Blog by Steve Laug

I was emailing back and forth with John, a pipeman in Edmonton who wanted to sell of his pipes. He was cleaning up things and thought he would see if I was interested in them. He said that he had several Bari’s that were in the lot and he wanted to move those out. He sent me photos of the pipes he had and we soon struck a deal. Since we were both in Canada it did not take long for the package to make its way to me. I opened it and went through his pipes to see what I had to work on. There were some pipe racks and accessories in the box as well. I went through the pipes and set them aside. Today I decided it was time to start working on them. I chose a little Bari De Luxe as the first of those Bari’s that I would work on. I have included two of the photos of the pipe that he sent to me before I purchased the lot.

I was emailing back and forth with John, a pipeman in Edmonton who wanted to sell of his pipes. He was cleaning up things and thought he would see if I was interested in them. He said that he had several Bari’s that were in the lot and he wanted to move those out. He sent me photos of the pipes he had and we soon struck a deal. Since we were both in Canada it did not take long for the package to make its way to me. I opened it and went through his pipes to see what I had to work on. There were some pipe racks and accessories in the box as well. I went through the pipes and set them aside. Today I decided it was time to start working on them. I chose a little Bari De Luxe as the first of those Bari’s that I would work on. I have included two of the photos of the pipe that he sent to me before I purchased the lot. You can see that it was a well-loved pipe and one that he smoked often. The finish was in good condition but dirty. The plateau on the shank end and the rim top was dusty and dirty. The rim top had a lot of tars and lava on the surface filling in some of the roughness of the finish. Under the grime the pipe looked to be in good condition. The stain highlighted the beautiful grain on the briar and the plateau was stained black in stark contrast to the reddish brown of the bowl. The bowl was caked and would need to be reamed but otherwise good condition. The stem had a sticky oily substance on it that almost smelled nutty. There was some oxidation under the oil but there were not any tooth marks or chatter on the surface. I took the following photos of the pipe before I began the cleanup. (The pipe came in an original Bari pipe sock. I have included it in the photos to give you an idea of the small, petite size of the pipe.)

You can see that it was a well-loved pipe and one that he smoked often. The finish was in good condition but dirty. The plateau on the shank end and the rim top was dusty and dirty. The rim top had a lot of tars and lava on the surface filling in some of the roughness of the finish. Under the grime the pipe looked to be in good condition. The stain highlighted the beautiful grain on the briar and the plateau was stained black in stark contrast to the reddish brown of the bowl. The bowl was caked and would need to be reamed but otherwise good condition. The stem had a sticky oily substance on it that almost smelled nutty. There was some oxidation under the oil but there were not any tooth marks or chatter on the surface. I took the following photos of the pipe before I began the cleanup. (The pipe came in an original Bari pipe sock. I have included it in the photos to give you an idea of the small, petite size of the pipe.)

I took a photo of the pipe with the stem removed to give a look at the style of the fancy stem.

I took a photo of the pipe with the stem removed to give a look at the style of the fancy stem. I took photos of the stamping on both sides of the shank. On the left it was stamped Bari over De Luxe and on the right side it was stamped Hand Made in Denmark. The stamping was faint toward the bowl on both sides of the shank but was still readable.

I took photos of the stamping on both sides of the shank. On the left it was stamped Bari over De Luxe and on the right side it was stamped Hand Made in Denmark. The stamping was faint toward the bowl on both sides of the shank but was still readable. I went to Pipedia and refreshed my memory on Bari pipes. I was pretty sure that they were connected to Viggo Nielson but wanted a reminder. Here is the link to the article on Pipedia: https://pipedia.org/wiki/Bari. I summarized the material that I found there as it gives a clear picture of the brand. I have been working on several pipes by Viggo Nielsen recently so it was a good reminder.

I went to Pipedia and refreshed my memory on Bari pipes. I was pretty sure that they were connected to Viggo Nielson but wanted a reminder. Here is the link to the article on Pipedia: https://pipedia.org/wiki/Bari. I summarized the material that I found there as it gives a clear picture of the brand. I have been working on several pipes by Viggo Nielsen recently so it was a good reminder.

