Blog by Anthony Cook

I’m turning in my third midterm exam today. This one is based on an old Thermofilter pipe. I’ve made plenty of mistakes while fumbling my way through the learning process of pipe restoration, but one of my biggest and earliest blunders was inflicted on this poor pipe.

Thermofilter seems to be one of those nearly forgotten brands that nevertheless still pops up on eBay on a fairly frequent basis. The best information that I can dig up on it comes from a comment that “emo” posted on the Dr. Grabow Collector’s Forum:

Thermofilter was made in Italy by Fratelli Rossi in Varese. Started about 1964 and continued till about 73/74. It was imported and sold by Mastercraft…. to, best I recall, Whitehall Products Co. in Wheeling WV… Division of CULBRO.

We had several “left over” and closed them out for $3.98 over a year or two… not as Thermofilter, but simply as a filter pipe, even though they were stamped Thermofilter. Pretty cheap stuff…

The pipe in my possession is a small billiard with carved rustication. The center letters of the stamping are very worn and faint, but there’s enough there to make out “THERMOFILTER” over “IMPORTED BRIAR” on the left side of the shank. The stem did not have any markings and the bit end had been hacked off. Below are some photos of the pipe that I took shortly after its arrival.

You may have noticed that I used past tense when mentioning the stem above. That’s because I dissolved the original, plastic stem from the inside out. Yes, you read that right. When I was running alcohol dampened pipe cleaners through the stem to clean it out, the first couple came out covered with the thickest, blackest, and stickiest goo that I had ever encountered and I surmised that I was working on some serious tar build-up. I was surprised to find that the amount goo wasn’t diminishing as I worked, but actually appeared to be increasing. Eventually, I noticed that the bore of the airway seemed larger than I had originally thought it was. That’s when I realized the horrible truth. The alcohol on the cleaners was causing the cheap, plastic material of the stem to break down and it was disintegrating from the inside out. You can see for yourself in the comparison photos below.

You may have noticed that I used past tense when mentioning the stem above. That’s because I dissolved the original, plastic stem from the inside out. Yes, you read that right. When I was running alcohol dampened pipe cleaners through the stem to clean it out, the first couple came out covered with the thickest, blackest, and stickiest goo that I had ever encountered and I surmised that I was working on some serious tar build-up. I was surprised to find that the amount goo wasn’t diminishing as I worked, but actually appeared to be increasing. Eventually, I noticed that the bore of the airway seemed larger than I had originally thought it was. That’s when I realized the horrible truth. The alcohol on the cleaners was causing the cheap, plastic material of the stem to break down and it was disintegrating from the inside out. You can see for yourself in the comparison photos below. You’d think that I would have noticed it earlier, but I honestly wasn’t paying attention to the diameter of the airway. I mean, who thinks that their stem is just going to dissolve, right?

You’d think that I would have noticed it earlier, but I honestly wasn’t paying attention to the diameter of the airway. I mean, who thinks that their stem is just going to dissolve, right?

In any case, I didn’t have any extra stems to replace the original with. So, I tossed the poor, mutilated stem into the trash and dropped the stummel back into the box. It’s been wasting away in there for the past several months. For my third midterm exam, I decided to pull it out to see if I could do right by this old pipe, try some new things, and correct my past mistakes.

I started by giving the stummel an alcohol bath and wiping it down with acetone. This removed the lacquer coat and much of the old stain. It also revealed some really nice grain between the areas of carved rustication. Then, I topped the bowl with 220-grit and 320-grit papers. I used the same grits to rough out a chamfer around the rim to remove the gouges along the edge. Even though the pipe had been hand cleaned before being boxed up, I wanted to do a retort since I didn’t have one at the time. So, I placed the original, aluminum tenon into the mortise and attached the retort tube directly to that. I flushed the boiling alcohol through the shank 8-10 times before setting the pipe aside to cool, and then I dumped the amber-colored alcohol and repeated the process. After the second flush, the alcohol remained nearly clear and I was satisfied that the retort had done all that it could do. I gave the shank a final scrub using a few pipe cleaners, cotton swabs, and a shank brush and considered the pipe to be clean as it was going to get.

