Blog by Dal Stanton

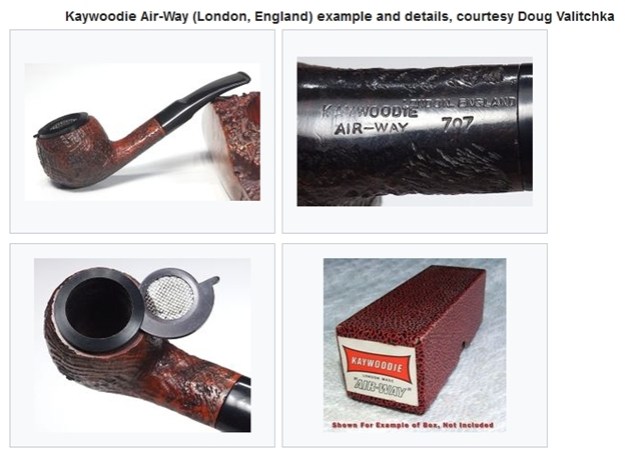

This is the second of 3 of Paw’s pipes that Joe sent to me from Athens, Greece, where he and his wife, Hannah, live and work. Paw is Hannah’s great grandfather who left behind several pipes that Joe has asked me to restore for the family. Paw, also known as, ‘2-Page Sam’ by those who knew him as a salesman of over 40 years of the tobacco giant, Brown & Williamson Tobacco, Corp, has a fascinating story that was described in an article in B&W’s company magazine that I included in the write up of Paw’s Medico Apollo Brylon, which I just completed that turned out well (See: Another Legacy Pipe of a Great-Grandfather: Challenges Working with ‘Brylon’ on a Medico Apollo). Next, two Kaywoodies remain to be restored – a Kaywoodie “500” and the one on my worktable now, a Kaywoodie Natural Burl 33. Here are pictures to take a closer look.

The nomenclature is on the underside of the shank’s smooth briar panel with ‘KAYWOODIE’ (as most of it is not legible as the upper half of ‘Kaywoodie’ bleeds into the craggy rusticated landscape) [over] ‘Natural Burl’ in fancy cursive script.

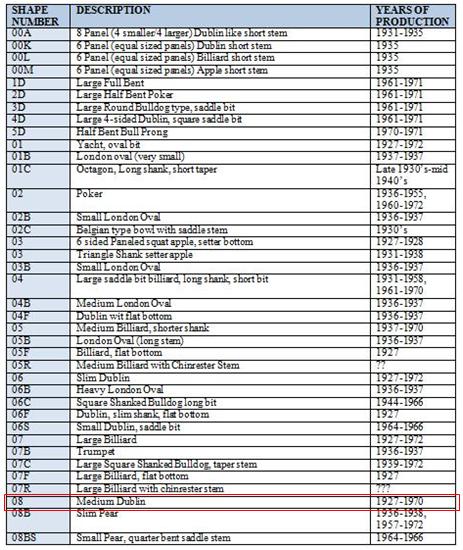

The nomenclature is on the underside of the shank’s smooth briar panel with ‘KAYWOODIE’ (as most of it is not legible as the upper half of ‘Kaywoodie’ bleeds into the craggy rusticated landscape) [over] ‘Natural Burl’ in fancy cursive script.  To the left of the nomenclature is stamped the Kaywoodie shape number of 33. In Pipedia’s listings of Kaywoodie shape numbers, 33 is listed as: “Large apple, rounded top” that was used as a shape designator from 1937 to 1972.

To the left of the nomenclature is stamped the Kaywoodie shape number of 33. In Pipedia’s listings of Kaywoodie shape numbers, 33 is listed as: “Large apple, rounded top” that was used as a shape designator from 1937 to 1972. The dating indicators of this Kaywoodie are good. The Natural Burl has a 4-holed stinger which were phased out at the end of the 1950s, though they still show up some in the 60s according to Pipephil.eu’s discussion about Kaywoodie’s stinger evolution. The inlaid white shamrock also points to an earlier period.

The dating indicators of this Kaywoodie are good. The Natural Burl has a 4-holed stinger which were phased out at the end of the 1950s, though they still show up some in the 60s according to Pipephil.eu’s discussion about Kaywoodie’s stinger evolution. The inlaid white shamrock also points to an earlier period. I found nothing specific in Pipedia or Pipephil.eu about Kaywoodie’s ‘Natural Burl’ line. Expanding my search, I did find very helpful anecdotal information in a February, 2013, thread by ‘kwguy’ on a Kaywoodie discussion group on Tapatalk.com:

I found nothing specific in Pipedia or Pipephil.eu about Kaywoodie’s ‘Natural Burl’ line. Expanding my search, I did find very helpful anecdotal information in a February, 2013, thread by ‘kwguy’ on a Kaywoodie discussion group on Tapatalk.com:

Natural Burls are in the catalogs from 1957 to 1962. They were $4.00 when they first came out and $5.00 by the time they were discontinued. They were basically a stained version of the Coral White Briar, which also debuted in 1957. The overall rough texture was described in the catalogs as having a rough texture like the outside of the burl. The rough texture in theory would create more surface area for a cooler feeling bowl. Carving of this type was done on bowls of less desirable grain and with excessive surface imperfections. On the lower side of the quality scale, Natural Burls would have had the white cloverleaf. There may have been the occasional higher grade pipe that was downgraded during production and hence would have the round logo, but I think you’ll mostly see them with the white logos.

