glue to the inner side of the silver shank cap and remount it on the end of the shank. It looks great!

Now in the homestretch, I remount the stem to the stummel and apply coats of carnauba wax to the entire pipe, still avoiding the silver inlay and band. After completing the application of wax, I give the pipe a rigorous hand-buffing to raise the shine of the briar and the luster of the silver.

Now in the homestretch, I remount the stem to the stummel and apply coats of carnauba wax to the entire pipe, still avoiding the silver inlay and band. After completing the application of wax, I give the pipe a rigorous hand-buffing to raise the shine of the briar and the luster of the silver.

My final theory for the origins of this silver laden Robinson Quarter Bent Paneled Tomato is that it was produced in England in the years immediately following the close of WWII after the British returned in 1946 after Japanese occupation and the Robinson department stores in Singapore and Malaya soared in sales – reaching 1 million US for the first time in its history (LINK) and saw expansion well into the 1950s with the acquisition of the John Little Co., the largest and older competitor to the Robinson presence in Singapore. This is only a guess as to the period, but with what appears to be an older Robinson stamping from the examples I found online, I’m thinking that this guess is pretty good but still a guess! How I viewed the pipe morphed from being a marginal basket pipe that had been maligned to a very nice pipe with a touch of opulent class. The briar grain itself is beautifully presented on the heel of the stummel and is showcased in each of the six silver-framed panels. The diminutive size puts this pipe squarely in English tradition and the gently bent stem is elegant with the striking silver band providing the bowl/stem transition. The absence of formal markings on the silver band is still a question, but it might be explained in that it was destined as a store pipe. My friend, Dave, commissioned this Robinson Paneled Tomato and he will have the first opportunity to claim it from The Pipe Steward Store. This pipe, as with others, benefits our work here in Bulgaria with the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for looking!

Jeff took a photo of the bowl and rim to show the condition of the pipe before he started his cleanup work. The spots of lava overflowing on the rim top made me thick that some of the lava had been scraped off by the seller. There was a thick cake in the bowl that would need to be reamed out. There was dust and debris in the curls and curves of the brass cap.

Jeff took a photo of the bowl and rim to show the condition of the pipe before he started his cleanup work. The spots of lava overflowing on the rim top made me thick that some of the lava had been scraped off by the seller. There was a thick cake in the bowl that would need to be reamed out. There was dust and debris in the curls and curves of the brass cap. He also took a photo of the right side and underside of the bowl and shank to show the amazing birdseye and swirling grain around the bowl. The classic WDC stain looked pretty good under the grime.

He also took a photo of the right side and underside of the bowl and shank to show the amazing birdseye and swirling grain around the bowl. The classic WDC stain looked pretty good under the grime. Jeff took photos of the stamping on the left side of the shank and the setting between the brass ferrule and the bowl. The WDC triangle logo stamping is legible and very readable.

Jeff took photos of the stamping on the left side of the shank and the setting between the brass ferrule and the bowl. The WDC triangle logo stamping is legible and very readable. The next photos show the rim cap and ferrule and highlight the heart and filigree patterns in the brass. You can also see the oxidation on the brass in the photos.

The next photos show the rim cap and ferrule and highlight the heart and filigree patterns in the brass. You can also see the oxidation on the brass in the photos. The next two photos show the stem surface. They show the tooth marks and chatter on both sides near the button. They also show the deep oxidation on the stem. The third photo below shows the threaded bone tenon.

The next two photos show the stem surface. They show the tooth marks and chatter on both sides near the button. They also show the deep oxidation on the stem. The third photo below shows the threaded bone tenon.

Jeff did a thorough clean up job on the pipe so that when it arrived here in Vancouver it looked amazingly good for a pipe that is at least a hundred years old. Jeff carefully reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl of the pipe. He rinsed it off under running water. He dried it off with a soft cloth. He was able to remove all of the lava build up on the beveled rim top of the pipe. The brass rim top and ferrule looked very good. The birdseye and cross grain was beautiful and the pipe looked very good. There were tooth marks and chatter visible on both sides of the stem at the button. I took photos of the pipe to show its condition before I started my work.

Jeff did a thorough clean up job on the pipe so that when it arrived here in Vancouver it looked amazingly good for a pipe that is at least a hundred years old. Jeff carefully reamed the bowl with a PipNet pipe reamer and followed up with a Savinelli Fitsall pipe knife to remove the cake. He scrubbed out the mortise and the airway in the shank and the stem with alcohol, cotton swabs and pipe cleaners. He scrubbed the exterior of the bowl, rim, shank and stem with a tooth brush and Murphy’s Oil Soap to remove the oils and tars on the rim and the grime on the finish of the bowl of the pipe. He rinsed it off under running water. He dried it off with a soft cloth. He was able to remove all of the lava build up on the beveled rim top of the pipe. The brass rim top and ferrule looked very good. The birdseye and cross grain was beautiful and the pipe looked very good. There were tooth marks and chatter visible on both sides of the stem at the button. I took photos of the pipe to show its condition before I started my work.

