Blog by Steve Laug

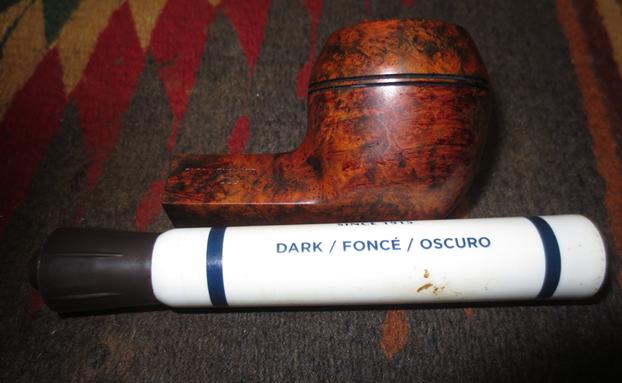

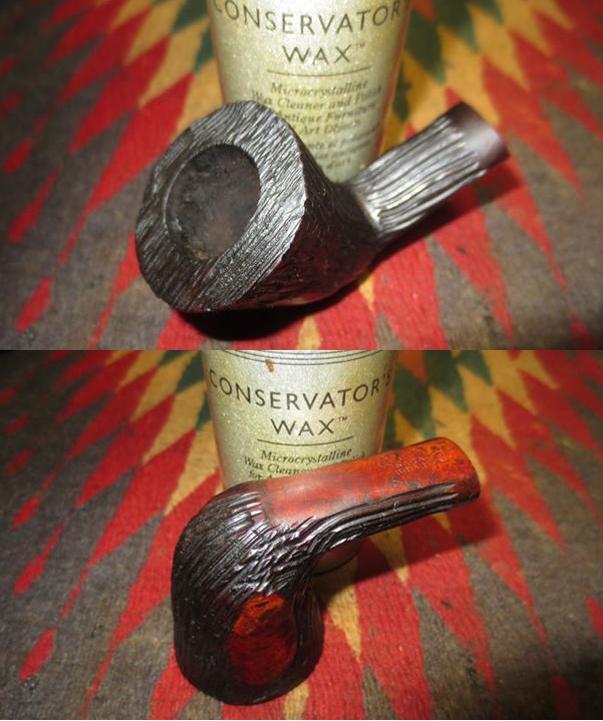

The next pipe from the estate lot my brother found and sent to me was a Barling Pot. It is stamped on the left side of the shank Barling over London England there is a thin line and under that it reads Vintage. On the underside of the shank it is stamped 6279 which is the shape number. My brother took the following photos of the pipe when he got home from the estate sale. These document the state of the pipe before he started his cleanup. Jeff took some photos of the rim top and the condition of the bowl. The bowl had a thick cake in it and it had overflowed onto the beveled rim top with a thick coat of lava.

Jeff took some photos of the rim top and the condition of the bowl. The bowl had a thick cake in it and it had overflowed onto the beveled rim top with a thick coat of lava. The next two photos show the grain on the pipe. There was one small sandpit on the bottom front of the bowl and another on the right side of the bowl. Both have been filled with tan putty that blends in really well with the stain on the briar.

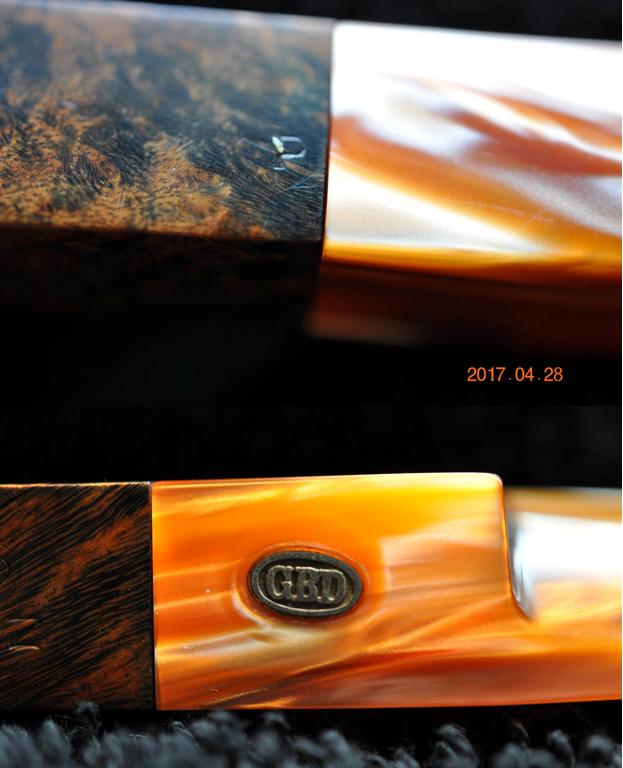

The next two photos show the grain on the pipe. There was one small sandpit on the bottom front of the bowl and another on the right side of the bowl. Both have been filled with tan putty that blends in really well with the stain on the briar. The next two photos show the stamping on the pipe. The first shows the left side and the second shows the underside of the shank. My brother had also turned the stem over to show the Barling cross on the stem. It had faded and the white paint that is usually in it was gone.