Based upon the information of this thread, the Natural Burl Apple before me dates from 1957 to 1962, when they were featured in Kaywoodie catalogs. I looked for a catalog during this period online, but unfortunately, I was unable to find one. The rusticated or carved surface theoretically provides a cooler feeling bowl. This pipe fits Sam’s low budget approach to his pipes. When the Natural Burl Apple first hit the market, it was in a working man’s modest budget range, $4! I’m hopeful that after I’ve completed working on Paw’s vintage Kaywoodie it will look like a million bucks!

The above thread from ‘kwguy’ also mentions that the ‘Natural Burl’ line was featured in Kaywoodie catalogs from 1957 to 1962. There are Kaywoodie catalogs and adds referenced on Pipedia and the Chris Keene Directory of Pictures, but I could find nothing in these ‘go-to’ places for catalogs or listing between 57 and 62. Emails to Steve and rebornpipes contributor, Al Jones, also came up empty. However, Al encouraged me to reach out to Bill Feuerbach, the current president of S.M. Frank with Kaywoodie production in New York. Al said that Bill had always been helpful and had seemed to enjoy providing info. Nothing like going to the top of the pipe food chain! I sent a note to Bill through the S.M. Frank website as well as to the ‘kwguy’ in the Natural Burl thread with the hope of getting a response and perhaps a historical Natural Burl add!

Al’s suggestion to me paid off! In a few days I received a response from Bill Feuerbach, president of S.M. Frank since taking over the role from his father in 1990 as the fourth generation of Feuerbachs overseeing the company. Bill’s note to me:

Dal

I’d love to be able to help you out with that. I’ve looked through what I have at the shop and most of those catalogs are later 60’s to later 70’s. I’m sure I’ll have those older catalogs from that range at home. I’ll try and check tonight.

Best regards

Bill

After arriving home that night, Bill sent an additional note that he hadn’t found anything at his home and would redouble his efforts the following day at the shop to find the sought after ’57 to 62’ catalog pages. Then, this note came in and the treasure hunt ended with success!

Dal

Success!! I found the catalogs at home. They were in a storage tub in the downstairs closet. Funny I don’t remember putting them there. It’s probably been 4 years since I referenced them. It is hell getting old, CRS is kicking in.

Anyway, I’ve attached three images from the 1958, 1960 and 1962 catalogs. I was only using my phone to take pictures and it was difficult not to get any flash or glare. Are they ok? You can tell the year by the retail prices for the Natural Burl.

1958- $4.00

1960- $5.00

1962- $5.95

Let me know when you’ve posted this and the link. I’d like to take a look. If you have any other questions let me know. If in the future you need other images from the catalogs, let me know.

Best regards

Bill

The images Bill sent were great depicting the Kaywoodie presentation of the Natural Burl line. Both the 1960 and 1962 pages, second and third below, showcase the Large Apple on my worktable. The pictures and descriptions are great helping to wrap Paw’s pipe in its historical context!

I appreciated the help of Bill Feuerbach, president of the S. M. Frank Co. & Inc. based in New Windsor, New York. The Frank website not only showcases the Kaywoodie, Yello-Bole and Medico brand lines, but has other interesting information as well. In my email response to Bill, I offered to digitize the ‘treasure tubs’ of Kaywoodie catalogs and adds if I only lived a bit closer to his neighborhood! Oh my….

I appreciated the help of Bill Feuerbach, president of the S. M. Frank Co. & Inc. based in New Windsor, New York. The Frank website not only showcases the Kaywoodie, Yello-Bole and Medico brand lines, but has other interesting information as well. In my email response to Bill, I offered to digitize the ‘treasure tubs’ of Kaywoodie catalogs and adds if I only lived a bit closer to his neighborhood! Oh my….

As I was waiting for word from Bill before he found the catalogs, I reread the Pipedia article on the S.M Frank Co. and discovered at the bottom of the article a reference to Brian Levine’s interview of Bill on the Pipes Magazine Radio Show. I tuned in to learn more about Bill and the Kaywoodie name. I was interested to hear in the interview that not only is Bill the CEO of the company, but he is an accomplished freehand pipe maker himself, likes single malts and owns and enjoys pipes in his rotation other than Kaywoodies! It was a great interview and I encourage readers to tune in too!

The name for this Kaywoodie series, ‘Natural Burl’, harkens back to a pipe’s origins – or at least its bowl. The Natural Burl adds above from Bill describe the ‘rugged, weather-carved briar’ that breathes more because of the increased surface of the bowl. Briar comes from a bush-like plant that grows in arid lands. The Kaywoodie motif focuses on the rough state of the burl in its natural form sporting rusticated or carved bowls to emulate a natural harvested burl. The burl is the base of the briar bush that is cut into blocks, each becoming the raw material for fashioning each unique bowl. I found this example online of the burl texture which looks very much like the pipe on my worktable! This interesting information was added about the process at the WorthPoint site:

The mother of briar is Erica Arborea, an evergreen bush / tree, that grows in all forests of the Mediterranean area, preferring acid soils (Cyprus, Greece, Italy, Spain, France, Portugal, Morocco, Algeria- these are the countries where it is found). The bush has a typical height of 3 – 12 feet. But not the visible parts are the wanted ones, the ball-like roots are the pipe makers desire. These are the raw material for the briar wood, which is cut in blocks (plateaux and ebauchons) by real specialists. After a long process of boiling them in clear water and drying periods, these briar blocks will be ready for the experienced hands of a pipe maker.

