Blog by Steve Laug

The next pipe on the work table came to me in a group of six pipes I bought from a fellow in Eastern Canada. It included two Canadian made pipes – a Blatter of Montreal and a Trypis. In the mix was an English made Charatan second stamped Mountbatten and two Peterson’s and an Irish Second. The pipes were well used and all had been smoked. The seller sent me a photo of the pipes so that I could see what he was selling. We discussed some options together and arrived at an agreement and the pipes were on their way to me in Vancouver. There was something about the circular shanked, slightly-bent-Dublin, the bottom pipe in the right column that grabbed my attention and made me want to work on it next. It arrived in its original box and sock. I knew that the pipe had been restemmed by Charles Lemon with fishtail stem rather than the original p-lip stem it had come with when new. I brought it to the worktable and examined it before starting my work. I took photos of the original box that the pipe arrived in and what I saw when I opened the box.

There was something about the circular shanked, slightly-bent-Dublin, the bottom pipe in the right column that grabbed my attention and made me want to work on it next. It arrived in its original box and sock. I knew that the pipe had been restemmed by Charles Lemon with fishtail stem rather than the original p-lip stem it had come with when new. I brought it to the worktable and examined it before starting my work. I took photos of the original box that the pipe arrived in and what I saw when I opened the box.

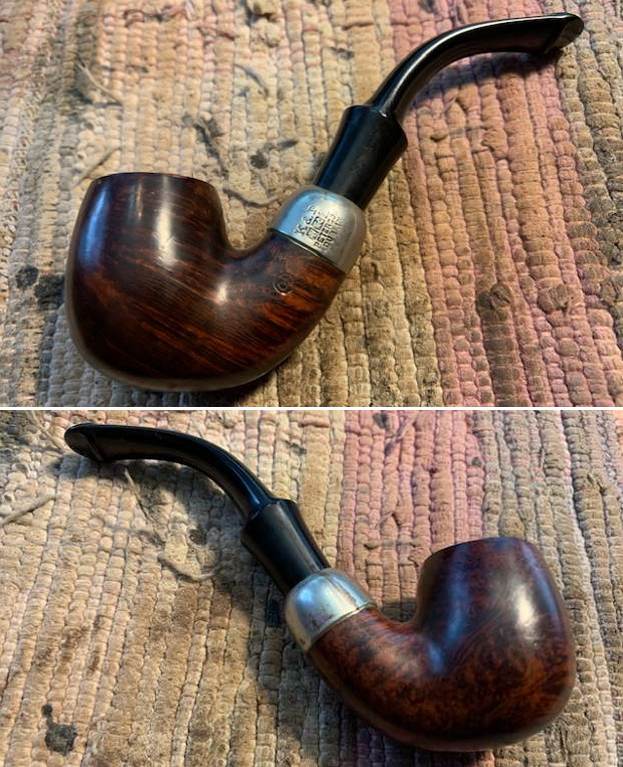

This is what I saw. It had a round shank, a stamped silver band and a vulcanite taper fishtail stem. The pipe is stamped on the right side of the shank and reads Peterson’s [arched over] of Dublin [arched over] SHERLOCK HOLMES in two lines. On the right side of the shank is stamped MYCROFT. On the fancy silver band on the shank end it is stamped on the left and has a profile of Sherlock Holmes with a pipe in his mouth and his deerstalker hat on his head. Arched over it is stamped PETERSON’S and under it is stamped STERLING SILVER. On the left side it is stamped Peterson over three hallmarks – a seated woman (Hibernia), an oval with 925 centered in it (quality of the silver used) and the italic letter I (the date letter). The finish had some grime ground into the finish on the bowl but still looked to be in good condition. The bowl was moderately caked with some light lava on the top at the back and some darkening on the top and the inner edge of the rim. The taper stem hand made by Charles Lemon had some light tooth chatter on the top and underside near the button. There was a silver “P” logo on the left side of the taper stem. It had promise but it was dirty. I took some photos of the pipe before I started my cleanup work.