Even though the pipe had been hand cleaned before being boxed up, I wanted to do a retort since I didn’t have one at the time. So, I placed the original, aluminum tenon into the mortise and attached the retort tube directly to that. I flushed the boiling alcohol through the shank 8-10 times before setting the pipe aside to cool, and then I dumped the amber-colored alcohol and repeated the process. After the second flush, the alcohol remained nearly clear and I was satisfied that the retort had done all that it could do. I gave the shank a final scrub using a few pipe cleaners, cotton swabs, and a shank brush and considered the pipe to be clean as it was going to get. The stummel had a few fills that needed to be dealt with. It also had a small, surface crack at the end of the shank that did not penetrate into the mortise. I had wondered about using black CA glue for fills for a while. When I saw Al’s work on the Chelsea pipe I knew that I had to give it a try. After picking the fill material out, I applied a bit of glue into the pits and crack with a round toothpick, and then packed in a little pre-stained briar dust that I had left over the Rogers pipe that I posted earlier. I repeated this until I had a good patch built up above the surface. When the glue was dry, I sanded it down with 220 and 320-grit paper. I also used a round, tapered needle file and 240/320-grit sanding needles to smooth and shape a patch inside the carved rustication.

The stummel had a few fills that needed to be dealt with. It also had a small, surface crack at the end of the shank that did not penetrate into the mortise. I had wondered about using black CA glue for fills for a while. When I saw Al’s work on the Chelsea pipe I knew that I had to give it a try. After picking the fill material out, I applied a bit of glue into the pits and crack with a round toothpick, and then packed in a little pre-stained briar dust that I had left over the Rogers pipe that I posted earlier. I repeated this until I had a good patch built up above the surface. When the glue was dry, I sanded it down with 220 and 320-grit paper. I also used a round, tapered needle file and 240/320-grit sanding needles to smooth and shape a patch inside the carved rustication. Once the fills and crack were repaired, it was time to do something about the stem. I had picked up a grab-bag batch of pre-made stems a short while earlier. I sifted through them until I found a decent match. I decided to trim the tenon rather refitting the old, aluminum one. So, I cut off the stepped end of the tenon with a Dremel, and then trimmed the tenon with the tenon turning tool chucked into the drill press. The tool was new to me and the first image in the picture below shows the result of my first cut. My speed was off and I didn’t take it up far enough to face it properly. No worries though, because it was still too large and the subsequent trims went much better.

Once the fills and crack were repaired, it was time to do something about the stem. I had picked up a grab-bag batch of pre-made stems a short while earlier. I sifted through them until I found a decent match. I decided to trim the tenon rather refitting the old, aluminum one. So, I cut off the stepped end of the tenon with a Dremel, and then trimmed the tenon with the tenon turning tool chucked into the drill press. The tool was new to me and the first image in the picture below shows the result of my first cut. My speed was off and I didn’t take it up far enough to face it properly. No worries though, because it was still too large and the subsequent trims went much better. After each turn of the tenon, I tested the fit by inserting it partially into the shank. When I thought I was getting very close, I attempted to insert the stem a bit farther and heard a sharp “snap”. It was the unmistakable sound of the shank cracking. It seems that the surface crack that I had thought was insignificant had suddenly become significant.

After each turn of the tenon, I tested the fit by inserting it partially into the shank. When I thought I was getting very close, I attempted to insert the stem a bit farther and heard a sharp “snap”. It was the unmistakable sound of the shank cracking. It seems that the surface crack that I had thought was insignificant had suddenly become significant.

To repair the crack, I smeared petroleum jelly over the tenon and inserted it into the mortise to spread the crack open. Then, I applied CA glue (clear, not black this time) into the crack and removed the stem to allow the crack to close. I squeezed the shank tightly together with my fingers for a couple of minutes until the glue had set. I wasn’t going to do anything more with the stem until I added some support to the shank. I considered trimming down the original, aluminum tenon to use an internal splint, but decided against it. Since the new crack had run longer than the length of the tenon. So, I decided to band the shank.

I wasn’t going to do anything more with the stem until I added some support to the shank. I considered trimming down the original, aluminum tenon to use an internal splint, but decided against it. Since the new crack had run longer than the length of the tenon. So, I decided to band the shank.

I had some trouble finding a band that would fit properly. A 13mm would slide most of the way up the shank easily, but a 12.5mm band wouldn’t even start over the end. So, using the 13mm as a guide, I marked off an area that was the width of the band and sanded it down until the 12.5mm band would just barely slide onto the shank. Then I held the band attached to the stummel over a heat gun to expand it. In less than a minute it had expanded enough that I could push the band the remaining distance up the shank by pressing the end into a soft cloth on a hard surface. With the band in place, I could continue working on the tenon. I continued to slightly reduce the diameter of the tenon with 220-grit, 320-grit, and 400-grit paper until the stem was held tightly in place but easily removed.