I took close up photos of the bowl, rim and stem surfaces to capture the condition of the pipe after Jeff had done his cleanup. The rim top was clean and the brass inner edge was in excellent condition. The stem was quite clean with some tooth marks and chatter on the top and underside near the button.

I took close up photos of the bowl, rim and stem surfaces to capture the condition of the pipe after Jeff had done his cleanup. The rim top was clean and the brass inner edge was in excellent condition. The stem was quite clean with some tooth marks and chatter on the top and underside near the button. I took a photo of the stamping on the left side of the shank and the flow of the grain on the shank and bowl side. It is a beautiful piece of briar.

I took a photo of the stamping on the left side of the shank and the flow of the grain on the shank and bowl side. It is a beautiful piece of briar. The bowl and rim top looked really good after Jeff’s clean up work. I decided to go straight to polishing the bowl. I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed the bowl with a cotton cloth to raise the shine. The following photos show the bowl at this point in the restoration process. The bowl and the rim top look really good and the grain really stood out on the smooth rim. The finish looks very good with the grain popping through the brown stain on the bowl and the brass on the rim top and shank end.

The bowl and rim top looked really good after Jeff’s clean up work. I decided to go straight to polishing the bowl. I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect it. I let the balm sit for a little while and then buffed the bowl with a cotton cloth to raise the shine. The following photos show the bowl at this point in the restoration process. The bowl and the rim top look really good and the grain really stood out on the smooth rim. The finish looks very good with the grain popping through the brown stain on the bowl and the brass on the rim top and shank end.

I set the bowl aside and turned my attention to the stem. I filled in the deep tooth marks on both sides with clear super glue. It takes a while to cure so I set it aside and worked on another pipe while it hardened.

I set the bowl aside and turned my attention to the stem. I filled in the deep tooth marks on both sides with clear super glue. It takes a while to cure so I set it aside and worked on another pipe while it hardened. Once the repairs had cured I used a needle file to sharpen the edge of the button and smooth out the repairs on the surface of the stem. I sanded it with 220 and 400 grit sand paper to smooth out the repairs and blend them into the surface of the stem.

Once the repairs had cured I used a needle file to sharpen the edge of the button and smooth out the repairs on the surface of the stem. I sanded it with 220 and 400 grit sand paper to smooth out the repairs and blend them into the surface of the stem.

I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad. I further polished it with Before & After Pipe Polish – both Fine and Extra Fine. I finished by giving it a final coat of Obsidian Oil and setting it aside to dry.

I polished the stem with micromesh sanding pads – wet sanding with 1500-2400 grit pads and dry sanding it with 3200-12000 grit pads. I wiped the stem down with Obsidian Oil after each pad. I further polished it with Before & After Pipe Polish – both Fine and Extra Fine. I finished by giving it a final coat of Obsidian Oil and setting it aside to dry.

Since I had finished both the bowl and stem I put them back together and carefully polished the bowl and stem with Blue Diamond polish on the buffing wheel. The combination of metal, Bakelite and briar makes this a very touch process. I gave the bowl and the stem multiple coats of Conservator’s Wax. I carefully buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The brass rim cap and shank end and the beautiful grain of the briar on the bowl came alive on the buffing wheel. The rich brown stain works well with polished amber coloured Bakelite stem. The finish looks amazing and it is smooth and light weight in the hand. Judging from the condition when we got it, I am sure that this will be another amazing smoker. Have a look at it with the photos below. The dimensions are Length: 5 1/4 inches, Height: 2 inches, Outside diameter of the bowl: 1 7/8 inches, Chamber diameter: 3/4 of an inch. This beauty will be going into my collection of old WDC and CPF. Thanks for walking through the restoration with me on this beautiful old time WDC Calabash pipe.

Since I had finished both the bowl and stem I put them back together and carefully polished the bowl and stem with Blue Diamond polish on the buffing wheel. The combination of metal, Bakelite and briar makes this a very touch process. I gave the bowl and the stem multiple coats of Conservator’s Wax. I carefully buffed the pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The pipe polished up pretty nicely. The brass rim cap and shank end and the beautiful grain of the briar on the bowl came alive on the buffing wheel. The rich brown stain works well with polished amber coloured Bakelite stem. The finish looks amazing and it is smooth and light weight in the hand. Judging from the condition when we got it, I am sure that this will be another amazing smoker. Have a look at it with the photos below. The dimensions are Length: 5 1/4 inches, Height: 2 inches, Outside diameter of the bowl: 1 7/8 inches, Chamber diameter: 3/4 of an inch. This beauty will be going into my collection of old WDC and CPF. Thanks for walking through the restoration with me on this beautiful old time WDC Calabash pipe.