This is what I saw. It had a round shank, a stamped silver band and a vulcanite taper fishtail stem. The pipe is stamped on the right side of the shank and reads Peterson’s [arched over] of Dublin [arched over] SHERLOCK HOLMES in two lines. On the right side of the shank is stamped MYCROFT. On the fancy silver band on the shank end it is stamped on the left and has a profile of Sherlock Holmes with a pipe in his mouth and his deerstalker hat on his head. Arched over it is stamped PETERSON’S and under it is stamped STERLING SILVER. On the left side it is stamped Peterson over three hallmarks – a seated woman (Hibernia), an oval with 925 centered in it (quality of the silver used) and the italic letter I (the date letter). The finish had some grime ground into the finish on the bowl but still looked to be in good condition. The bowl was moderately caked with some light lava on the top at the back and some darkening on the top and the inner edge of the rim. The taper stem hand made by Charles Lemon had some light tooth chatter on the top and underside near the button. There was a silver “P” logo on the left side of the taper stem. It had promise but it was dirty. I took some photos of the pipe before I started my cleanup work.

I took photos of the rim top and bowl to give a clear picture of the thickness of the cake and the overflow of lava on the rim top. I also took photos of the top and underside of the stem to show the oxidation and the chatter and tooth marks.

I took photos of the rim top and bowl to give a clear picture of the thickness of the cake and the overflow of lava on the rim top. I also took photos of the top and underside of the stem to show the oxidation and the chatter and tooth marks.  I took photos of the sides and heel of the bowl to give a picture of what the briar around the pipe looked like. There is some stunning grain under the grime.

I took photos of the sides and heel of the bowl to give a picture of what the briar around the pipe looked like. There is some stunning grain under the grime.

I took photos of the stamping on the sides of the shank and on the band. It reads as noted above and is clear and readable.

I took photos of the stamping on the sides of the shank and on the band. It reads as noted above and is clear and readable.  I removed the stem from the shank and took a photo of the pipe to give a sense of the proportion of this round shank Dublin.

I removed the stem from the shank and took a photo of the pipe to give a sense of the proportion of this round shank Dublin. I am including the information from Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson).

I am including the information from Pipedia’s article on Peterson pipes. It is a great read in terms of the history of the brand (https://pipedia.org/wiki/Peterson).

I turned to “The Peterson Pipe” by Mark Irwin and Gary Malmberg to get some background on the Peterson’s The Return of Sherlock Holmes Line. On page 184 it had the following information.

Even before O’Neill had settled in Peterson launched The Return of Sherlock Holmes, the second set of seven original shapes. These include the Rathbone…Hudson… Mycroft… Lestrade… Milverton…Strand…Hansom.

The chapter goes on to describe the Mycroft smooth as follows:

A circular shanked, slightly-bent-Dublin and the second design by Ian Harry Seiffert, the Mycroft (XL22) is named after Holmes’s brother, who appears in four stories, “The Greek Interpreter,” “The Final Problem,” “The Empty House” and “The Bruce-Partington Plans.”

I then turned to Pipedia and found a link to the Peterson’s Sherlock Holmes series of pipes (https://pipedia.org/wiki/A_closer_look_at_the_Peterson_Sherlock_Holmes_series_of_pipes). I quote the following information on the series as a whole then the section on the Return of Sherlock Holmes series

The subject for this pipe focus is the Sherlock Holmes issue of briar pipes, let us look more closely at the individual pipes in more detail.

Probably the most successful series of pipes ever introduced by Peterson in terms of numbers. They were first issued in 1987 to honour Sir Arthur Conan Doyle’s famous fictitious detective character, Sherlock Holmes.

Holmes is perhaps the most famous pipe smoking character in fiction. He is reputed to have kept a selection of favourite pipes – from plain black clay pipes to richly grained briar pipes – to which he frequently resorted to for inspiration, while unravelling a mystery, or solving a knotty problem. For solace, after bringing a difficult case to successful conclusion, and always for pleasure. A man who kept his tobacco in a Persian slipper has to be something of a character, and a colourful one to boot, as indeed was Mr. Holmes of 221B Baker Street, London.

The pipes, crafted in Ireland from selected Mediterranean sourced briar, are made to honour the novels original characters, places and items encountered by Sherlock Holmes in his various adventures.

I quote that portion of the article below. I have highlighted the portion on the Mycroft in red.

The Return of Sherlock Holmes Series

The second issue was called “The Return of” – and was based on the success of “the Original”, with seven additional new shapes and dedicated wooden rack being created. All similar to the first issue, with XL bowl sizes and similar sterling silver bands with the SH stamp.