The next two photos show the stamping on the pipe. The first shows the left side and the second shows the underside of the shank. My brother had also turned the stem over to show the Barling cross on the stem. It had faded and the white paint that is usually in it was gone. The last two photos showed the now familiar tooth chatter and marks on the top and underside of the stem next to the button. Fortunately these were not too deep in the vulcanite either and should be able to be cleaned up quite easily.

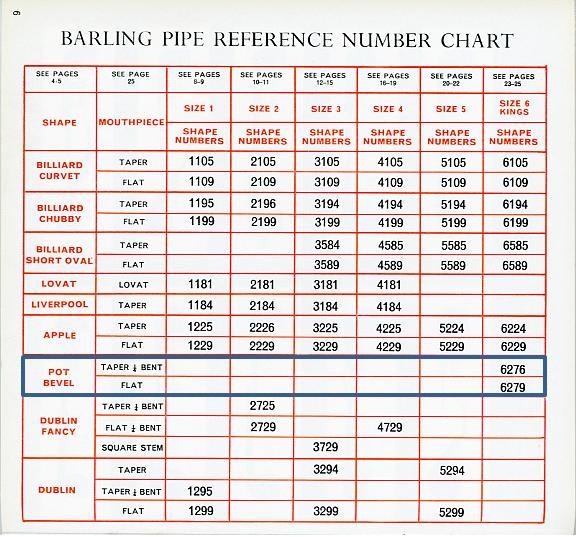

The last two photos showed the now familiar tooth chatter and marks on the top and underside of the stem next to the button. Fortunately these were not too deep in the vulcanite either and should be able to be cleaned up quite easily. Dating Barling pipes always proves interesting to me. I get all of the eras confused and find that pinning down some dates is difficult if not nigh on impossible (at least for me). The four digit shape number was the first thing I checked out. I found a catalogue page from a 1962 Barling Catalogue on Pipedia’s post on Barling Pipes that gave me a listing of shape numbers. The 6279 shape is a Pot Bevel with a flat stem according to the chart. The pipe I have indeed a Pot shape with a beveled rim top. However, it did not have a flat stem. It had a taper stem. That was the first anomaly I found regarding this pipe. I like the taper stem on this one. It works well with the shape. (I have outlined the shape of this pipe with a blue box in the photo below.)

Dating Barling pipes always proves interesting to me. I get all of the eras confused and find that pinning down some dates is difficult if not nigh on impossible (at least for me). The four digit shape number was the first thing I checked out. I found a catalogue page from a 1962 Barling Catalogue on Pipedia’s post on Barling Pipes that gave me a listing of shape numbers. The 6279 shape is a Pot Bevel with a flat stem according to the chart. The pipe I have indeed a Pot shape with a beveled rim top. However, it did not have a flat stem. It had a taper stem. That was the first anomaly I found regarding this pipe. I like the taper stem on this one. It works well with the shape. (I have outlined the shape of this pipe with a blue box in the photo below.) I did some more work on the internet to try to figure out when the Vintage finish pipes were made and sold. I read several articles but found nothing specific until I found another article on Pipedia under the following heading. I quote that section of the article in full.

I did some more work on the internet to try to figure out when the Vintage finish pipes were made and sold. I read several articles but found nothing specific until I found another article on Pipedia under the following heading. I quote that section of the article in full.

Lines and Nomenclature (https://pipedia.org/index.php?title=Barling)

During the late 1970’s additional lines of pipes were introduced and the Company was restyled as Barling of England. In the late 1970’s production of Barling pipes was shifted to Denmark where Eric Nording manufactured Barling pipes for Imperial. There may have been other factories, but as of this writing, none has been identified. Nording stated that he made approximately 100.000 pipes for Imperial.

It was at this point that Ronald Harden, general manager of Barling, stepped in to attempt to save the brand from extinction. Through the efforts of Mr. Harden, Bucktrout and Company bought the rights to the Barling name and at this point operations were moved to the Isle of Man with Mr. Harden as chairman. The company was renamed Barling Pipes Ltd. From that point on, the goal was to restore the old tradition of pipemaking from the family era. New equipment was installed and pipes were made following the Pre-Transition patterns. In 1980, rather than becoming a footnote in pipemaking history, the new line of Barling pipes was introduced.