The mother of briar is Erica Arborea, an evergreen bush / tree, that grows in all forests of the Mediterranean area, preferring acid soils (Cyprus, Greece, Italy, Spain, France, Portugal, Morocco, Algeria- these are the countries where it is found). The bush has a typical height of 3 – 12 feet. But not the visible parts are the wanted ones, the ball-like roots are the pipe makers desire. These are the raw material for the briar wood, which is cut in blocks (plateaux and ebauchons) by real specialists. After a long process of boiling them in clear water and drying periods, these briar blocks will be ready for the experienced hands of a pipe maker.

With a deepened understanding and appreciation for Paw’s Kaywoodie on my worktable, I look more closely at the issues it brings from its years of service. As one would expect, the craggy Burl bowl is full of grime. The chamber has thickening cake as you go down toward the floor. This needs to be cleaned out as well to inspect the chamber wall and to give the briar a fresh start.  The rim has evidences of Sam’s penchant for knocking the stummel on the back side of the rim. It is worn and tapers away from the chamber.

The rim has evidences of Sam’s penchant for knocking the stummel on the back side of the rim. It is worn and tapers away from the chamber.  The rim was fashioned to be somewhat rough complementing the craggy bowl motif, but there is a large chip or divot out of the rim that will need to be filled and then blended.

The rim was fashioned to be somewhat rough complementing the craggy bowl motif, but there is a large chip or divot out of the rim that will need to be filled and then blended.

The bowl itself, along with the rim, is faded and skinned up. I suspect that the original finish bent toward a light brown, but it is now thin and will need refreshing with new dye to blend the rim and bowl. The 1962 add above describes a ‘2-tone brown finish’ characterizing the ‘Natural Burl’ line. This is helpful information that hints at the depth of the final finish.

The bowl itself, along with the rim, is faded and skinned up. I suspect that the original finish bent toward a light brown, but it is now thin and will need refreshing with new dye to blend the rim and bowl. The 1962 add above describes a ‘2-tone brown finish’ characterizing the ‘Natural Burl’ line. This is helpful information that hints at the depth of the final finish. The stem is in rough shape. The oxidation is thick and deep. The bit has calcium caked on it and some lower tooth compressions – not as bad as I’ve seen on Paw’s previous pipes!

The stem is in rough shape. The oxidation is thick and deep. The bit has calcium caked on it and some lower tooth compressions – not as bad as I’ve seen on Paw’s previous pipes!

The stem orientation is also over-clocked which is a normal phenomenon with Kaywoodie screw in stems that happens over years of use with repeated loosening and tightening. This will need to be adjusted as well.

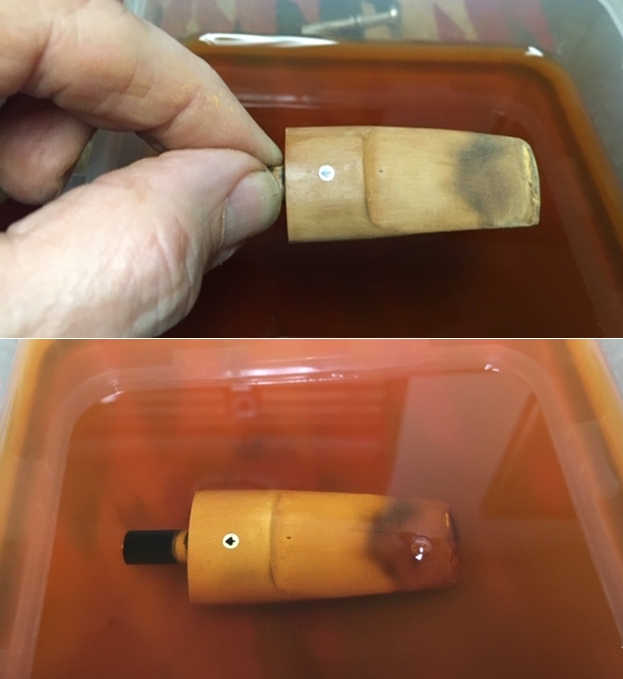

The stem orientation is also over-clocked which is a normal phenomenon with Kaywoodie screw in stems that happens over years of use with repeated loosening and tightening. This will need to be adjusted as well.  I begin the restoration of Paw’s Kaywoodie Natural Burl Large Apple by addressing the severe oxidation in the stem. Before placing the stem in a soak of Before & After Deoxidizer, I get a head-start on removing the oxidation by pre-sanding the stem. I use both 240 grade sanding paper and 000 grade steel wool to sand the stem to remove as much oxidation and caked calcium as possible. The nickel 4-hole stinger also is cleaned up with the steel wool.

I begin the restoration of Paw’s Kaywoodie Natural Burl Large Apple by addressing the severe oxidation in the stem. Before placing the stem in a soak of Before & After Deoxidizer, I get a head-start on removing the oxidation by pre-sanding the stem. I use both 240 grade sanding paper and 000 grade steel wool to sand the stem to remove as much oxidation and caked calcium as possible. The nickel 4-hole stinger also is cleaned up with the steel wool. After the sanding, the stem joins other pipes in the queue in a soak of Before & After Deoxidizer.

After the sanding, the stem joins other pipes in the queue in a soak of Before & After Deoxidizer.  After a few hours, the Kaywoodie’s stem is extracted from the Deoxidizer and after draining, I squeegee the liquid off the stem with my fingers. I then run a pipe cleaner wetted with isopropyl 95% through the airway to clear the Deoxidizer. Using a cotton pad and alcohol, the stem is wiped to remove the raised oxidation resulting from the soak.