The second issue was called “The Return of” – and was based on the success of “the Original”, with seven additional new shapes and dedicated wooden rack being created. All similar to the first issue, with XL bowl sizes and similar sterling silver bands with the SH stamp.

- The first pipe in the “Return” series was “The Rathbone”‘ – a large elegant bent, with a large stack bowl. In honour of the actor who played Holmes in the old black and white pictures of the nineteen thirties and forties. This is shape XL20. A great comfortable bent shape with a good draw. Scoring a solid 8.

- Next pipe is “The Hudson” – a large quarter bent bulldog. A great classic bulldog shape that smokes as well as it looks. This is shape XL21. I would score this one 7.5.

- Third is “The Mycroft” – named after Holmes’s brother. A classy elegant horn shape that is an excellent smoker. This is Peterson shape XL22. Scoring a good 8 on the scale.

- The fourth pipe in the series “The Lestrade” – is my personal favourite of all of the Sherlock Holmes series. This is the instantly recognisable, full-bent apple shape XL23. It is the quintessential dangler/clench-er pipe. It is equally tactile in the hand when not dangling, in this form I prefer it with a tapered fishtail stem to maximise the draw and smoking pleasure. Being a wee bit biased in regard to this one, I have to give it a very worthy 9 score.

- Next is “The Milverton” – a large full bent with an angular stem. Peterson shape XL24. I have to admit, it is not one of my favourites. I just do not like the angular stem. In terms of smoking it is average by me. I would rate it a 7 on the scale.

- Number six is “The Strand” – a quarter bent apple, it is Peterson shape XL25. To my mind a very pleasing elegant flowing shape. Very tactile for a straighter stemmed pipe and an excellent smoker. I would score this one a credible 8.5 on the scale.

- Finally, the last of the seven is “The Hansom” – a shape I just cannot warm to. I find it seriously wanting in regard to it’s aesthetic appeal. A bent Rhodesian, Peterson shape XL26. I only have one to complete the collection. I find it neither pleasing to hold, or to look at. Others may feel differently, I can only award it a 7.

The information given I knew I was dealing with a pipe from the Return of Sherlock Holmes Line. The Mycroft smooth was one named after Sherlock’s brother. It also has a silver band on the shank that is stamped on the left side of the band with a profile of Sherlock Holmes with the words Peterson’s [arched over the profile] and Sterling Silver [arched under the profile]. On the right side of the band it is stamped Peterson [over] the three hallmarks as noted above.

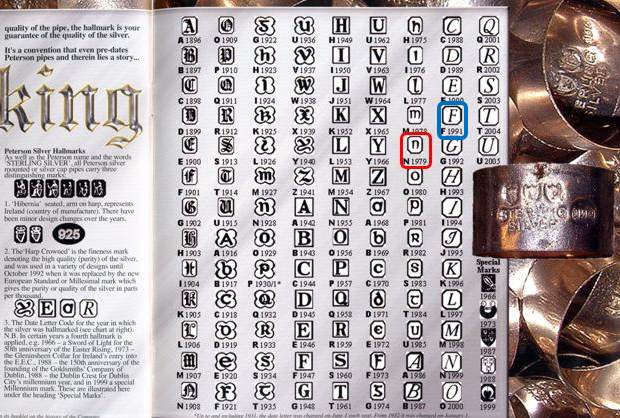

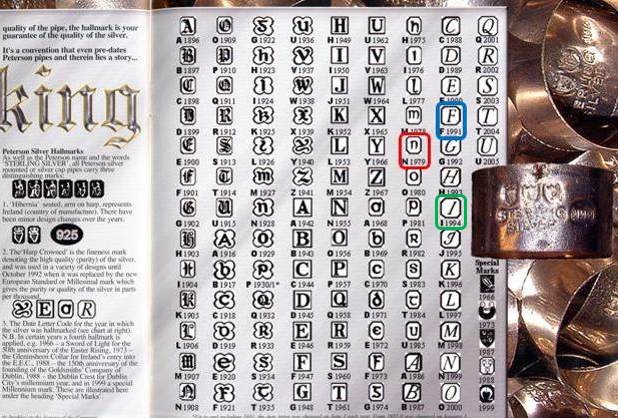

I wanted to be able to interpret the hallmarks on the silver band. I have captured a portion of the chart that include below that helps to clarify the meaning of each of the three hallmarks. I like the Hallmark feature on the higher end Peterson pipes with Sterling silver bands. It helps to pin down the date even further.