Some of the Pre-Transition nomenclature was restored, such as the old SS thru EXEXEL size system even though the pipes continued to be stamped with a 4-digit number that also included a size designation. The use of a “Barling’s Make” block letter logo was reintroduced on the 1978 series of pipes, though the logo is on one line with no arched lettering. And both the “Ye Olde Wood” and “TVF” stamping was brought back.

Barling was established as a mid market level pipe and remained such through a portion of the 1990’s. Most recently inexpensive pipes bearing the Barling name, but made by Peterson have been available for sale in the US.

The first highlighted box above gives the information on the Vintage finish Barling in the part of the quoted article that notes the four ranges. The one I had was found in Number 2 above. The information included there gave me a starting date of the late 1970’s for the manufacture of the Barling that I was working on. In the second highlighted box I found a date of 1980 when Imperial closed down Barling operations entirely. This gives a 5-7 year window when the pipe could have been made. So I am working on either a 40-42 year old pipe or a 30-32 year old pipe. I was actually successful in finding the information on the little Barling Vintage Pot that was on my work table. Better informed than when I began, I could turn my attention to working on the pipe itself.

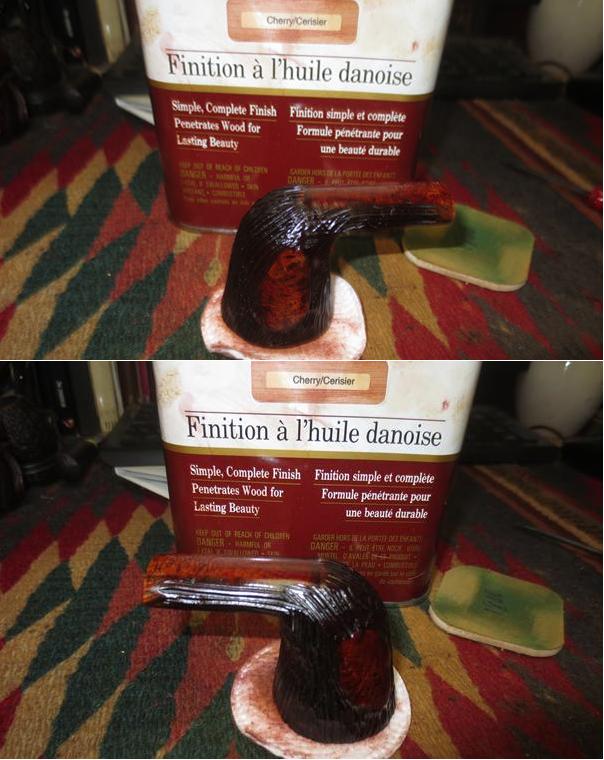

I took the next four photos of the pipe when it arrived in Vancouver. My brother had done an exceptional job cleaning it up. The pipe looked really good. The finish was clean and the rim was spotless.

I took a close up photo of the rim to show the condition it was in when it came. Jeff had reamed it really well and had cleaned off all of the lava on the rim. Somehow the lava had protected the beveled rim from damage or burn marks. It was in excellent shape.

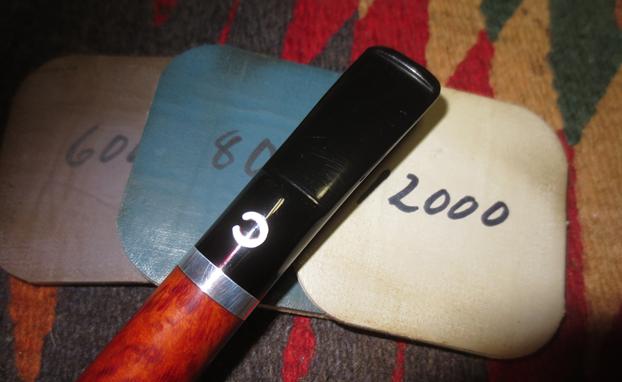

I took a close up photo of the rim to show the condition it was in when it came. Jeff had reamed it really well and had cleaned off all of the lava on the rim. Somehow the lava had protected the beveled rim from damage or burn marks. It was in excellent shape. The stem showed oxidation as well as tooth chatter and marks on the top and underside near the button. The Barling cross on the stem was faded but it was well stamped and could be repainted.