With the band in place, I could continue working on the tenon. I continued to slightly reduce the diameter of the tenon with 220-grit, 320-grit, and 400-grit paper until the stem was held tightly in place but easily removed.

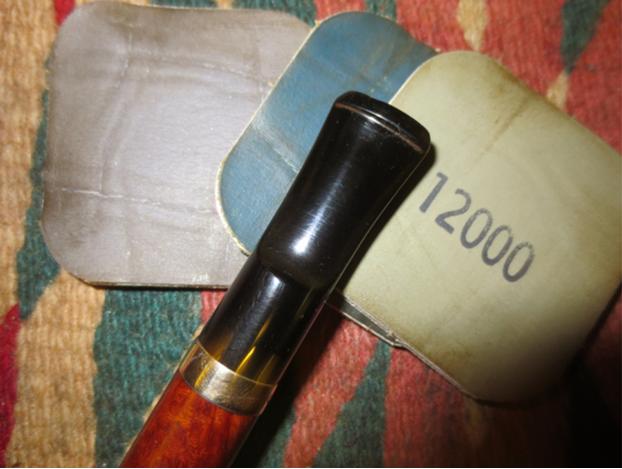

The stem was already a pretty close match to the width of the stummel but it needed some refinement and the artifacts from the mold needed to be removed. I kept the stem attached to the stummel and wrapped a strip of painters tape around the band to keep from dragging fine metal shavings into the vulcanite (which dulls it). Then, I began shaping the stem and removing the extra material with sandpaper and sanding sticks. I began roughing it with 220-grit and 320-grit (results in first picture below) and refined it with 400-grit and 600-grit (results in second picture below). I used a set of needle files and sanding needles to open the slot and funnel it. This was my first time trying my hand at this and I’m going to need some more practice because the results were rough. I also funneled the tenon to remove the whistle when the stem was drawn on. Finally, I lightly sanded the entire stem with 1200-grit paper before polishing with micro-mesh pads 1500-12000. The final stem, along with a whole lot of lint, can be seen in the bottom image below.

I used a set of needle files and sanding needles to open the slot and funnel it. This was my first time trying my hand at this and I’m going to need some more practice because the results were rough. I also funneled the tenon to remove the whistle when the stem was drawn on. Finally, I lightly sanded the entire stem with 1200-grit paper before polishing with micro-mesh pads 1500-12000. The final stem, along with a whole lot of lint, can be seen in the bottom image below. Between the large areas of carved rustication (blech!) on the stummel there was some really nice grain. I can appreciate straight grain for its rarity, but I love a good bird’s eye. When it’s stained well, it has a depth that’s almost like looking at an x-ray of the briar. So, I wanted to do everything that I could to accent that grain and take your eyes away from the ugly, carved, tobacco leaf swirls.

Between the large areas of carved rustication (blech!) on the stummel there was some really nice grain. I can appreciate straight grain for its rarity, but I love a good bird’s eye. When it’s stained well, it has a depth that’s almost like looking at an x-ray of the briar. So, I wanted to do everything that I could to accent that grain and take your eyes away from the ugly, carved, tobacco leaf swirls.

Three main stains were used to achieve the final look of the pipe; black to accent the grain, mahogany to give the overall tone, and ox blood at the end to add a bit of vibrancy. The first two colors were mixed at a 3:1 ratio of isopropyl alcohol to stain. The final color was mixed as a thin wash that I just eyeballed. The stummel was sanded between each staining; starting with 400-grit after black, 600-grit after mahogany, and 1200-grit after the ox blood wash, and then a micro-mesh polish 1500-12000. I also did a lot of grain massaging between each stain using a variety of tools including liner brushes and markers and inks and dyes of a few different colors. You can see how the staining progressed from start to finish in the pictures below. When the staining was complete, I reattached the stem and buffed the entire pipe with White Diamond, gave it several layers of carnauba wax, and added a bowl coating to the well worn chamber. Here’s the pipe that I’m turning in for my third exam.

When the staining was complete, I reattached the stem and buffed the entire pipe with White Diamond, gave it several layers of carnauba wax, and added a bowl coating to the well worn chamber. Here’s the pipe that I’m turning in for my third exam.