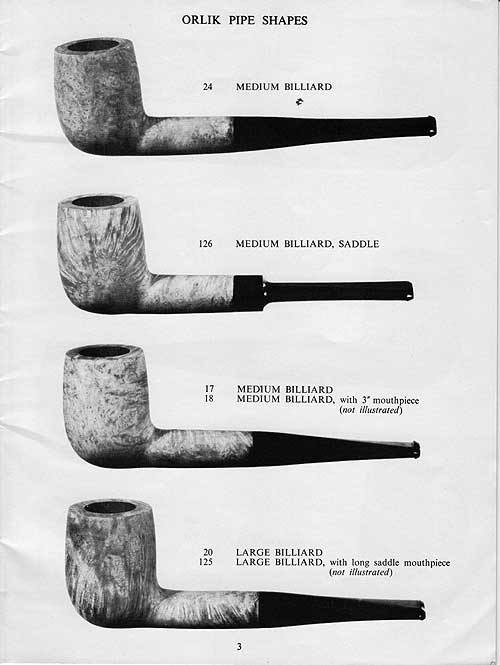

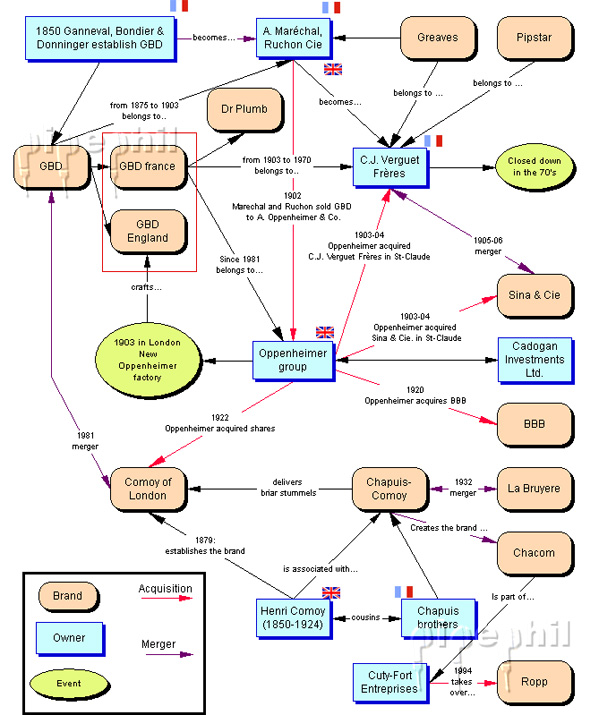

Pipedia states that Bari Piber was founded by Viggo Nielsen in Kolding, Denmark around the turn of 1950/51. His sons Kai and Jørgen both grew into their father’s business from a very young age and worked there till 1975. Both have become successful pipe makers.

Bari successfully adapted the new Danish design that had been started mainly by Stanwell for its own models. Bari was sold in 1978 to Van Eicken Tobaccos in Hamburg, Germany though the pipes were still made in Denmark. From 1978 to 1993 Åge Bogelund and Helmer Thomsen headed Bari’s pipe production.

Helmer Thomson bought the company in 1993 re-naming it to “Bari Piber Helmer Thomsen”. The workshop moved to more convenient buildings in Vejen. Bogelund, who created very respectable freehands of his own during the time at Bari got lost somehow after 1993. Bari’s basic conception fundamentally stayed the same for decades: series pipes pre-worked by machines and carefully finished by hand – thus no spectacular highgrades but solid, reliable every day’s companions were what they turned out. The most famous series are the smooth “Classic Diamond” and the blasted “Wiking”.

I started my cleanup of this pipe by working on the internals. I scraped out the remaining cake in the bowl with a Savinelli Fitsall Pipe Knife (I totally forgot to take photos of that part of the process). I cleaned out the airway in the shank and the stem with pipe cleaners and alcohol. I cleaned out the mortise in the shank with cotton swabs and alcohol. It was dirty but I was surprised it was as clean as it was.

I rubbed some Before & After Restoration Balm into the surface of the briar to enliven, clean and preserve it. I rubbed it in with my fingertips working it into the briar. I worked it into the nooks and crannies in the plateau on the rim and the shank end using a cotton swab. I brushed those areas with a shoe brush to work it in more deeply and spread it out. I set it aside for a little while to let the balm do its work. I buffed it off with a cotton cloth and then buffed it with a microfiber cloth. The photos below show the pipe at this point in the restoration process.