The stem showed oxidation as well as tooth chatter and marks on the top and underside near the button. The Barling cross on the stem was faded but it was well stamped and could be repainted. I ran a pipe cleaner and alcohol through the airway in the stem and the shank and cleaned out the mortise with a cotton swab and alcohol to remove any remaining tars or oils in those areas. The pipe was really clean as I expected.

I ran a pipe cleaner and alcohol through the airway in the stem and the shank and cleaned out the mortise with a cotton swab and alcohol to remove any remaining tars or oils in those areas. The pipe was really clean as I expected. I buffed the stem with red Tripoli and wiped it down with a damp cotton pad to remove the dust and grit that remained in the Barling Cross. I painted that area on the stem with white acrylic paint to fill in the vertical and horizontal Barling name that was crossed on the top side of the stem near the tenon end. I pushed the paint into the letters and wiped off the excess with a soft, dry cotton pad.

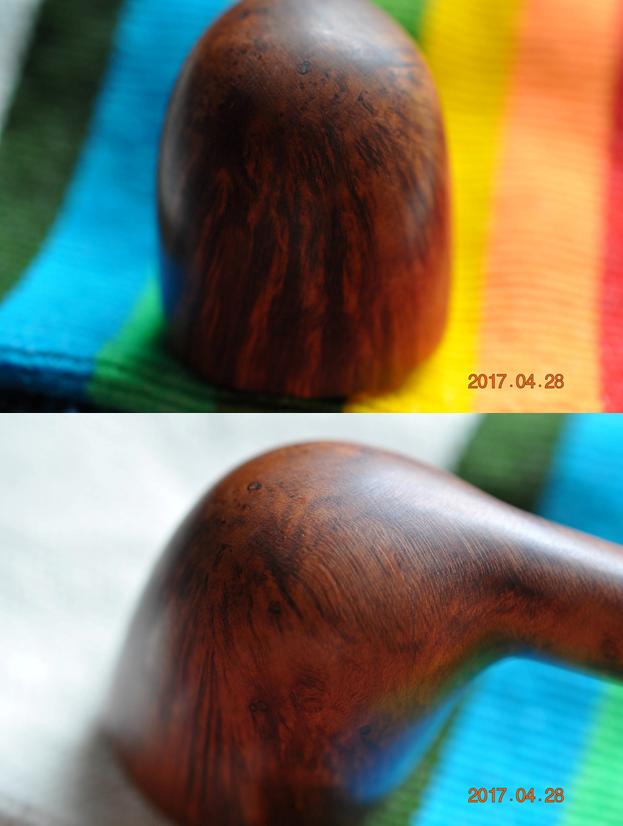

I buffed the stem with red Tripoli and wiped it down with a damp cotton pad to remove the dust and grit that remained in the Barling Cross. I painted that area on the stem with white acrylic paint to fill in the vertical and horizontal Barling name that was crossed on the top side of the stem near the tenon end. I pushed the paint into the letters and wiped off the excess with a soft, dry cotton pad. I buffed the bowl with Blue Diamond on the buffing wheel to polish the briar. You can see the three small filled sandpits in the first photo and the one toward the bottom of the bowl in the second photo. The fourth photo shows three small fills on the bottom of the bowl. I circled the fills in red in the photos. These fills showed me what I was expecting in a pipe from this era. In the second highlighted portion of the Pipedia article that spoke of closing the pipe, it noted that:“Despite these attempts to diversify the line, Barling lost its market. These pipes just weren’t equivalent to the family era pipes.”

I buffed the bowl with Blue Diamond on the buffing wheel to polish the briar. You can see the three small filled sandpits in the first photo and the one toward the bottom of the bowl in the second photo. The fourth photo shows three small fills on the bottom of the bowl. I circled the fills in red in the photos. These fills showed me what I was expecting in a pipe from this era. In the second highlighted portion of the Pipedia article that spoke of closing the pipe, it noted that:“Despite these attempts to diversify the line, Barling lost its market. These pipes just weren’t equivalent to the family era pipes.”

I set the bowl aside and turned my attention to working on the stem. I polished the stem with micromesh sanding pads. I wet sanded it with 1500-2400 grit pads and rubbed it down with Obsidian Oil. I buffed the stem with red Tripoli to further remove the oxidation on the stem. I dry sanded it with 3200-12000 grit pads to polish it further. I rubbed it down with Obsidian Oil after each sanding pad to enliven the vulcanite. I gave it a final coat after the 12000 grit pad and set it aside to dry.

I set the bowl aside and turned my attention to working on the stem. I polished the stem with micromesh sanding pads. I wet sanded it with 1500-2400 grit pads and rubbed it down with Obsidian Oil. I buffed the stem with red Tripoli to further remove the oxidation on the stem. I dry sanded it with 3200-12000 grit pads to polish it further. I rubbed it down with Obsidian Oil after each sanding pad to enliven the vulcanite. I gave it a final coat after the 12000 grit pad and set it aside to dry.

