Guest Blog by Robert M. Boughton

Member, North American Society of Pipe Collectors

http://www.naspc.org

http://www.roadrunnerpipes.com

http://about.me/boughtonrobert

Photos © the Author

The Wizard of Oz: “As for you, my galvanized friend, you want a heart. You don’t know how lucky you are not to have one. Hearts will never be practical until they can be made unbreakable.”

The Tin Woodsman: “But I still want one.”

― From “The Wizard of Oz” (movie, 1939)

INTRODUCTION

As a movie and trivia buff, not necessarily together, one of my favorite questions that comes up now and then in conversation and on quiz shows is “When was the Golden Age of Hollywood?” I like it because of the slippery term Golden Age, which implies years forming a great period of time with specific world-changing events and personages, as in the Bronze Age or the Age of Enlightenment. It’s also a trick question, the expected (but incorrect if often accepted) answer being 1939. Granted, in that one year, some of the great movies in Hollywood history were made, including “The Wizard of Oz,” “Gone with the Wind,” “Stagecoach,” “Mr. Smith Goes to Washington” and “Wuthering Heights”. But the true and more agreed upon answer would be 1930-1959, which encompassed “All Quiet on the Western Front” to “Anatomy of a Murder”.

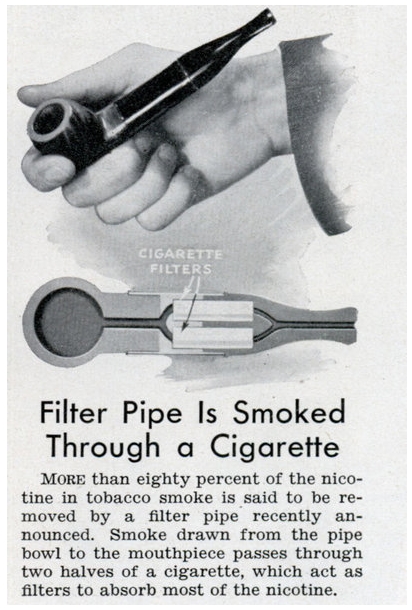

All of this is my way of approaching a term I often refer to but did not coin, the Golden Age of Pipe Smoking. In my mind, although the exact timeline is sometimes said to have begun as long ago as the mid-1800s, this period was from the 1930s into the ’70s, when pipes were ubiquitous and respected all over the world, as reflected in motion pictures, TV and society in general. Below are a few famous Hollywood pipe men: Fred Astaire, John and Lionel Barrymore, Harry Belafonte and Fred MacMurray. My own dad and almost all of his friends enjoyed and in many cases had collections of the magic briar social lubricant. The subject of this blog, a brand of pipe named with perhaps tongue-in-cheek humor, is one of the quirkiest, most unusual examples conceived during this wonderful age that I believe is experiencing a renascence: the Aristocob, invented by Joseph W. Zarikta for the Al Cobb Corporation and granted U.S. Patent №. 3,292,639 on December 20, 1966.

My own dad and almost all of his friends enjoyed and in many cases had collections of the magic briar social lubricant. The subject of this blog, a brand of pipe named with perhaps tongue-in-cheek humor, is one of the quirkiest, most unusual examples conceived during this wonderful age that I believe is experiencing a renascence: the Aristocob, invented by Joseph W. Zarikta for the Al Cobb Corporation and granted U.S. Patent №. 3,292,639 on December 20, 1966. The Al Cobb Corp. became Al-Cob Corp. in Grand Haven, Michigan, and still later Aristocob Inc. in Caledonia, Michigan before being taken over by the Missouri Meerschaum Company in Washington, Missouri. Missouri Meerschaum made the corncob inserts from the early 1970s until 1983, and since then replacements have not been manufactured, but with dedicated searching some will, on occasion, show up when they are found and offered online. Even though I could not locate any for this restoration, I know they still pop up because of several sold-out listings I found on eBay. However, by most accounts the original inserts, or even self-styled replacements, are high maintenance contraptions that quickly become wet, mushy and, in short, nasty to use. Still, our esteemed host, Steve, emailed me the following message: “I love those old aristocobs. They are sweet looking retro experiments.” Indeed they are. I even found several sites where this pipe is given the high description of “art deco.”