I rubbed some Before & After Restoration Balm into the surface of the briar to enliven, clean and preserve it. I rubbed it in with my fingertips working it into the briar. I worked it into the nooks and crannies in the plateau on the rim and the shank end using a cotton swab. I brushed those areas with a shoe brush to work it in more deeply and spread it out. I set it aside for a little while to let the balm do its work. I buffed it off with a cotton cloth and then buffed it with a microfiber cloth. The photos below show the pipe at this point in the restoration process.

I set the bowl aside and turned my attention to the stem. I wiped the oily, sticky stuff off of the surface of the stem with alcohol on a cotton pad. The smell of the stuff was almost nutty, like peanuts or something similar. It needed to go so that I could work on the stem.

I set the bowl aside and turned my attention to the stem. I wiped the oily, sticky stuff off of the surface of the stem with alcohol on a cotton pad. The smell of the stuff was almost nutty, like peanuts or something similar. It needed to go so that I could work on the stem. I sanded the light tooth chatter out of the surface of the stem and also worked over the oxidation that was prevalent in the grooves and spindles of the stem using 220 grit sandpaper. I forgot to take photos of that part of the process. I polished the stem using micromesh sanding pads – wet sanding with 1500-2400 grit pads and then buffing on the wheel with red Tripoli. I dry sanded the stem with 3200-12000 grit pads to further polish it. After each pad I wiped it down with Obsidian Oil to protect and enliven the stem. When I finished the last pad I gave it a final coat of oil and set it aside to dry.

I sanded the light tooth chatter out of the surface of the stem and also worked over the oxidation that was prevalent in the grooves and spindles of the stem using 220 grit sandpaper. I forgot to take photos of that part of the process. I polished the stem using micromesh sanding pads – wet sanding with 1500-2400 grit pads and then buffing on the wheel with red Tripoli. I dry sanded the stem with 3200-12000 grit pads to further polish it. After each pad I wiped it down with Obsidian Oil to protect and enliven the stem. When I finished the last pad I gave it a final coat of oil and set it aside to dry.

This small Bari De Luxe Freehand is a real beauty with straight and flame grain all around the bowl. The shank end and bowl rim are both beautiful plateau that is deep and craggy. The brown of the bowl and the black of the plateau look really good with the black of the turned vulcanite stem. I buffed the bowl and the stem with Blue Diamond polish to raise the shine on the briar and the vulcanite. I lightly buffed the rim top and shank end as well. I was careful to not buff the stamping and damage it. I gave the bowl and stem multiple coats of carnauba wax. I buffed the entire pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The finished pipe is shown in the photos below. The dimensions of the pipe are: Length: 5 1/4 inches, Height: 1 3/4 inches, Outside Diameter: 1 1/2 inches, Diameter of the chamber: ¾ of an inch. This is the first Bari De Luxe that I have worked on and the petite size and rugged looking plateau make it a pipe that I may hang on to for a while and enjoy. I am looking forward to enjoying my first bowl in it. Thanks for walking through the restoration with me.

This small Bari De Luxe Freehand is a real beauty with straight and flame grain all around the bowl. The shank end and bowl rim are both beautiful plateau that is deep and craggy. The brown of the bowl and the black of the plateau look really good with the black of the turned vulcanite stem. I buffed the bowl and the stem with Blue Diamond polish to raise the shine on the briar and the vulcanite. I lightly buffed the rim top and shank end as well. I was careful to not buff the stamping and damage it. I gave the bowl and stem multiple coats of carnauba wax. I buffed the entire pipe with a clean buffing pad to raise the shine. I hand buffed it with a microfiber cloth to deepen the shine. The finished pipe is shown in the photos below. The dimensions of the pipe are: Length: 5 1/4 inches, Height: 1 3/4 inches, Outside Diameter: 1 1/2 inches, Diameter of the chamber: ¾ of an inch. This is the first Bari De Luxe that I have worked on and the petite size and rugged looking plateau make it a pipe that I may hang on to for a while and enjoy. I am looking forward to enjoying my first bowl in it. Thanks for walking through the restoration with me.