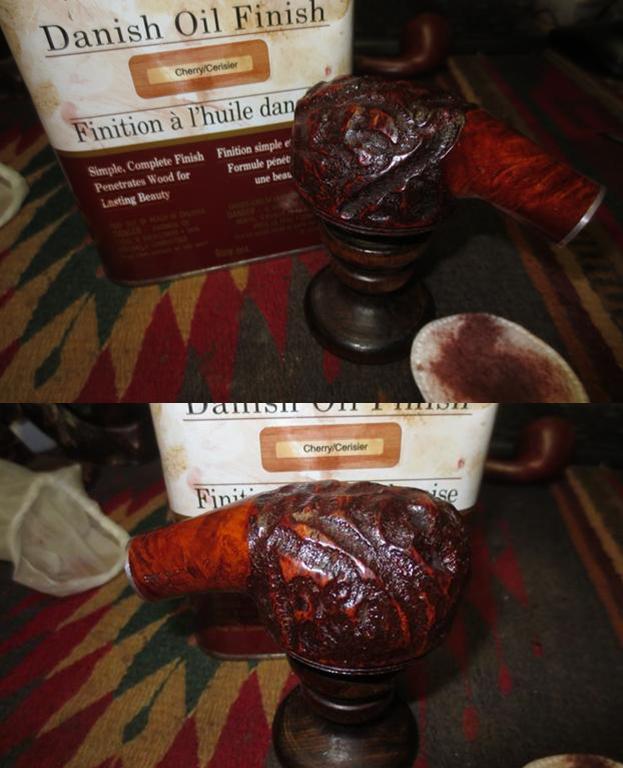

I polished the briar with micromesh sanding pads as well. I wet sanded it with 1500-2400 grit sanding pads and wiped it down with a damp cotton pad. I dry sanded it with 3200-12000 grit pads and wiped it down after each set of three sanding pads.

I polished the briar with micromesh sanding pads as well. I wet sanded it with 1500-2400 grit sanding pads and wiped it down with a damp cotton pad. I dry sanded it with 3200-12000 grit pads and wiped it down after each set of three sanding pads.

The more I polished the briar the more the fills on the right side and the front began to blend into the briar. Notice how they are disappearing in the following photos.

The more I polished the briar the more the fills on the right side and the front began to blend into the briar. Notice how they are disappearing in the following photos.

After polishing with the final three pads (6000-12000 grit) the briar really shined and the fills though still present did not stick out so much.

After polishing with the final three pads (6000-12000 grit) the briar really shined and the fills though still present did not stick out so much.

I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel. I gave both multiple coats of carnauba wax and buffed it with a clean buffing pad to raise a shine. I hand buffed it with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. It is a beautiful pipe. Even the small fills that are around the sides and bottom of the bowl do not detract from the great shape and look of the pipe. This Barling Vintage pipe will soon be on sale on the rebornpipes store. It will make a great addition to someone’s rack and should be a good smoker as the mechanics are really well done. The dimensions are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside bowl diameter: 1 ½ inches, Chamber diameter: 7/8 inches. Check it out there and if you are interested email me at slaug@uniserve.com or send me a message on Facebook and the pipe can be yours. Thanks for looking.

I put the stem back on the bowl and buffed the pipe with Blue Diamond on the buffing wheel. I gave both multiple coats of carnauba wax and buffed it with a clean buffing pad to raise a shine. I hand buffed it with a microfibre cloth to deepen the shine. The finished pipe is shown in the photos below. It is a beautiful pipe. Even the small fills that are around the sides and bottom of the bowl do not detract from the great shape and look of the pipe. This Barling Vintage pipe will soon be on sale on the rebornpipes store. It will make a great addition to someone’s rack and should be a good smoker as the mechanics are really well done. The dimensions are Length: 5 ¾ inches, Height: 1 ¾ inches, Outside bowl diameter: 1 ½ inches, Chamber diameter: 7/8 inches. Check it out there and if you are interested email me at slaug@uniserve.com or send me a message on Facebook and the pipe can be yours. Thanks for looking.

I ran a pipe cleaner through the airway in the stem and the shank and they were very clean. I used a cotton swab to clean around the step down on the tenon and in the mortise. These too were clean.

I ran a pipe cleaner through the airway in the stem and the shank and they were very clean. I used a cotton swab to clean around the step down on the tenon and in the mortise. These too were clean.