After a few hours, the Kaywoodie’s stem is extracted from the Deoxidizer and after draining, I squeegee the liquid off the stem with my fingers. I then run a pipe cleaner wetted with isopropyl 95% through the airway to clear the Deoxidizer. Using a cotton pad and alcohol, the stem is wiped to remove the raised oxidation resulting from the soak. After cleaning the stem, paraffin oil is applied to help condition the vulcanite. I put the stem aside to absorb the oil. The stem looks great compared to where it started. It’s cleaning up nicely.

After cleaning the stem, paraffin oil is applied to help condition the vulcanite. I put the stem aside to absorb the oil. The stem looks great compared to where it started. It’s cleaning up nicely. Next, I turn the attention to the stummel. I begin by reaming the Kaywoodie’s chamber to remove the cake. Using the Pipnet Reaming Kit, I use two of the four blade heads available in the Kit. I don’t know how long this cake has been waiting to be removed, but it is as hard as a brick. I’m careful not to force the blades beyond their torque endurance level – simply allowing the scraping action to wear away the brick cake. When both blades do what they can, the Savinelli Fitsall Tool continues the scraping of the chamber walls. Finally, to remove the last remaining carbon remnants, a 240 grade sanding paper is wrapped around a Sharpie Pen to sand the chamber getting down to fresh briar.

Next, I turn the attention to the stummel. I begin by reaming the Kaywoodie’s chamber to remove the cake. Using the Pipnet Reaming Kit, I use two of the four blade heads available in the Kit. I don’t know how long this cake has been waiting to be removed, but it is as hard as a brick. I’m careful not to force the blades beyond their torque endurance level – simply allowing the scraping action to wear away the brick cake. When both blades do what they can, the Savinelli Fitsall Tool continues the scraping of the chamber walls. Finally, to remove the last remaining carbon remnants, a 240 grade sanding paper is wrapped around a Sharpie Pen to sand the chamber getting down to fresh briar.  After wiping the chamber with a cotton pad wetted with alcohol, and inspection reveals a perfectly healthy chamber. The picture on the 10th floor Man Cave balcony where I’m working, does not allow a very good picture of the chamber, but it looks good. Moving on.

After wiping the chamber with a cotton pad wetted with alcohol, and inspection reveals a perfectly healthy chamber. The picture on the 10th floor Man Cave balcony where I’m working, does not allow a very good picture of the chamber, but it looks good. Moving on. Next, using undiluted Murphy’s Oil Soap, I go to work on the wonderfully craggy but grime-filled surface of the Natural Burl bowl. I use a cotton pad a bit, but transfer to using a bristled toothbrush which gets into the nooks and crannies of the landscape much more effectively.

Next, using undiluted Murphy’s Oil Soap, I go to work on the wonderfully craggy but grime-filled surface of the Natural Burl bowl. I use a cotton pad a bit, but transfer to using a bristled toothbrush which gets into the nooks and crannies of the landscape much more effectively. Next, after transferring the bowl to the kitchen sink, I continue to clean the surface and use shank brushes and liquid anti-oil dish soap and warm water to work on the internals. After rinsing thoroughly, back on the worktable I take some pictures of the results.

Next, after transferring the bowl to the kitchen sink, I continue to clean the surface and use shank brushes and liquid anti-oil dish soap and warm water to work on the internals. After rinsing thoroughly, back on the worktable I take some pictures of the results.  The cleaning has totally removed what was left of the old finish – not unexpected. The cleaning reveals some white fills on the right side of the stummel which are fully embraced in the craggy landscape cover and seem to be solid after testing them with a sharp dental probe.

The cleaning has totally removed what was left of the old finish – not unexpected. The cleaning reveals some white fills on the right side of the stummel which are fully embraced in the craggy landscape cover and seem to be solid after testing them with a sharp dental probe. Next, I focus again on the internal cleaning using pipe cleaners and cotton buds wetted with isopropyl 95%. Cleaning Kaywoodie pipes tends not to be easy. Working through the threaded metal shank facing makes access to the mortise difficult. Along with pipe cleaners and buds, the full arsenal added the use of shank brushes, and a dental spoon to scrape the mortise walls. After quite a bit of time and effort, the buds start to emerge lighter and a cease fire is called. I’ll continue the cleaning later with a kosher salt and alcohol soak to work through the night to further clean and freshen the internals of the Kaywoodie stummel.

Next, I focus again on the internal cleaning using pipe cleaners and cotton buds wetted with isopropyl 95%. Cleaning Kaywoodie pipes tends not to be easy. Working through the threaded metal shank facing makes access to the mortise difficult. Along with pipe cleaners and buds, the full arsenal added the use of shank brushes, and a dental spoon to scrape the mortise walls. After quite a bit of time and effort, the buds start to emerge lighter and a cease fire is called. I’ll continue the cleaning later with a kosher salt and alcohol soak to work through the night to further clean and freshen the internals of the Kaywoodie stummel. Turning now to the rim, the next step is to fill the divot, or perhaps, the crater on the rim. I go along with the ‘rough’ motif of this Kaywoodie Natural Burl. The rim is rough and the only repair I plan for the stummel is this divot. The damage of Paw’s knocking will remain – it simply adds to the rough rustic look and will be a remembrance of Paw when it is put into service by the family.

Turning now to the rim, the next step is to fill the divot, or perhaps, the crater on the rim. I go along with the ‘rough’ motif of this Kaywoodie Natural Burl. The rim is rough and the only repair I plan for the stummel is this divot. The damage of Paw’s knocking will remain – it simply adds to the rough rustic look and will be a remembrance of Paw when it is put into service by the family. I place a small mound of briar dust on the mixing palette that I’ve covered with scotch tape for ease of cleaning. Next to the briar dust a small amount of BCI Extra Thick CA glue is puddled.