I wanted to be able to interpret the hallmarks on the silver band. I have captured a portion of the chart that include below that helps to clarify the meaning of each of the three hallmarks. I like the Hallmark feature on the higher end Peterson pipes with Sterling silver bands. It helps to pin down the date even further.

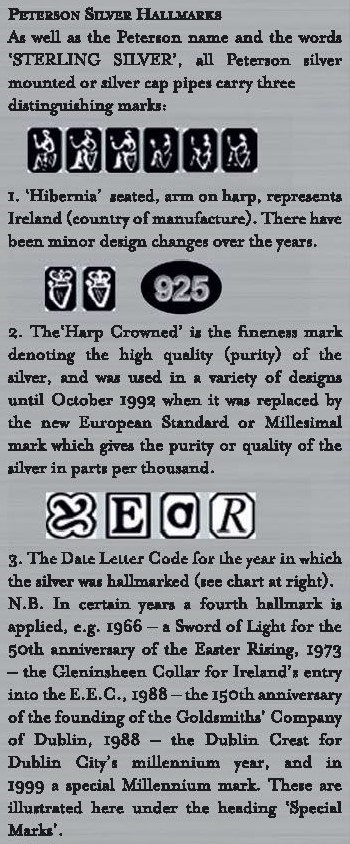

“Hibernia” seated, arm on harp represents Ireland (country of manufacture). There have been minor design changes over the years.

The “Harp Crowned” is the fineness mark denoting the high quality (purity) of the silver, and was used in a variety of designs until October 1992 when it was replaced by the new European Standard or Millesimal mark which gives the purity or quality of the silver in parts per thousand.

The Date Letter Code for the year in which the silver was hallmarked (see the chart below). In certain years a fourth hallmark is applied – for example 1966 – a Sword of Light for the 50th anniversary of the Easter Rising 1973. There were also other marks used for the fourth hallmark.

I turned to a blog I wrote on rebornpipes that had a Peterson’s catalogue and a hallmarking chart (https://rebornpipes.com/tag/peterson-hallmark-chart/). I have included it below. On the chart I looked for an upper case italic F in a hexagonal cartouche. I also included a enlargement of the chart and drawn a box around the “I” in green in the second photo below showing a close up of the dates. From that I am able to date the pipe to 1994.

Now I knew I was dealing with a pipe made in 1994. It really is a beautiful pipe. Now it was time to work on the pipe itself.

Now I knew I was dealing with a pipe made in 1994. It really is a beautiful pipe. Now it was time to work on the pipe itself.

I started my work on the pipe by reaming the bowl the pipe with a PipNet Pipe Reamer using the first and second and third cutting heads to remove the cake. I cleaned up the remnants of the cake on the walls with a Savinelli Fitsall Pipe Knife. I finished by sanding the bowl smooth with 220 grit sandpaper wrapped around a piece of dowel.

I cleaned up the inner edge of the rim with a folded piece of 220 grit sandpaper. I was able to remove almost all of the darkening with the sandpaper.

I cleaned up the inner edge of the rim with a folded piece of 220 grit sandpaper. I was able to remove almost all of the darkening with the sandpaper.  I scrubbed the externals of the pipe with undiluted Murphy’s Oil Soap with a tooth brush. I rinsed it under running warm water to remove the soap and grime. The bowl and rim top cleaned up really well with the lava coat removed. The inner edge of the rim was in good condition.

I scrubbed the externals of the pipe with undiluted Murphy’s Oil Soap with a tooth brush. I rinsed it under running warm water to remove the soap and grime. The bowl and rim top cleaned up really well with the lava coat removed. The inner edge of the rim was in good condition.

I cleaned out the inside of the mortise, shank and the airway in the stem with isopropyl alcohol, cotton swabs and pipe cleaners.

I cleaned out the inside of the mortise, shank and the airway in the stem with isopropyl alcohol, cotton swabs and pipe cleaners.  The pipe had a strong aromatic smell just like the other two Petersons I just completed. It smelled like a mix of fruit and vanilla so it needed to be deghosted. I filled the bowl with cotton boles and twisted a plug into the shank end. I used and ear syringe to fill the bowl with alcohol. The alcohol will eventually evaporate from the bowl wicking out the oils and tars in the briar into the cotton. I let it sit over night and in the morning pulled it out and took photos of the cotton at that point.