The Al Cobb Corp. became Al-Cob Corp. in Grand Haven, Michigan, and still later Aristocob Inc. in Caledonia, Michigan before being taken over by the Missouri Meerschaum Company in Washington, Missouri. Missouri Meerschaum made the corncob inserts from the early 1970s until 1983, and since then replacements have not been manufactured, but with dedicated searching some will, on occasion, show up when they are found and offered online. Even though I could not locate any for this restoration, I know they still pop up because of several sold-out listings I found on eBay. However, by most accounts the original inserts, or even self-styled replacements, are high maintenance contraptions that quickly become wet, mushy and, in short, nasty to use. Still, our esteemed host, Steve, emailed me the following message: “I love those old aristocobs. They are sweet looking retro experiments.” Indeed they are. I even found several sites where this pipe is given the high description of “art deco.”

Nevertheless, I believe I have found a more suitable and permanent solution to the problem, even if it does detract from the good, old timey flavor of the maker’s intent: briar inserts made to fit the Aristocob. [See http://www.owlpipes.com/#!new-collection/c1jn5.%5D For this restoration I ordered one, and considering I bought the beat-up old pipe itself for $2 at a yard sale, the $25 cost of the briar insert should be worth it. As timing allowed, the insert arrived on Friday but was too big for my home mailbox, where the package was sent due to a mix-up with PayPal, instead of the Post Office Box I use most often. And the Postman being too lazy to walk to my door (or just afraid to do so in my neighborhood), I picked it up at the Post Office Saturday.

This restoration, therefore, takes place in real-time, as I write this.

RESTORATION

Before venturing to my neighborhood Postal Station, which is the local training site and therefore deplorable, I decide to do a preliminary clean-up of the metal. The oxidation on the bowl, in particular in the threads and deep grooves, comes off with ease using a pair of small, thin, cotton gun cleaning patches soaked in Everclear. I am able to use the same patches to clean the threaded lid inside and out. The identical process on the chamber removes most of the old tobacco juice and minimal oxidation except for the brown grime near the opening of the air hole. For that I dip a bristly cleaner in the alcohol and run it through the wide open, tubular shank and into the bottom of the chamber. The shank needs a second swabbing.

Before venturing to my neighborhood Postal Station, which is the local training site and therefore deplorable, I decide to do a preliminary clean-up of the metal. The oxidation on the bowl, in particular in the threads and deep grooves, comes off with ease using a pair of small, thin, cotton gun cleaning patches soaked in Everclear. I am able to use the same patches to clean the threaded lid inside and out. The identical process on the chamber removes most of the old tobacco juice and minimal oxidation except for the brown grime near the opening of the air hole. For that I dip a bristly cleaner in the alcohol and run it through the wide open, tubular shank and into the bottom of the chamber. The shank needs a second swabbing.

The pipe cleaner dipped in freshener that I run through the air hole of the bit comes out clear, but it doesn’t hurt to try. The outside of the bit, with almost no scratches, buffs up nicely using micromesh. I place the filter, in this case a Medico because it fits and I have a few – and with this pipe, a filter really will be necessary – into the stem.

The pipe cleaner dipped in freshener that I run through the air hole of the bit comes out clear, but it doesn’t hurt to try. The outside of the bit, with almost no scratches, buffs up nicely using micromesh. I place the filter, in this case a Medico because it fits and I have a few – and with this pipe, a filter really will be necessary – into the stem.

And so the time to face the ordeal of the long, slow line at the Post Office comes. An hour later I am home again with my new briar insert and a surprise: a small key chain fashioned with a little chunk of lightweight, pale briar, both of them in a nice bag with a drawstring.

And so the time to face the ordeal of the long, slow line at the Post Office comes. An hour later I am home again with my new briar insert and a surprise: a small key chain fashioned with a little chunk of lightweight, pale briar, both of them in a nice bag with a drawstring.

Now, something about the nakedness of the insert, being briar instead of the traditional corncob, just doesn’t sit right with me. Even when I test the fit by dropping it in the chamber and screwing on the lid, while indeed the briar is the correct size, the raw part of the rim that shows, beneath the top of the aluminum lid when I screw it on, is wrong. I ask myself (not out loud, but in my head – I’m not crazy, even if at times I ramble and digress), “Would I ever, even on the most rushed or easygoing project, conceivably consider leaving any rim unpolished?”

Now, something about the nakedness of the insert, being briar instead of the traditional corncob, just doesn’t sit right with me. Even when I test the fit by dropping it in the chamber and screwing on the lid, while indeed the briar is the correct size, the raw part of the rim that shows, beneath the top of the aluminum lid when I screw it on, is wrong. I ask myself (not out loud, but in my head – I’m not crazy, even if at times I ramble and digress), “Would I ever, even on the most rushed or easygoing project, conceivably consider leaving any rim unpolished?”