I place a small mound of briar dust on the mixing palette that I’ve covered with scotch tape for ease of cleaning. Next to the briar dust a small amount of BCI Extra Thick CA glue is puddled. Using the toothpick, briar dust is pulled into the glue and mixed as it is added. As more is added, the resulting briar dust putty thickens. When it reaches the thickness of molasses, with the toothpick the putty is troweled to fill the rim divot.

Using the toothpick, briar dust is pulled into the glue and mixed as it is added. As more is added, the resulting briar dust putty thickens. When it reaches the thickness of molasses, with the toothpick the putty is troweled to fill the rim divot. With the briar putty applied, I place the stummel aside for several hours for the putty to cure.

With the briar putty applied, I place the stummel aside for several hours for the putty to cure. Turning now to the stem, the upper bit is in good shape after the ‘pre-sanding’ that was done before putting the stem into the Deoxidizer. The lower bit, pictured below, has some compressions and a button bite compression that need addressing.

Turning now to the stem, the upper bit is in good shape after the ‘pre-sanding’ that was done before putting the stem into the Deoxidizer. The lower bit, pictured below, has some compressions and a button bite compression that need addressing. I start by using the heating method with a Bic lighter. Using the flame of a Bic lighter, I paint the bit using a back and forth motion heating the vulcanite. As the vulcanite heats, it also expands to regain the disposition of the stem before the compressions were made by Paw. The picture below is after the heating and the process has helped the bit compressions so that only sanding should be needed to remove the damage. However, the button is still in need of additional steps.

I start by using the heating method with a Bic lighter. Using the flame of a Bic lighter, I paint the bit using a back and forth motion heating the vulcanite. As the vulcanite heats, it also expands to regain the disposition of the stem before the compressions were made by Paw. The picture below is after the heating and the process has helped the bit compressions so that only sanding should be needed to remove the damage. However, the button is still in need of additional steps. To fill the button lip bite, after wiping the area with alcohol to clean it, I spot drop black CA glue on the compression and put the stem aside for the patch to cure.

To fill the button lip bite, after wiping the area with alcohol to clean it, I spot drop black CA glue on the compression and put the stem aside for the patch to cure. The patch on the rim is now ready for filing. I use both the flat and half-rounded needle files to remove the excess putty and to shape the internal curve of the rim.

The patch on the rim is now ready for filing. I use both the flat and half-rounded needle files to remove the excess putty and to shape the internal curve of the rim.

I put a stop on sanding and further cleaning the rim because the hour is late, and through the night I want to use a kosher salt and alcohol soak to advance the cleaning of the internals of the stummel. I first fashion a cotton ball into a ‘wick’ by pulling and twisting it. It is then inserted down the mortise into the airway with the help of a stiff wire. The wick helps to draw out the latent residue of tars and oils.

I put a stop on sanding and further cleaning the rim because the hour is late, and through the night I want to use a kosher salt and alcohol soak to advance the cleaning of the internals of the stummel. I first fashion a cotton ball into a ‘wick’ by pulling and twisting it. It is then inserted down the mortise into the airway with the help of a stiff wire. The wick helps to draw out the latent residue of tars and oils. The bowl is then filled with kosher salt, which leaves no aftertaste as with regular iodized salt. After placing it in the egg carton to keep it stable, I then fill the chamber with isopropyl 95% until it surfaces over the salt. After a few minutes, as the alcohol is drawn into the stummel, the alcohol is topped off and it is set aside to work through the night.

The bowl is then filled with kosher salt, which leaves no aftertaste as with regular iodized salt. After placing it in the egg carton to keep it stable, I then fill the chamber with isopropyl 95% until it surfaces over the salt. After a few minutes, as the alcohol is drawn into the stummel, the alcohol is topped off and it is set aside to work through the night.

The next morning, the salt and wick are slightly soiled which hopefully means that the internals are already clean from earlier. After dumping the expended salt and wiping the bowl with a paper towel, I blow through the mortise to make sure all the salt crystals have been dislodged.

The next morning, the salt and wick are slightly soiled which hopefully means that the internals are already clean from earlier. After dumping the expended salt and wiping the bowl with a paper towel, I blow through the mortise to make sure all the salt crystals have been dislodged.  To make sure that the internals are clean, and nothing has been left behind after the soak, I use only one pipe cleaner and cotton bud as confirmation of the cleaning. Moving on.

To make sure that the internals are clean, and nothing has been left behind after the soak, I use only one pipe cleaner and cotton bud as confirmation of the cleaning. Moving on. I return now to the rim. I plan to apply a fresh color to the stummel and the only preparation for applying the new stain to the stummel is on the rim. I plan to leave it in the rough motif of the Natural Burl line, but I want the rim cleaned. I lightly sand the internal rim edge as well as lightly around the rough external rim edge as it transitions into the Burl landscape. I’m looking for ‘rough’ and ‘rustic’ but ‘fresh’ to give this unique Kaywoodie a fresh start.

I return now to the rim. I plan to apply a fresh color to the stummel and the only preparation for applying the new stain to the stummel is on the rim. I plan to leave it in the rough motif of the Natural Burl line, but I want the rim cleaned. I lightly sand the internal rim edge as well as lightly around the rough external rim edge as it transitions into the Burl landscape. I’m looking for ‘rough’ and ‘rustic’ but ‘fresh’ to give this unique Kaywoodie a fresh start. I follow the 240 paper with 600 grade paper with the same approach – keep the rustic but refresh the rim.