The pipe had a strong aromatic smell just like the other two Petersons I just completed. It smelled like a mix of fruit and vanilla so it needed to be deghosted. I filled the bowl with cotton boles and twisted a plug into the shank end. I used and ear syringe to fill the bowl with alcohol. The alcohol will eventually evaporate from the bowl wicking out the oils and tars in the briar into the cotton. I let it sit over night and in the morning pulled it out and took photos of the cotton at that point.

I polished the smooth briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiped it down with a damp cloth after each sanding pad. By the end of the last set of three the bowl took on a rich shine.

I polished the smooth briar with micromesh sanding pads – dry sanding with 1500-12000 grit pads and wiped it down with a damp cloth after each sanding pad. By the end of the last set of three the bowl took on a rich shine.

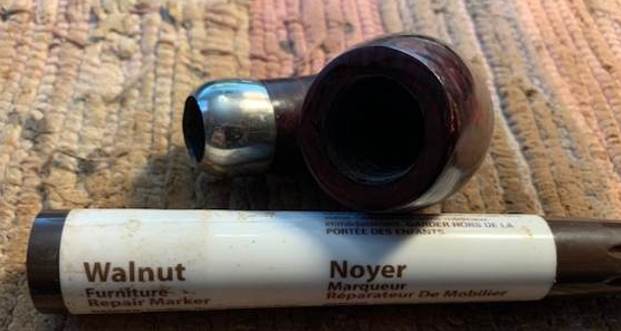

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I worked some Before & After Restoration Balm into the surface of the briar with my fingertips to clean, enliven and protect the briar. I let the balm sit for 15 minutes and then buffed with a cotton cloth to raise the shine. The photos show the bowl at this point in the restoration process.

I set the bowl aside and turned my attention to the stem. I wiped down the surface of the stem near the shank with Soft Scrub to remove the light oxidation that was present for the first inch up the stem from the shank end.

I set the bowl aside and turned my attention to the stem. I wiped down the surface of the stem near the shank with Soft Scrub to remove the light oxidation that was present for the first inch up the stem from the shank end. I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped the stem down with Obsidian Oil after each sanding pad. I polished the stem with Before and After Stem Polish – both Fine and Extra Fine. I rubbed it down with some more Obsidian Oil.

I polished the vulcanite stem with micromesh sanding pads – 1500-12000 grit pads. I wiped the stem down with Obsidian Oil after each sanding pad. I polished the stem with Before and After Stem Polish – both Fine and Extra Fine. I rubbed it down with some more Obsidian Oil.

It was great to finish this 1994 Peterson’s of Dublin Sherlock Holmes Mycroft. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with deep sandblast all around it. Added to that the polished black, vulcanite, fishtail stem was beautiful. This Silver Banded Return of Sherlock Holmes Series Mycroft is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 61 grams/2.15 ounces. It is a beautiful pipe and one that will soon be on the rebornpipes store in the Irish Pipe Makers Section of the store. If you want to add it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.

It was great to finish this 1994 Peterson’s of Dublin Sherlock Holmes Mycroft. I put the pipe back together and buffed it with Blue Diamond on the buffing wheel. I gave the bowl and the stem multiple coats of carnauba wax. I buffed the pipe with a clean buffing pad to raise the shine. I hand buffed the pipe with a microfiber cloth to deepen the shine. It is fun to see what the polished bowl looks like with deep sandblast all around it. Added to that the polished black, vulcanite, fishtail stem was beautiful. This Silver Banded Return of Sherlock Holmes Series Mycroft is great looking and the pipe feels great in my hand. It is light and well balanced. Have a look at it with the photos below. The dimensions are Length: 6 ½ inches, Height: 2 ¼ inches, Outside diameter of the bowl: 1 ½ inches, Chamber diameter: 7/8 of an inch. The weight of the pipe is 61 grams/2.15 ounces. It is a beautiful pipe and one that will soon be on the rebornpipes store in the Irish Pipe Makers Section of the store. If you want to add it to your collection let me know. Thanks for walking through the restoration with me as I worked over this pipe. Thanks to each of you who are reading this blog.