“Hell, no,” is my immediate response, though still silent. And so the next stage begins with what is intended to be just a quick sanding, micro-meshing and waxing of the rim. In point of fact, I try only the progression of micromesh, but that reveals the need for sanding, which I accomplish with 400-grit paper before re-doing the micromesh.

SUNDAY

SUNDAY

But of course, once I start down that road – as simple as settling for the polished rim of the insert with its newly exposed even grain would be, given that it is the only part that will show through the lid – I simply cannot bring myself to leave the sides completely unfinished. Still, I approach this task with nowhere near the detail I would give a regular briar bowl. A fast sanding with 320-grit paper followed by 400, then micro-meshing, satisfies me, and it shows in the photos below. I consider doing the bottom of the insert, with a small hole drilled to allow moisture to pass in this most bizarre system pipe, but good sense does get the better of me, when my mind comes around to the reality of the resulting damage to anything sitting for long in the potential quagmire that the lucky buyer of this fine pipe might create even without the genuine, disposable corncob inserts.

Now, as midnight approaches, the second day of sporadic work on the Aristocob reaches its end and extends into another, as seems to be the nature of my life so often these hectic days. I need to run to the nearest Walmart anyway, to buy more distilled water, distilled white vinegar and baking soda to continue with the final few steps of this experimental restoration.

Now, as midnight approaches, the second day of sporadic work on the Aristocob reaches its end and extends into another, as seems to be the nature of my life so often these hectic days. I need to run to the nearest Walmart anyway, to buy more distilled water, distilled white vinegar and baking soda to continue with the final few steps of this experimental restoration.

MONDAY

Having secured the necessary ingredients for the culmination of an exciting and hopefully successful restoration, the next stage is to soak the aluminum for ten minutes or so in enough of the pure vinegar to cover all of the metal. As I have never before had occasion to work with aluminum in this sort of project, I have not tried the unusual method of cleaning any part of a pipe, and must trust a fellow pipe club member who actually makes his living engaging daily in this process to remove dirt and other substances from industrial parts made of the same material, and at the same time brighten it. I do, at least, confirm online that the procedure is an established and excellent means of accomplishing the goal. While the aluminum soaks, I enjoy a brief respite from my toils, with a pipe-full of some of the last of my C&D Pirate Kake in a newly-acquired Castello Old Antiquari KKKK Sandblasted Bulldog. There is no doubt this is a bulldog compared to the dubious designation of Rhodesian that, with clear reservations, I suggest for the Aristocob by way of calling the art deco thing anything other than that.

While the aluminum soaks, I enjoy a brief respite from my toils, with a pipe-full of some of the last of my C&D Pirate Kake in a newly-acquired Castello Old Antiquari KKKK Sandblasted Bulldog. There is no doubt this is a bulldog compared to the dubious designation of Rhodesian that, with clear reservations, I suggest for the Aristocob by way of calling the art deco thing anything other than that.

Alright, then; the aluminum Rhodesian has soaked for 12 minutes now in white vinegar, and I am one step closer to seeing if the well-intentioned advice of my fellow piper has any merit to it. First giving the metal pieces a basic rinse with tap water, I replace them in the plastic container for a thorough dousing in a concoction of the same with an unspecified and therefore liberal amount of baking soda stirred in to rid the aluminum of any residual acidic vinegar.

After a long day involving far more than this restoration, which details I will spare the reader and try to make myself forget, I suspect the Old Antiquari is up for another ten-minute smoke, and I know I am.

Ten more minutes fly by, and the water and baking soda have done as much as they can to ensure the complete removal of vinegar. I rinse the metal again and dry the lid, bowl, shank and chamber with a cotton rag. I decide to use another cleaner to dry the inside of the shank and chamber air hole, only to discover that the combination of the vinegar and the following water-baking soda soaks has dredged up much more vintage grime. Both ends of the one dry cleaner, then a second dipped in Everclear and a third dry cleaner clear out the remaining mess, and I re-wipe the chamber with a rag.

The pipe is as ready as I can make it for reassembly. I drop the polished briar insert in place, screw on the lid and slide the bit with its new Medico filter into the shank, and give the whole thing a rubbing with the cotton rag.

CONCLUSION

CONCLUSION

Although not as shimmering as it once looked new in its package with a couple of spare corncob inserts, the vintage Aristocob Rhodesian, like the Tin Woodsman in Oz, has a new briar heart that matches the second part of “my galvanized friend[’s]” name. And this new transplant will last much longer than the original.