I follow the 240 paper with 600 grade paper with the same approach – keep the rustic but refresh the rim. Before moving to the next step, I notice that the nickel shank facing after the cleaning had not been spruced up. A quick revolution of 000 steel wool takes care of this. This is the only bling this Kaywoodie has and I’m making the most of it!

Before moving to the next step, I notice that the nickel shank facing after the cleaning had not been spruced up. A quick revolution of 000 steel wool takes care of this. This is the only bling this Kaywoodie has and I’m making the most of it! As I think about applying a fresh color to Paw’s Kaywoodie, I have only one picture of another Natural Burl online and it is no help in hinting at the original 2-toned brown coloring Kaywoodie used. The best clue I have is on Paw’s pipe. The smooth briar panel on the underside of the shank holding the nomenclature holds a clue. To guard the stamping on the panel I’ve not sanded it – only cleaned with the rest of the stummel. I’m guessing that the coloring of the panel leans toward a light brown. I’m thinking that Kaywoodie’s approach was straightforward with this less expensive line of pipes. Yet, the craggy surface now is so dry and bare, showing pristine briar, that applying even a light brown dye will probably darken considerably as the thirsty briar drinks it in.

As I think about applying a fresh color to Paw’s Kaywoodie, I have only one picture of another Natural Burl online and it is no help in hinting at the original 2-toned brown coloring Kaywoodie used. The best clue I have is on Paw’s pipe. The smooth briar panel on the underside of the shank holding the nomenclature holds a clue. To guard the stamping on the panel I’ve not sanded it – only cleaned with the rest of the stummel. I’m guessing that the coloring of the panel leans toward a light brown. I’m thinking that Kaywoodie’s approach was straightforward with this less expensive line of pipes. Yet, the craggy surface now is so dry and bare, showing pristine briar, that applying even a light brown dye will probably darken considerably as the thirsty briar drinks it in. Looking at the craggy landscape in the picture above brings the next question in my mind about applying a new finish. My normal way of staining with aniline dye is to flame it to combust the alcohol which encourages a deeper embrace of the dye by the briar grain. My normal follow-up to this is then to apply compounds to remove the crusting the combustion creates and to further shine the surface with the fine abrasives of Tripoli and Blue Diamond compounds. The roughness of this stummel causes me to question my normal approach. My concern is that if compounds are used on this craggy rough surface, I will forever be trying to clean out the compound residue lodged in the rough surface! I think I can utilize buffing wheels on the Dremel without too much problem, but without compounds. I decide in the end to apply a dye wash instead of flaming the dye because of this concern.

Looking at the craggy landscape in the picture above brings the next question in my mind about applying a new finish. My normal way of staining with aniline dye is to flame it to combust the alcohol which encourages a deeper embrace of the dye by the briar grain. My normal follow-up to this is then to apply compounds to remove the crusting the combustion creates and to further shine the surface with the fine abrasives of Tripoli and Blue Diamond compounds. The roughness of this stummel causes me to question my normal approach. My concern is that if compounds are used on this craggy rough surface, I will forever be trying to clean out the compound residue lodged in the rough surface! I think I can utilize buffing wheels on the Dremel without too much problem, but without compounds. I decide in the end to apply a dye wash instead of flaming the dye because of this concern.

After wiping the stummel down with a cloth and alcohol to clean it the best I could, the stummel is heated with the hot air gun to open the briar. Then, with the use of a folded pipe cleaner, the surface is painted with Fiebing’s Light Brown Leather Dye. I make sure the dye is getting into all the cracks, crevasses, nooks and crannies. The rim also receives the dye.

Then, with the use of a folded pipe cleaner, the surface is painted with Fiebing’s Light Brown Leather Dye. I make sure the dye is getting into all the cracks, crevasses, nooks and crannies. The rim also receives the dye. After the dye is applied, the stummel is set aside to rest for several hours before continuing with the next steps of finishing. This ‘rest’ helps the new dye to stabilize in the briar.

After the dye is applied, the stummel is set aside to rest for several hours before continuing with the next steps of finishing. This ‘rest’ helps the new dye to stabilize in the briar. Turning back to the stem, the patch applied to the lower button lip is cured and I use a flat needle file to remove the excess patch material and to shape and refresh the button lip. I also file the bit area to remove any residual tooth compression.

Turning back to the stem, the patch applied to the lower button lip is cured and I use a flat needle file to remove the excess patch material and to shape and refresh the button lip. I also file the bit area to remove any residual tooth compression. Flipping over to the upper bit, I file residual compressions as well as refresh the button lip. Refreshing the button lip is helpful to allow a better ‘hang’ grip of the pipe without biting and clenching, and extreme chewing!

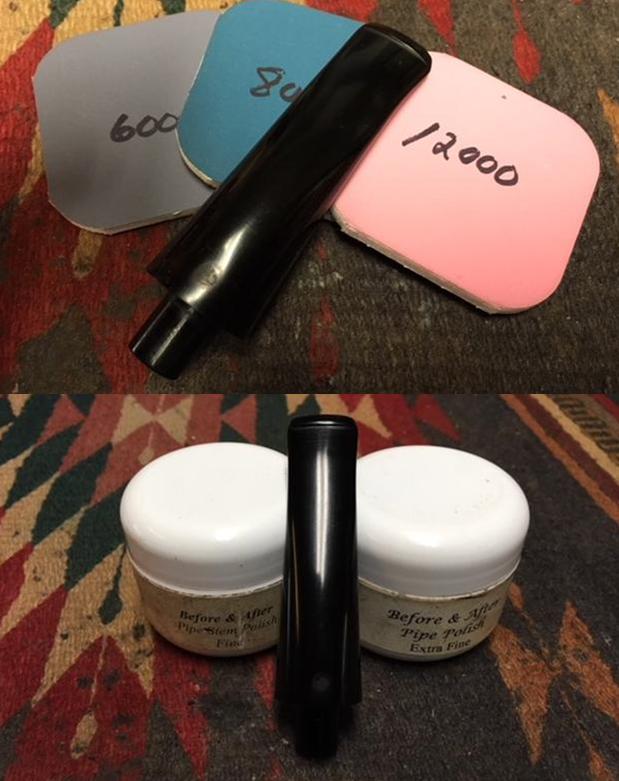

Flipping over to the upper bit, I file residual compressions as well as refresh the button lip. Refreshing the button lip is helpful to allow a better ‘hang’ grip of the pipe without biting and clenching, and extreme chewing! Continuing now with 240 grade sanding paper on the upper side, the file scratches are removed, and the button is smoothed further. The same is done on the lower bit and to further blend the button patch. I expand the 240 sanding to the entire stem to make sure that residual oxidation has been addressed.

Continuing now with 240 grade sanding paper on the upper side, the file scratches are removed, and the button is smoothed further. The same is done on the lower bit and to further blend the button patch. I expand the 240 sanding to the entire stem to make sure that residual oxidation has been addressed.

Following the 240 sanding, I wet sand the entire stem with 600 grade paper and follow with applying 000 steel wool. The nickel stinger is also a benefactor of the steel wool polishing again.

Following the 240 sanding, I wet sand the entire stem with 600 grade paper and follow with applying 000 steel wool. The nickel stinger is also a benefactor of the steel wool polishing again. Moving on, the full regimen of 9 micromesh pads are applied by first wet sanding with pads 1500 to 2400 and dry sanding with pads 3200 to 4000 and 6000 to 12000. Between each set of 3 pads, Obsidian Oil is applied to condition the vulcanite and to guard against oxidation. I love the glossy pop of newly micromeshed vulcanite!

Moving on, the full regimen of 9 micromesh pads are applied by first wet sanding with pads 1500 to 2400 and dry sanding with pads 3200 to 4000 and 6000 to 12000. Between each set of 3 pads, Obsidian Oil is applied to condition the vulcanite and to guard against oxidation. I love the glossy pop of newly micromeshed vulcanite!

I had observed earlier that the Kaywoodie screw in stem was over clocked a few degrees. This happens over time with tightening and loosening.

I had observed earlier that the Kaywoodie screw in stem was over clocked a few degrees. This happens over time with tightening and loosening. To correct this problem and to bring the stem back to an accurate orientation, a Bic lighter is used to heat the nickel 4-hole stinger. Since the stinger is gripped by the vulcanite of the stem, the goal is to warm the stinger so that the vulcanite gripping the stinger heats and loosens its grip allowing the stinger to rotate.

To correct this problem and to bring the stem back to an accurate orientation, a Bic lighter is used to heat the nickel 4-hole stinger. Since the stinger is gripped by the vulcanite of the stem, the goal is to warm the stinger so that the vulcanite gripping the stinger heats and loosens its grip allowing the stinger to rotate.  After heating the stinger, I quickly re-screw the stem into the threaded shank facing and when it tightens to the orientation pictured above, I continue to apply clockwise pressure and the heated vulcanite releases its grip and it allows me to turn the stem one full revolution to line it up correctly. I had to heat the stinger twice as the first try did not loosen the grip. After lining the stem orientation correctly, I leave the stem in place and as the vulcanite cools, the grip on the stinger is re-engaged holding the stem again in the proper orientation.

After heating the stinger, I quickly re-screw the stem into the threaded shank facing and when it tightens to the orientation pictured above, I continue to apply clockwise pressure and the heated vulcanite releases its grip and it allows me to turn the stem one full revolution to line it up correctly. I had to heat the stinger twice as the first try did not loosen the grip. After lining the stem orientation correctly, I leave the stem in place and as the vulcanite cools, the grip on the stinger is re-engaged holding the stem again in the proper orientation. Time to address the dyed stummel. It has been resting for several hours to help stabilize the dye in the briar.

Time to address the dyed stummel. It has been resting for several hours to help stabilize the dye in the briar. I use a cotton pad wetted with alcohol to wipe down the dyed stummel. I do this to remove excesses of dye on the surface and to lighten and blend the new dye.

I use a cotton pad wetted with alcohol to wipe down the dyed stummel. I do this to remove excesses of dye on the surface and to lighten and blend the new dye. Next, I mount a cotton cloth buffing wheel onto the Dremel and simply buff the stummel. I do not use any compounds so that the compound dust does not fowl up the surface getting lodged in the plethora of hiding places on the Burl surface causing me to have to clean it! The Dremel is a great tool for getting into the nooks and crannies of the Natural Burl landscape. I’m able to rotate and move up and down ridges and to reach into crevasses. The newly dyed surface responds well to the buffing wheel. The coloring of the wheel shows that new dye is leeching out of the surface. The more I’m able to remove now, less likely to come off on hands later!

Next, I mount a cotton cloth buffing wheel onto the Dremel and simply buff the stummel. I do not use any compounds so that the compound dust does not fowl up the surface getting lodged in the plethora of hiding places on the Burl surface causing me to have to clean it! The Dremel is a great tool for getting into the nooks and crannies of the Natural Burl landscape. I’m able to rotate and move up and down ridges and to reach into crevasses. The newly dyed surface responds well to the buffing wheel. The coloring of the wheel shows that new dye is leeching out of the surface. The more I’m able to remove now, less likely to come off on hands later! Next, I use the 1500 grade micromesh pad and lightly sand over the Burl surface. The aim is to ‘scalp’ the peaks of the mountain tops on the craggy surface to lighten them. The lightening of the peaks creates more contrast and depth definition to the landscape. I follow the scalp sanding by running the Dremel’s buffing wheel over the surface again. This, I believe, achieves the ‘2-toned’ look of Kaywoodie’s design for the ‘Natural Burl’ line.

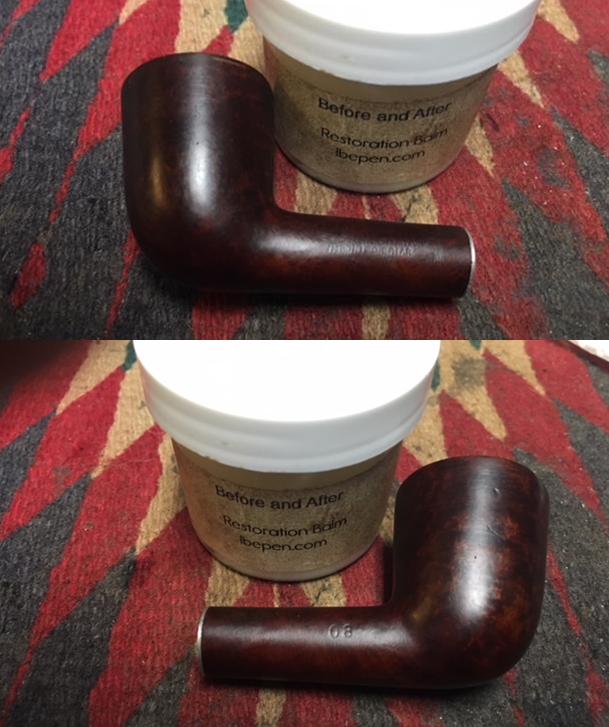

Next, I use the 1500 grade micromesh pad and lightly sand over the Burl surface. The aim is to ‘scalp’ the peaks of the mountain tops on the craggy surface to lighten them. The lightening of the peaks creates more contrast and depth definition to the landscape. I follow the scalp sanding by running the Dremel’s buffing wheel over the surface again. This, I believe, achieves the ‘2-toned’ look of Kaywoodie’s design for the ‘Natural Burl’ line. In the homestretch – next, I mount another buffing wheel onto the Dremel setting the speed at about 40% full power. After reuniting the Kaywoodie’s stem and stummel, Blue Diamond compound is applied to the rim and smooth briar surface on the underside and end of the shank. The compound is also applied to the stem. After applying the Blue Diamond compound, the pipe is buffed with a felt cloth to remove the compound dust from the areas on the stummel and from the stem. Next, another cotton cloth buffing wheel is mounted and set at the same speed and carnauba wax is applied to the entire pipe. I’m careful to apply with a very light touch of wax to the Natural Burl surface not to allow wax to build up in the crannies. Wax is applied to both stummel and stem and then the pipe receives a rigorous hand buffing with a microfiber cloth to raise the shine.

In the homestretch – next, I mount another buffing wheel onto the Dremel setting the speed at about 40% full power. After reuniting the Kaywoodie’s stem and stummel, Blue Diamond compound is applied to the rim and smooth briar surface on the underside and end of the shank. The compound is also applied to the stem. After applying the Blue Diamond compound, the pipe is buffed with a felt cloth to remove the compound dust from the areas on the stummel and from the stem. Next, another cotton cloth buffing wheel is mounted and set at the same speed and carnauba wax is applied to the entire pipe. I’m careful to apply with a very light touch of wax to the Natural Burl surface not to allow wax to build up in the crannies. Wax is applied to both stummel and stem and then the pipe receives a rigorous hand buffing with a microfiber cloth to raise the shine.

Wow! I’m very pleased with how this Kaywoodie Natural Burl Apple shaped up. The brown craggy finish is flecked with shade differences that give it a depth and warmth – a rustic knobby feel. I always enjoy the contrast nuances that the coalescing of rough and smooth briar creates. The smooth briar underside and shank ring alongside of the Burl texture is nice. I’m amazed that this pipe occupied the lower shelf on Kaywoodie’s offerings back in the day when Sam chose it and added it to his rotation of pipes. The TLC it has received has enhanced the briar presentation with this unique Natural Burl finish. I appreciate the collaborative help from Bill Feurbach who even as the president of the S.M. Frank Co., was not hindered from helping with the recommissioning of this one vintage Kaywoodie – a pipe man at heart. Thanks, Bill! I like the Natural Burl a lot and I trust that Joe likes it too. Paw’s Kaywoodie Natural Burl 33 – Large Apple, that was put into production in the mid-50s/early 60s, is a venerable 60-year-old(!), and is starting a new lifetime in the loving care and stewardship of Paw’s family. Adding frosting to the Kaywoodie cake, Joe’s commissioning of this restoration of Paw’s Natural Burl also benefits the Daughters of Bulgaria – women and girls who have been trafficked and sexually exploited. Thanks for joining me!